sensor ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1789 of 6020

6E-172 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

DTC P0500 (Flash Code 25)

Circuit Description

The vehicle speed sensor (VSS) is used by the ECM

and speedometer, which generates a speed signal from

the transmission output shaft rotational speed or

transfer output shaft rotational speed. The sensor has

the following circuits.

• Ignition voltage circuit

• Low reference circuit

• VSS signal circuit

The VSS uses a hall effect element. It interacts with the

magnetic field created by the rotating magnet and

outputs square wave pulse signal. The ECM calculates

the vehicle speed by the VSS. If the 2WD fitted with

Jatco automatic transmission, VSS signals are sent

from the TCM. If the ECM detects VSS signals are not

generated, this DTC will set.

Condition for Running the DTC • The ignition voltage is more than 9 volts.

• The ignition switch is ON.

• The engine speed is more than 1000 RPM.

• The commanded fuel injection quantity is OFF (accelerator pedal is not depressed). Condition for Setting the DTC

• The ECM detects that the VSS signals are not generated for 5 seconds.

Action Taken When the DTC Sets • The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

• Electromagnetic interference in the VSS circuits may set this DTC.

Notice: • If this DTC set, the Vehicle Speed parameter on the scan tool will display 3 km/h (2 MPH).

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P0500 (2WD fitted with Jatco A/T)

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Turn ON the ignition, with the engine OFF.

4. Monitor the DTC Information with a scan tool.

Is DTC P0219 also set? —

Go to DTC P0219 Go to Step 3

3 Monitor the transmission DTC Information with a

scan tool.

Is DTC P0722 set? —Go to P0722 in

Automatic

Transmission

Section Go to Step 4

4 Drive the vehicle while observing the Vehicle

Speed parameter with a scan tool.

