relay ISUZU KB P190 2007 Workshop Owner's Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1056 of 6020

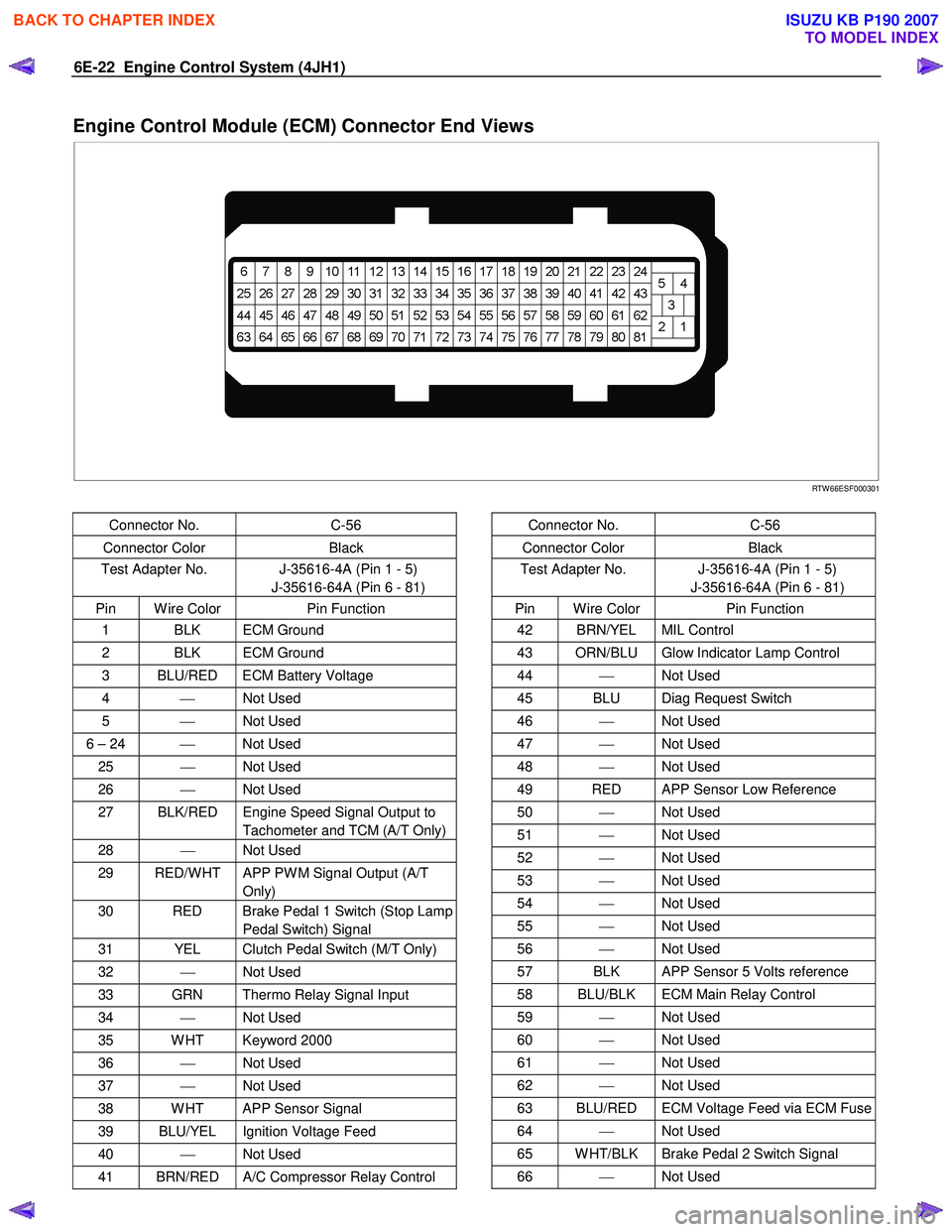

6E-22 Engine Control System (4JH1)

Engine Control Module (ECM) Connector End Views

RTW 66ESF000301

Connector No. C-56

Connector Color Black

Test Adapter No. J-35616-4A (Pin 1 - 5)

J-35616-64A (Pin 6 - 81)

Pin W ire Color Pin Function

1 BLK ECM Ground

2 BLK ECM Ground

3 BLU/RED ECM Battery Voltage

4 Not Used

5 Not Used

6 – 24 Not Used

25 Not Used

26 Not Used

27 BLK/RED Engine Speed Signal Output to

Tachometer and TCM (A/T Only)

28 Not Used

29 RED/W HT APP PW M Signal Output (A/T

Only)

30 RED Brake Pedal 1 Switch (Stop Lamp Pedal Switch) Signal

31 YEL Clutch Pedal Switch (M/T Only)

32 Not Used

33 GRN Thermo Relay Signal Input

34 Not Used

35 W HT Keyword 2000

36 Not Used

37 Not Used

38 W HT APP Sensor Signal

39 BLU/YEL Ignition Voltage Feed

40 Not Used

41 BRN/RED A/C Compressor Relay Control

Connector No. C-56

Connector Color Black

Test Adapter No. J-35616-4A (Pin 1 - 5)

J-35616-64A (Pin 6 - 81)

