ECU ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4083 of 6020

TRANSMISSION CONTROL SYSTEM (AW30–40LE) 7A2-117

(3) All of the following conditions are met.

• Device Control is not operating.

• Disable Normal Communication is receiving

enable.

• DTC Clear is not operating.

(4) DTC U2104 is not detecting failure or not deciding failure.

Condition For Setting The DTC

Detection standard is met for 2.5 second continuously.

Detection standard:

If one or more ID sent from Engine Control Module

(ECM) is not completed receiving for 2 basic cycles

since last receiving completion.

Action Taken When The DTC Sets

• Throttle judgment on torque reduction control, line

pressure control at stationary status, line pressure

reduction control at gear change and line pressure

reduction control at garage. (Throttle opening 100%)

• Line pressure FULL output.

• Throttle judgment on gear change control (Throttle

opening 0%).

• No line pressure reduction control at gear change.

• No torque reduction control.

• No squat control.

• No slope control (keep mode).

• No L-up control.

• Control Engine rpm at 7000rpm (No inertia

calculation).

• Control actual torque at MAX.

• Control driver torque at MAX.

• Control engine coolant temperature at 80 °C (176 °F).

• No coast control.

• No 3rd Start mode control.

• No line pressure reduction control at garage.

• No output revolution sensor failure detection.

• No C-0 rev sensor failure detection.

• No selector position switch failure detection.

• No oil temperature sensor failure detection.

• No T/F Hi-Low SW failure detection (Execute T/F

judgment using only T/F-SW ).

• No speed mater signal failure detection.

• No throttle signal failure detection.

• No Engine torque signal failure detection.

• No engine coolant temperature signal failure

detection.

• No Engine revolution signal failure detection.

• No shift solenoid functional failure detection.

• No L-up solenoid functional failure detection.

• Cancel engine rpm condition of prerequisite of suppl

y

voltage failure detection.

• Control vehicle speed of speed meter at 0km/h.

• No torque reduction at stall.

• No cruise control.

• No warm up control.

• Check Trans “ON”.

• DTC stored.

• MIL request “ON”. (EURO 4 only)

Conditions For Clearing The DTC

• The DTC can be cleared from the TCM history by

using a scan tool.

• The DTC will be cleared from history when the vehicle has achieved 40 warm-up cycles without a

failure reported.

• After more than 1 second has elapsed after the ignition key has been turned “ON”, short between

No.11 and No.4 (ground) of DLC (Data Link

Connector). Then, after 1 second, but within 6

seconds, discontinue shorting.

Diagnostic Aids

• Inspect the wiring for poor electrical connection at the

TCM. Look for possible bent, backed out, deformed

or damaged terminals. Check for weak terminal

tension as well. Also check for a chafed wire that

could short to bare metal or other wiring. Inspect for a

broken wire inside the insulation.

• W hen diagnosing for a possible intermittent short o

r

open condition, move the wiring harness while

observing test equipment for a change.

• Inspect the wiring for EMI (Electro-Magnetic

Interference). Check that all wires are properly routed

away from coil, and generator. Also check fo

r

improperly installed electrical options. W hen this test

is performed, turn “OFF” on electronic auto parts

switches to improperly for a noise preventing.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4104 of 6020

ON-VEHICLE SERVICE (AW30–40LE) 7A3-19

ATF Replacement

Inspection

NOTE: Do not overfill.

1. Remove the drain plug from oil pan and drain the

fluid.

RUW 17ASH013401

2. Reinstall the drain plug securely.

Torque: 19 N ⋅

⋅⋅

⋅

m (1.9 kgf ⋅

⋅⋅

⋅

m/14 Ib ⋅

⋅⋅

⋅

ft)

3. W ith the engine OFF, add new fluid through the fille

r

tube.

Drain and refill 5.2 liter

Dry fill 8.7 liter

Fluid Exxon Mobil ATF-3309

4. Start the engine and shift the selector into all

position from “P" through “L", and then shift into “P".

5. W ith the engine idling, check the fluid level. Add fluid up to the “COLD" level on the dipstick.

6. The ATF level must be checked again for correct level with the “HOT" level.

NOTE: To prevent fluid leaks, the drain plug gasket

must be replaced each time this plug is removed.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4111 of 6020

7A3-26 ON-VEHICLE SERVICE (AW30–40LE)

Remove or Disconnect

1. Block the wheels.

2. Disconnect the negative battery cable.

3. Remove the rear console and the front console.

4. Remove the 2 screws fixing the select lever knob.

5. Remove the knob together with the knob button and spring from the lever.

6. Turn the sleeve counterclockwise to remove it. Make a note of the number of turns required to free

the sleeve.