Does the scan tool indicate correct vehicle speed? —

Go to Diagnostic

Aids Go to Step 5

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1791 of 6020

6E-174 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

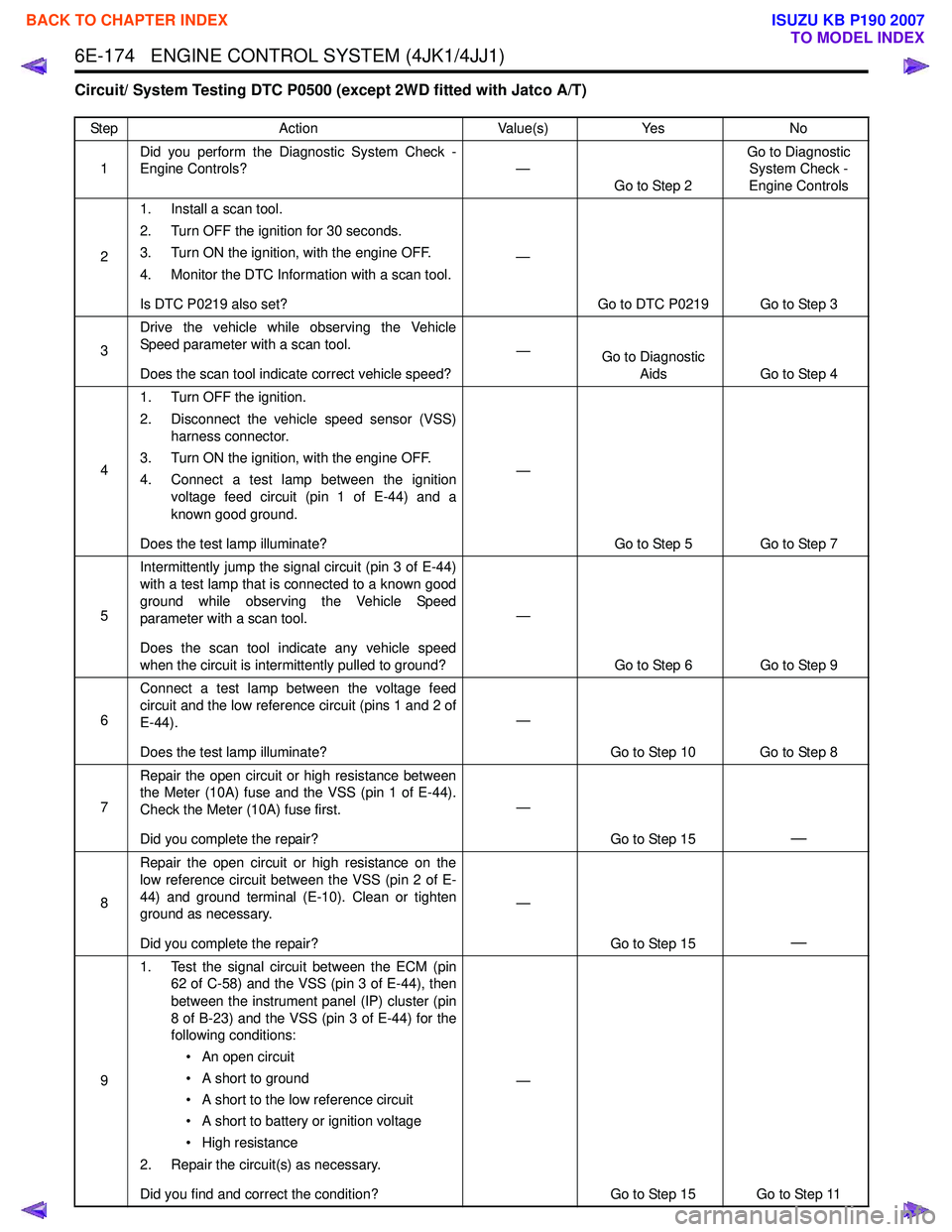

Circuit/ System Testing DTC P0500 (except 2WD fitted with Jatco A/T)

StepAction Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Turn ON the ignition, with the engine OFF.

4. Monitor the DTC Information with a scan tool.

Is DTC P0219 also set? —

Go to DTC P0219 Go to Step 3

3 Drive the vehicle while observing the Vehicle

Speed parameter with a scan tool.

Does the scan tool indicate correct vehicle speed? —

Go to Diagnostic

Aids Go to Step 4

4 1. Turn OFF the ignition.

2. Disconnect the vehicle speed sensor (VSS) harness connector.

3. Turn ON the ignition, with the engine OFF.

4. Connect a test lamp between the ignition voltage feed circuit (pin 1 of E-44) and a

known good ground.

Does the test lamp illuminate? —

Go to Step 5 Go to Step 7

5 Intermittently jump the signal circuit (pin 3 of E-44)

with a test lamp that is connected to a known good

ground while observing the Vehicle Speed

parameter with a scan tool.

Does the scan tool indicate any vehicle speed

when the circuit is intermittently pulled to ground? —

Go to Step 6 Go to Step 9

6 Connect a test lamp between the voltage feed

circuit and the low reference circuit (pins 1 and 2 of

E-44).

Does the test lamp illuminate? —

Go to Step 10 Go to Step 8

7 Repair the open circuit or high resistance between

the Meter (10A) fuse and the VSS (pin 1 of E-44).

Check the Meter (10A) fuse first.

Did you complete the repair? —

Go to Step 15

—

8Repair the open circuit or high resistance on the

low reference circuit between the VSS (pin 2 of E-

44) and ground terminal (E-10). Clean or tighten

ground as necessary.

Did you complete the repair? —

Go to Step 15

—

91. Test the signal circuit between the ECM (pin

62 of C-58) and the VSS (pin 3 of E-44), then

between the instrument panel (IP) cluster (pin

8 of B-23) and the VSS (pin 3 of E-44) for the

following conditions:

• An open circuit

• A short to ground

• A short to the low reference circuit

• A short to battery or ignition voltage

• High resistance

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 15 Go to Step 11

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1792 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-175

101. Inspect for an intermittent and for poor

connections at the harness connector of the

VSS (pin 1, 2 and 3 of E-44).

2. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 15 Go to Step 12

11 1. Turn OFF the ignition.

2. Disconnect the ECM harness connector.

3. Inspect for an intermittent and for a poor connection at the harness connector of the

ECM (pin 62 of C-58).

4. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 15 Go to Step 14

12 1. Inspect the VSS, drive gear, driven gear or

output shaft for the following conditions:

• Physical damage of sensor, drive gear or driven gear

• Loose or improper installation of sensor, drive gear or driven gear

• Transmission output shaft teeth damage

• Excessive transmission output shaft play

• Transfer output shaft teeth damage

• Excessive transfer output shaft play

2. Repair or replace as necessary.

Did you find and correct the condition? —

Go to Step 15 Go to Step 13

13 Replace the VSS. Refer to VSS Replacement.

Did you complete the replacement? —

Go to Step 15

—

14Important:

Replacement ECM must be

programmed and learned.

Replace the ECM. Refer to ECM Replacement.

Did you complete the replacement? —

Go to Step 15

—

151. Reconnect all previously disconnected fuse or

harness connector(s).

2. Clear the DTCs with a scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Drive the vehicle while observing the Vehicle Speed parameter with a scan tool.

Does the scan tool indicate correct vehicle speed? —

Go to Step 16 Go to Step 4

16 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1793 of 6020

6E-176 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

DTC P0501 (Flash Code 25)

Circuit Description

The vehicle speed sensor (VSS) is used by the ECM

and speedometer, which generates a speed signal from

the transmission output shaft rotational speed or

transfer output shaft rotational speed. The sensor has

the following circuits.

• Ignition voltage feed circuit

• Low reference circuit

• VSS signal circuit

The VSS uses a hall effect element. It interacts with the

magnetic field created by the rotating magnet and

outputs square wave pulse signal. The ECM calculates

the vehicle speed by the VSS. If the 2WD fitted with

Jatco automatic transmission, VSS signals are sent

from the TCM. If the ECM detects VSS signals are

sharply changed, this DTC will set.

Condition for Running the DTC • The ignition voltage is more than 9 volts.

• The ignition switch is ON.

Condition for Setting the DTC • The ECM detects that the VSS signal are changed larger than a predetermined vehicle speed within a

very short calibrated time. Action Taken When the DTC Sets

• The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

• Electromagnetic interference in the VSS circuits may set this DTC.

Notice: • If this DTC set, the Vehicle Speed parameter on the scan tool will display 3 km/h (2 MPH).

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P0501

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Inspect all of the circuits going to the vehicle

speed sensor (VSS) for the following

conditions:

• Routed too closely to fuel injection wiring or components

• Routed too closely to after-market add- on electrical equipment

• Routed too closely to solenoids, relays, and motors

2. If you find incorrect routing, correct the harness routing.

Did you find and correct the condition? —

Go to Step 8 Go to Step 3

3 1. Inspect for an intermittent, for poor

connections and corrosion at the Meter (10A)

fuse.

2. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 8 Go to Step 4

4 1. Inspect for an intermittent, a poor connection

and corrosion at the ground terminal (E-10).

2. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 8 Go to Step 5

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1794 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-177

51. Turn OFF the ignition.

2. Disconnect the VSS harness connector.

3. Inspect for an intermittent, for poor connections and corrosion at the harness

connector of the VSS (pins 1, 2 and 3 of E-

44).

4. Disconnect the ECM harness connector.

5. Inspect for an intermittent, for a poor connection and corrosion at the harness

connector of the ECM (pin 62 of C-58).

6. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 8 Go to Step 6

6 1. Inspect the VSS, drive gear, driven gear or

output shaft for the following conditions:

• Physical damage of sensor, drive gear or driven gear

• Loose or improper installation of sensor, drive gear or driven gear

• Transmission output shaft teeth damage

• Excessive transmission output shaft play

• Transfer output shaft teeth damage

• Excessive transfer output shaft play

2. Repair or replace as necessary.

Did you find and correct the condition? —

Go to Step 8 Go to Step 7

7 Replace the VSS. Refer to VSS Replacement.

Did you complete the replacement? —

Go to Step 8

—

81. Reconnect all previously disconnected

harness connector(s).

2. Clear the DTCs with a scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Drive the vehicle while observing the Vehicle Speed with a scan tool.

