torque ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2169 of 6020

STARTING AND CHARGING SYSTEM 6D3-21

Technical Data

(mm)

Brush wear - Minimum Length 3.8

Sliprings - Minimum Diameter 26.7

Sliprings - Trueness <0.06

Pole claws - Trueness <0.05(93.25 ±0.05)

Torque N.m(kgf⋅m)

Pulley retaining nut 54-68(5.5-6.9)

Capacitor retaining screw 2.7-3.8(0.3-0.4)

Capacitor whiz nut 1.5-2.2(0.1-0.2)

B+ terminal nut M8 7.5-8.5(0.8-0.9)

B+ terminal rectifier nut 6.0-7.5(0.6-0.8)

Regulator retaining screw 1.6-2.3(0.1-0.2)

Rectifier retaining screw 1.6-2.3(0.1-0.2)

Bearing retaining plate screw 2.1-3.0(0.2-0.3)

Through bolt 3.8-5.5(0.4-0.6)

W inding resistance(between phases) (Ω )

Stator Rotor

70 Amp generator 0.086+10% 2.6 ±0.13

85 Amp generator 0.058+10% 2.6 ±0.13

90 Amp generator 0.056+10% 2.6 ±0.13

W arning lamp fault indication

Fault running Generator not

running Ignition ON Generator

Iginiton ON

Generator out cable

O/C ON

ON

Battery "S" cable O/C ONON

Battery overcharged ONON

Positive diode short OFFON

Negative diode short ONON

Positive diode open ONOFF

Negative diode open ONOFF

Phase voltage sensing ONON

cable open circuit

Power transistor

shorted ON

ON

W arnign lamp driver

O/C OFF

OFF

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2225 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–55

Low or high spark plug installation torque or improper

seating can result in the spark plug running too hot and

can cause excessive center electrode wear. The plug

and the cylinder head seats must be in good contact for

proper heat transfer and spark plug cooling. Dirty or

damaged threads in the head or on the spark plug can

keep it from seating even though the proper torque is

applied. Once spark plugs are properly seated, tighten

them to the torque shown in the Specifications Table.

Low torque may result in poor contact of the seats due

to a loose spark plug. Over tightening may cause the

spark plug shell to be stretched and will result in poor

contact between the seats. In extreme cases, exhaust

blow-by and damage beyond simple gap wear may

occur.

Cracked or broken insulators may be the result of

improper installation, damage during spark plug re-

gapping, or heat shock to the insulator material. Upper

insulators can be broken when a poorly fitting tool is

used during installation or removal, when the spark plug

is hit from the outside, or is dropped on a hard surface.

Cracks in the upper insulator may be inside the shell

and not visible. Also, the breakage may not cause

problems until oil or moisture penetrates the crack later. A broken or cracked lower insulator tip (around the

center electrode) may result from damage during re-

gapping or from “heat shock” (spark plug suddenly

operating too hot).

• Damage during re-gapping can happen if the gapping tool is pushed against the center electrode or the

insulator around it, causing the insulator to crack.

When re-gapping a spark plug, make the adjustment

by bending only the ground side terminal, keeping the

tool clear of other parts.

• “Heat shock” breakage in the lower insulator tip generally occurs during several engine operating

conditions (high speeds or heavy loading) and may

be caused by over-advanced timing or low grade

fuels. Heat shock refers to a rapid increase in the tip

temperature that causes the insulator material to

crack.