7. Remove the harness connectors from the base plate.

8. Remove the upper housing (held in place by 4 latched fasteners).

9. Remove the lamp assembly by turning it counterclockwise.

10. Remove the spring plate.

11. Remove the grooved pin.

12. Disconnect the shift cable from the select lever.

13. Remove the lever assembly by pressing the rod down (lever in N position).

14. Remove the harness connectors from the shift lock unit, then remove the shift lock unit.

15. Remove the interlock controller.

16. If the replacement of shift lock release button o

r

shift lock button spring is required, remove the

position indicator housing, the shift lock button

spring and shift lock release button can be

removed.

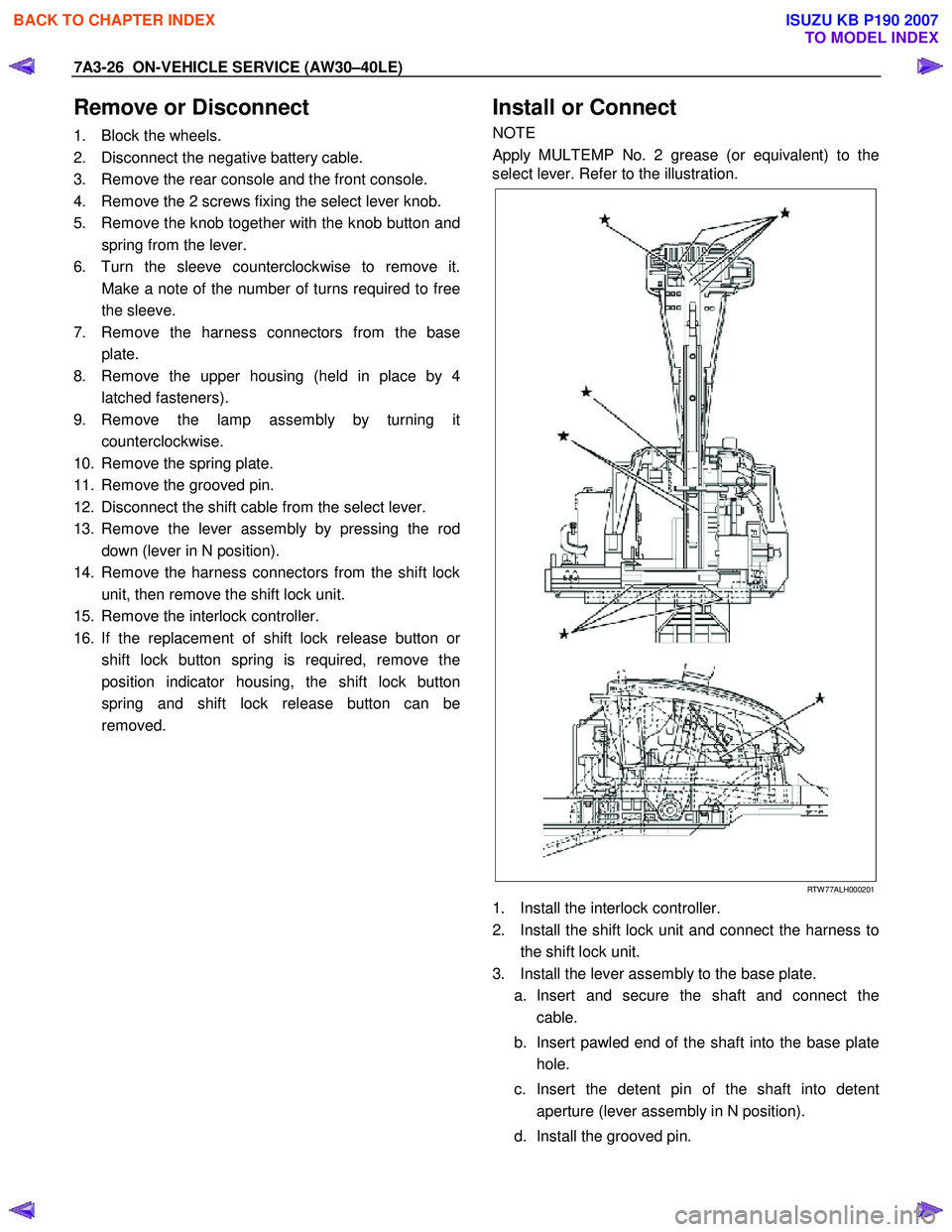

Install or Connect

NOTE

Apply MULTEMP No. 2 grease (or equivalent) to the

select lever. Refer to the illustration.

