Neutral switch ISUZU KB P190 2007 Workshop Manual PDF

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3914 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–1

7C4

Automatic Transmission – 4L60E –

On-vehicle Servicing

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to General Information Warnings, Cautions and Notes for correct workshop practices with regard to safety and/or property damage.

1 General Information ............................................................................................................ ...................3

1.1 General Service Information ................................................................................................................................. 3

Description ............................................................................................................................................................. 3

Service Information ............................................................................................................ ................................... 3

1.2 WARNINGS, CAUTIONS and NOTES................................................................................................... ................. 3

Definition of WARNING, CAUTION and NOTE Statements ............................................................................. .... 3

WARNING Defined............................................................................................................................................. 4

CAUTION Defined .............................................................................................................................................. 4

NOTE Defined .................................................................................................................................................... 4

2 Maintenance Operations......................................................................................................... ...............5

2.1 Transmission Fluid ................................................................................................................................................ 5

Transmission Fluid Colour...................................................................................................... .............................. 5

Transmission Fluid Level ...................................................................................................................................... 5

2.2 Reverse Flush and Flow Rate Test ............................................................................................... ........................ 6

Reverse Flush ........................................................................................................................................................ 6

Flow Rate Test........................................................................................................................................................ 7

3 Service Operations ............................................................................................................. ....................8

3.1 Fluid Change and Filter Replacement ............................................................................................ ...................... 8

Remove ................................................................................................................................................................... 8

Reinstall .................................................................................................................................................................. 9

3.2 Shift Selector Assembly ...................................................................................................................................... 11

Remove ................................................................................................................................................................. 11

Reinstall ................................................................................................................................................................ 12

3.3 Selector Cable Assembly .................................................................................................................................... 14

Remove ................................................................................................................................................................. 15

Reinstall ................................................................................................................................................................ 15

3.4 Neutral Start and Back-up Lamp Switch ............................................................................................................ 16

Remove ................................................................................................................................................................. 16

Reinstall ................................................................................................................................................................ 17

Adjust .................................................................................................................................................................... 17

3.5 Vehicle Speed Sensor ......................................................................................................................................... 18

Remove ................................................................................................................................................................. 18

Reinstall ................................................................................................................................................................ 19

3.6 Manual Shaft Oil Seal .......................................................................................................................................... 19

Replace ................................................................................................................................................................. 19

3.7 Transmission Support and Mount ................................................................................................. ..................... 20

Remove ................................................................................................................................................................. 20

Reinstall ................................................................................................................................................................ 21

3.8 Extension Housing Oil Seal, RWD ...................................................................................................................... 22

Replace ................................................................................................................................................................. 22

3.9 Extension Housing and Rear Bush, RWD ........................................................................................... ............... 22

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3916 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–3

1 General Information

This Section describes the removal and reinstallation procedures of the four speed 4L60E hydra-matic automatic

transmission as well as the service operations which can be performed with the transmission still fitted to the vehicle.

1.1 General Service Information

Description

The shift selector mechanism is linked to the transmission manual shaft with a selector cable. A heat protector is fitted

over the neutral start and back-up switch and manual shaft select lever.

For rear wheel drive (RWD) vehicles an extension housing is fitted to the rear of the transmission case.

Four wheel drive (4W D) vehicles have an adaptor housing and transfer case fitted to the rear of the transmission case,

for description and service operation refer to 7D Transfer Case and Adaptor Housing.

The four speed 4L60E hydra-matic automatic transmission is fitted with a filler tube, a breather hose and a vent pipe for

hot fluid overflow.

The transmission fluid is driven through a cooler within the radiator via the cooler line/hose assemblies to maintain

normal operating temperature.

Service Information

Throughout the service operations within this

Section, when handling retaining clips, using

compressed air or cleaning fluids, wear safety

equipment to avoid personal injury.

Refer to 7C1 Automatic Transmission – 4L60E – General Information for the following:

• information relating to mechanical and electrical operations,

• abbreviations, transmission specifications, special tools and torque wrench specifications,

• servicing, cleaning and inspection procedure recommendations.

It is essential to read and understand the General Information, W arnings, Cautions and Service Notes contained in that

same Section, before any service operation is performed on the four speed 4L60E hydra-matic automatic transmission or

any associated components.

Failure to comply with the procedures and service notes can affect the reliable and efficient operation of this automatic

transmission.

1.2 WARNINGS, CAUTIONS and NOTES

This Section contains various W ARNINGS, CAUTIONS and NOTE statements that you must observe carefully to reduce

the risk of death or injury during service, repair procedures or vehicle operation. Incorrect service or repair procedures

may damage the vehicle or cause operational faults. W ARNINGS, CAUTION and NOTE statements are not exhaustive.

GM HOLDEN LTD can not possibly warn of all the potentially hazardous consequences of failure to follow these

instructions.