Spark plugs with less than the recommended amount of

service can sometimes be cleaned and re-gapped, then

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2434 of 6020

6E–264 ENGINE DRIVEABILITY AND EMISSIONS

ON-VEHICLE SERVICE PROCEDURE

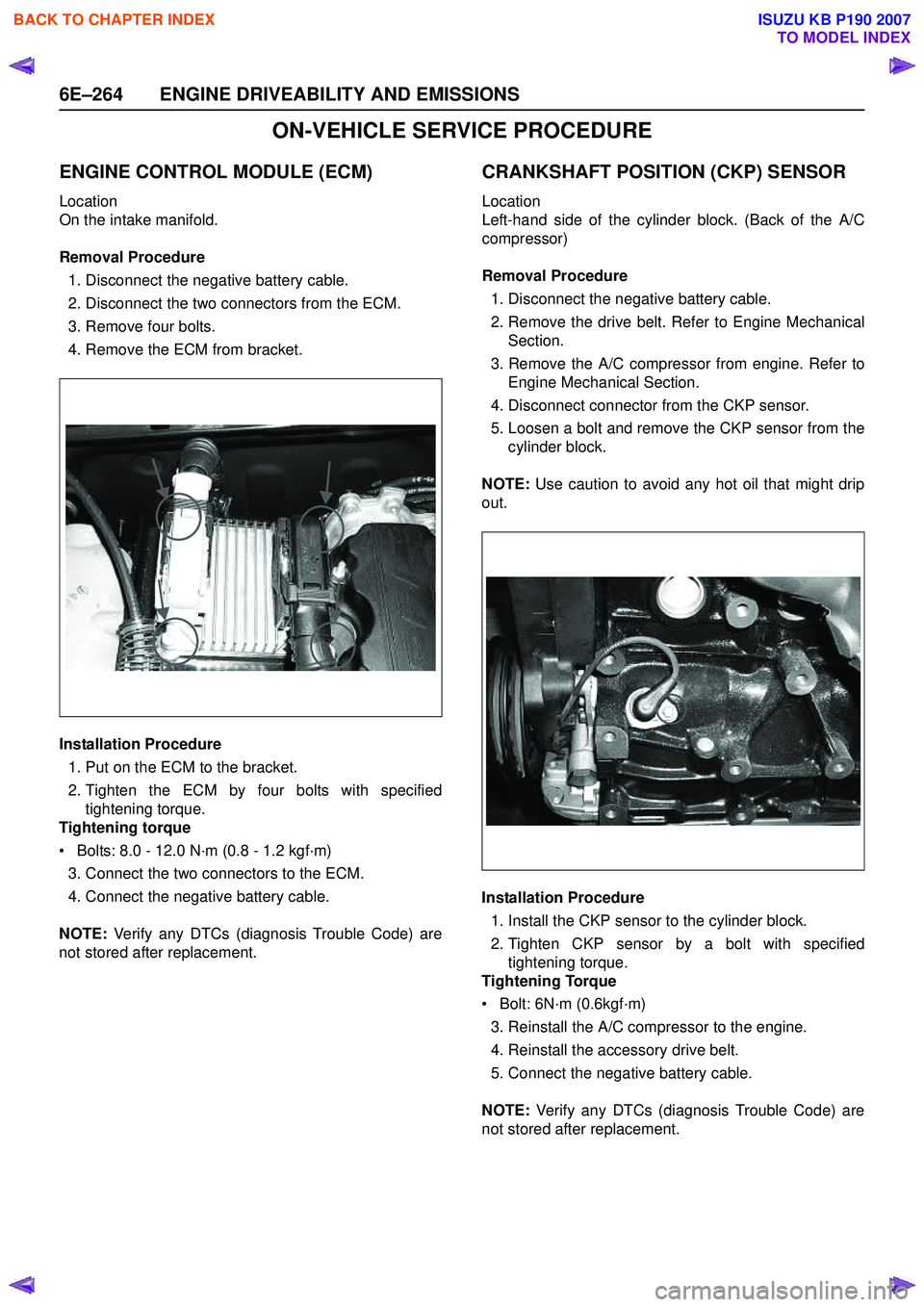

ENGINE CONTROL MODULE (ECM)

Location

On the intake manifold.

Removal Procedure 1. Disconnect the negative battery cable.

2. Disconnect the two connectors from the ECM.

3. Remove four bolts.

4. Remove the ECM from bracket.

Installation Procedure 1. Put on the ECM to the bracket.

2. Tighten the ECM by four bolts with specified tightening torque.

Tightening torque

• Bolts: 8.0 - 12.0 N·m (0.8 - 1.2 kgf·m) 3. Connect the two connectors to the ECM.

4. Connect the negative battery cable.

NOTE: Verify any DTCs (diagnosis Trouble Code) are

not stored after replacement.

CRANKSHAFT POSITION (CKP) SENSOR

Location

Left-hand side of the cylinder block. (Back of the A/C

compressor)

Removal Procedure 1. Disconnect the negative battery cable.

2. Remove the drive belt. Refer to Engine Mechanical Section.

3. Remove the A/C compressor from engine. Refer to Engine Mechanical Section.

4. Disconnect connector from the CKP sensor.

5. Loosen a bolt and remove the CKP sensor from the cylinder block.

NOTE: Use caution to avoid any hot oil that might drip

out.

Installation Procedure 1. Install the CKP sensor to the cylinder block.

2. Tighten CKP sensor by a bolt with specified tightening torque.

Tightening Torque

• Bolt: 6N·m (0.6kgf·m)

3. Reinstall the A/C compressor to the engine.

4. Reinstall the accessory drive belt.

5. Connect the negative battery cable.

NOTE: Verify any DTCs (diagnosis Trouble Code) are

not stored after replacement.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2435 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–265

ENGINE COOLANT TEMPERATURE (ECT)

SENSOR

Location

Installed to the thermostat housing.