RTW 77ALH000201

1. Install the interlock controller.

2. Install the shift lock unit and connect the harness to the shift lock unit.

3. Install the lever assembly to the base plate. a. Insert and secure the shaft and connect the cable.

b. Insert pawled end of the shaft into the base plate hole.

c. Insert the detent pin of the shaft into detent aperture (lever assembly in N position).

d. Install the grooved pin.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4112 of 6020

ON-VEHICLE SERVICE (AW30–40LE) 7A3-27

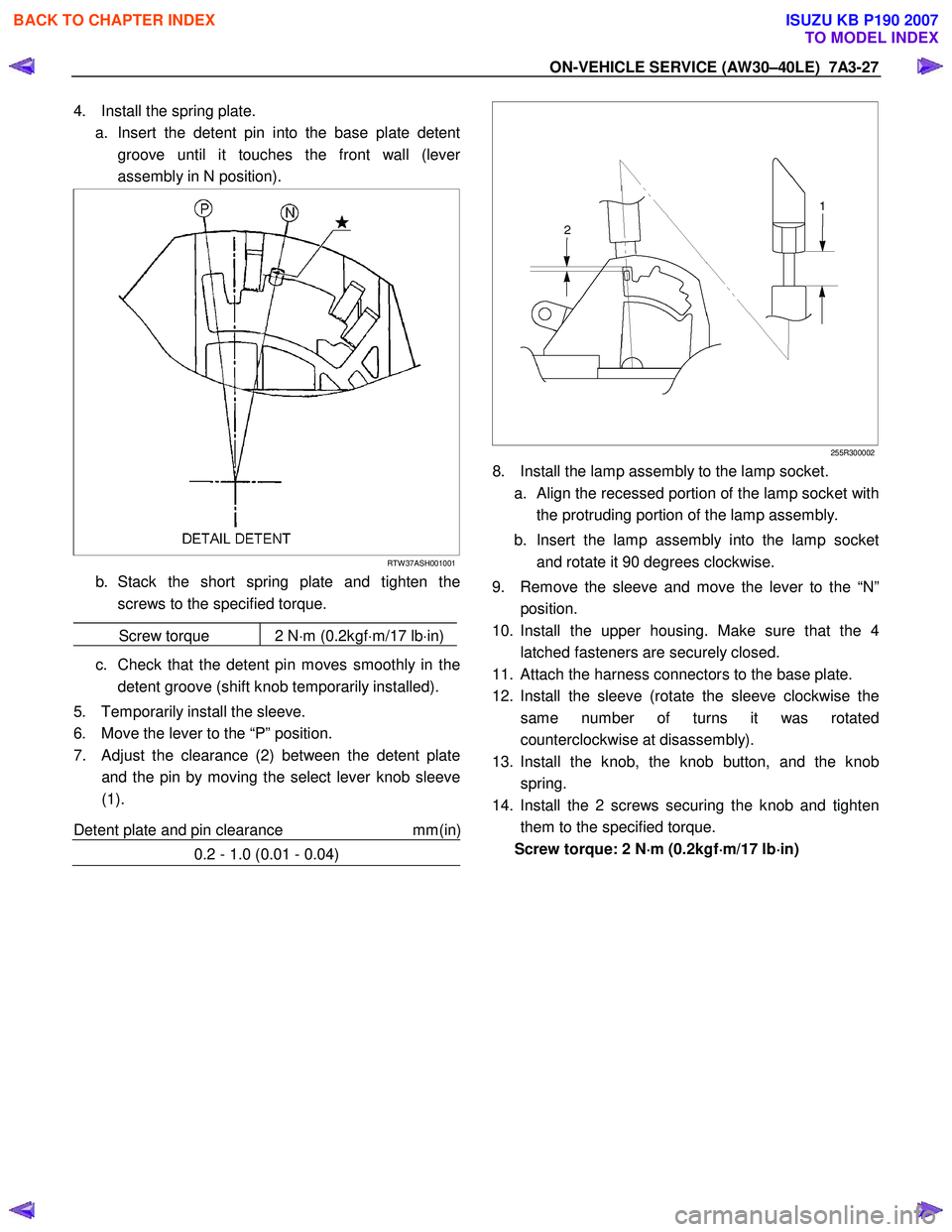

4. Install the spring plate.

a. Insert the detent pin into the base plate detent groove until it touches the front wall (leve

r

assembly in N position).

RTW 37ASH001001

b. Stack the short spring plate and tighten thescrews to the specified torque.

Screw torque 2 N ⋅m (0.2kgf ⋅m/17 lb ⋅in)

c. Check that the detent pin moves smoothly in the

detent groove (shift knob temporarily installed).

5. Temporarily install the sleeve.

6. Move the lever to the “P” position.

7. Adjust the clearance (2) between the detent plate and the pin by moving the select lever knob sleeve

(1).

Detent plate and pin clearance mm(in

)

0.2 - 1.0 (0.01 - 0.04)

255R300002

8. Install the lamp assembly to the lamp socket.

a.

Align the recessed portion of the lamp socket with

the protruding portion of the lamp assembly.

b. Insert the lamp assembly into the lamp socket and rotate it 90 degrees clockwise.

