Circuit ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2150 of 6020

6D3-2 STARTING AND CHARGING SYSTEM

Starting System

General Description

Cranking Circuit

The cranking system consists of a battery, starter, starter

switch, starter relay, etc. These main components are

connected.

Starter

The cranking system employs a magnetic type reduction

starter in which the motor shaft is also used as a pinion shaft.

W hen the starter switch is turned on, the contacts of magnetic

switch are closed, and the armature rotates. At the same time,

the plunger is attracted, and the pinion is pushed forward by

the shift lever to mesh with the ring gear.

Then, the ring gear runs to start the engine. W hen the engine

starts and the starter switch is turned off, the plunger returns,

the pinion is disengaged from the ring gear, and the armature

stops rotation. W hen the engine speed is higher than the

pinion, the pinion idles, so that the armature is not driven.

Service Precaution

CAUTION:

Always use the correct fastener in the proper location.

When you replace a fastener, use ONLY the exact part

number for that application. ISUZU will call out those

fasteners that require a replacement after removal. ISUZU

will also call out the fasteners that require thread lockers

or thread sealant. UNLESS OTHERWISE SPECIFIED, do

not use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or fastener

joint interfaces. Generally, such coatings adversely affect

the fastener torque and the joint clamping force, and may

damage the fastener. When you install fasteners, use the

correct tightening sequence and specifications. Following

these instructions can help you avoid damage to parts

and systems.

Diagnosis

Condition Possible cause Correction

Starter does not run Charging failure Repair charging system

Battery Failure Replace Battery

Terminal connection failure Repair or replace terminal connector

and/or wiring harness

Starter switch failure Repair or replace starter switch

Starter failure Repair or replace starter

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2156 of 6020

6D3-8 STARTING AND CHARGING SYSTEM

General On-Vehicle Inspection

The operating condition of charging system is indicated by the

charge warning lamp. The warning lamp comes on when the

starter switch is turned to "ON" position. The charging system

operates normally if the lamp goes off when the engine starts.

If the warning lamp shows abnormality or if undercharged or

overcharged battery condition is suspected, perform diagnosis

by checking the charging system as follows:

1. Check visually the belt and wiring connector.

2. W ith the engine stopped, turn the stator switch to "ON" position and observe the warning lamp.

If lamp does not come on:

Disconnect wiring connector from generator, and ground the terminal "L" on connector side.

If lamp comes on:

Repair or replace the generator.

