low oil pressure ISUZU KB P190 2007 Workshop Owner's Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1372 of 6020

6A-12 ENGINE MECHANICAL (4JK1/4JJ1)

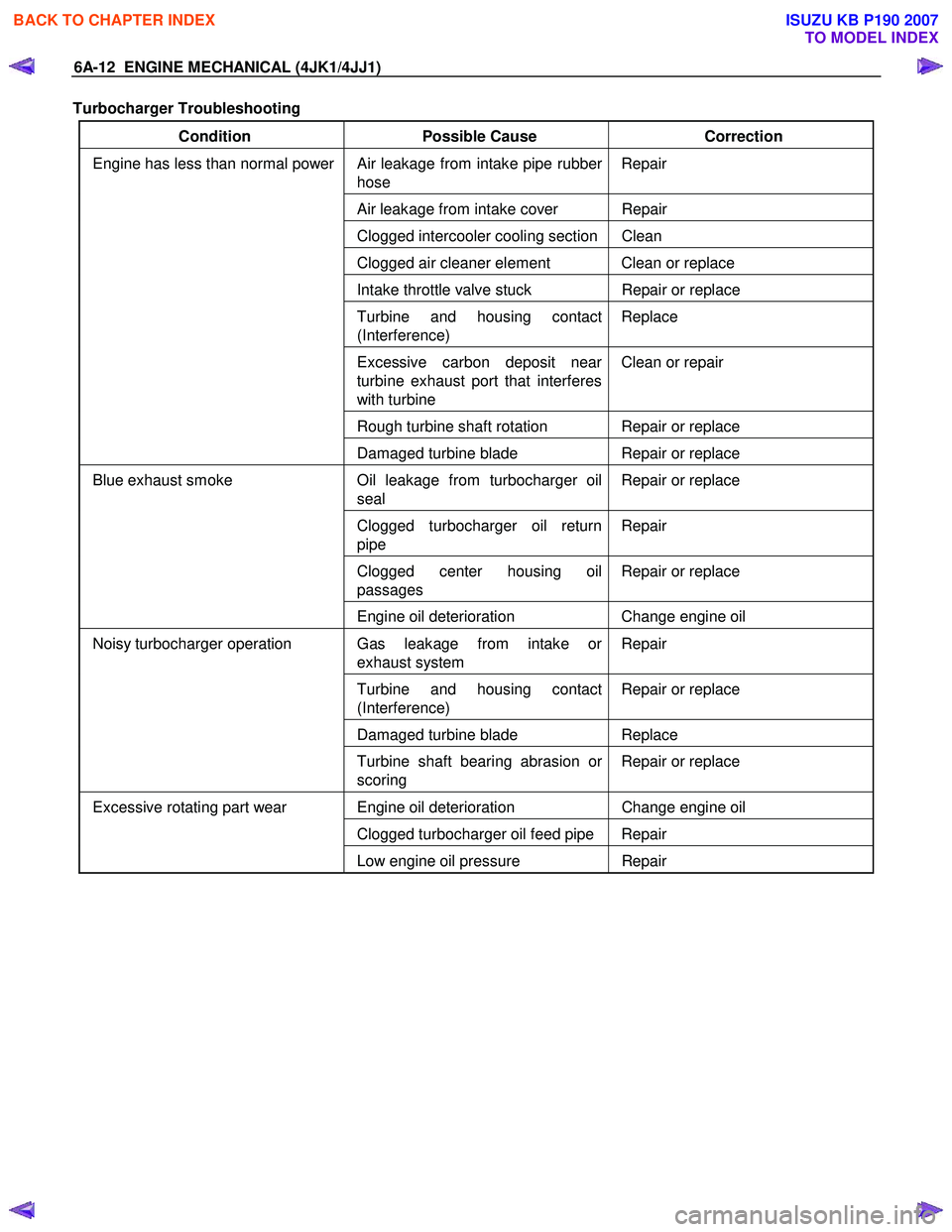

Turbocharger Troubleshooting

Condition Possible Cause Correction

Air leakage from intake pipe rubber

hose Repair

Air leakage from intake cover Repair

Clogged intercooler cooling section Clean

Clogged air cleaner element Clean or replace

Intake throttle valve stuck

Repair or replace

Turbine and housing contact

(Interference) Replace

Excessive carbon deposit near

turbine exhaust port that interferes

with turbine Clean or repair

Rough turbine shaft rotation Repair or replace

Engine has less than normal power

Damaged turbine blade Repair or replace

Oil leakage from turbocharger oil

seal Repair or replace

Clogged turbocharger oil return

pipe Repair

Clogged center housing oil

passages Repair or replace

Blue exhaust smoke

Engine oil deterioration Change engine oil

Gas leakage from intake or

exhaust system Repair

Turbine and housing contact

(Interference) Repair or replace

Damaged turbine blade

Replace

Noisy turbocharger operation

Turbine shaft bearing abrasion or

scoring Repair or replace

Engine oil deterioration

Change engine oil

Clogged turbocharger oil feed pipe Repair

Excessive rotating part wear

Low engine oil pressure Repair

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1373 of 6020

ENGINE MECHANICAL (4JK1/4JJ1) 6A-13

Main Data and specifications

Item Engine model 4JK1 Engine model 4JJ1

Type Diesel/4-cycle/water cooling-type in-line DOHC

Combustion chamber type Direct injection type

Cylinder liner type Liner less

Number of cylinders -cylinder

bore × strokes mm (in) 4-95.4 (3.76) × 87.4 (3.44) 4-95.4(3.76) × 104.9(4.13)

Displacement