Definition of WARNING, CAUTION and NOTE Statements

Diagnosis and repair procedures in this Section contain both general and specific W ARNING, CAUTION and NOTE

statements. GM HOLDEN LTD is dedicated to the presentation of service information that helps the technician to

diagnose and repair the systems necessary for proper operation of the vehicle. Certain procedures may present a hazard

to the technician if they are not followed in the recommended manner. W ARNING, CAUTION and NOTE statements are

designed to help prevent these hazards from occurring, but not all hazards can be foreseen.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3929 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–16

8 Slide the cover (3) in the direction shown by the

arrow (1).

9 Using a small flat blade screwdriver, move the lock piece (4) from the position indicated by the arrow (2).

Continue to move the lock piece until the adjuster (5)

position begins to change.

Figure 7C4 – 12

10 Connect the selector cable to the transmission external manual shaft linkage.

11 Insert the lock piece in the adjuster to engage with the serrated cable end (cable length adjustment).

12 Slide the cover (1) on the adjuster and secure the lock piece.

Figure 7C4 – 13

13 Install the heat shield (7) and tighten the attaching screws (1 and 6) to the correct torque specification, refer to Figure 7C4 – 10.

Heat shield front attaching screw

torque specification ............................................ 25.0 Nm

Heat shield rear attaching screw torque specification ..............................................9.0 Nm

14 Move the selector lever to the P position and press the selector lever knob button five times.

15 Ensure the selector lever moves smoothly to each of its positions.

16 Check if the shift position indicated by the selector lever and the actual shift position are the same, rectify if required.

17 Lower the vehicle to the ground. Ensure the engine can only be started with the transmission selector lever in Park or Neutral position and the back-up lamps work correctly. If required, adjust the neutral start and back-up lamp

switch, refer to 3.4 Neutral Start and Back-up Lamp Switch.

18 Ensure the gear selection operates correctly.

19 Install the front and rear console, refer to 10 Cab.

3.4 Neutral Start and Back-up Lamp Switch

Remove

1 Position the transmission selector lever to the P position.

2 Raise the vehicle and support in a safe manner, refer to 0A General Information for the location of support points.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3930 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–17