Removal Procedure 1. Disconnect the negative battery cable.

2. Drain enough engine coolant so that the coolant level will be below the ECT sensor.

3. Disconnect connector from the ECT sensor.

4. Loosen and remove the ECT sensor from the thermostat housing.

NOTE: Cool down the engine before above procedures

are carried out.

Installation Procedure

1. Apply sealer to threads of screw at the ECT sensor.

2. Tighten the ECT sensor with specified tightening torque.

Tightening Torque

• Bolt: 13N·m (1.3kgf·m)

3. Connect a ECT sensor connector to the ECT sensor.

4. Fill the engine coolant.

5. Connect the negative battery cable.

NOTE: Verify any DTCs (diagnosis Trouble Code) are

not stored after replacement.

Verify no engine coolant leaking from the sensor

threads after replacement.

INTAKE AIR TEMPERATURE (IAT) SENSOR

Location

Installed to the intake duct housing.

Removal Procedure 1. Disconnect the negative battery cable.

2. Disconnect a IAT sensor connector from the IAT sensor.

3. Remove the IAT sensor from the intake duct.

Installation Procedure 1. Install the IAT sensor into intake air duct.

2. Connect a IAT sensor connector to the IAT sensor.

3. Connect the negative battery cable.

NOTE: Verify any DTCs (diagnosis Trouble Code) are

not stored after replacement.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2436 of 6020