9. Remove the sleeve and move the lever to the “N” position.

10. Install the upper housing. Make sure that the 4 latched fasteners are securely closed.

11. Attach the harness connectors to the base plate.

12. Install the sleeve (rotate the sleeve clockwise the same number of turns it was rotated

counterclockwise at disassembly).

13. Install the knob, the knob button, and the knob spring.

14. Install the 2 screws securing the knob and tighten them to the specified torque.

Screw torque: 2 N ⋅

⋅⋅

⋅

m (0.2kgf ⋅

⋅⋅

⋅

m/17 lb ⋅

⋅⋅

⋅

in)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4114 of 6020

ON-VEHICLE SERVICE (AW30–40LE) 7A3-29

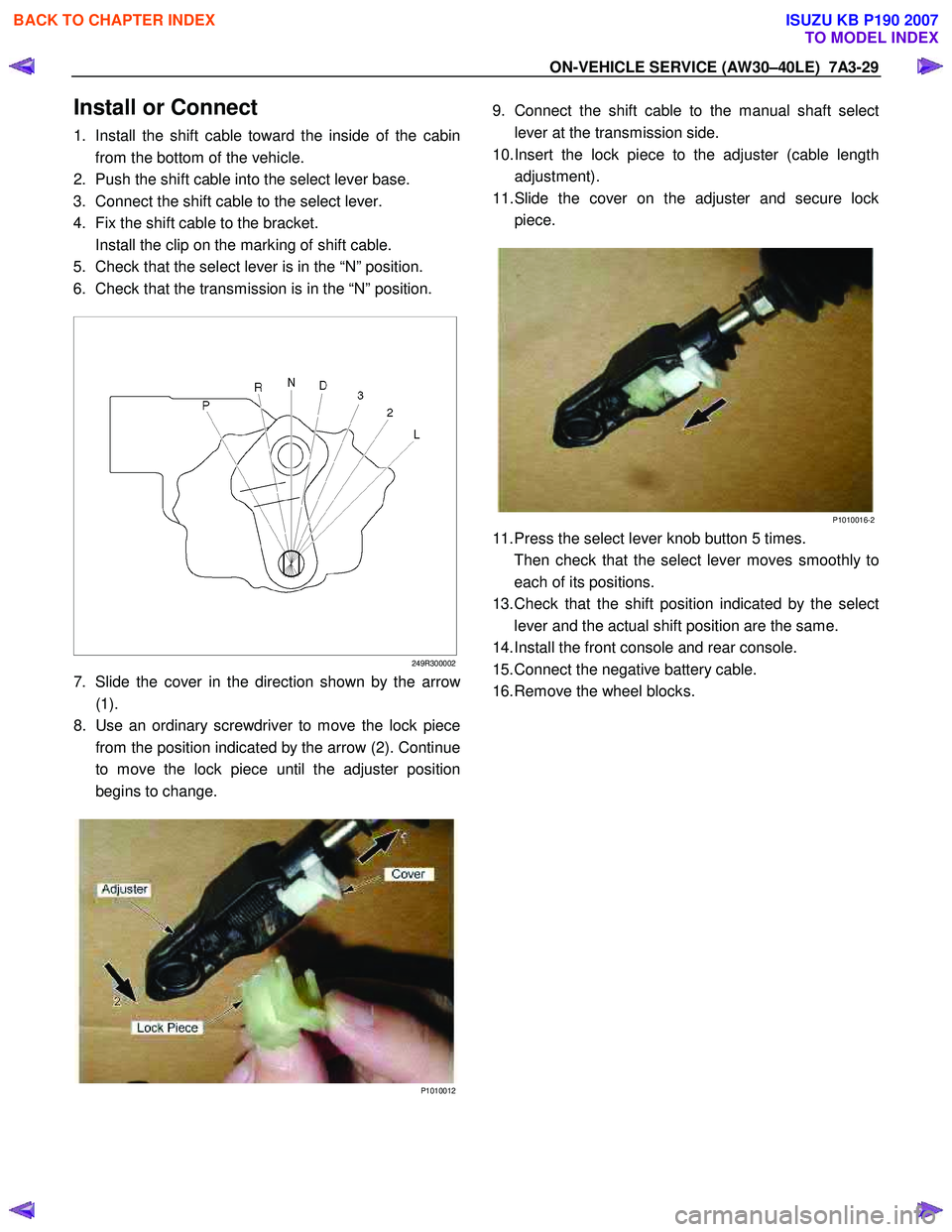

Install or Connect

1. Install the shift cable toward the inside of the cabin

from the bottom of the vehicle.

2. Push the shift cable into the select lever base.

3. Connect the shift cable to the select lever.

4. Fix the shift cable to the bracket.

Install the clip on the marking of shift cable.

5. Check that the select lever is in the “N” position.

6. Check that the transmission is in the “N” position.

249R300002

7. Slide the cover in the direction shown by the arrow

(1).