Pin W ire Color Pin Function

42 BRN/YEL MIL Control

43 ORN/BLU Glow Indicator Lamp Control

44 Not Used

45 BLU Diag Request Switch

46 Not Used

47 Not Used

48 Not Used

49 RED APP Sensor Low Reference

50 Not Used

51 Not Used

52 Not Used

53 Not Used

54 Not Used

55 Not Used

56 Not Used

57 BLK APP Sensor 5 Volts reference

58 BLU/BLK ECM Main Relay Control

59 Not Used

60 Not Used

61 Not Used

62 Not Used

63 BLU/RED ECM Voltage Feed via ECM Fuse

64 Not Used

65 W HT/BLK Brake Pedal 2 Switch Signal

66 Not Used

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1058 of 6020

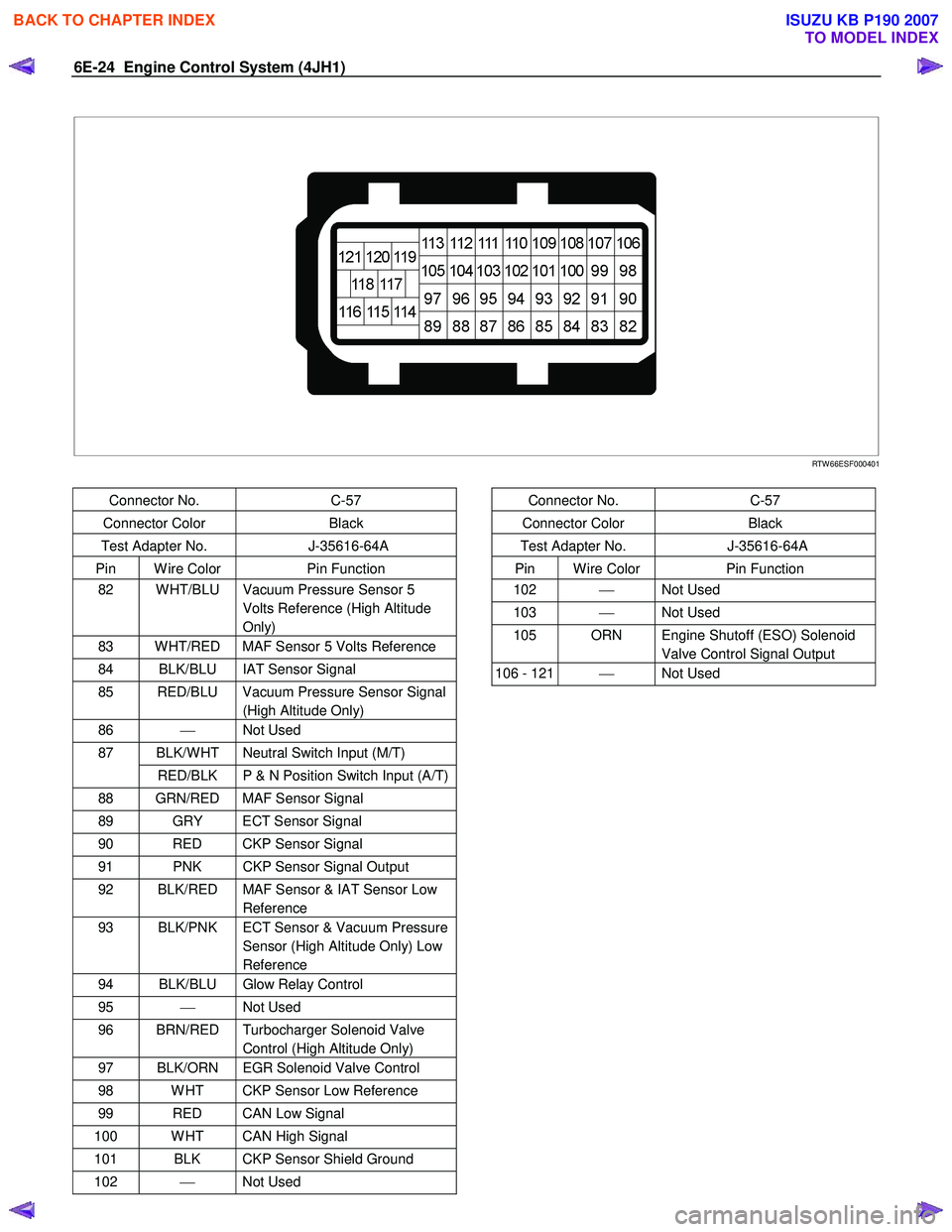

6E-24 Engine Control System (4JH1)

RTW 66ESF000401

Connector No. C-57

Connector Color Black

Test Adapter No. J-35616-64A

Pin W ire Color Pin Function

82 W HT/BLU Vacuum Pressure Sensor 5

Volts Reference (High Altitude

Only)

83 W HT/RED MAF Sensor 5 Volts Reference

84 BLK/BLU IAT Sensor Signal

85 RED/BLU Vacuum Pressure Sensor Signal (High Altitude Only)

86 Not Used

BLK/W HT Neutral Switch Input (M/T) 87

RED/BLK P & N Position Switch Input (A/T)

88 GRN/RED MAF Sensor Signal

89 GRY ECT Sensor Signal

90 RED CKP Sensor Signal

91 PNK CKP Sensor Signal Output

92 BLK/RED MAF Sensor & IAT Sensor Low Reference

93 BLK/PNK ECT Sensor & Vacuum Pressure Sensor (High Altitude Only) Low

Reference

94 BLK/BLU Glow Relay Control

95 Not Used

96 BRN/RED Turbocharger Solenoid Valve

Control (High Altitude Only)

97 BLK/ORN EGR Solenoid Valve Control

98 W HT CKP Sensor Low Reference

99 RED CAN Low Signal

100 W HT CAN High Signal

101 BLK CKP Sensor Shield Ground

102 Not Used

Connector No. C-57

Connector Color Black

Test Adapter No. J-35616-64A

Pin W ire Color Pin Function

102 Not Used

103 Not Used

105 ORN Engine Shutoff (ESO) Solenoid

Valve Control Signal Output

106 - 121 Not Used

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1067 of 6020

Engine Control System (4JH1) 6E-33

Diagnostic System Check - Engine

Controls

Description

The Diagnostic System Check-Engine Controls is an

organized approach to identifying a condition that is

created by a malfunction in the electronic engine control

system. The Diagnostic System Check must be the

starting point for any driveability concern. The

Diagnostic System Check directs the service technician

to the next logical step in order to diagnose the concern.

Understanding and correctly using the diagnostic table

reduces diagnostic time, and prevents the replacement

of good parts.

Test Description

The numbers below refer to the step numbers on the

diagnostic table.

2. Lack of communication may be because of a partial

or a total malfunction of the Keyword 2000 serial data

circuit. The specified procedure determines the

particular condition.

11. If there are other modules with DTCs set, refer to

the DTC list. The DTC list directs you to the appropriate

diagnostic procedure. If the control module stores

multiple DTCs, diagnose the DTCs in the following

order.

• Component level DTCs, such as sensor DTCs,

solenoid DTCs, actuator DTCs, and relay DTCs.

Diagnose the multiple DTCs within this category in

numerical order. Begin with the lowest numbered

DTC, unless the diagnostic table directs you

otherwise.

Important:

• DO NOT perform this diagnostic if there is not a

driveability concern, unless another procedure

directs you to this diagnostic.

• Before you proceed with diagnosis, search fo

r

applicable service bulletins.

• Unless a diagnostic procedure instructs you, DO

NOT clear the DTCs.

• If there is a condition with the starting system, refe

r

to the starting system section in the engine

mechanical.

• Ensure the battery has a full charge.

• Ensure the battery cables (+) (-) are clean and

tight.

• Ensure the ECM grounds are clean, tight, and in

the correct location.

• Ensure the ECM harness connectors are clean and

correctly connected.

• Ensure the ECM terminals are clean and correctl

y

mating.

• Ensure the fuel injection pump control unit (PCU)

ground is clean, tight, and in the correct location.

• Ensure the PCU harness connectors are clean and

correctly connected.

• Ensure the PCU terminals are clean and correctl

y

mating.

• Ensure the vehicle maintenance has been done

enough.

Step Action Value(s) Yes No

1 Install the scan tool.

Does the scan tool turn ON?