cc (cu.in) 2499 (152) 2999 (183)

Compression ratio 18.3 17.5

Compression pressure MPa (psi)/rpm 3 (435)/200

Idling speed rpm 700 ± 25

Valve clearance Intake 0.15 (0.006) (cold)

mm (in) Exhaust 0.15 (0.006) (cold)

Ignition type Compressed ignition

Injection order 1 - 3 - 4 - 2

Lubricating system

Lubricating type Pressure delivery type

Oil pump type Gear type

Volume of lubricating oil L (qts) 8.0 (8.5)

Oil filter type Full flow filter (cartridge type)

Oil cooling type Built-in-type, water cooling

Cooling system

Cooling type W ater cooling type

Radiator type Corrugated fin (pressure type)

W ater pump type Centrifugal, belt drive type

Thermostat type W ax-type units

Thermostat valve-opening temperature °C ( °F) 85 (185)

Volume of coolant L (qts) M/T8.7 (9.2) A/T 8.6 (9.1) (incl. radiator)

Fuel system

Injection pump type Fuel supply pump fuel rail type

Fuel injector type Electronic control injector

6-hole

Fuel pump type Into the fuel tank type

Charging system

Generator type AC type

Power output V-A 12 - 90

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1500 of 6020

6A-140 ENGINE MECHANICAL (4JK1/4JJ1)

Lubrication System

Service Precautions

• During each disassembly, remove the old gasket

adhering to each part and mating part completel

y

using a scraper at the location, where the fluid

gasket is to be used, clean the traces of oil,

moisture, and dirt completely using waste cotton

and apply the specified new fluid gasket at each

location.

•

Avoid excessive or insufficient coating volume.

Note that seizure may occur in case of excessive

coating due to clogging of the oil gallery and oil jet,

and oil and water leakage may occur if the coating

is insufficient.

• Always, the start and end of the application should

be overlapped.