8. Use an ordinary screwdriver to move the lock piece

from the position indicated by the arrow (2). Continue

to move the lock piece until the adjuster position

begins to change.

P1010012

9. Connect the shift cable to the manual shaft select

lever at the transmission side.

10. Insert the lock piece to the adjuster (cable length

adjustment).

11. Slide the cover on the adjuster and secure lock

piece.

P1010016-2

11. Press the select lever knob button 5 times.

Then check that the select lever moves smoothly to each of its positions.

13. Check that the shift position indicated by the select

lever and the actual shift position are the same.

14. Install the front console and rear console.

15. Connect the negative battery cable.

16. Remove the wheel blocks.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4270 of 6020

CONSTRUCTION AND FUNCTION 7A1-31

As a result, the lock-up piston is fitted slowly to the converter cover under pressure securing smooth lock-

up engagement.

Figure 51. Lock-up Control

DIRECT ELECTRIC SHIFT CONTROL (DESC)

Feature

• Based on each switch signal (low & reverse brake pressure, 2-4 brake pressure & high clutch pressure)

and each sensor signal (turbine sensor, speed sensor, engine speed signal & APP position signal), the

duty cycle type solenoid adjusts the clutch pressure to match the engine load and vehicle travel

conditions. Controlling the engagement and disengagement of the clutch and brake pressure is directly

and accurately controlled via TCM, which is different to the previous accumulator type.

Operation

• Instead of the previous system (on/off type of shift solenoid and shift valve), the combination of the duty

cycle type solenoid and the amplifier (Amp) valve are used to adjust the clutch pressure to match the

engine load and vehicle travel conditions, based on the signal from the TCM. Also, the pressure switch

provided in the oil passage of the control valve transmits the oil pressure condition (at that time) to TCM,

enabling the engagement and disengagement control of the clutch and brake to be directly and finely

carried out.

• When the gear is shifted from the 2nd to 3rd, 3rd to 4th (O/D), 4th (O/D) to 3rd and 3rd to 2nd, the clutch

pressures on the engagement side and disengagement side are simultaneously controlled.

As a result, engine racing or clutch drag is prevented which enables a smooth and quick shift response.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4336 of 6020

7A2-52 TRANSMISSION CONTROL SYSTEM (JR405E)