Generator

Removal

1. Disconnect battery ground cable.

2. Move drive belt tensioner to loose side using wrench then remove drive belt.

3. Disconnect terminal "B" wiring connector and connector.

4. Remove generator assembly.

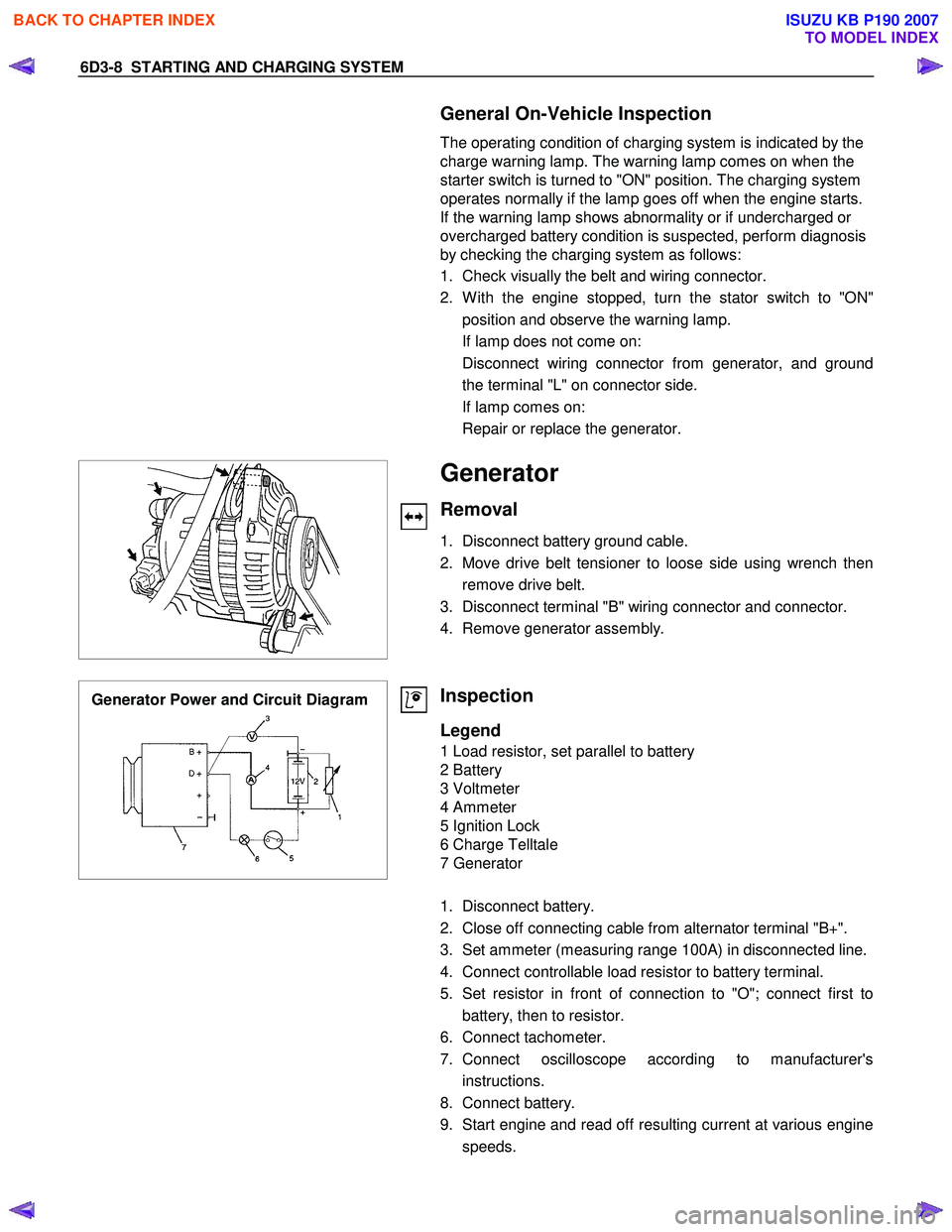

Generator Power and Circuit Diagram

Inspection

Legend

1 Load resistor, set parallel to battery

2 Battery

3 Voltmeter

4 Ammeter

5 Ignition Lock

6 Charge Telltale

7 Generator

1. Disconnect battery.

2. Close off connecting cable from alternator terminal "B+".

3. Set ammeter (measuring range 100A) in disconnected line.

4. Connect controllable load resistor to battery terminal.

5. Set resistor in front of connection to "O"; connect first to battery, then to resistor.

6. Connect tachometer.

7. Connect oscilloscope according to manufacturer's instructions.

8. Connect battery.

9. Start engine and read off resulting current at various engine speeds.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2157 of 6020