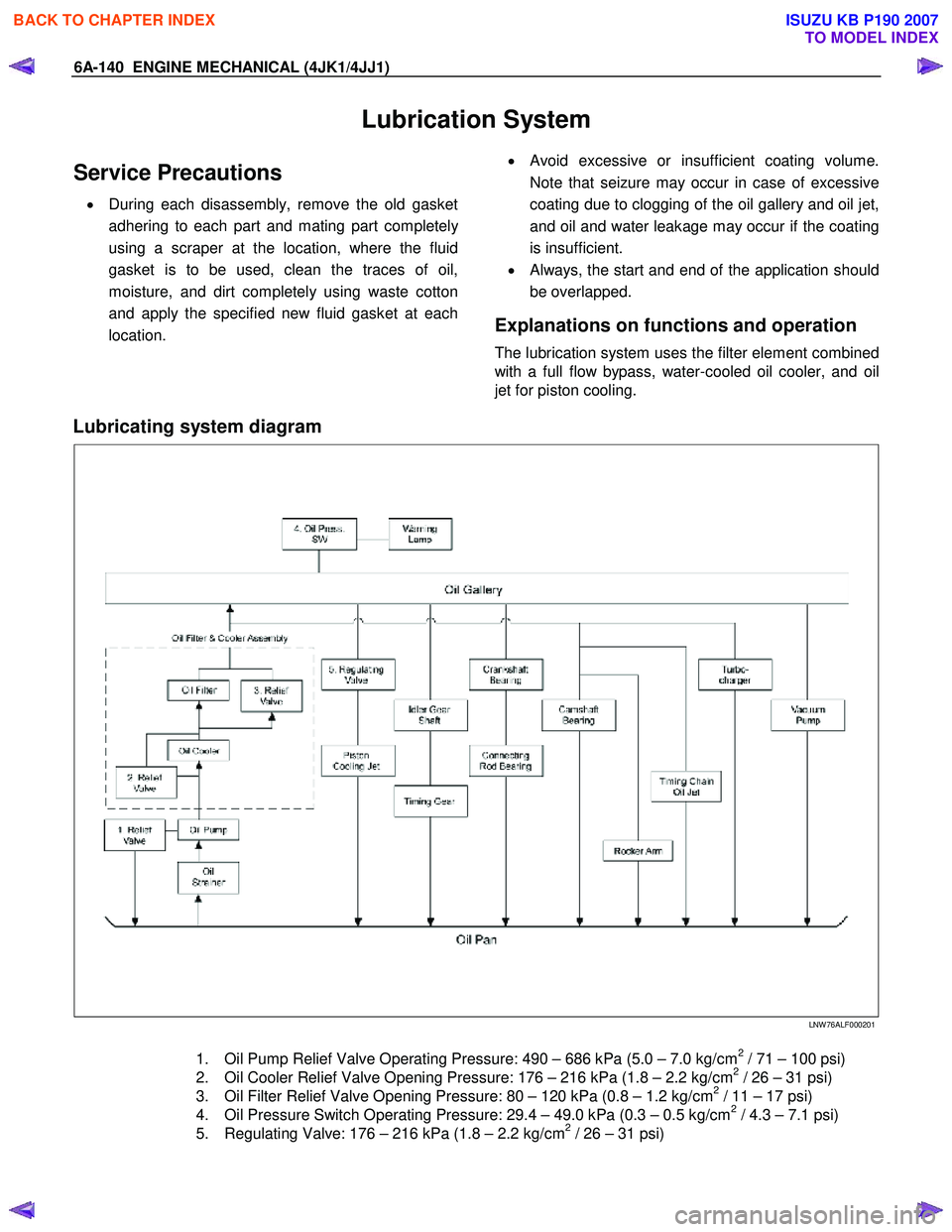

Explanations on functions and operation

The lubrication system uses the filter element combined

with a full flow bypass, water-cooled oil cooler, and oil

jet for piston cooling.

Lubricating system diagram

LNW 76ALF000201

1. Oil Pump Relief Valve Operating Pressure: 490 – 686 kPa (5.0 – 7.0 kg/cm2 / 71 – 100 psi)

2. Oil Cooler Relief Valve Opening Pressure: 176 – 216 kPa (1.8 – 2.2 kg/cm2 / 26 – 31 psi)

3. Oil Filter Relief Valve Opening Pressure: 80 – 120 kPa (0.8 – 1.2 kg/cm2 / 11 – 17 psi)

4. Oil Pressure Switch Operating Pressure: 29.4 – 49.0 kPa (0.3 – 0.5 kg/cm2 / 4.3 – 7.1 psi)

5. Regulating Valve: 176 – 216 kPa (1.8 – 2.2 kg/cm2 / 26 – 31 psi)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1501 of 6020

ENGINE MECHANICAL (4JK1/4JJ1) 6A-141

Functional Check

Oil pressure check

1. Check whether the engine oil is contaminated with

dirt, light oil, or water. If contaminated with dirt,

light oil, or water (after examining the cause and

taking the appropriate measures for light oil o

r

water contamination), replace the oil.