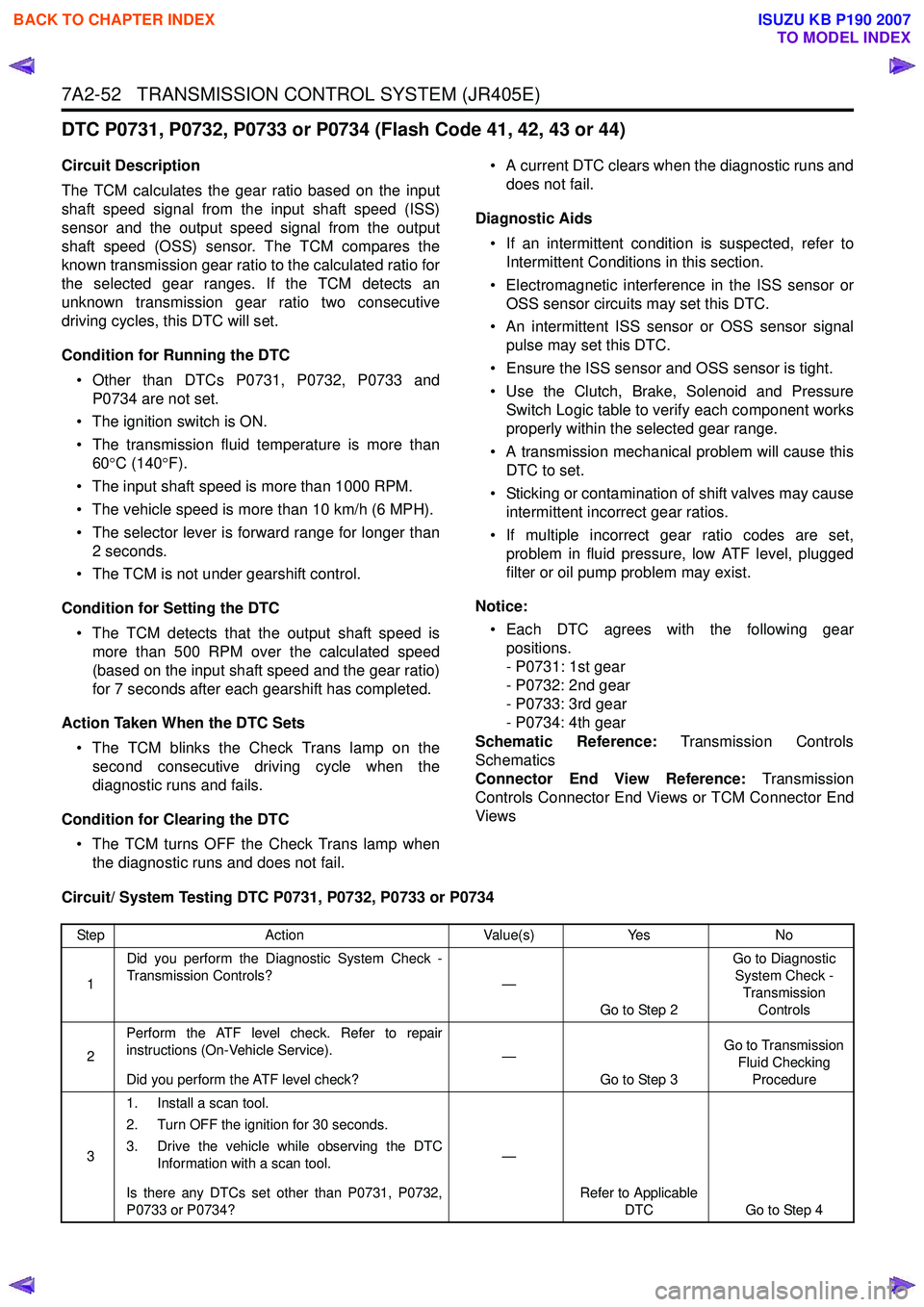

DTC P0731, P0732, P0733 or P0734 (Flash Code 41, 42, 43 or 44)

Circuit Description

The TCM calculates the gear ratio based on the input

shaft speed signal from the input shaft speed (ISS)

sensor and the output speed signal from the output

shaft speed (OSS) sensor. The TCM compares the

known transmission gear ratio to the calculated ratio for

the selected gear ranges. If the TCM detects an

unknown transmission gear ratio two consecutive

driving cycles, this DTC will set.

Condition for Running the DTC • Other than DTCs P0731, P0732, P0733 and P0734 are not set.

• The ignition switch is ON.

• The transmission fluid temperature is more than 60 °C (140 °F).

• The input shaft speed is more than 1000 RPM.

• The vehicle speed is more than 10 km/h (6 MPH).

• The selector lever is forward range for longer than 2 seconds.

• The TCM is not under gearshift control.

Condition for Setting the DTC • The TCM detects that the output shaft speed is more than 500 RPM over the calculated speed

(based on the input shaft speed and the gear ratio)

for 7 seconds after each gearshift has completed.

Action Taken When the DTC Sets • The TCM blinks the Check Trans lamp on the second consecutive driving cycle when the

diagnostic runs and fails.

Condition for Clearing the DTC • The TCM turns OFF the Check Trans lamp when the diagnostic runs and does not fail. • A current DTC clears when the diagnostic runs and

does not fail.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

• Electromagnetic interference in the ISS sensor or OSS sensor circuits may set this DTC.

• An intermittent ISS sensor or OSS sensor signal pulse may set this DTC.

• Ensure the ISS sensor and OSS sensor is tight.

• Use the Clutch, Brake, Solenoid and Pressure Switch Logic table to verify each component works

properly within the selected gear range.

• A transmission mechanical problem will cause this DTC to set.

• Sticking or contamination of shift valves may cause intermittent incorrect gear ratios.

• If multiple incorrect gear ratio codes are set, problem in fluid pressure, low ATF level, plugged

filter or oil pump problem may exist.

Notice: • Each DTC agrees with the following gear positions.

- P0731: 1st gear

- P0732: 2nd gear

- P0733: 3rd gear

- P0734: 4th gear

Schematic Reference: Transmission Controls

Schematics

Connector End View Reference: Transmission

Controls Connector End Views or TCM Connector End

Views

Circuit/ System Testing DTC P0731, P0732, P0733 or P0734

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Transmission Controls? —

Go to Step 2 Go to Diagnostic

System Check - Transmission Controls

2 Perform the ATF level check. Refer to repair

instructions (On-Vehicle Service).

Did you perform the ATF level check? —

Go to Step 3 Go to Transmission

Fluid Checking Procedure

3 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Drive the vehicle while observing the DTC Information with a scan tool.

Is there any DTCs set other than P0731, P0732,

P0733 or P0734? —

Refer to Applicable DTC Go to Step 4

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4423 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-139

Repair Instructions

Transmission Controls Module (TCM) Replacement

Description

The following A - C steps provide an overview

procedure to replace and reprogram a TCM. Each A -C

steps is explained further in this section.

A. Replace the old TCM with the new TCM.

B. Program the latest software and calibrations into the

new TCM using the Service Programming System

(SPS) if released. If not released, do not perform this

and skip to Step C.

C. Program the vehicle identification number (VIN) into

the TCM.

A. Removal and Installation

Removal Procedure 1. Disconnect the negative battery cable.