STARTING AND CHARGING SYSTEM 6D3-9

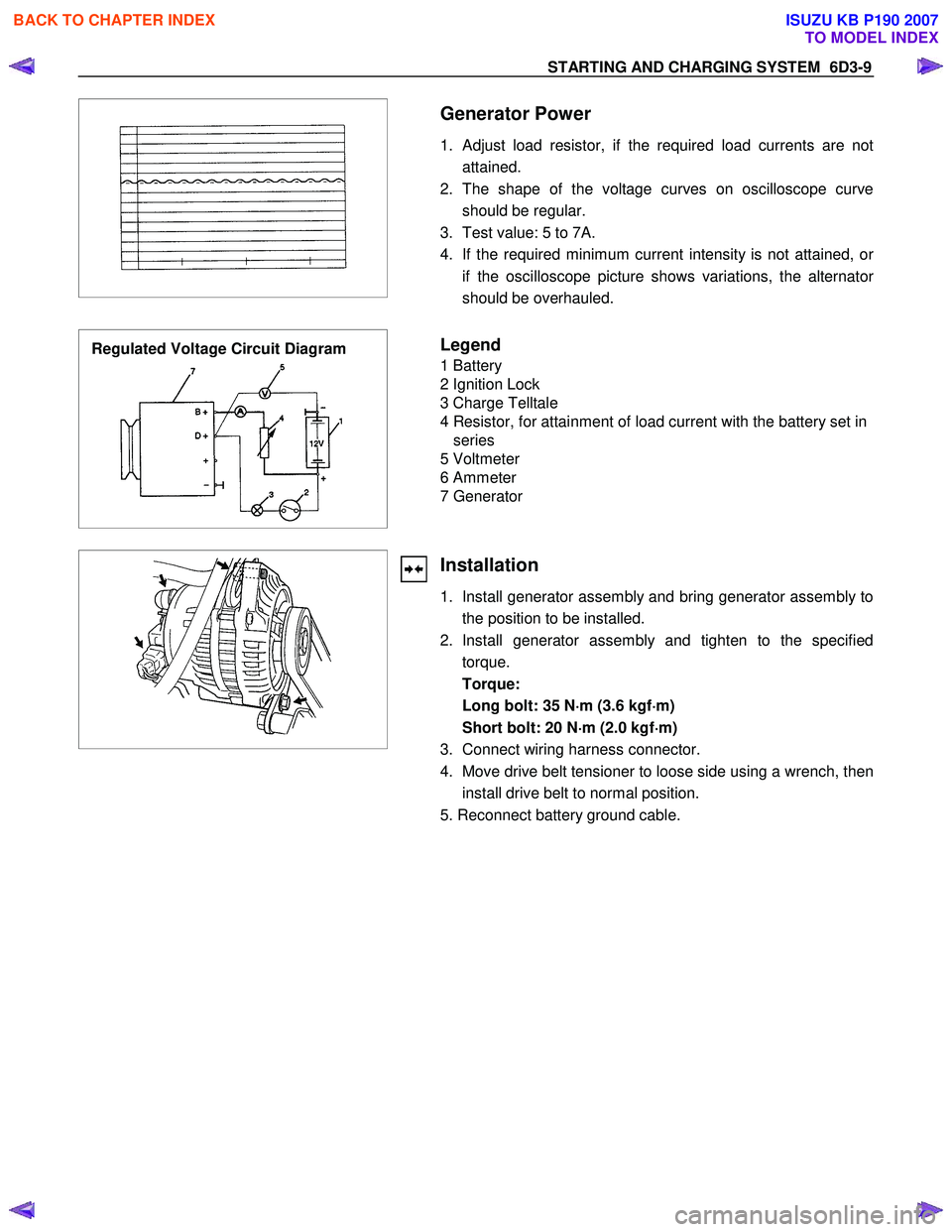

Generator Power

1. Adjust load resistor, if the required load currents are not attained.

2. The shape of the voltage curves on oscilloscope curve should be regular.

3. Test value: 5 to 7A.

4. If the required minimum current intensity is not attained, o

r

if the oscilloscope picture shows variations, the alternator

should be overhauled.