Go to Step 2 Go to scan tool

Does Not Power Up

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1070 of 6020

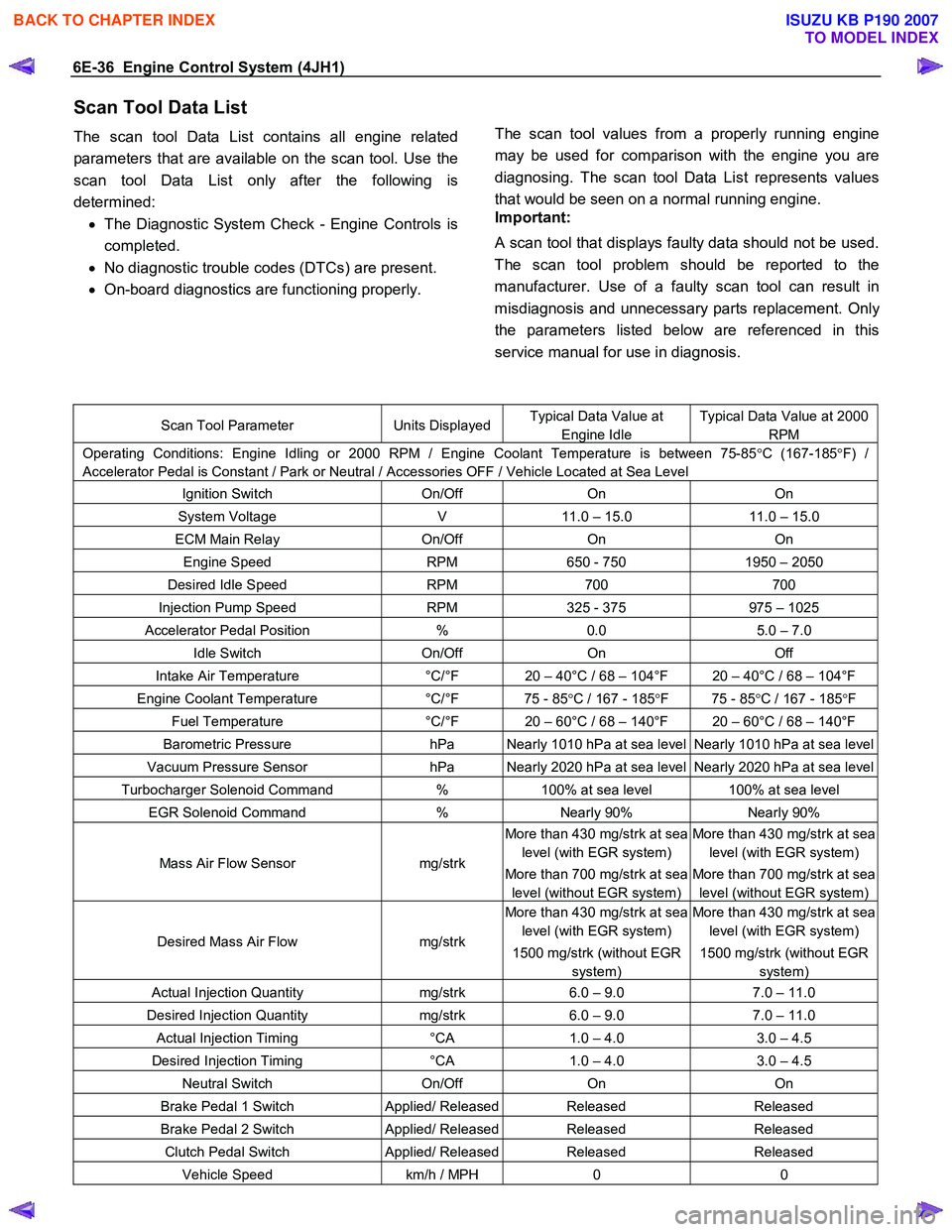

6E-36 Engine Control System (4JH1)

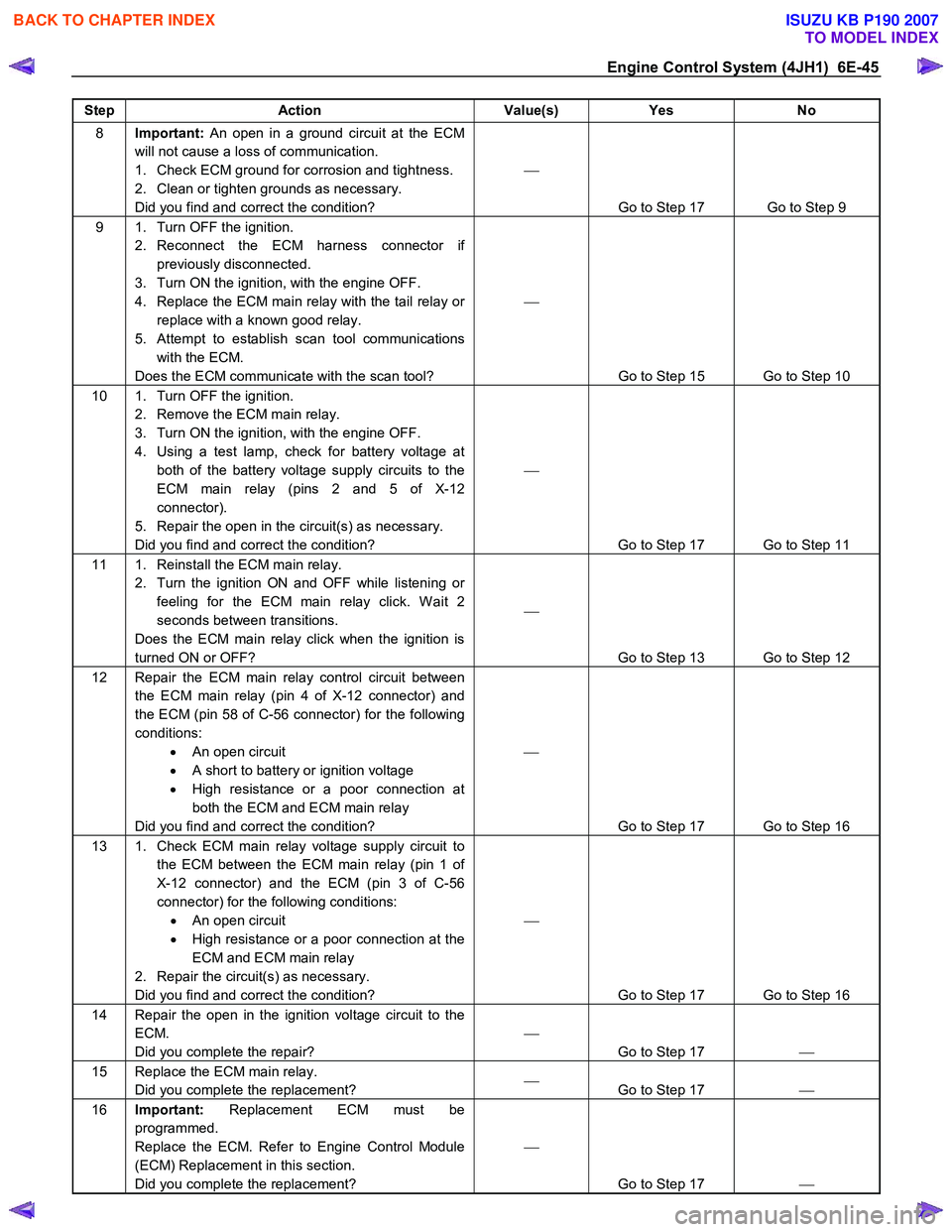

Scan Tool Data List

The scan tool Data List contains all engine related

parameters that are available on the scan tool. Use the

scan tool Data List only after the following is

determined: • The Diagnostic System Check - Engine Controls is

completed.

• No diagnostic trouble codes (DTCs) are present.

• On-board diagnostics are functioning properly.

The scan tool values from a properly running engine

may be used for comparison with the engine you are

diagnosing. The scan tool Data List represents values

that would be seen on a normal running engine.

Important:

A scan tool that displays faulty data should not be used.

