sensor ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1765 of 6020

6E-148 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

DTC P0335 (Flash Code 15)

Circuit Description

The crankshaft position (CKP) sensor is located on the

left-hand of the cylinder block rear and it is behind the

starter motor. The sensor rotor is fixed on the

crankshaft. There are 56 notches spaced 6 ° apart and

a 30 ° section that is open span. This open span portion

allows for the detection of top dead center (TDC). The

CKP sensor is a magnetic resistance element (MRE)

type sensor, which generates a square wave signal

pulse. The sensor has the following circuits.

• 5 volts reference circuit

• Low reference circuit

• CKP sensor signal circuit

The ECM monitors both CKP sensor and camshaft

position (CMP) sensor signal pulses to ensure they

correlate with each other. If the ECM receives a certain

amount of CMP sensor signal pulses without a CKP

sensor signal pulse, this DTC will set.

Condition for Running the DTC • The battery voltage is more than 9 volts.

• The ignition switch is ON.

• The CMP sensor signal pulse is detected.

Condition for Setting the DTC • The ECM detects that the CKP sensor signal pulses are not generated during engine rotations. Action Taken When the DTC Sets

• The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

• The ECM limits fuel injection quantity.

• The ECM inhibits pilot injection.

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

• Electromagnetic interference in the CKP sensor circuits may set this DTC.

• An intermittent CKP sensor signal pulse may set this DTC.

• Ensure the sensor is tight and the sensor rotor teeth are not damaged.

Notice: • If the CKP sensor signal pulse is lost while running, the engine will stop.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