Regulated Voltage Circuit Diagram

Legend

1 Battery

2 Ignition Lock

3 Charge Telltale

4 Resistor, for attainment of load current with the battery set in series

5 Voltmeter

6 Ammeter

7 Generator

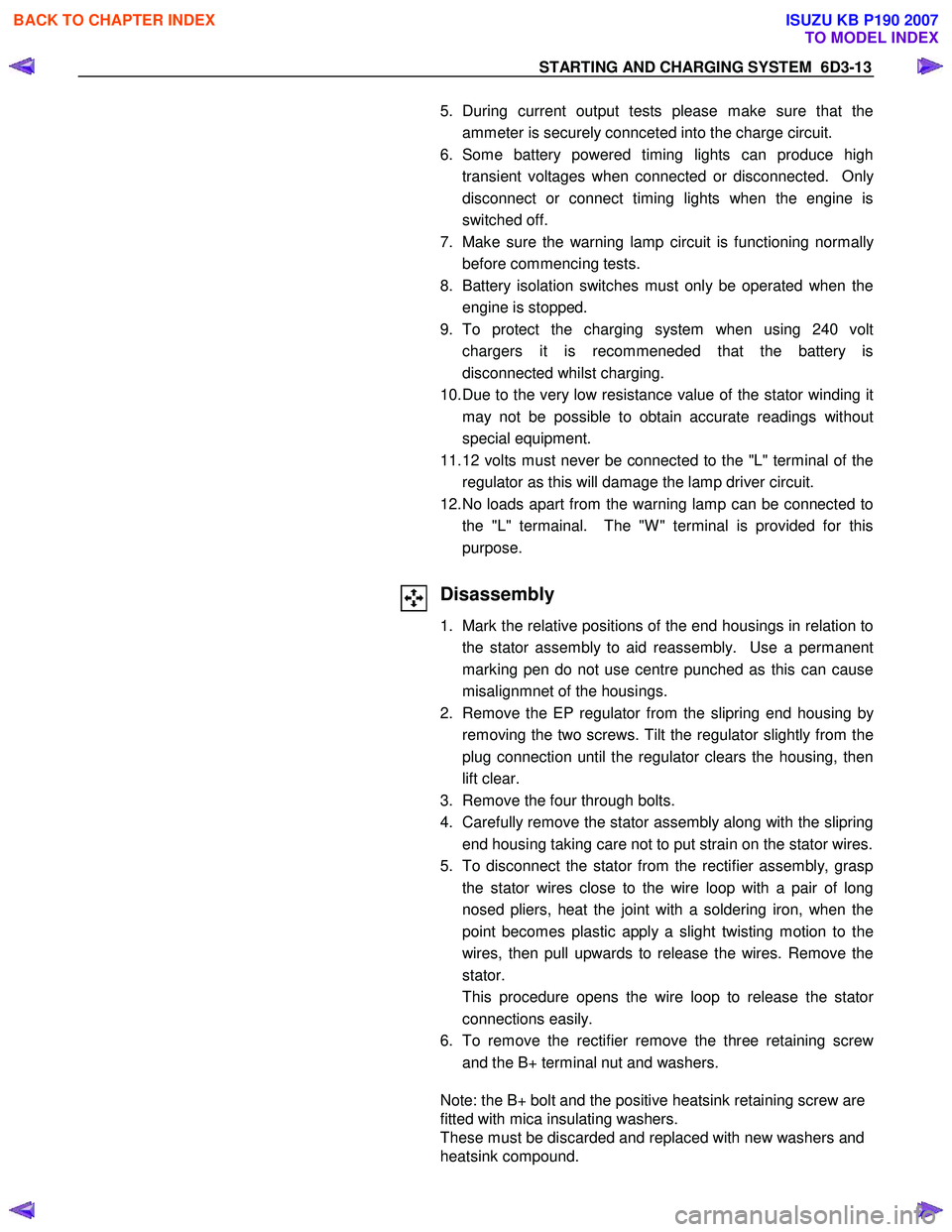

Installation

1. Install generator assembly and bring generator assembly to the position to be installed.

2. Install generator assembly and tighten to the specified torque.

Torque:

Long bolt: 35 N ⋅

⋅⋅

⋅

m (3.6 kgf ⋅

⋅⋅

⋅

m)

Short bolt: 20 N ⋅

⋅⋅

⋅

m (2.0 kgf ⋅

⋅⋅

⋅

m)

3. Connect wiring harness connector.

4. Move drive belt tensioner to loose side using a wrench, then install drive belt to normal position.

5. Reconnect battery ground cable.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2158 of 6020

6D3-10 STARTING AND CHARGING SYSTEM

The generator has four external connections; the "B+" lead to

battery positive, "L" lead to the warning lamp circuit(max. 2

watts), "S" lead to battery positive terminal for battery sensing

and an earth connection.

Explanation of type inscripiton

Example:KC-A--> 14V 50-90A.

K = Code for Stator OD(126mm OD).

C = Compact Generator.

A = Ausland (countries other than Germany)

> = Direction of rotation(clockwise).

14V = Generator Operating Voltage.