2. Check the engine oil level. The oil level should be between the two holes of the level gauge. If the oil

level is insufficient, replenish it.

3. Remove the oil pressure switch on the nipple.

4. Install the oil pressure gauge on the nipple.

RTW 56ASH015501

Legend

1. Oil Pressure Switch

5. W arm the engine.

6. Measure the oil pressure, to check whether it is more than 400 kPa (4 kg/cm

2 / 58 psi) at 3600

rpm.

7. Stop the engine.

8. Remove the oil pressure gauge.

9. Install the oil pressure switch.

10. Start the engine and check for oil leakage.

Engine oil

•

Ensure the car is on level ground. Before starting

the engine or when 30 minutes or more have

elapsed after stopping the engine, check the

engine oil volume using the level gauge. The

volume is appropriate if the engine oil is between

the upper and lower limits of the level gauge.

Replenish the engine oil, if level is below the lowe

r

limit. Also, check for contamination of the engine

oil.

RTW 56ASH015601

RTW 56ASH015701

Legend

1. Lower Limit

2. Upper Limit

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1530 of 6020

ENGINE COOLING (4JK1/4JJ1) 6B-7

Draining and Refilling Cooling System

Before draining the cooling system, inspect the system

and perform any necessary service to ensure that it is

clean, does not leak and is in proper working order.

The engine coolant (EC) level should be between the

“MIN" and “MAX" lines of the reserve tank when the

engine is cold. If low, check for leakage and add EC up

to the “MAX" line.

There should not be any excessive deposit of rust o

r

scales around the radiator cap or radiator filler hole, and

the EC should also be free from oil.

Replace the EC if excessively dirty.

1. Remove the radiator skid plate.

2. Completely drain the cooling system by opening the drain plug at the bottom of the radiator.

RTW 56BSH000301

3. Remove the radiator cap.

WARNING:

To avoid the danger of being burned, do not

remove the cap while the engine and radiator are

still hot. Scalding fluid and steam can be blown out

under pressure.

4. Disconnect all hoses from the EC reserve tank.

Scrub and clean the inside of the reserve tank with soap and water. Flush it well with clean water,

then drain it. Install the reserve tank and hoses.

5. Refill the cooling system with the EC using a

solution that is at least 50 percent antifreeze.

Procedure for filling with coolant (in case of full change).

• Make sure that the engine is cool.

• Open radiator cap and pour coolant up to fille

r

neck.

• Pour coolant into reservoir tank up to “MAX" line.

• Tighten radiator cap and start the engine. Afte

r

idling for 2 to 3 minutes, stop the engine and

reopen the radiator cap. If the water level is lower,

replenish.

WARNING:

When the coolant is heated to a high temperature,

be sure not to loosen or remove the radiator cap.

Otherwise you might get scalded by hot vapor o

r

boiling water. To open the radiator cap, put a piece

of thick cloth on the cap and loosen the cap slowly

to reduce the pressure when the coolant has

become cooler.

• After tightening the radiator cap, warm up the

engine at about 2000 rpm. Set heater adjustment

to the highest temperature position, and let the

coolant circulate also into heater water system.

• Check to see the thermostat has opened through

the needle position of the water thermometer,

conduct a 5–minute idling again and stop the

engine.

• W hen the engine has been cooled, check fille

r

neck for water level and replenish if required.

Should extreme shortage of coolant be found,

check the cooling system and reservoir tank hose

for leakage.

• Pour coolant into the reservoir tank up to “MAX"

line.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1682 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-65

Circuit/ System Testing Engine Cranks but Does Not Run (2 of 2)

StepAction Value(s)Yes No

1 1. Remove the engine cover.