The scan tool problem should be reported to the

manufacturer. Use of a faulty scan tool can result in

misdiagnosis and unnecessary parts replacement. Onl

y

the parameters listed below are referenced in this

service manual for use in diagnosis.

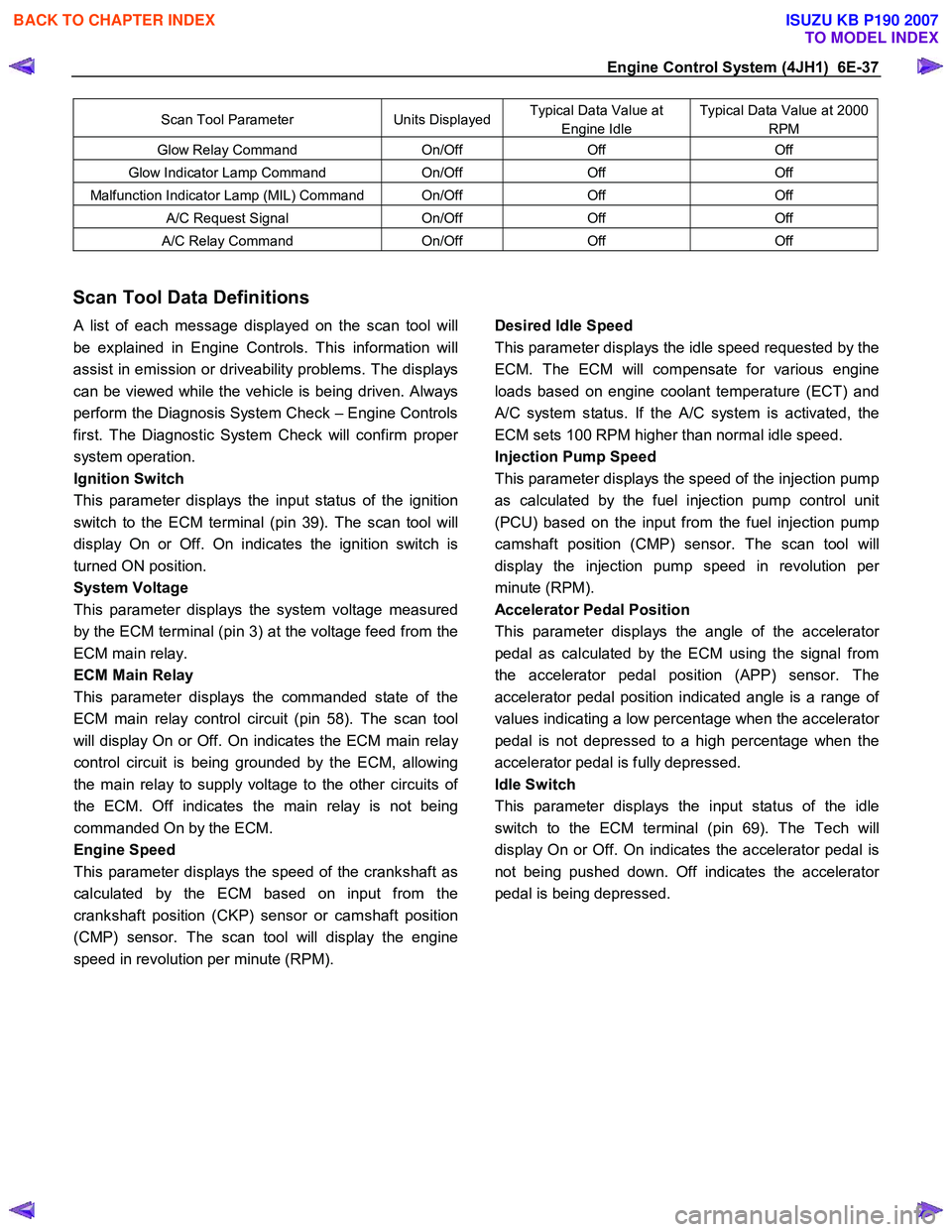

Scan Tool Parameter Units DisplayedTypical Data Value at

Engine Idle

Typical Data Value at 2000

RPM

Operating Conditions: Engine Idling or 2000 RPM / Engine Coolant Temperature is between 75-85 °C (167-185 °F) /

Accelerator Pedal is Constant / Park or Neutral / Accessories OFF / Vehicle Located at Sea Level

Ignition Switch On/Off On On

System Voltage V 11.0 – 15.0 11.0 – 15.0

ECM Main Relay On/Off On On

Engine Speed RPM 650 - 750 1950 – 2050

Desired Idle Speed RPM 700 700

Injection Pump Speed RPM 325 - 375 975 – 1025

Accelerator Pedal Position % 0.0 5.0 – 7.0

Idle Switch On/Off On Off

Intake Air Temperature °C/°F 20 – 40°C / 68 – 104°F 20 – 40°C / 68 – 104°F

Engine Coolant Temperature °C/°F 75 - 85 °C / 167 - 185 °F 75 - 85 °C / 167 - 185 °F

Fuel Temperature °C/°F 20 – 60°C / 68 – 140°F 20 – 60°C / 68 – 140°F

Barometric Pressure hPa Nearly 1010 hPa at sea level Nearly 1010 hPa at sea level

Vacuum Pressure Sensor hPa Nearly 2020 hPa at sea level Nearly 2020 hPa at sea level

Turbocharger Solenoid Command % 100% at sea level 100% at sea level

EGR Solenoid Command % Nearly 90% Nearly 90%

Mass Air Flow Sensor mg/strk

More than 430 mg/strk at sea

level (with EGR system)

More than 700 mg/strk at sea

level (without EGR system)

More than 430 mg/strk at sea

level (with EGR system)

More than 700 mg/strk at sea

level (without EGR system)

Desired Mass Air Flow mg/strk

More than 430 mg/strk at sea

level (with EGR system)

1500 mg/strk (without EGR

system)

More than 430 mg/strk at sea

level (with EGR system)

1500 mg/strk (without EGR

system)

Actual Injection Quantity mg/strk 6.0 – 9.0 7.0 – 11.0

Desired Injection Quantity mg/strk 6.0 – 9.0 7.0 – 11.0

Actual Injection Timing °CA 1.0 – 4.0 3.0 – 4.5

Desired Injection Timing °CA 1.0 – 4.0 3.0 – 4.5

Neutral Switch On/Off On On

Brake Pedal 1 Switch Applied/ ReleasedReleased Released

Brake Pedal 2 Switch Applied/ ReleasedReleased Released

Clutch Pedal Switch Applied/ ReleasedReleased Released

Vehicle Speed km/h / MPH 0 0

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1071 of 6020

Engine Control System (4JH1) 6E-37

Scan Tool Parameter Units DisplayedTypical Data Value at

Engine Idle

Typical Data Value at 2000

RPM

Glow Relay Command On/Off Off Off

Glow Indicator Lamp Command On/Off Off Off

Malfunction Indicator Lamp (MIL) Command On/Off Off Off

A/C Request Signal On/Off Off Off

A/C Relay Command On/Off Off Off

Scan Tool Data Definitions

A list of each message displayed on the scan tool will

be explained in Engine Controls. This information will

assist in emission or driveability problems. The displays

can be viewed while the vehicle is being driven. Always

perform the Diagnosis System Check – Engine Controls

first. The Diagnostic System Check will confirm prope

r

system operation.