50A = Stabilised output at 25 C at 1800 RPM./13.5

Volts.

90A = Stabilised output at 25 C at 1800 RPM./13.5

Volts.

Generator Connetions.

B+ : Battery Main Connection (battery positive)

S : Battery Sense Connection(battery positive)

L : W aring lamp(via warning lamp to Ignition switch)

BATT.SENSE

REGULATOR ASSEMBLYHYBR10 ALTERNATOR ASSEMBLY

12V BATT. 1GN.SW .

300a*

W ARN.LAMP

1.2 W ATT L

S 8+

SUPPRESSOR

CAPACITOR

0.5 µf

NOTE: * RESISTOR IS RECOMMENDED TO

ENSURE THAT THE GENERATOR

REMAINS FUNCTIONAL IN CASE OF

W ARNING LAMP FAILURE

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2159 of 6020

STARTING AND CHARGING SYSTEM 6D3-11

Warning

Do not reverse S and L connections as this will destroy the

warning lamp circuit of the regulator.

Ensure good electrical contact beween generator earth and

battery negative,

Operation

W ith the Iginiton switch turnded "ON", current is supplied via

the warning lamp to the "L" terminal of the regulator. Base

current is fed to T15 causing it to turn on, current then flows

from B+ through the rotor winding via the regulator brushes

and the collector emitter junction of T15 to earth completing

the circuit. The current in the rotor causes a magnetic field

between adjacent poles to be created, this field is rotated and

cuts the windings of the stator at right angles inducing a

voltage into them.

As the speed is increased this induced voltage increases and

results in curent being rectified in the 3 phase diode bridge and

supplied as DC to the B+ output and hence to the battery.

W hen the voltage at the B+ terminal of the battery reaches

around 14.2 volts, this voltage is monitored by the "S" lead and

turns the regulator Hybrid base current to T15 OFF removing

rotor current, resulting in a decrease in output voltage to below

the regulating voltage, T15 base current turns ON and the

whole cycle is repeated very rapidly.

D38 protects T15 and the regulator against the back voltage

developed across the rotor winding when T15 turns OFF.

The new generated EP regulators incorporate current limiting

in the warning lamp circuit.

Backup Regulation

The EP regulator will limit the output voltage to a safe level

should either the main B+ cable or the battery sense wire

become decoupled, the output voltage will be slightly above the

normal setting(1-3 volts).

Start up phase

W hen the Iginition switch is turned on and the engine is not

running, the current to the rotor is reduced by switching it on

and off at a 50% duty cycle, the frequency is approximately 4

KHz and may be audible at times.

This is quite normal, once the engine is started normal

regulation commences.

Warning lamp failure

Should the warning lamp fail, the generator will self excite by

deriving a small current from the phase connecion allowing the

voltage to build up to regulating level.

Note: no filed current will flow when the engine is cranking.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2160 of 6020

6D3-12 STARTING AND CHARGING SYSTEM

Diagnosis

The EP regulator incorporates diagnostics which will illuminate

the warning lamp as a result of fault conditions in the generator

and external circuitry.

These conditions include:

1.

An open circuit in the regulator battery sensing wire (S

Terninal)

2. An open circuit or excessive voltage drop in the B+ cable.

3. An open circuit in the generator phase connection.

4. Overcharging of the battery.

5. Regulator output stage short circuit.

6. Open circuit rotor.

The regulator compares the voltage at B+ with the voltage at

the "S" terminal connceted to battery positive. If the voltage

differential exceeds a predetermined threshold, the regulator

will operate in backup mode to limit the output voltage to a safe

level. The warning lamp; will remain illuminated as along as

these conditions prevail.

Sources of high resistance which will trigger the warning lamp

are:

a. Poor contact in wiring harness connectors.

b. Poor contact between rectifier and regulator.

c. High resistance in fusible link assembly.

Caution:

When bench testing the generator it is important that the

warning lamp wattage of 2 watts is not exceeded.

Reversal of the "S" and "L" on the regulator will damage

the regulator.

The correct plug for the regulator is a 9 122 067 011 for the

Bosch tye and for the Shinagawa connector the number is

X02FW.