2. Perform the Injector Force Drive with a scan tool.

3. Command each injector ON and verify clicking noise (solenoid operating noise).

Is there an injector that does not create a clicking

noise (solenoid operating noise), contains an

interrupted noise or abnormal noise when

commanded ON? —

Go to Step 8 Go to Step 2

2 1. Inspect the high pressure side between the

fuel supply pump and the fuel injectors for fuel

leakage. The following components may

contain an external leak.

• Fuel supply pump

• Fuel rail

•Pressure limiter valve

• Fuel rail pressure (FRP) sensor

• Fuel pipe between the fuel supply pump and fuel rail

• Fuel pipe between the fuel rail and fuel injectors

• Each fuel pipe sleeve nuts

Notice: Fuel may leak under the cylinder head

cover from the inlet high pressure line. In such

case, the engine oil level will rise. Inspect for fuel

leakage into the engine oil.

2. Repair any fuel system leaks as necessary.

Did you find and correct the condition? —

Go to Step 12 Go to Step 3

3 1. Check the fuel system line connections

between the fuel tank and the fuel supply

pump for tightness and all fuel hoses for cuts,

cracks and for the use of proper clamps.

2. Repair or replace as necessary.

Did you find and correct the condition? —

Go to Step 12 Go to Step 4

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1708 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-91

21. Inspect the high pressure side between the

fuel supply pump and the fuel injectors for fuel

leakage. The following components may

contain an external leak.

• Fuel supply pump

• Fuel rail

•Pressure limiter valve

• Fuel rail pressure (FRP) sensor

• Fuel pipe between the fuel supply pump and fuel rail

• Fuel pipe between the fuel rail and fuel injectors

• Each fuel pipe sleeve nuts

Notice: Fuel may leak under the cylinder head

cover from the inlet high pressure line. In such

case, the engine oil level will rise. Inspect for fuel

leakage into the engine oil.

Notice: Remove and inspect the inlet high

pressure joint to the fuel injectors for fuel leaking

from the sleeve nut(s). Replace the fuel injector

and injection pipe when foreign material was in

contact.

2. Repair any fuel system leaks as necessary.

Did you find and correct the condition? —

Go to Step 16 Go to Step 3

3 1. Remove each glow plug from the cylinder

head.

2. Inspect for fuel leakage into the combustion chamber.

Is there a cylinder that fuel leakage into the

combustion chamber? —

Go to Step 13 Go to Step 4

4 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with a scan tool.

Is DTC P0087, P0091, P0092, P0192, P0193,

P0201 - P0204, P1064, P1065, P124B or P2146 -

P2151 set? —

Go to Applicable DTC Go to Step 5

5 1. Turn OFF the ignition.

2. Wait 1 minute for the fuel pressure to bleed down from the fuel rail.

3. Turn ON the ignition, with the engine OFF. DO NOT start the engine.

4. Observe the FRP Sensor parameter with the scan tool.

Does the scan tool indicate within the specified

value? 0.9 to 1.0 volt

Go to Step 6 Go to Step 11

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1760 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-143

4Compare the BARO value to the range specified in

the altitude vs. barometric pressure table. Refer to

Altitude vs Barometric Pressure.

Is the BARO parameter within the range specified? —

Go to Step 6 Go to Step 7

5 1. Inspect the following for possible causes of

high boost pressure.

• Misrouted turbocharger nozzle control actuator vacuum hoses

• Turbocharger nozzle control actuator or solenoid valve for a stuck condition.

Refer to Turbocharger Control System

Check in this section.

• Intake throttle valve sticking. Perform the Intake Throttle Solenoid Control with a

scan tool

• Oil in the air induction tubing causing an incorrect boost pressure sensor signal.

When there is adhesion of oil inside of

the tubing, intercooler or turbocharger it

needs to be wiped off.

2. Repair or replace as necessary.

Did you find and correction the condition? —

Go to Step 10 Go to Diagnostic

Aids

6 1. Turn OFF the ignition.

2. Disconnect the boost pressure sensor harness connector.

3. Inspect for an intermittent and for a poor connection at the harness connector of the

boost pressure sensor (pin 2 of E-107).