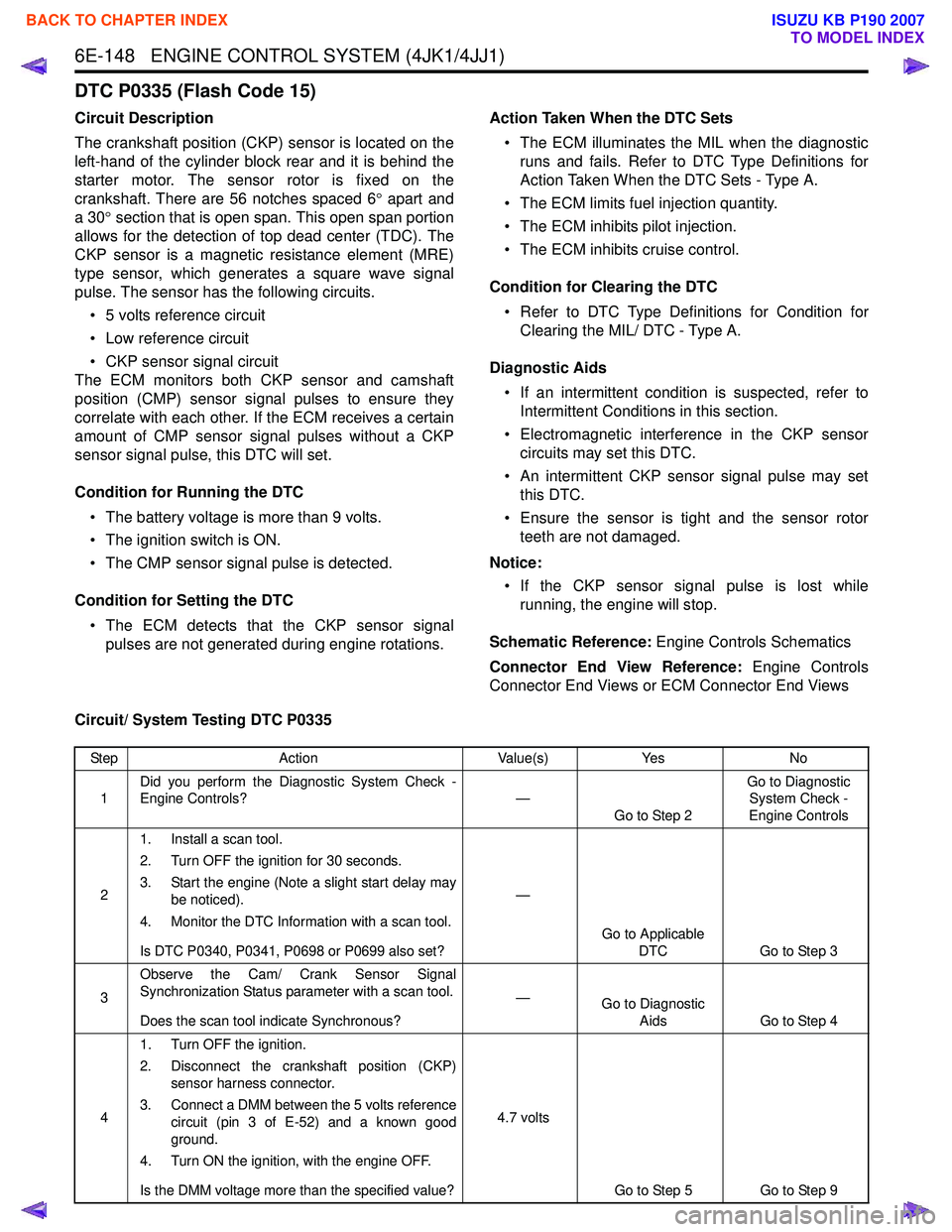

Circuit/ System Testing DTC P0335

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine (Note a slight start delay may be noticed).

4. Monitor the DTC Information with a scan tool.

Is DTC P0340, P0341, P0698 or P0699 also set? —

Go to Applicable DTC Go to Step 3

3 Observe the Cam/ Crank Sensor Signal

Synchronization Status parameter with a scan tool.

Does the scan tool indicate Synchronous? —

Go to Diagnostic

Aids Go to Step 4

4 1. Turn OFF the ignition.

2. Disconnect the crankshaft position (CKP) sensor harness connector.

3. Connect a DMM between the 5 volts reference circuit (pin 3 of E-52) and a known good

ground.

4. Turn ON the ignition, with the engine OFF.

Is the DMM voltage more than the specified value? 4.7 volts

Go to Step 5 Go to Step 9

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1766 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-149

5Connect a DMM between the signal circuit (pin 1 of

E-52) and a known good ground.

Is the DMM voltage more than the specified value? 5.3 volts

Go to Step 12 Go to Step 6

6 Is the DMM voltage more than the specified value

at Step 5? 4.7 volts

Go to Step 7 Go to Step 11

7 1. Connect a test lamp between the signal circuit

(pin 1 of E-52) and a known good ground.

2. Connect a DMM between the probe of the test lamp and a known good ground.

Is the DMM voltage more than the specified value? 4.7 volts

Go to Step 13 Go to Step 8

8 Connect a DMM between the 5 volts reference

circuit and low reference circuit (pins 2 and 3 of E-

52).

Is the DMM voltage more than the specified value? 4.7 volts

Go to Step 14 Go to Step 10

9 1. Test the 5 volts reference circuit between the

ECM (pin 37 of E-90) and the CKP sensor (pin

3 of E-52) for an open circuit or high

resistance.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 19 Go to Step 15

10 1. Test the low reference circuit between the

ECM (pin 39 of E-90) and the CKP sensor (pin

2 of E-52) for an open circuit or high

resistance.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 19 Go to Step 15

11 1. Test the signal circuit between the ECM (pin

58 of E-90) and the CKP sensor (pin 1 of E-

52) for the following conditions:

• An open circuit

• A short to ground

• A short to the low reference circuit

• High resistance

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 19 Go to Step 15

12 Important:

The CKP sensor may be damaged if

the sensor signal circuit is shorted to a voltage

source.

1. Test the signal circuit between the ECM (pin 58 of E-90) and the CKP sensor (pin 1 of E-

52) for a short to battery or ignition voltage.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 19 Go to Step 18

13 1. Test the signal circuit between the ECM (pin

58 of E-90) and the CKP sensor (pin 1 of E-

52) for a short to any 5 volts reference.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 19 Go to Step 18

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1767 of 6020

6E-150 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

141. Inspect for an intermittent and for poor

connections at the harness connector of the

CKP sensor (pins 1, 2 and 3 of E-52).

2. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 19 Go to Step 16

15 1. Turn OFF the ignition.

2. Disconnect the ECM harness connector.

3. Inspect for an intermittent and for poor connections at the harness connector of the

ECM (pins 37, 38, 39 and 58 of E-90).

4. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 19 Go to Step 18

16 1. Inspect the CKP sensor and sensor rotor for

the following conditions:

• Physical damage of sensor

• Loose or improper installation of sensor

• Excessive air gap

• Foreign material passing between sensor and sensor rotor

• Physical damage of sensor rotor

• Loose or improper installation of sensor rotor

2. Repair or replace as necessary.

Did you find and correct the condition? —

Go to Step 19 Go to Step 17

17 Replace the CKP sensor. Refer to CKP Sensor

Replacement.