2. Disconnect the TCM harness connectors (1).

3. Loosen nuts (2) and remove the TCM (3) from the bracket (4).

Installation Procedure

Follow the removal steps in the reverse order. Be sure

that the connectors are securely fastened.

B. Programming Software and Calibrations

Program the latest software/ calibrations if released.

Refer to Service Programming System (SPS)

Description and SPS (Remote Procedure) or SPS

(Pass-Thru Procedure) in this section. If not released,

do not perform this and skip to Step C.

C. Programming Vehicle Identification Number

(VIN) Notice:

If you have performed SPS in the previous

step, VIN has prgrommaned already. Programming VIN

is not necessary in this step.

1. Install a scan tool.

2. Turn ON the ignition, with the engine OFF.

3. Select Diagnostics > appropriate vehicle identification > AT JR405E > Programming >

Program VIN.

4. If you installed a new, skip to step 8. If you installed a reused TCM from another vehicle or incorrect

VIN is programmed before, the TCM might be

locked already. In order to get programming

approval, the on-screen displays a message to

user. Get programming approval from the TIS

2000 using the following procedure:

a. Connect a scan tool to the terminal that installed TIS 2000 with the latest software and

the hardware key is plugged into port.

b. Turn ON the scan tool and keep at title screen.

c. Launch the TIS application.

d. Select the Security Access at the main screen.

e. Highlight the “Tech 2" on the Diagnostic Tool Selection screen and click “Next”.

f. Click “Close” on the Security Access Enabled screen.

g. Turn OFF the scan tool.

h. Disconnect the scan tool from the terminal.

5. Install a scan tool to the vehicle.

6. Turn ON the ignition, with the engine OFF.

7. Select Diagnostics > appropriate vehicle identification > AT JR405E > Programming >

Program VIN.

8. Input 17 digits of correct VIN.

9. After complete the programming, turn OFF/ ON the ignition.

10. Select Diagnostics > Lock ECU.

11. Follow the on-screen instructions and turn OFF/ ON the ignition.

Service Programming System (SPS)

Description

The service programming system (SPS) allows a

technician to program a control module through the

data link connector (DLC). The information transfer

circuit that is used at the DLC is the same serial data

circuit used by the scan tool for retrieving DTCs,

displaying data, clearing DTCs etc. This procedure

offers the ability to install software/ calibrations

matched to a particular vehicle.

Most control modules have two types of memory. The

software/ calibrations reside in the flash memory. The

two types of memory are listed below:

1

3 42

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4424 of 6020

7A2-140 TRANSMISSION CONTROL SYSTEM (JR405E)

• Electrically Erasable Programmable Read OnlyMemory (EEPROM)

This type of memory allows selected portions of

memory to be programmed while other portions

remain unchanged.

Certain learned values reside in the EEPROM,

such as:

- The vehicle identification number (VIN)

- The software/ calibrations identification numbers

- The control module security information

• Flash Read Only Memory-Flash Memory

Flash memory has increased memory storage capacity.

During programming, all information within this type of

memory is erased, and then replaced with entirely new

information.

Service Programming Methods

The two methods of programming a TCM are listed

below:

• Remote Programming

• Pass Thru Programming

For information on programming a TCM using one of

the methods listed above, refer to Service

Programming System (SPS) (Remote Procedure) or

Service Programming System (SPS) (Pass-Thru

Procedure).

Before Programming a Control Module

Important: DO NOT program an existing TCM with the

identical software/ calibration package. This procedure

is not a short cut to correct the driveability condition.

This is an ineffective repair. An TCM should only be

programmed when the following occurs:

• When a service procedure instructs you to replace the TCM.

• An updated software/ calibrations is released.

Ensure that the following conditions are met before

programming a TCM:

• The scan tool PCMCIA card is programmed with the latest software.

• The TIS 2000 is installed with the latest software.

• The hardware key is plugged into the computer port.

• Vehicle system voltage:

- There are no charging system concerns. Allcharging system concerns must be repaired

before programming the TCM.

- The battery voltage is greater than 12 volts but less than 16 volts. The battery must be fully

charged before programming the TCM.

- A battery charger is NOT connected to the vehicles battery. Incorrect system voltage or

voltage fluctuations from a battery charger may

cause programming failure or TCM damage. - Turn OFF or disable any system that may put a

load on the vehicles battery. Turn OFF or

disable systems such as:

◊ Heating, ventilation, and air conditioning

(HVAC) systems

◊ Headlights

◊ Room lights

◊ Accessory equipment

• The ignition switch is in the proper position. The scan tool prompts you to turn ON the ignition, with

the engine OFF. DO NOT change the position of

the ignition switch during the programming

procedure unless instructed to do so.

• All tool connections are secure:

- The RS-232 cable

- The connection at the DLC

- The voltage supply circuits

• DO NOT disturb the tool harnesses while programming. If an interruption occurs during the

programming procedure, programming failure or

TCM damage may occur.