4. Disconnect the ECM harness connector.

5. Inspect for an intermittent, for a poor connection and corrosion at the harness

connector of the ECM (pin 23 of E-90).

6. Test for high resistance of the low reference circuit.

7. Repair the connection(s) or circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 10 Go to Step 8

7 1. Turn OFF the ignition.

2. Disconnect the BARO sensor harness connector.

3. Inspect for an intermittent and for poor connections at the harness connector of the

BARO sensor (pins 2 and 3 of E-40).

4. Disconnect the ECM harness connector.

5. Inspect for an intermittent, for poor connections and corrosion at the harness

connector of the ECM (pins 18 and 19 of E-

90).

6. Test for high resistance on each circuit.

7. Repair the connection(s) or circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 10 Go to Step 9

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1763 of 6020

6E-146 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

31. Inspect the following for possible causes of

low boost pressure.

• Air leakage around the boost pressure sensor or objects that block the sensor

hole.

• Air leaking around any of the air induction tubing between the turbocharger and

intake manifold. Check for damaged

components and for loose clamps.

• Misrouted, disconnected or kinked turbocharger nozzle control actuator

vacuum hose.

• Turbine shaft binding causing lower turbocharger shaft spinning speeds.

Refer to the Turbocharger in Engine

Mechanical section for diagnosis.

• Turbocharger nozzle control actuator or solenoid valve for a stuck condition.

Refer to Turbocharger Control System

Check in this section.

• Intake throttle valve sticking. Perform the Intake Throttle Solenoid Control with a

scan tool.

• Restricted air cleaner element, restricted or collapsed air tubing between the air

cleaner and the boost pressure sensor.

• Oil in the air induction tubing causing an incorrect boost pressure sensor signal.

When there is adhesion of oil inside of

the tubing, intercooler or turbocharger it

needs to be wiped off.

2. Repair or replace as necessary.

Did you find and correct the condition? —

Go to Step 10 Go to Step 4

4 1. Turn ON the ignition, with the engine OFF.

2. Observe the Boost Pressure and Barometric Pressure (BARO) with a scan tool.

Does the scan tool indicate that the difference

between the Boost Pressure and BARO is more

than the specified value? 10 kPa (1.5

psi)

Go to Step 5 Go to Diagnostic

Aids

5 Compare the BARO value to the range specified in

the altitude vs. barometric pressure table. Refer to

Altitude vs Barometric Pressure.