Did you complete the replacement? —

Go to Step 19

—

18Important:

Replacement ECM must be

programmed and learned.

Replace the ECM. Refer to ECM Replacement.

Did you complete the replacement? —

Go to Step 19

—

191. Reconnect all previously disconnected

harness connector(s).

2. Clear the DTCs with a scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine.

5. Operate the vehicle within the Conditions for Running the DTC. You may also operate the

vehicle within the conditions that you

observed from the Freeze Frame/ Failure

Records.

Did the DTC fail this ignition? —

Go to Step 2 Go to Step 20

20 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1768 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-151

DTC P0336 (Flash Code 15)

Circuit Description

The crankshaft position (CKP) sensor is located on the

left-hand of the cylinder block rear and it is behind the

starter motor. The sensor rotor is fixed on the

crankshaft. There are 56 notches spaced 6 ° apart and

a 30 ° section that is open span. This open span portion

allows for the detection of top dead center (TDC). The

ECM monitors both CKP sensor and camshaft position

(CMP) sensor signal pulses to ensure they correlate

with each other. If the ECM receives extra or missing

CKP sensor signal pulse, this DTC will set.

Condition for Running the DTC • DTC P0335 is not set.

• The battery voltage is more than 9 volts.

• The ignition switch is ON.

• The CKP sensor signal pulse is detected.

Condition for Setting the DTC • The ECM detects extra or missing CKP sensor signal pulses during engine rotations. Action Taken When the DTC Sets

• The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

• The ECM limits fuel injection quantity.

• The ECM inhibits pilot injection.

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

• Electromagnetic interference in the CKP sensor circuits may set this DTC.

• An intermittent CKP sensor signal pulse may set this DTC.

• Ensure the sensor is tight and the sensor rotor teeth are not damaged.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