Does the scan tool parameter indicate correct

vehicle speed? —

Go to Step 9 Go to Step 2

9 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1818 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-201

DTC P0638 (Flash Code 61)

Circuit Description

The ECM controls the intake throttle valve opening

based on the engine running condition and by

controlling the intake throttle solenoid. The intake

throttle valve position is detected by the position

sensor, and relayed to the ECM. If the ECM detects a

variance between the actual intake throttle position and

desired intake throttle position while the intake throttle

solenoid is commanded ON, this DTC will set.

Condition for Running the DTC • DTCs P0122, P0123, P0698 and P0699 are not set.

• The battery voltage is between 11 to 16 volts.

• The ignition switch is ON.

• The intake throttle solenoid commanded ON.

• The desired intake throttle position is stable.

Condition for Setting the DTC • The ECM detects that the difference between the actual and the desired intake throttle position is

more than 10% for 5 seconds. Action Taken When the DTC Sets

• The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

• The ECM limits fuel injection quantity.

• The ECM inhibits pilot injection.

• The ECM inhibits EGR control.

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

• A sticking or intermittently sticking intake throttle valve may set this DTC.

• A sticking intake throttle valve at full closed position will cause engine starting problem.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P0638

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with a scan tool.

Is DTC P0122, P0123, P2100, P2101 or P2103

also set? —

Go to Applicable DTC Go to Step 3

3 1. Perform the Intake Throttle Solenoid Control

with a scan tool several times.

2. Command the Desired Intake Throttle Position Increase and Decrease while observing the

Intake Throttle Position.

Does the Intake Throttle Position parameter follow

within the specified value quick enough (compare

with a similar unit if available)? ±

5%

Go to Diagnostic Aids Go to Step 4

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1820 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-203

DTC P0642 or P0643 (Flash Code 55)

Circuit Description

The ECM provides 5 volts reference voltage through

the reference circuit 1 to the accelerator pedal position

(APP) sensor 1. The ECM monitors the voltage on the

5 volts reference circuit 1. If the ECM detects the

voltage is excessively low or high, DTC P0642 or

P0643 will set.

Condition for Running the DTC • The battery voltage is more than 6 volts.

• The ignition switch is ON.

Condition for Setting the DTC • The ECM detects that the 5 volts reference circuit 1 voltage is less than 4.7 volts. (DTC P0642)

• The ECM detects that the 5 volts reference circuit 1 voltage is more than 5.3 volts. (DTC P0643)

Action Taken When the DTC Sets • The ECM illuminates the SVS lamp when the diagnostic runs and fails. Refer to DTC Type

Definitions for Action Taken When the DTC Sets -

Type C. (Euro 4 Specification) • The ECM illuminates the MIL when the diagnostic

runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

(Except Euro 4 Specification)

• The ECM limits fuel injection quantity

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the SVS Lamp/ DTC - Type C. (Euro 4

Specification)

• Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A. (Except Euro 4

Specification)

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P0642

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with a scan tool.

Does the DTC fail this ignition? —

Go to Step 3 Go to Diagnostic

Aids

3 1. Turn OFF the ignition.

2. Disconnect the accelerator pedal position (APP) sensor harness connector.

3. Connect a DMM between the 5 volts reference circuit (pin 10 of C-40) and a known good

ground.

4. Turn ON the ignition, with engine OFF.

Is the DMM voltage more than the specified value? 4.7 volts

Go to Step 5 Go to Step 4

4 1. Test the 5 volts reference circuit between the

ECM (pin 11 of C-58) and the APP sensor (pin

10 of C-40) for the following conditions:

• A short to ground

• A short to the low reference circuit

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 7 Go to Step 6

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1821 of 6020

6E-204 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

Circuit/ System Testing DTC P0643

5Replace the APP sensor. Refer to APP Sensor

Replacement.

Did you complete the replacement? —

Go to Step 7

—

6Important:

Replacement ECM must be

programmed and learned.

Replace the ECM. Refer to ECM Replacement.

Did you complete the replacement? —

Go to Step 7

—

71. Reconnect all previously disconnected

harness connector(s).

2. Clear the DTCs with a scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine.

5. Operate the vehicle within the Conditions for Running the DTC. You may also operate the

vehicle within the conditions that you

observed from the Freeze Frame/ Failure

Records.

Did the DTC fail this ignition? —

Go to Step 3 Go to Step 8

8 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

Step

Action Value(s)Yes No

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with a scan tool.