• If you are performing the Pass-Thru programming procedure using a notebook computer without the

power cord, ensure that the internal battery is fully

charged.

Service Programming System (SPS)

(Remote Procedure)

Notice: Some module will not accept SPS remote

procedure using 10MB PCMCIA card. In such case,

use 32MB PCMCIA card or SPS pass-thru procedure.

The Remote SPS method is a three-step process that

involves the following procedures:

1. Connecting the scan tool to the vehicle and obtaining the information from the TCM.

2. Connecting the scan tool to the terminal and downloading a new calibration file from the

terminal into the scan tool memory.

3. Reconnecting the scan tool to the vehicle and uploading the new calibration file into the TCM.

Performing the Remote Procedure 1. Connect a scan tool to the vehicle and obtain the TCM information using the following procedure:

Notice: Ensure the TCM is installed in the vehicle and

the battery is fully charged before programming.

a. Install a scan tool.

b. Turn ON the ignition, with the engine OFF.

c. Select Service Programming System (SPS) > Request Info.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4425 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-141

d. If there is already stored in the scan tool, theexisting data is displayed on the screen. The

scan tool asks user to keep existing data “Keep

Data” or “Continue” to request new vehicle

information from the TCM. If there is no data in

the scan tool, it will immediately start vehicle

identification.

e. Select the vehicle description by following the on-screen instructions based on stamped VIN

or affixed VIN plate on the vehicle.

f. During obtaining information, the scan tool is receiving information from all modules at the

same time. But only ECM information is

displayed on the screen.

g. Turn OFF all accessories and press “Okay”.

h. Verify that the correct VIN is displayed on the scan tool. If the VIN is incorrect or no VIN,

record the correct VIN.

2. Turn OFF the ignition.

3. Turn OFF the scan tool and disconnect from the vehicle.

4. Transfer the data from the terminal to the scan tool using the following procedure:

Notice: The TIS supports service programming with

the Tech 2 scan tool only.

a. Connect the scan tool to the terminal.

b. Launch the TIS application.

c. Select the Service Programming System at the main screen.

d. Highlight the following information on the Select Diagnostic Tool and Programming Process

screen, then click “Next”.

• Select Diagnostic Tool - Tech 2

• Select Programming Process - Identify whether an existing TCM is being

reprogrammed or a TCM is being replaced

with a new one

• Select ECU Location - Vehicle

e. Verify the connections on the Preparing for Communication screen, then click “Next”.

f. Verify the VIN on the Validate Vehicle Identification Number (VIN) screen, then click

“Next”.

Notice: If the TCM is replaced to new one, VIN does

not displayed. Input correct VIN reading from stamped

VIN or affixed VIN plate on the vehicle. If the TCM from

another vehicle is installed, input correct VIN by same

way.

g. Highlight Transmission on the Select SystemType screen, then click “Next”, if on-screen

instruction displayed.

h. Complete the following information based on the service ID plate on the Validate Vehicle

Data screen until “Next” is highlighted, then

click “Next”.

• Model • Model year

• Engine type

• Model designator

• Destination code

• Transmission type

i. Verify your selection on the Summary screen.

Notice: Refer to Service Bulletin and Description

column before service programming is performed if the

bulletins are listed along with the calibration files.

Notice: Select Cancel if you receive a message stating

that the calibration selected is already the current

calibration in the TCM and reprogramming with the

same download is not allowed.

j. Click “Reprog”.

k. The Transfer Data screen will appear until the progress bar reaches 100%.

5. Close the application and return to the TIS application selection screen after the download is

completed.

6. Turn OFF the scan tool and disconnect from the terminal.

7. Transfer the data from the scan tool to the TCM using the following procedure:

a. Install a scan tool.

b. Turn ON the ignition, with the engine OFF.

c. Select Service Programming System (SPS) > Program ECU.

d. Turn OFF all accessories and press “Continue”.

e. Programming in Process will appear until the progress bar reaches 100%.

Notice: Some warning lamp may turn ON or blink while

programming the TCM since communication between

the TCM and other modules are interrupted. Clear DTC

in any module after programming.

f. Press “Continue” and exit the program after thescan tool displays “Programming Was

Successful”.

8. Turn OFF the ignition.

9. Turn OFF the scan tool and disconnect from the vehicle.

Service Programming System (SPS) (Pass-

Thru Procedure)

Pass-Thru programming allows the scan tool to remain

connected to the terminal and to the vehicle throughout

the programming process. The vehicle must be in close

proximity to the terminal while using Pass-Thru.

1. Launch the TIS application.

2. Select the Service Programming System at the main screen.

3. Highlight the following information on the Select Diagnostic Tool and Programming Process screen,

then click “Next”:

• Select Diagnostic Tool-Select Pass - Thru

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007