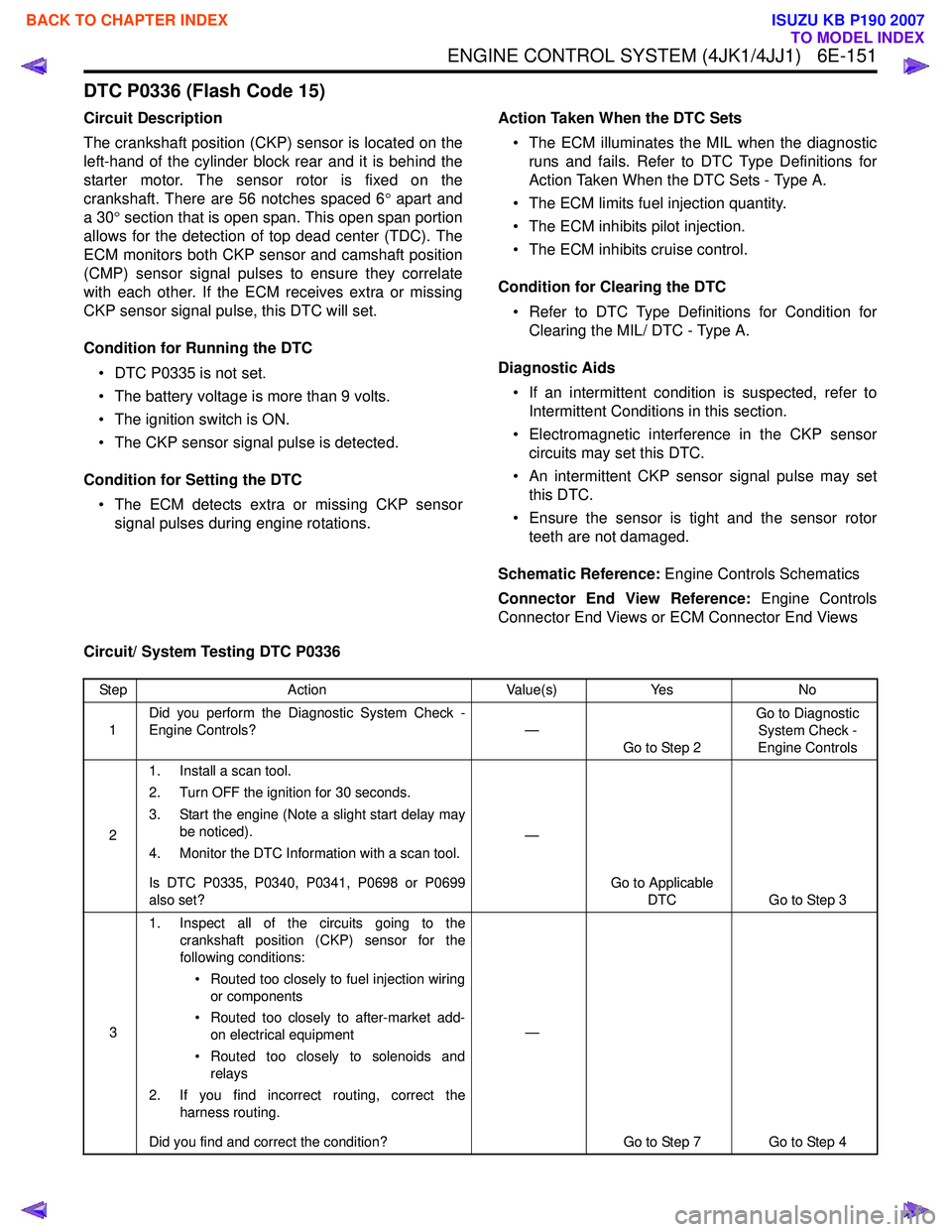

Circuit/ System Testing DTC P0336

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine (Note a slight start delay may be noticed).

4. Monitor the DTC Information with a scan tool.

Is DTC P0335, P0340, P0341, P0698 or P0699

also set? —

Go to Applicable DTC Go to Step 3

3 1. Inspect all of the circuits going to the

crankshaft position (CKP) sensor for the

following conditions:

• Routed too closely to fuel injection wiring or components

• Routed too closely to after-market add- on electrical equipment

• Routed too closely to solenoids and relays

2. If you find incorrect routing, correct the harness routing.

Did you find and correct the condition? —

Go to Step 7 Go to Step 4

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1769 of 6020

6E-152 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

41. Turn OFF the ignition.

2. Disconnect the ECM harness connector.

3. Inspect for an intermittent, for poor connections and corrosion at the harness

connector of the ECM (pins 37, 38, 39 and 58

of E-90).

4. Disconnect the CKP sensor harness connector.

5. Inspect for an intermittent, for poor connections and corrosion at the harness

connector of the CKP sensor (pins 1, 2 and 3

of E-52).

6. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 7 Go to Step 5

5 1. Inspect the CKP sensor and sensor rotor for

the following conditions:

• Physical damage of sensor

• Loose or improper installation of sensor

• Excessive air gap

• Foreign material passing between sensor and sensor rotor

• Physical damage of sensor rotor

• Loose or improper installation of sensor rotor

2. Repair or replace as necessary.

Did you find and correct the condition? —

Go to Step 7 Go to Step 6

6 Replace the CKP sensor. Refer to CKP Sensor

Replacement.

Did you complete the replacement? —

Go to Step 7

—

71. Reconnect all previously disconnected

harness connector(s).

2. Clear the DTCs with a scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine.

5. Operate the vehicle within the Conditions for Running the DTC. You may also operate the

vehicle within the conditions that you

observed from the Freeze Frame/ Failure

Records.

Did the DTC fail this ignition? —

Go to Step 2 Go to Step 8

8 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1770 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-153

DTC P0340 (Flash Code 14)

Circuit Description

The camshaft position (CMP) sensor is installed on the

timing chain sprocket cover at the front of the camshaft

idle gear. The CMP sensor detects total of five

projections per one engine cycle (four projections

arranged equally every 90 ° and one reference

projection on the timing chain sprocket surface). The

CMP sensor is a magnetic resistance element (MRE)

type sensor, which generates a square wave signal

pulse. The sensor has the following circuits.

• 5 volts reference circuit

• Low reference circuit

• CMP sensor signal circuit

The ECM monitors both crankshaft position (CKP)

sensor and CMP sensor signal pulses to ensure they

correlate with each other. If the ECM receives a certain

amount of CKP sensor signal pulses without a CMP

sensor signal pulse, this DTC will set.

Condition for Running the DTC • DTCs P0016 and P0341are not set.

• The battery voltage is more than 9 volts.