Does the DTC fail this ignition? —

Go to Step 3 Go to Diagnostic

Aids

3 1. Test the 5 volts reference circuit between the

ECM (pin 11 of C-58) and the APP sensor 1

(pin 10 of C-40) for a short to battery or

ignition voltage.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 5 Go to Step 4

4 Important:

Replacement ECM must be

programmed and learned.

Replace the ECM. Refer to ECM Replacement.

Did you complete the replacement? —

Go to Step 5

—

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1826 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-209

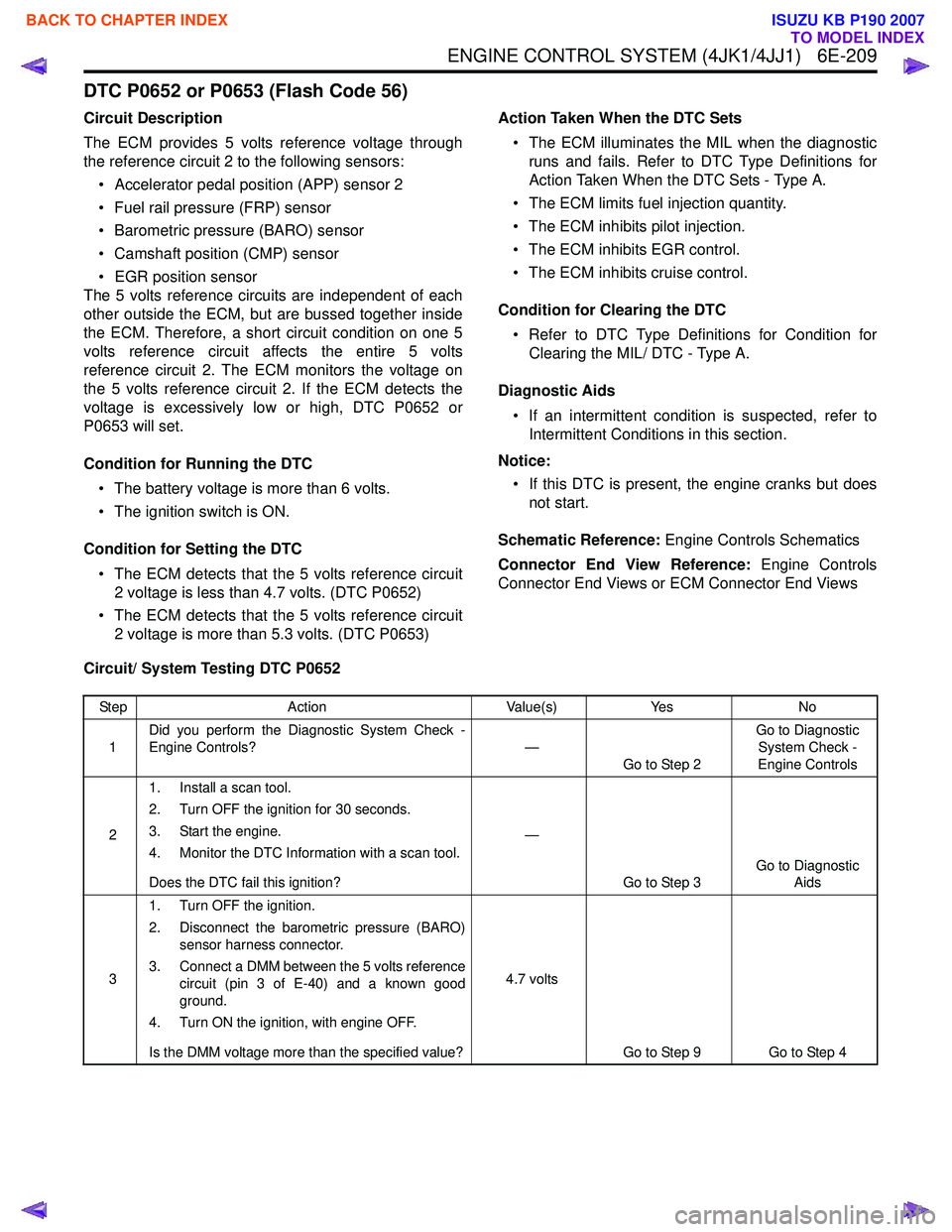

DTC P0652 or P0653 (Flash Code 56)