Ignition Switch

This parameter displays the input status of the ignition

switch to the ECM terminal (pin 39). The scan tool will

display On or Off. On indicates the ignition switch is

turned ON position.

System Voltage

This parameter displays the system voltage measured

by the ECM terminal (pin 3) at the voltage feed from the

ECM main relay.

ECM Main Relay

This parameter displays the commanded state of the

ECM main relay control circuit (pin 58). The scan tool

will display On or Off. On indicates the ECM main rela

y

control circuit is being grounded by the ECM, allowing

the main relay to supply voltage to the other circuits o

f

the ECM. Off indicates the main relay is not being

commanded On by the ECM.

Engine Speed

This parameter displays the speed of the crankshaft as

calculated by the ECM based on input from the

crankshaft position (CKP) sensor or camshaft position

(CMP) sensor. The scan tool will display the engine

speed in revolution per minute (RPM).

Desired Idle Speed

This parameter displays the idle speed requested by the

ECM. The ECM will compensate for various engine

loads based on engine coolant temperature (ECT) and

A/C system status. If the A/C system is activated, the

ECM sets 100 RPM higher than normal idle speed.

Injection Pump Speed

This parameter displays the speed of the injection pump

as calculated by the fuel injection pump control unit

(PCU) based on the input from the fuel injection pump

camshaft position (CMP) sensor. The scan tool will

display the injection pump speed in revolution pe

r

minute (RPM).

Accelerator Pedal Position

This parameter displays the angle of the accelerato

r

pedal as calculated by the ECM using the signal from

the accelerator pedal position (APP) sensor. The

accelerator pedal position indicated angle is a range o

f

values indicating a low percentage when the accelerator

pedal is not depressed to a high percentage when the

accelerator pedal is fully depressed.

Idle Switch

This parameter displays the input status of the idle

switch to the ECM terminal (pin 69). The Tech will

display On or Off. On indicates the accelerator pedal is

not being pushed down. Off indicates the accelerato

r

pedal is being depressed.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1073 of 6020

Engine Control System (4JH1) 6E-39

Brake Pedal 2 Switch

This parameter displays the state of the brake pedal 2

switch as determined by the ECM terminal (pin 65). The

scan tool will display Released or Applied. Released

indicates the brake pedal is not being pushed down.

Applied indicates the brake switch is being depressed.

Clutch Pedal Switch (M/T Only)

This parameter displays the state of the clutch pedal as

determined by the ECM terminal (pin 31) based on an

input from the clutch pedal switch. The scan tool will

display Release or Applied. Release indicates the clutch

pedal is not being push down. Applied indicates the

clutch switch is being depressed.

Vehicle Speed

This parameter displays the vehicle speed calculated b

y

the ECM based on an input from the vehicle speed

sensor (VSS). The scan tool will display a high value at

higher vehicle speeds, and low value at lower vehicle

speeds.

Glow Relay Command

This parameter displays the commanded state of the

glow plug relay control circuit (pin 94). The scan tool will

display On or Off. On indicates the glow plug rela

y

control circuit is being grounded by the ECM, allowing

voltage to the glow plugs. Off indicates the glow plug

relay is not being commanded On by the ECM.

Glow Indicator Lamp Command

This parameter displays the commanded state of the

glow indicator lamp control circuit (pin 43). The glo

w

indicator lamp should be On when the scan tool

indicates On. The glow indicator should be Off when the

scan tool indicates Off.

Malfunction Indicator Lamp (MIL) Command

This parameter displays the commanded state of the

malfunction indicator lamp (MIL) control circuit (pin 42).

The MIL should be On when the scan tool indicates On.

The MIL should be Off when the scan tool indicates Off.

The ECM will command the MIL On for a certain length

of time when the ignition is On with the engine Off in

order to perform a bulb check.

A/C Request Signal

This parameter displays the state of the air conditioning

(A/C) request input to the ECM terminal (pin 33) from

the heating, ventilation, and air conditioning (HVAC)

controls. The scan tool will display On or Off. On

indicates the ECM is receiving a request from the HVAC

system to ground the A/C compressor relay control

circuit, engaging the

A/C compressor clutch. Off

indicates the ECM is not receiving a request from the

HVAC system.

A/C Relay Command

This parameter displays the commanded state of the

A/C compressor relay control circuit (pin 41). The scan

tool will display On or Off. On indicates the

A/C

compressor relay control circuit is being grounded b

y

the ECM, allowing voltage to the A/C compressor

clutch. Off indicates the A/C compressor relay is not

being commanded On by the ECM.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1074 of 6020

6E-40 Engine Control System (4JH1)