• The ignition switch is ON.

• The CKP sensor signal pulse is detected.

Condition for Setting the DTC • The ECM detects that the CMP sensor signal pulses are not generated during engine rotations.

Action Taken When the DTC Sets • The ECM illuminates the SVS lamp when the diagnostic runs and fails. Refer to DTC Type

Definitions for Action Taken When the DTC Sets -

Type C. (Euro 4 Specification) • The ECM illuminates the MIL when the diagnostic

runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

(Except Euro 4 Specification)

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the SVS Lamp/ DTC - Type C. (Euro 4

Specification)

• Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A. (Except Euro 4

Specification)

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

• Electromagnetic interference in the CMP sensor circuits may set this DTC.

• An intermittent CMP sensor signal pulse may set this DTC.

• Ensure the sensor is tight and the timing chain sprocket is not damaged.

Notice: • If the CMP sensor signal pulse is lost while running, the engine will operate normally. If the

CMP sensor signal pulse is not present on start-

up, the engine will not start.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P0340

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine. If the engine does not start, crank over the engine for 10 seconds.

4. Monitor the DTC Information with a scan tool.

Is DTC P0652 or P0653 also set? —

Go to Applicable DTC Go to Step 3

3 Start the engine. If the engine does not start, crank

over the engine for 10 seconds while observing the

Cam/ Crank Sensor Signal Synchronization Status

parameter with a scan tool.

Does the scan tool indicate Synchronous? —

Go to Diagnostic Aids Go to Step 4

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1771 of 6020

6E-154 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

41. Turn OFF the ignition.

2. Disconnect the camshaft position (CMP) sensor harness connector.

3. Connect a DMM between the 5 volts reference circuit (pin 3 of E-39) and a known good

ground.

4. Turn ON the ignition, with the engine OFF.

Is the DMM voltage more than the specified value? 4.7 volts

Go to Step 5 Go to Step 9

5 Connect a DMM between the signal circuit (pin 1 of

E-39) and a known good ground.

Is the DMM voltage more than the specified value? 5.3 volts

Go to Step 12 Go to Step 6

6 Is the DMM voltage more than the specified value

at Step 5? 4.7 volts

Go to Step 7 Go to Step 11

7 1. Connect a test lamp between the signal circuit

(pin 1 of E-39) and a known good ground.

2. Connect a DMM between the probe of the test lamp and a known good ground.

Is the DMM voltage more than the specified value? 4.7 volts

Go to Step 13 Go to Step 8

8 Connect a DMM between the 5 volts reference

circuit and low reference circuit (pins 2 and 3 of E-

39).

Is the DMM voltage more than the specified value? 4.7 volts

Go to Step 14 Go to Step 10

9 1. Test the 5 volts reference circuit between the

ECM (pin 46 of E-90) and the CMP sensor

(pin 3 of E-39) for an open circuit or high

resistance.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 19 Go to Step 15

10 1. Test the low reference circuit between the

ECM (pin 44 of E-90) and the CMP sensor

(pin 2 of E-39) for an open circuit or high

resistance.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 19 Go to Step 15

11 1. Test the signal circuit between the ECM (pin

45 of E-90) and the CKP sensor (pin 1 of E-

39) for the following conditions:

• An open circuit

• A short to ground

• A short to the low reference circuit

• High resistance

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 19 Go to Step 15

12 Important:

The CMP sensor may be damaged if

the sensor signal circuit is shorted to a voltage

source.

1. Test the signal circuit between the ECM (pin 45 of E-90) and the CMP sensor (pin 1 of E-

39) for a short to battery or ignition voltage.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 19 Go to Step 18

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1772 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-155

131. Test the signal circuit between the ECM (pin

45 of E-90) and the CMP sensor (pin 1 of E-

39) for a short to any 5 volts reference.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 19 Go to Step 18

14 1. Inspect for an intermittent and for poor

connections at the harness connector of the

CMP sensor (pins 1, 2 and 3 of E-39).

2. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 19 Go to Step 16

15 1. Turn OFF the ignition.

2. Disconnect the ECM harness connector.

3. Inspect for an intermittent and for poor connections at the harness connector of the

ECM (pins 44, 45, 46 and 64 of E-90).

4. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 19 Go to Step 18

16 1. Inspect the CMP sensor and chain sprocket

for the following conditions:

• Physical damage of sensor

• Loose or improper installation of sensor

• Excessive air gap

• Foreign material passing between sensor and chain sprocket

• Physical damage of chain sprocket

• Loose or improper installation of chain sprocket

2. Repair or replace as necessary.

Did you find and correct the condition? —

Go to Step 19 Go to Step 17

17 Replace the CMP sensor. Refer to CMP Sensor

Replacement.

Did you complete the replacement? —

Go to Step 19

—

18Important:

Replacement ECM must be

programmed and learned.

Replace the ECM. Refer to ECM Replacement.

Did you complete the replacement? —

Go to Step 19

—

191. Reconnect all previously disconnected

harness connector(s).

2. Clear the DTCs with a scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine.

5. Operate the vehicle within the Conditions for Running the DTC. You may also operate the

vehicle within the conditions that you

observed from the Freeze Frame/ Failure

Records.

Did the DTC fail this ignition? —

Go to Step 2 Go to Step 20

20 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1773 of 6020

6E-156 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

DTC P0341 (Flash Code 14)

Circuit Description

The camshaft position (CMP) sensor is installed on the

timing chain sprocket cover at the front of the camshaft

idle gear. The CMP sensor detects total of five

projections per one engine cycle (four projections

arranged equally every 90 ° and one reference

projection on the timing chain sprocket surface). The

ECM monitors both crankshaft position (CKP) sensor

and CMP sensor signal pulses to ensure they correlate

with each other. If the ECM receives extra or missing

CMP sensor signal pulse, this DTC will set.

Condition for Running the DTC • DTCs P0016 and P0340 are not set.

• The battery voltage is more than 9 volts.

• The ignition switch is ON.

• The CMP sensor signal pulse is detected.

Condition for Setting the DTC • The ECM detects extra or missing CMP sensor signal pulses during engine rotations.

Action Taken When the DTC Sets • The ECM illuminates the SVS lamp when the diagnostic runs and fails. Refer to DTC Type

Definitions for Action Taken When the DTC Sets -

Type C. (Euro 4 Specification) • The ECM illuminates the MIL when the diagnostic

runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

(Except Euro 4 Specification)

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the SVS Lamp/ DTC - Type C. (Euro 4

Specification)

• Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A. (Except Euro 4

Specification)

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

• Electromagnetic interference in the CMP sensor circuits may set this DTC.

• An intermittent CMP sensor signal pulse may set this DTC.

• Ensure the sensor is tight and the timing chain sprocket is not damaged.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P0341

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine. If the engine does not start, crank over the engine for 10 seconds.

4. Monitor the DTC Information with a scan tool.

Is DTC P0340, P0652 or P0653 also set? —

Go to Applicable DTC Go to Step 3

3 1. Inspect all of the circuits going to the camshaft

position (CMP) sensor for the following

conditions:

• Routed too closely to fuel injection wiring or components

• Routed too closely to after-market add- on electrical equipment

• Routed too closely to solenoids and relays

2. If you find incorrect routing, correct the harness routing.

Did you find and correct the condition? —

Go to Step 7 Go to Step 4

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1774 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-157

41. Turn OFF the ignition.

2. Disconnect the CMP sensor harness connector.

3. Inspect for an intermittent, for poor connections and corrosion at the harness

connector of the CMP sensor (pins 1, 2 and 3

of E-39).

4. Disconnect the ECM harness connector.

5. Inspect for an intermittent, for poor connections and corrosion at the harness

connector of the ECM (pins 44, 45, 46 and 64

of E-90).

6. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 7 Go to Step 5

5 1. Inspect the CMP sensor and chain sprocket

for the following conditions:

• Physical damage of sensor

• Loose or improper installation of sensor

• Excessive air gap

• Foreign material passing between sensor and chain sprocket

• Physical damage of chain sprocket

• Loose or improper installation of chain sprocket

2. Repair or replace as necessary.

Did you find and correct the condition? —

Go to Step 7 Go to Step 6

6 Replace the CMP sensor. Refer to CMP Sensor

Replacement.

Did you complete the replacement? —

Go to Step 7

—

71. Reconnect all previously disconnected

harness connector(s).

2. Clear the DTCs with a scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine.

5. Operate the vehicle within the Conditions for Running the DTC. You may also operate the

vehicle within the conditions that you

observed from the Freeze Frame/ Failure

Records.

Did the DTC fail this ignition? —

Go to Step 2 Go to Step 8

8 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007