6E–266 ENGINE DRIVEABILITY AND EMISSIONS

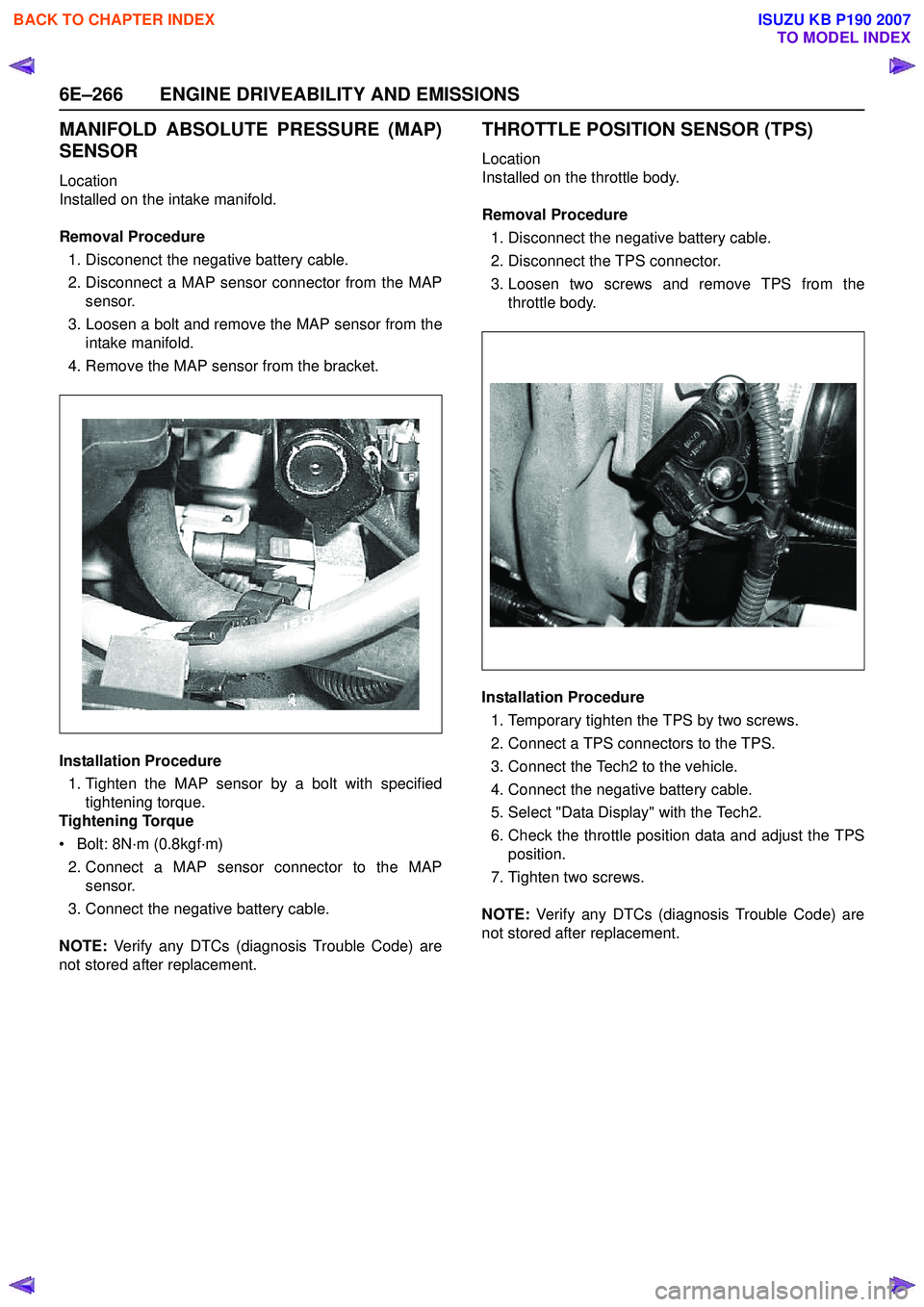

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSOR

Location

Installed on the intake manifold.

Removal Procedure 1. Disconenct the negative battery cable.

2. Disconnect a MAP sensor connector from the MAP sensor.

3. Loosen a bolt and remove the MAP sensor from the intake manifold.

4. Remove the MAP sensor from the bracket.

Installation Procedure 1. Tighten the MAP sensor by a bolt with specified tightening torque.

Tightening Torque

• Bolt: 8N·m (0.8kgf·m) 2. Connect a MAP sensor connector to the MAP sensor.

3. Connect the negative battery cable.

NOTE: Verify any DTCs (diagnosis Trouble Code) are

not stored after replacement.

THROTTLE POSITION SENSOR (TPS)

Location

Installed on the throttle body.

Removal Procedure 1. Disconnect the negative battery cable.

2. Disconnect the TPS connector.

3. Loosen two screws and remove TPS from the throttle body.

Installation Procedure 1. Temporary tighten the TPS by two screws.

2. Connect a TPS connectors to the TPS.

3. Connect the Tech2 to the vehicle.

4. Connect the negative battery cable.

5. Select "Data Display" with the Tech2.

6. Check the throttle position data and adjust the TPS position.

7. Tighten two screws.

NOTE: Verify any DTCs (diagnosis Trouble Code) are

not stored after replacement.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2438 of 6020

6E–268 ENGINE DRIVEABILITY AND EMISSIONS

KNOCK SENSOR

Location

Right-hand side of the cylinder block.

Removal Procedure 1. Disconnect the negative battery cable.

2. Disconnect the knock sensor connector.

3. Loosen a bolt and remove knock sensor from the cylinder block.

Installation Procedure 1. Tighten the knock sensor by a bolt with specified tightening torque.

Tightening Torque

• Bolt: 20N·m (2.0kgf·m) 2. Connect a knock sensor connector to the knock sensor.

3. Connect the negative battery cable.

NOTE: Verify any DTCs (diagnosis Trouble Code) are

not stored after replacement.

POWER STEERING PRESSURE (PSP)

SWITCH

Location

Installed on the power steering pump assembly.

Removal Procedure 1. Disconnect the negative battery cable.

2. Disconnect the power steering pressure switch connector.

3. Loosen and remove the power steering pressure switch from the power steering pump.

Installation Procedure 1. Install the power steering pressure switch to the power steering pump.

2. Tighten the power steering pressure switch.

3. Connect a connector to the power steering pressure switch.

4. Connect the negative battery cable.

NOTE: Verify any DTCs (diagnosis Trouble Code) are

not stored after replacement.

Verify no power steering fluid leaking from the sensor

threads after replacement.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2439 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–269

HEATED OXYGEN SENSOR (HO2S)

Location

Installed on the exhaust pipe.

Removal Procedure 1. Disconnect the negative battery cable.

2. Disconnect the O

2 sensor connector.

3. Loosen and remove the O

2 sensor from the exhaust

pipe.

Inspection

Inspect the louvered end of the sensor for grease, dirt,

excessive carbon build up or other contamination.

Installation Procedure

1. Install the O

2 sensor to the exhaust pipe.

2. Tighten the O

2 sensor with specified tightening

torque.

Tightening Torque

• Bolt: 42N·m (4.3kgf·m)

3. Connect a O

2 sensor connector to the O2 sensor.

4. Connect the negative battery cable.

NOTE: Verify any DTCs (diagnosis Trouble Code) are

not stored after replacement.

Verify no exhaust gas leaking from the sensor threads

after replacement.