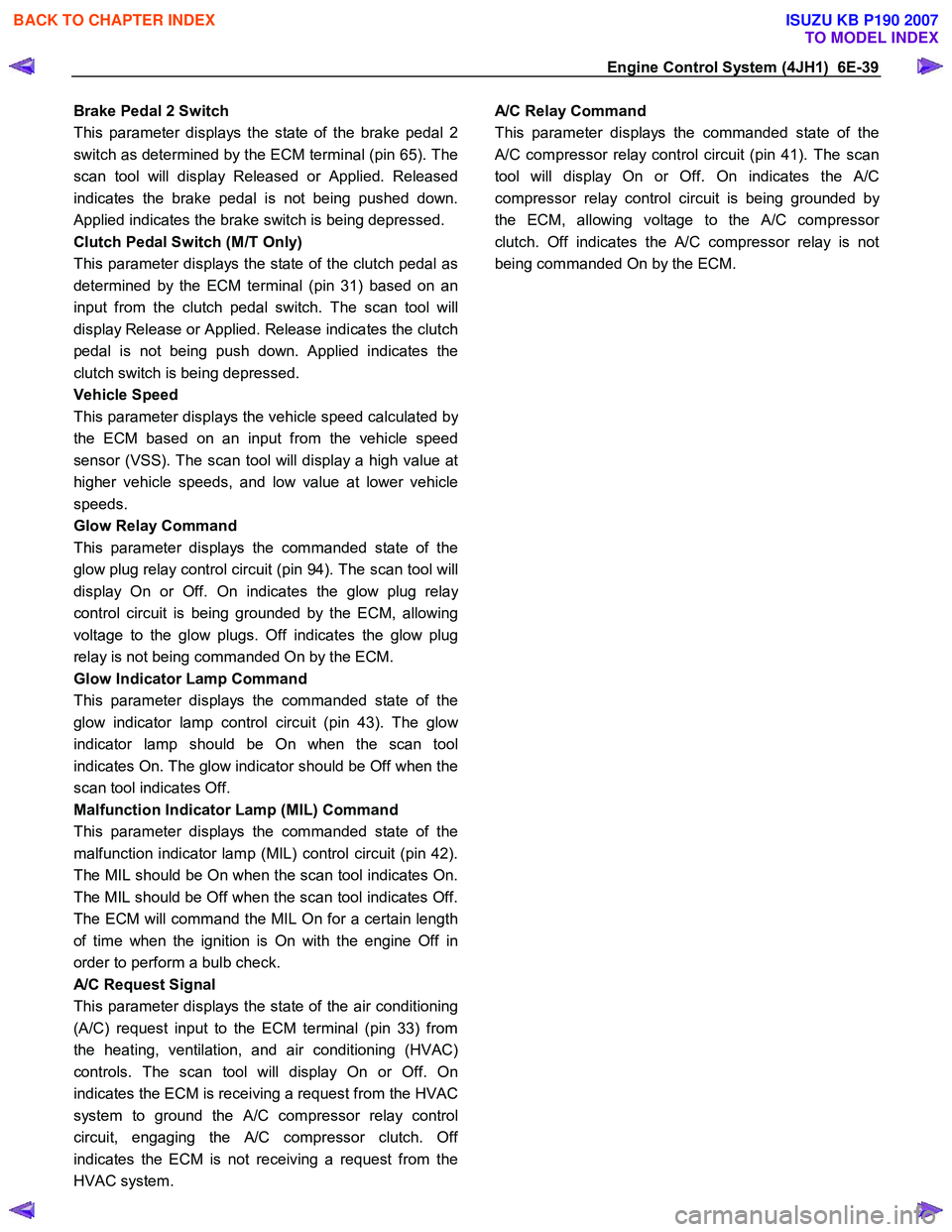

Scan Tool Output Controls

scan tool Output Control Additional Menu

Selection(s) Descriptions

EGR Solenoid Valve Solenoids The purpose of this test is for checking whether the EGR valve is correctly

moved with command. Restricted valve movement by foreign materials,

excessive deposits, a faulty vacuum hose routing, a faulty EGR valve or a

faulty EGR solenoid could be considered if the mass air flow (MAF) sensor

is not changed when commanded ON or OFF.

Engine Speed (RPM) Control

The purpose of this test is for checking whether the actual engine idle

speed can change to match the commanded RPM.

Glow Indicator Lamps The purpose of this test is for checking whether the glow indicator lamp is

operating when commanded ON. Faulty circuit(s) or an open bulb could be

considered if not operating when commanded ON.

Glow Relay Relays The purpose of this test is for checking whether the glow relay is operating

when commanded ON. Faulty circuit(s) or a faulty glow relay could be

considered if not energizing when commanded ON.

Malfunction Indicator Lamp Lamps The purpose of this test is for checking whether the malfunction indicator

lamp (MIL) is operating when commanded ON. Faulty circuit(s) or an open

bulb could be considered if not operating when commanded ON.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1079 of 6020

Engine Control System (4JH1) 6E-45

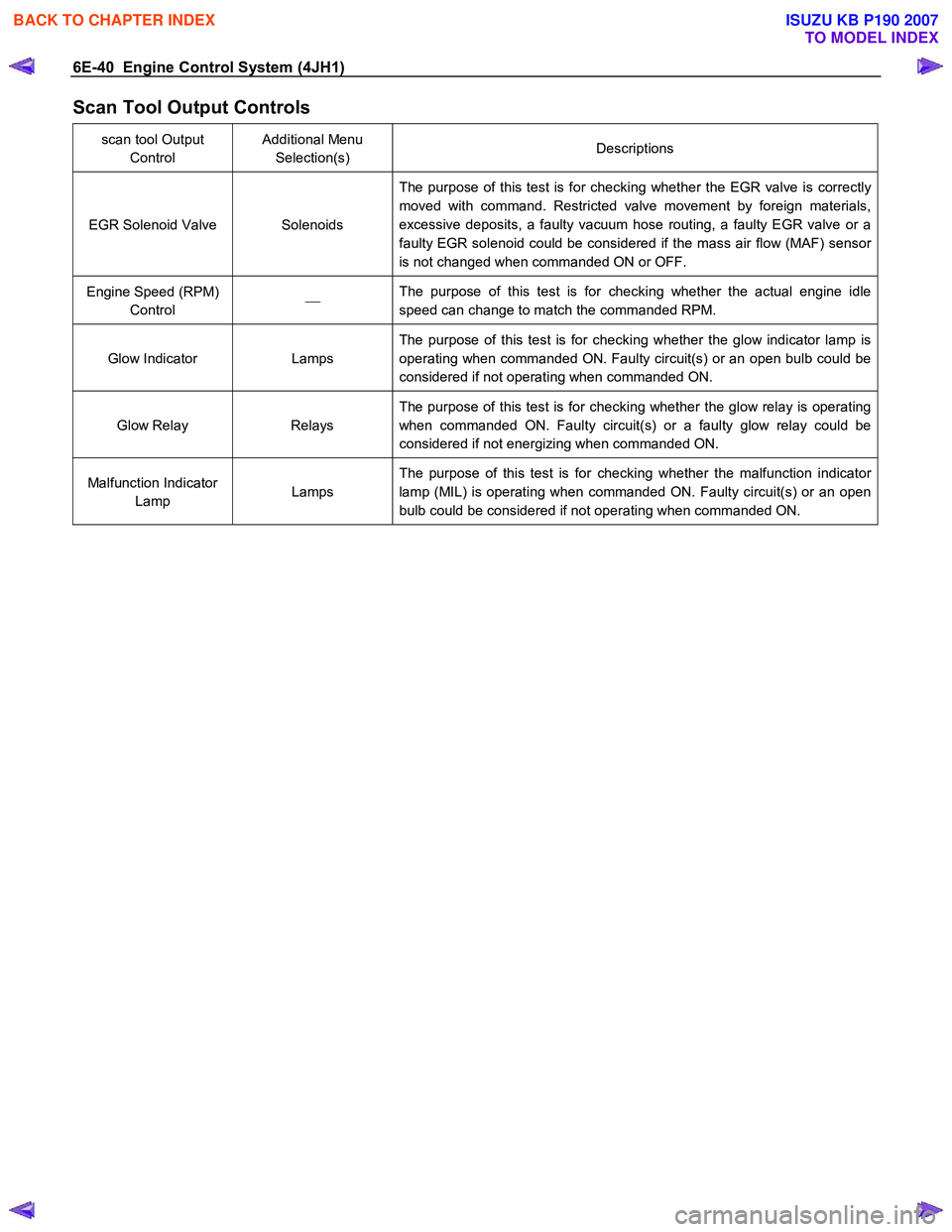

Step Action Value(s) Yes No

8 Important: An open in a ground circuit at the ECM

will not cause a loss of communication.

1. Check ECM ground for corrosion and tightness.

2. Clean or tighten grounds as necessary.

Did you find and correct the condition?

Go to Step 17 Go to Step 9

9 1. Turn OFF the ignition. 2. Reconnect the ECM harness connector if previously disconnected.

3. Turn ON the ignition, with the engine OFF.

4. Replace the ECM main relay with the tail relay or replace with a known good relay.

5. Attempt to establish scan tool communications with the ECM.

Does the ECM communicate with the scan tool?

Go to Step 15 Go to Step 10

10 1. Turn OFF the ignition. 2. Remove the ECM main relay.

3. Turn ON the ignition, with the engine OFF.

4. Using a test lamp, check for battery voltage at both of the battery voltage supply circuits to the

ECM main relay (pins 2 and 5 of X-12

connector).

5. Repair the open in the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 17 Go to Step 11

11 1. Reinstall the ECM main relay. 2. Turn the ignition ON and OFF while listening or feeling for the ECM main relay click. W ait 2

seconds between transitions.