Is the BARO parameter within the range specified? —

Go to Step 6 Go to Step 7

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1849 of 6020

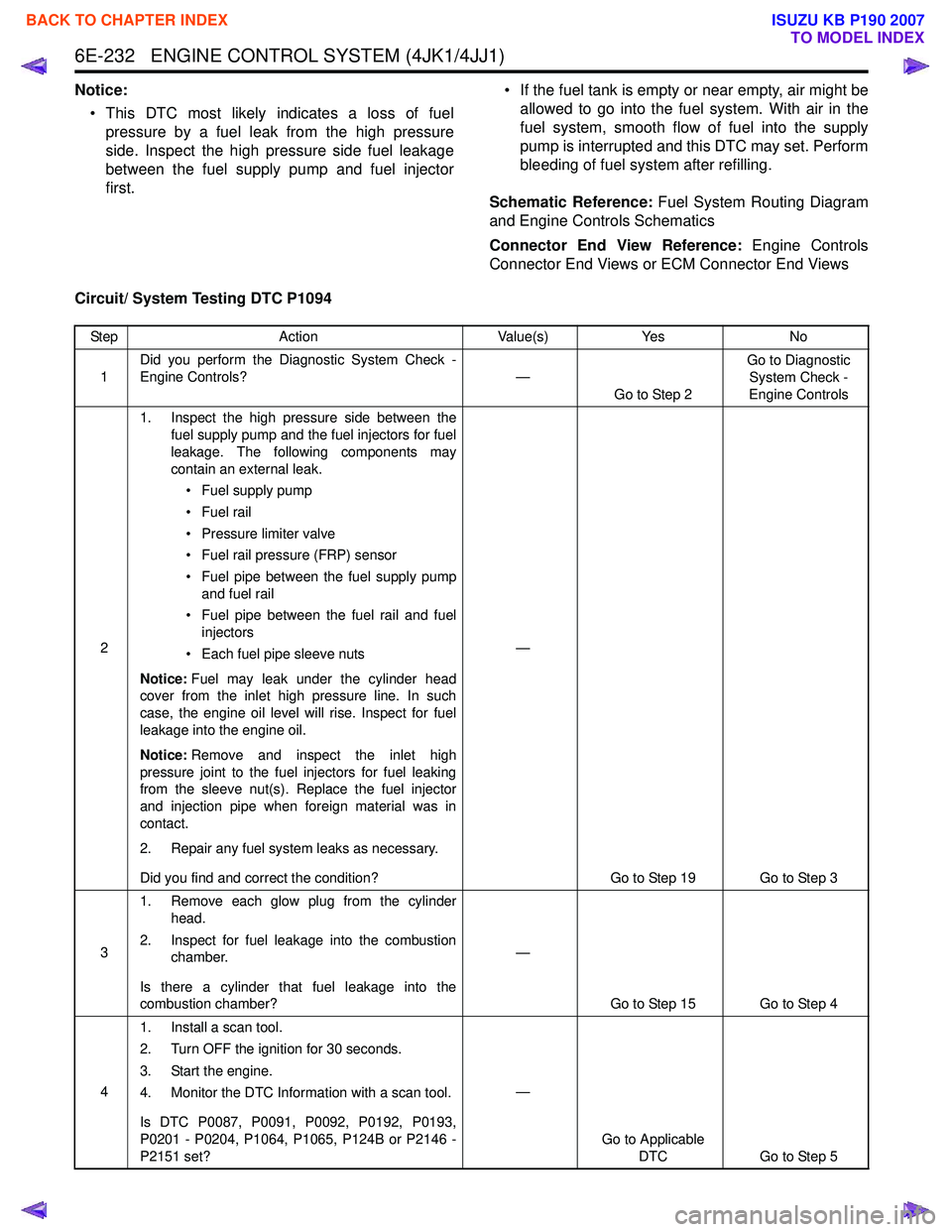

6E-232 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

Notice:• This DTC most likely indicates a loss of fuel pressure by a fuel leak from the high pressure

side. Inspect the high pressure side fuel leakage

between the fuel supply pump and fuel injector

first. • If the fuel tank is empty or near empty, air might be

allowed to go into the fuel system. With air in the

fuel system, smooth flow of fuel into the supply

pump is interrupted and this DTC may set. Perform

bleeding of fuel system after refilling.

Schematic Reference: Fuel System Routing Diagram

and Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P1094

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Inspect the high pressure side between the

fuel supply pump and the fuel injectors for fuel

leakage. The following components may

contain an external leak.

• Fuel supply pump

• Fuel rail

• Pressure limiter valve

• Fuel rail pressure (FRP) sensor

• Fuel pipe between the fuel supply pump and fuel rail

• Fuel pipe between the fuel rail and fuel injectors

• Each fuel pipe sleeve nuts

Notice: Fuel may leak under the cylinder head

cover from the inlet high pressure line. In such

case, the engine oil level will rise. Inspect for fuel

leakage into the engine oil.

Notice: Remove and inspect the inlet high

pressure joint to the fuel injectors for fuel leaking

from the sleeve nut(s). Replace the fuel injector

and injection pipe when foreign material was in

contact.

2. Repair any fuel system leaks as necessary.

Did you find and correct the condition? —

Go to Step 19 Go to Step 3

3 1. Remove each glow plug from the cylinder

head.

2. Inspect for fuel leakage into the combustion chamber.

Is there a cylinder that fuel leakage into the

combustion chamber? —

Go to Step 15 Go to Step 4

4 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with a scan tool.

Is DTC P0087, P0091, P0092, P0192, P0193,

P0201 - P0204, P1064, P1065, P124B or P2146 -

P2151 set? —

Go to Applicable DTC Go to Step 5

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007