See appendix 1 for daignostic matrix.

Before testing or disassembling the generator please observe

the following points.

1. W hen testing the diodes with AC type testers the RMS.

Vlotage output must not exceed 12.0 volts, it is

recommended that the stator should be disconnected

during this test.

2. W here zener power diodes are used, the breakdown voltage should be tested to ensure all diodes have the

same zener voltage.

3. Insulation tests on the rotor and stator should use a voltage not exceeding 110v for a series test lamp. The rectifie

r

must be disconnected from the stator prior to testing.

4. W hen carrying out repairs to the charging system always disconnected the battery negative first, and reconnect it

last.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2161 of 6020

STARTING AND CHARGING SYSTEM 6D3-13

5. During current output tests please make sure that the

ammeter is securely connceted into the charge circuit.

6. Some battery powered timing lights can produce high transient voltages when connected or disconnected. Onl

y

disconnect or connect timing lights when the engine is

switched off.

7. Make sure the warning lamp circuit is functioning normall

y

before commencing tests.

8. Battery isolation switches must only be operated when the engine is stopped.

9. To protect the charging system when using 240 volt chargers it is recommeneded that the battery is

disconnected whilst charging.

10. Due to the very low resistance value of the stator winding it may not be possible to obtain accurate readings without

special equipment.

11. 12 volts must never be connected to the "L" terminal of the regulator as this will damage the lamp driver circuit.

12. No loads apart from the warning lamp can be connected to the "L" termainal. The "W " terminal is provided for this

purpose.

Disassembly

1. Mark the relative positions of the end housings in relation to the stator assembly to aid reassembly. Use a permanent

marking pen do not use centre punched as this can cause

misalignmnet of the housings.

2. Remove the EP regulator from the slipring end housing b

y

removing the two screws. Tilt the regulator slightly from the

plug connection until the regulator clears the housing, then

lift clear.

3. Remove the four through bolts.

4. Carefully remove the stator assembly along with the slipring end housing taking care not to put strain on the stator wires.

5. To disconnect the stator from the rectifier assembly, grasp the stator wires close to the wire loop with a pair of long

nosed pliers, heat the joint with a soldering iron, when the

point becomes plastic apply a slight twisting motion to the

wires, then pull upwards to release the wires. Remove the

stator.

This procedure opens the wire loop to release the stato

r

connections easily.

6. To remove the rectifier remove the three retaining scre

w

and the B+ terminal nut and washers.

Note: the B+ bolt and the positive heatsink retaining screw are

fitted with mica insulating washers.

These must be discarded and replaced with new washers and

heatsink compound.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2162 of 6020

6D3-14 STARTING AND CHARGING SYSTEM

7. To remove the pulley, mount an 8mm Allen key in the vice

with the short end upwards, place a 24mm ring spanner on

the puley nut, position the internal hexagon of the roto

r

shaft onto the Allen ken, loosen the nut and remove the

pulley.

Note: the pulley has an integral boss which locks up against

the bearing,

therefore no thrust collar is provided.

8. Removing the rotor assembly. Remove the four retaining screws from the drive end housing, withdraw the roto

r

complete with the bearing.

Note: the rotor must not be pressed from the drive end housing

using a press as the bearing retaining plate and drive end

housing will be damaged or distorted. Parts removed in this

way must be replaced if the integrity of the generator is to be

maintained.

9. Remove the drive end bearing from the rotor shaft using a

chuck type puler, take care not to distort the fan assembl

y

during this process.

10. Remove the slipring end bearing using the same meghod as in 9.

Clean

Thoroughly clean all components except the rotor and stator

with an approved cleaning agent. Ensure that all traced of oil

and dirt are removed. If an abrasive cleaner is used to remove

scale and paint from the housings take care not to abrade the

bearing and mounting spigot surfaces. The rotor and stator

must be cleaned with compressed air only, the use of solvents

could cause damage to the insulating materials.

Inspection

1. Rectifier assembly

The following test equipment is required.

The recitifier assembly is not repairable and must be replaced

if a faulty diode is detected during inspection.