Does the ECM main relay click when the ignition is

turned ON or OFF?

Go to Step 13 Go to Step 12

12 Repair the ECM main relay control circuit between the ECM main relay (pin 4 of X-12 connector) and

the ECM (pin 58 of C-56 connector) for the following

conditions: • An open circuit

• A short to battery or ignition voltage

• High resistance or a poor connection at

both the ECM and ECM main relay

Did you find and correct the condition?

Go to Step 17 Go to Step 16

13 1. Check ECM main relay voltage supply circuit to the ECM between the ECM main relay (pin 1 of

X-12 connector) and the ECM (pin 3 of C-56

connector) for the following conditions: • An open circuit

• High resistance or a poor connection at the

ECM and ECM main relay

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 17 Go to Step 16

14 Repair the open in the ignition voltage circuit to the ECM.

Did you complete the repair?

Go to Step 17

15 Replace the ECM main relay.

Did you complete the replacement?

Go to Step 17

16 Important: Replacement ECM must be

programmed.

Replace the ECM. Refer to Engine Control Module

(ECM) Replacement in this section.

Did you complete the replacement?

Go to Step 17

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1090 of 6020

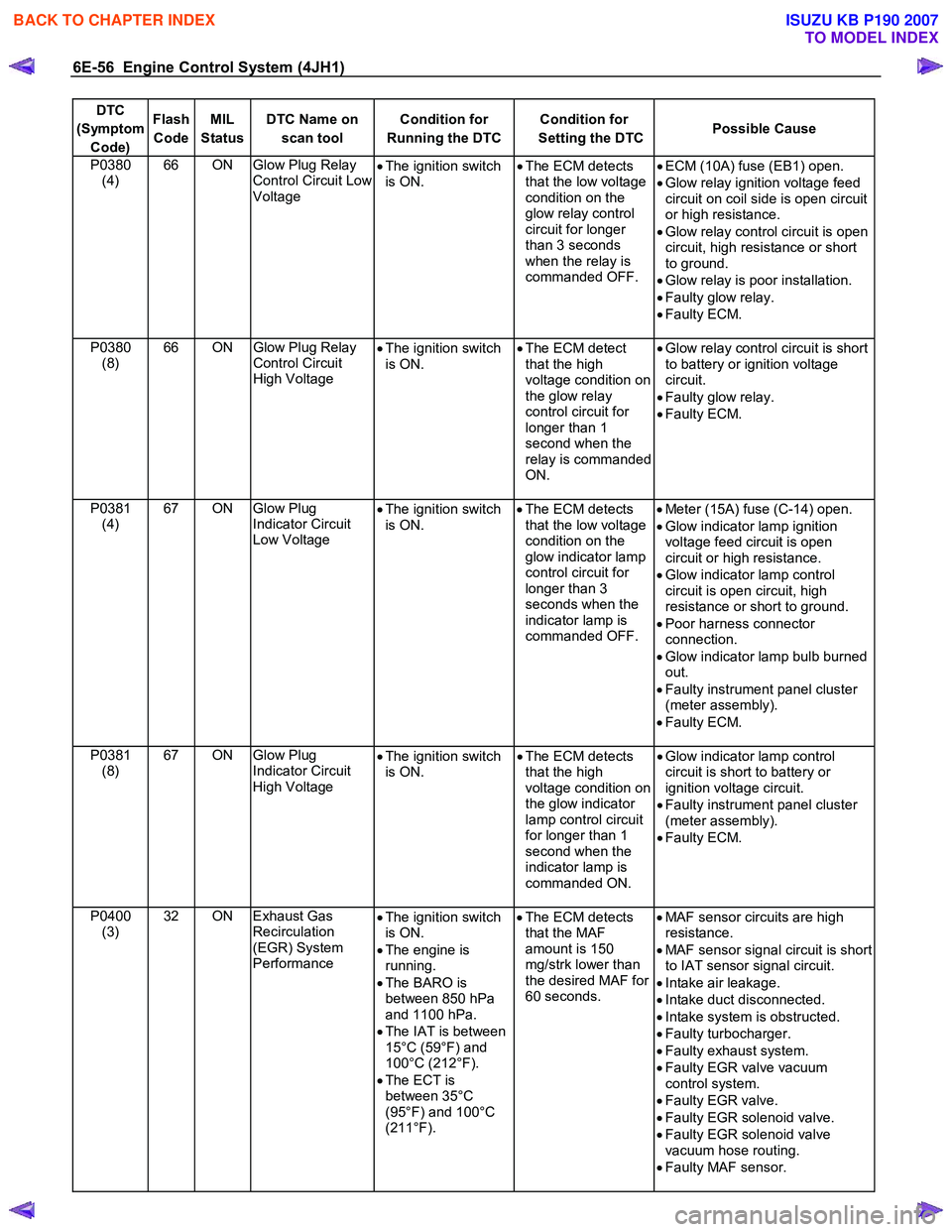

6E-56 Engine Control System (4JH1)

DTC

(Symptom Code) Flash

Code MIL

Status DTC Name on

scan tool Condition for

Running the DTC Condition for

Setting the DTC Possible Cause

P0380

(4) 66 ON Glow Plug Relay

Control Circuit Low

Voltage •

The ignition switch

is ON. •

The ECM detects

that the low voltage

condition on the

glow relay control

circuit for longer

than 3 seconds

when the relay is

commanded OFF.

•

ECM (10A) fuse (EB1) open.

• Glow relay ignition voltage feed

circuit on coil side is open circuit

or high resistance.

• Glow relay control circuit is open

circuit, high resistance or short

to ground.

• Glow relay is poor installation.

• Faulty glow relay.

• Faulty ECM.

P0380 (8) 66 ON

Glow Plug Relay

Control Circuit

High Voltage •

The ignition switch

is ON. •

The ECM detect

that the high

voltage condition on

the glow relay

control circuit for

longer than 1

second when the

relay is commanded

ON.

•

Glow relay control circuit is short

to battery or ignition voltage

circuit.

• Faulty glow relay.

• Faulty ECM.

P0381 (4) 67 ON Glow Plug

Indicator Circuit

Low Voltage •

The ignition switch

is ON.

•

The ECM detects

that the low voltage

condition on the

glow indicator lamp

control circuit for

longer than 3

seconds when the

indicator lamp is

commanded OFF.

•

Meter (15A) fuse (C-14) open.

• Glow indicator lamp ignition

voltage feed circuit is open

circuit or high resistance.

• Glow indicator lamp control

circuit is open circuit, high

resistance or short to ground.

• Poor harness connector

connection.

• Glow indicator lamp bulb burned

out.

• Faulty instrument panel cluster

(meter assembly).

• Faulty ECM.

P0381 (8) 67 ON Glow Plug

Indicator Circuit

High Voltage •

The ignition switch

is ON. •

The ECM detects

that the high

voltage condition on

the glow indicator

lamp control circuit

for longer than 1

second when the

indicator lamp is

commanded ON.

•

Glow indicator lamp control

circuit is short to battery or

ignition voltage circuit.

• Faulty instrument panel cluster

(meter assembly).

• Faulty ECM.

P0400 (3) 32 ON Exhaust Gas

Recirculation

(EGR) System

Performance •

The ignition switch

is ON.