EVAP CANISTER PURGE VALVE

SOLENOID

Location

On the intake manifold.

Removal Procedure 1. Disconenct the negative battery cable.

2. Disconnect a purge solenoid connector from the purge solenoid.

3. Disconnect two hoses from the purge solenoid valve.

4. Slide from the bracket and remove the purge solenoid.

Installation Procedure 1. Insert EVAP purge solenoid valve onto the bracket.

2. Connect two hoses to the purge solenoid valve.

3. Connect a purge solenoid connector to the purge solenoid.

4. Connect the negative battery cable.

NOTE: Verify any DTCs (diagnosis Trouble Code) are

not stored after replacement.

Verify proper connection of two hoses.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2446 of 6020

6E–276 ENGINE DRIVEABILITY AND EMISSIONS

• Oil in the combustion chamber.

• The spark plug gap is not set correctly.

If spark plug fouling is excessive, check the fuel and al

system for possible causes of trouble. If fuel and al

system are normal, install spark plugs of a higher heat

range which have the same physical dimensions as the

original equipment spark plugs.

The following symptoms are characteristics of spark

plugs that are running too hot:

• Fuel mixture is too lean.

• Heat range is incorrect.

If vehicle usage does not conform to normal driving

conditions, a more suitable spark plug may be

substituted.

If fuel and al system are normal, in most cases of this

sort, the problem can be corrected by using a colder

type spark plug with the same physical dimensions as

the original equipment spark plug.

3. Check the gaskets for damage and replace if necessary.

4. Measure the spark plug gap. The specification is 1.0 to 1.1mm (0.039 to 0.043").

5. Adjust the spark gap by bending the grounded electrode. Installation

1. Tighten the spark plug to the 25N·m (2.5kgf·m).

2. Push the spark plug cable in until it snaps in.

Installation Procedure 1. Install the spark plug to the cylinder head.

2. Tighten the spark plug with specified tightening torque.

Tightening Torque

• Bolt: 25N·m (2.5kgf·m) 3. Connect the spark plug cable to the spark plug.

4. Connect the negative battery cable.

NOTE: Verify any DTCs (diagnosis Trouble Code) are

not stored after replacement.

Verify proper connection of spark plug cables for each

cylinders.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2450 of 6020

ENGINE EXHAUST 6F-1

SECTION 6F

ENGINE EXHAUST

TABLE OF CONTENTS

PAGE

General Description ....................................................................................................... 6F- 2

Service Precaution ......................................................................................................... 6F- 4

Exhaust Pipe ................................................................................................................... 6F- 5

Exhaust pipe and Associated parts ......................................................................... 6F- 5

Removal ...................................................................................................................... 6F- 5

Installation .................................................................................................................. 6F- 6

Inspection ................................................................................................................... 6F- 6

Front Exhaust Pipe ......................................................................................................... 6F- 7

Front Exhaust Pipe and Associated Parts ............................................................... 6F- 7

Removal ...................................................................................................................... 6F- 7

Installation .................................................................................................................. 6F- 7

Mid Pipe....................................................................................................................... .... 6F- 8

Mid Pipe and associated Parts ................................................................................. 6F- 8

Removal ...................................................................................................................... 6F- 8

Installation .................................................................................................................. 6F- 8

Catalytic Converter (If applicable)................................................................................. 6F- 9 Catalytic Converter and Associated Parts ............................................................... 6F- 9

Removal ...................................................................................................................... 6F- 9

Installation .................................................................................................................. 6F- 9

3 way Catalytic Converter System............................................................................ 6F- 10

Exhaust Silencer ............................................................................................................ 6F- 12

Exhaust Silencer and Associated Parts .................................................................. 6F- 12

Removal ...................................................................................................................... 6F- 12

Installation .................................................................................................................. 6F- 13

Main Data and Specifications ........................................................................................ 6F- 14

Torque Specification ................................................................................................. 6F- 15

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2453 of 6020

6F-4 ENGINE EXHAUST

Service Precaution

CAUTION:

Always use the correct fastener in the proper location.

When you replace a fastener, use ONLY the exact part

number for that application. ISUZU will call out those

fasteners that require a replacement after removal. ISUZU

will also call out the fasteners that require thread lockers

or thread sealant. UNLESS OTHERWISE SPECIFIED, do

not use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or fastener

joint interfaces. Generally, such coatings adversely affect

the fastener torque and the joint clamping force, and may

damage the fastener. When you install fasteners, use the

correct tightening sequence and specifications. Following

these instructions can help you avoid damage to parts

and systems.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007