Circuit Description

The ECM provides 5 volts reference voltage through

the reference circuit 2 to the following sensors:

• Accelerator pedal position (APP) sensor 2

• Fuel rail pressure (FRP) sensor

• Barometric pressure (BARO) sensor

• Camshaft position (CMP) sensor

• EGR position sensor

The 5 volts reference circuits are independent of each

other outside the ECM, but are bussed together inside

the ECM. Therefore, a short circuit condition on one 5

volts reference circuit affects the entire 5 volts

reference circuit 2. The ECM monitors the voltage on

the 5 volts reference circuit 2. If the ECM detects the

voltage is excessively low or high, DTC P0652 or

P0653 will set.

Condition for Running the DTC • The battery voltage is more than 6 volts.

• The ignition switch is ON.

Condition for Setting the DTC • The ECM detects that the 5 volts reference circuit 2 voltage is less than 4.7 volts. (DTC P0652)

• The ECM detects that the 5 volts reference circuit 2 voltage is more than 5.3 volts. (DTC P0653) Action Taken When the DTC Sets

• The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

• The ECM limits fuel injection quantity.

• The ECM inhibits pilot injection.

• The ECM inhibits EGR control.

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

Notice: • If this DTC is present, the engine cranks but does not start.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P0652

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with a scan tool.

Does the DTC fail this ignition? —

Go to Step 3 Go to Diagnostic

Aids

3 1. Turn OFF the ignition.

2. Disconnect the barometric pressure (BARO) sensor harness connector.

3. Connect a DMM between the 5 volts reference circuit (pin 3 of E-40) and a known good

ground.

4. Turn ON the ignition, with engine OFF.

Is the DMM voltage more than the specified value? 4.7 volts

Go to Step 9 Go to Step 4

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1827 of 6020

6E-210 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

41. Leave the DMM connected to the BARO

sensor harness connector.

2. Turn OFF the ignition.

3. Disconnect the EGR valve harness connector.

4. Turn ON the ignition, with the engine OFF.

Does the DMM voltage change to more than the

specified value? 4.7 volts

Go to Step 10 Go to Step 5

5 1. Leave the DMM connected to the BARO

sensor harness connector.

2. Turn OFF the ignition.

3. Disconnect the fuel rail pressure (FRP) sensor harness connector.

4. Turn ON the ignition, with the engine OFF.

Does the DMM voltage change to more than the

specified value? 4.7 volts

Go to Step 11 Go to Step 6

6 1. Leave the DMM connected to the BARO

sensor harness connector.

2. Turn OFF the ignition.

3. Disconnect the camshaft position (CMP) sensor harness connector.

4. Turn ON the ignition, with the engine OFF.

Does the DMM voltage change to more than the

specified value? 4.7 volts

Go to Step 12 Go to Step 7

7 1. Leave the DMM connected to the BARO

sensor harness connector.

2. Turn OFF the ignition.

3. Disconnect the accelerator pedal position (APP) sensor harness connector.

4. Turn ON the ignition, with the engine OFF.

Does the DMM voltage change to more than the

specified value? 4.7 volts

Go to Step 13 Go to Step 8

8 1. Test the 5 volts reference circuit between the

ECM and the following components for a short

to ground or short to the low reference circuit:

• ECM (pin 19 of E-90) and BARO sensor (pin 3 of E-40)

• ECM (pin 31 of E-90) and EGR position sensor (pin 1 of E-71)

• ECM (pin 47 of E-90) and FRP sensor (pin 3 of E-48)

• ECM (pin 46 of E-90) and CMP sensor (pin 3 of E-39)

• ECM (pin 9 of C-58) and APP sensor 2 (pin 8 of C-40)

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 15 Go to Step 14

9 Replace the BARO sensor. Refer to BARO Sensor

Replacement.

Did you complete the replacement? —

Go to Step 15

—

10Replace the EGR valve. Refer to EGR Valve

Replacement.

Did you complete the replacement? —

Go to Step 15

—

Step Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007