• The engine is

running.

• The BARO is

between 850 hPa

and 1100 hPa.

• The IAT is between

15°C (59°F) and

100°C (212°F).

• The ECT is

between 35°C

(95°F) and 100°C

(211°F).

•

The ECM detects

that the MAF

amount is 150

mg/strk lower than

the desired MAF for

60 seconds.

•

MAF sensor circuits are high

resistance.

• MAF sensor signal circuit is short

to IAT sensor signal circuit.

• Intake air leakage.

• Intake duct disconnected.

• Intake system is obstructed.

• Faulty turbocharger.

• Faulty exhaust system.

• Faulty EGR valve vacuum

control system.

• Faulty EGR valve.

• Faulty EGR solenoid valve.

• Faulty EGR solenoid valve

vacuum hose routing.

• Faulty MAF sensor.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1092 of 6020

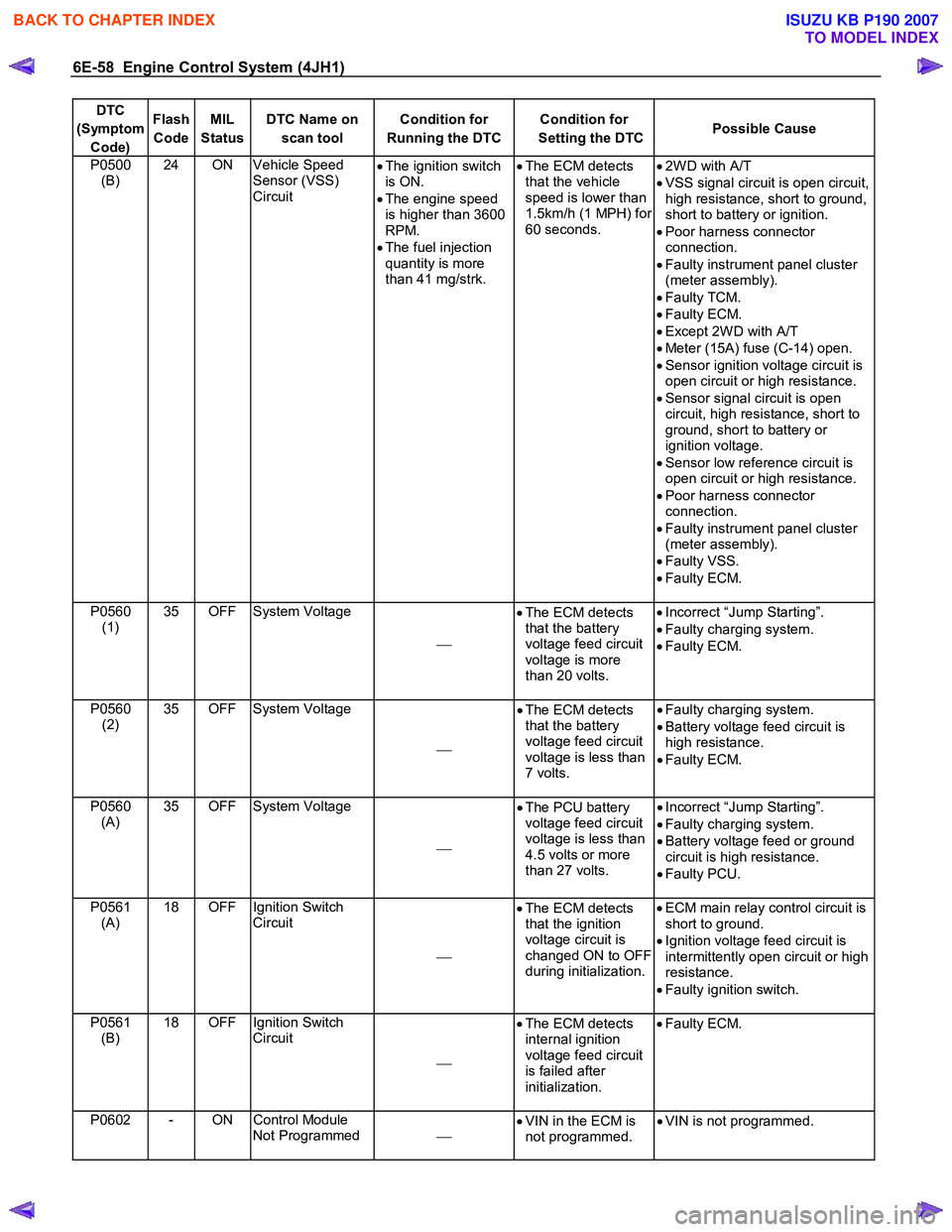

6E-58 Engine Control System (4JH1)

DTC

(Symptom Code) Flash

Code MIL

Status DTC Name on

scan tool Condition for

Running the DTC Condition for

Setting the DTC Possible Cause

P0500

(B) 24 ON Vehicle Speed

Sensor (VSS)

Circuit

•

The ignition switch

is ON.

• The engine speed

is higher than 3600

RPM.

• The fuel injection

quantity is more

than 41 mg/strk.

•

The ECM detects

that the vehicle

speed is lower than

1.5km/h (1 MPH) for

60 seconds.

•

2W D with A/T

• VSS signal circuit is open circuit,

high resistance, short to ground,

short to battery or ignition.

• Poor harness connector

connection.

• Faulty instrument panel cluster

(meter assembly).

• Faulty TCM.

• Faulty ECM.

• Except 2W D with A/T

• Meter (15A) fuse (C-14) open.

• Sensor ignition voltage circuit is

open circuit or high resistance.

• Sensor signal circuit is open

circuit, high resistance, short to

ground, short to battery or

ignition voltage.

• Sensor low reference circuit is

open circuit or high resistance.

• Poor harness connector

connection.

• Faulty instrument panel cluster

(meter assembly).

• Faulty VSS.

• Faulty ECM.

P0560 (1) 35 OFF System Voltage

•

The ECM detects

that the battery

voltage feed circuit

voltage is more

than 20 volts.

•

Incorrect “Jump Starting”.

• Faulty charging system.

• Faulty ECM.

P0560 (2) 35 OFF System Voltage

•

The ECM detects

that the battery

voltage feed circuit

voltage is less than

7 volts.

•

Faulty charging system.

• Battery voltage feed circuit is

high resistance.

• Faulty ECM.

P0560 (A) 35 OFF System Voltage

•

The PCU battery

voltage feed circuit

voltage is less than

4.5 volts or more

than 27 volts.

•

Incorrect “Jump Starting”.

• Faulty charging system.

• Battery voltage feed or ground

circuit is high resistance.

• Faulty PCU.

P0561 (A) 18 OFF Ignition Switch

Circuit

•

The ECM detects

that the ignition

voltage circuit is

changed ON to OFF

during initialization.

•

ECM main relay control circuit is

short to ground.

• Ignition voltage feed circuit is

intermittently open circuit or high

resistance.

• Faulty ignition switch.

P0561 (B) 18 OFF Ignition Switch

Circuit

•

The ECM detects

internal ignition

voltage feed circuit

is failed after

initialization.

•

Faulty ECM.

P0602 - ON Control Module

Not Programmed

•

VIN in the ECM is

not programmed. •

VIN is not programmed.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007