(a)

Adiode tester where the DC output at the test probes does

not exceed 14 volts or in the case of AC testers 12 volts

RMS. This is to ensue that when inspection rectifiers fitted

with zener power diodes the forward and reverse checks

are completer and are not masked by the diode turning on

due to the zener breakdown voltage.

(b) A zenere diode tester with a DC output in excess of 30 volts, the tester should also incorporate internal current

limiting set to 5 Ma. to prevent high currents during

inspection.

(c) Diodes can be destroyed during service due to high temperature and overload, open circuits are usually a result

of excessive voltage.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2165 of 6020

STARTING AND CHARGING SYSTEM 6D3-17

fan.

4. Replacing the brushes (inbuilt regulator)

Check the brushes for length, this is measured from the brush

holder to the end of the brush along it's centre line. Also

inspect for any sideways wear. If worn replace both brushes.

The minimum length is 3.8mm. Inspect the brush springs for

signs of corrosion or loss of tension or uneven tension.

Replacing the brushes, using a soldering iron apply heat to the

soldered joints on the rear of the brush holder of the regulator,

using a small lever prise up the retaining tabs to release the

brush lead and spring. Thread the new brush lead up the

brush holder along with the spring, pull the lead through the

tabs until the brush is protruding 12mm from the holder.

Bend down the tabs and solder the brush lead taking care not

to allow the solder to run up the lead which will reduce

flexibility. Use 60/40 resin cored solder.

5. Ball bearing

Please note the bearings used in this KCA generator are a

high

tolerance type, only fully sealed bearings of the same

specification are to be used as replacements. It is

recommended that the bearings be replaced during the

reconditioning process to restore the unit to original

specification.

6. Regulator

The regulator can only be tested when fitted into an altenator.

Warning: do not reverse"S" and "L" connections or put 12

volt supply to "L" terminal, this connection must not be

used as a supply source other than to supply the

requirements of the warning lamp 2(watts).

Such action will destroy the regulator warning lamp

circuit.

For test voltages refer to Generator output testing section.

See also additional information on regulator function earlier in

this instruction.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2167 of 6020

STARTING AND CHARGING SYSTEM 6D3-19

Inspection

Generator

Before any in field testing can be undertaken it is important

that the battery's conditions is established and the terminals

are clean and tight.

Check the condition of the generator drive belt and ensure that

it is adjusted in accordance with the engine manufacturer's

recommnedations.

Battery conditions:

Note: This assessment may be difficult with maintenance free

assemblies.

Test the specific gravity of the individual cells the readings

should be within 10 points of each other, it is recommended

that the average SG should be 1.260 or higher.

A load test should be carried out to determine the ability of the

battery to supply and accept current. This is a good indicator

as to the general condition of the battery.

A load equal to the normal starting current should be placed

across the battery, the duration of this load test should not

exceed 10 seconds, during this time the terminal voltage

across the battery should not drop below 9.6 volts. Observe

each cell for signs of excessive gas liberation, usuall an

indication of cell failure.

If the battery test is clear proceed with the Generator tests as

follows.

Care should be taken when making the following connections.

It is recommended that the battery negative terminal be

disconnected before the test meters are connected, and

reconnecting the negative terminal when the meters are

inserted into the circuit under test. The warning lamp in the D+

circuit should not exceed 2 watts.

Regulating voltage test on the vehicle.

Connect a voltmeter to the generator, the positive lead to the

B+ terminal and the nagative lead to the generator casing.

Select the voltage range to suit the system, i.e. 20v for 12 volt

sysytems or 40v for 24 volt systems. Connect an ammeter in

series with the main output cable from the B+ terminal on the

generator, the range selected must be capable of reading the

maximum output from the generator.

Note the voltmeter reading before starting the engine. This

reading should increase when the engine is running indicating

generator output, start the engine and increase the engine

speed until the generator is running at 4000 rpm, switch on

vehicle loads of 5-10 A is indcated on the ammeter, the

voltmeter shoud read 14.0-14.2 v for a 12 volt system, for a 24

volt system the readings should be 5-10 A and 27.7-28.5 volts.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007