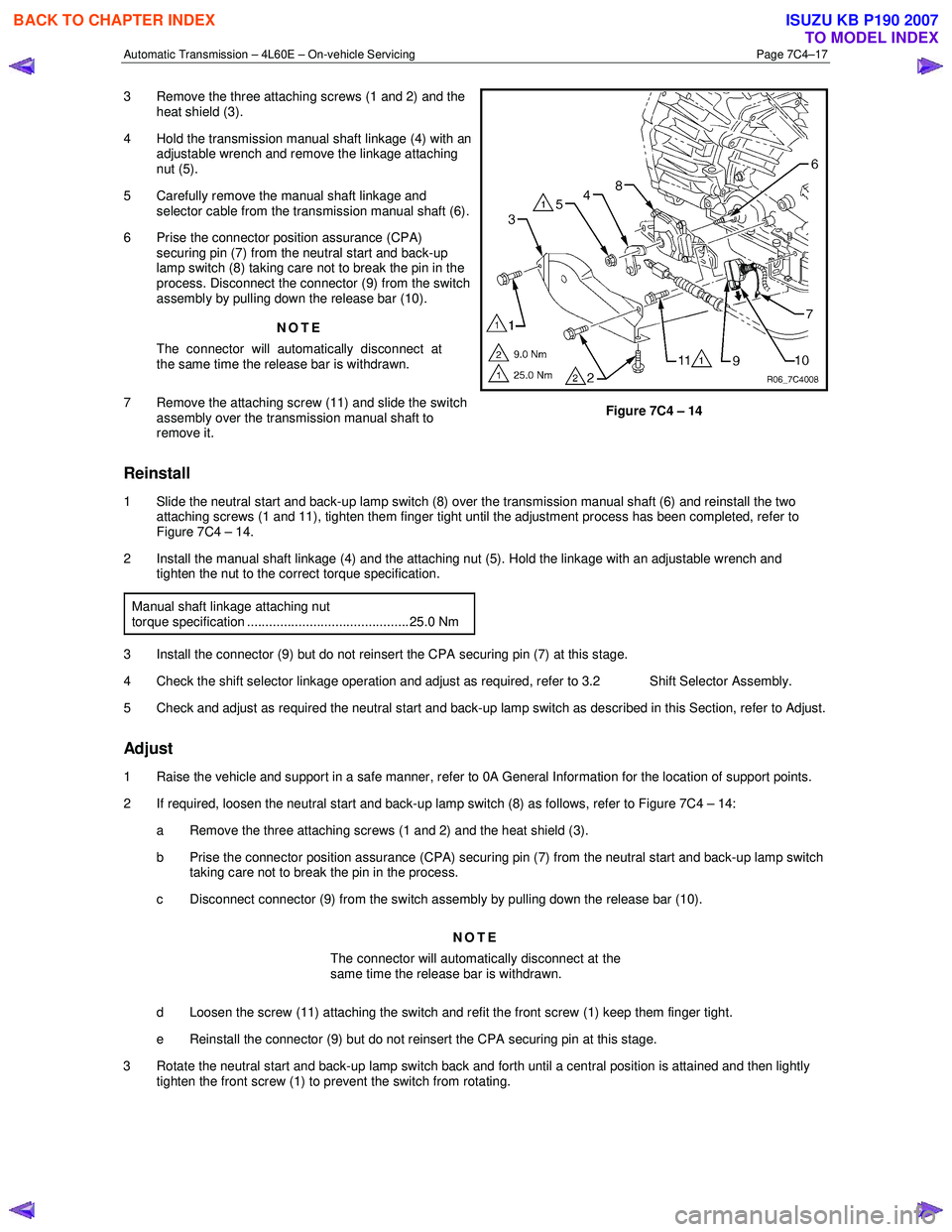

3 Remove the three attaching screws (1 and 2) and the

heat shield (3).

4 Hold the transmission manual shaft linkage (4) with an adjustable wrench and remove the linkage attaching

nut (5).

5 Carefully remove the manual shaft linkage and selector cable from the transmission manual shaft (6).

6 Prise the connector position assurance (CPA) securing pin (7) from the neutral start and back-up

lamp switch (8) taking care not to break the pin in the

process. Disconnect the connector (9) from the switch

assembly by pulling down the release bar (10).

NOTE

The connector will automatically disconnect at

the same time the release bar is withdrawn.

7 Remove the attaching screw (11) and slide the switch assembly over the transmission manual shaft to

remove it.

Figure 7C4 – 14

Reinstall

1 Slide the neutral start and back-up lamp switch (8) over the transmission manual shaft (6) and reinstall the two

attaching screws (1 and 11), tighten them finger tight until the adjustment process has been completed, refer to

Figure 7C4 – 14.

2 Install the manual shaft linkage (4) and the attaching nut (5). Hold the linkage with an adjustable wrench and tighten the nut to the correct torque specification.

Manual shaft linkage attaching nut

torque specification ............................................ 25.0 Nm

3 Install the connector (9) but do not reinsert the CPA securing pin (7) at this stage.

4 Check the shift selector linkage operation and adjust as required, refer to 3.2 Shift Selector Assembly.

5 Check and adjust as required the neutral start and back-up lamp switch as described in this Section, refer to Adjust.

Adjust

1 Raise the vehicle and support in a safe manner, refer to 0A General Information for the location of support points.

2 If required, loosen the neutral start and back-up lamp switch (8) as follows, refer to Figure 7C4 – 14: a Remove the three attaching screws (1 and 2) and the heat shield (3).

b Prise the connector position assurance (CPA) securing pin (7) from the neutral start and back-up lamp switch taking care not to break the pin in the process.

c Disconnect connector (9) from the switch assembly by pulling down the release bar (10).

NOTE

The connector will automatically disconnect at the

same time the release bar is withdrawn.

d Loosen the screw (11) attaching the switch and refit the front screw (1) keep them finger tight.

e Reinstall the connector (9) but do not reinsert the CPA securing pin at this stage.

3 Rotate the neutral start and back-up lamp switch back and forth until a central position is attained and then lightly tighten the front screw (1) to prevent the switch from rotating.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3931 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–18

Ensure the four wheels are off the ground

before performing the starting test.

4 W ith the ignition switched to the ON position, check if the engine can only be started in the Park and Neutral shift selector positions and ensure the back-up lamps illuminate when Reverse is selected. A further minor adjustment

may be required to achieve this state.

NOTE

To gain access to the rear attaching screw (11) it

will be necessary to remove the connector.

5 After the switch has been adjusted, tighten the rear attaching screw (11) to the correct torque specification. Neutral start and back-up lamp switch

attaching screw torque specification .................. 25.0 Nm

6 Reinstall the connector and the CPA securing pin.

7 Remove the switch front attaching screw (1).

8 Install the heat shield (3) and tighten the attaching screws (1 and 2) to the correct torque specification.

Heat shield front attaching screw

torque specification ............................................ 25.0 Nm

Heat shield rear attaching screw torque specification ..............................................9.0 Nm

9 Lower the vehicle to the ground and re-check the operation of the neutral start and back-up lamp switch. The vehicle must start only with the shift selector in the Park or Neutral positions and the back-up lamps should only

illuminate when Reverse is selected.

3.5 Vehicle Speed Sensor

NOTE

For the speed sensor fitted to four wheel drive

vehicles (4WD), refer to 7D Transfer Case and

Adaptor Housing.

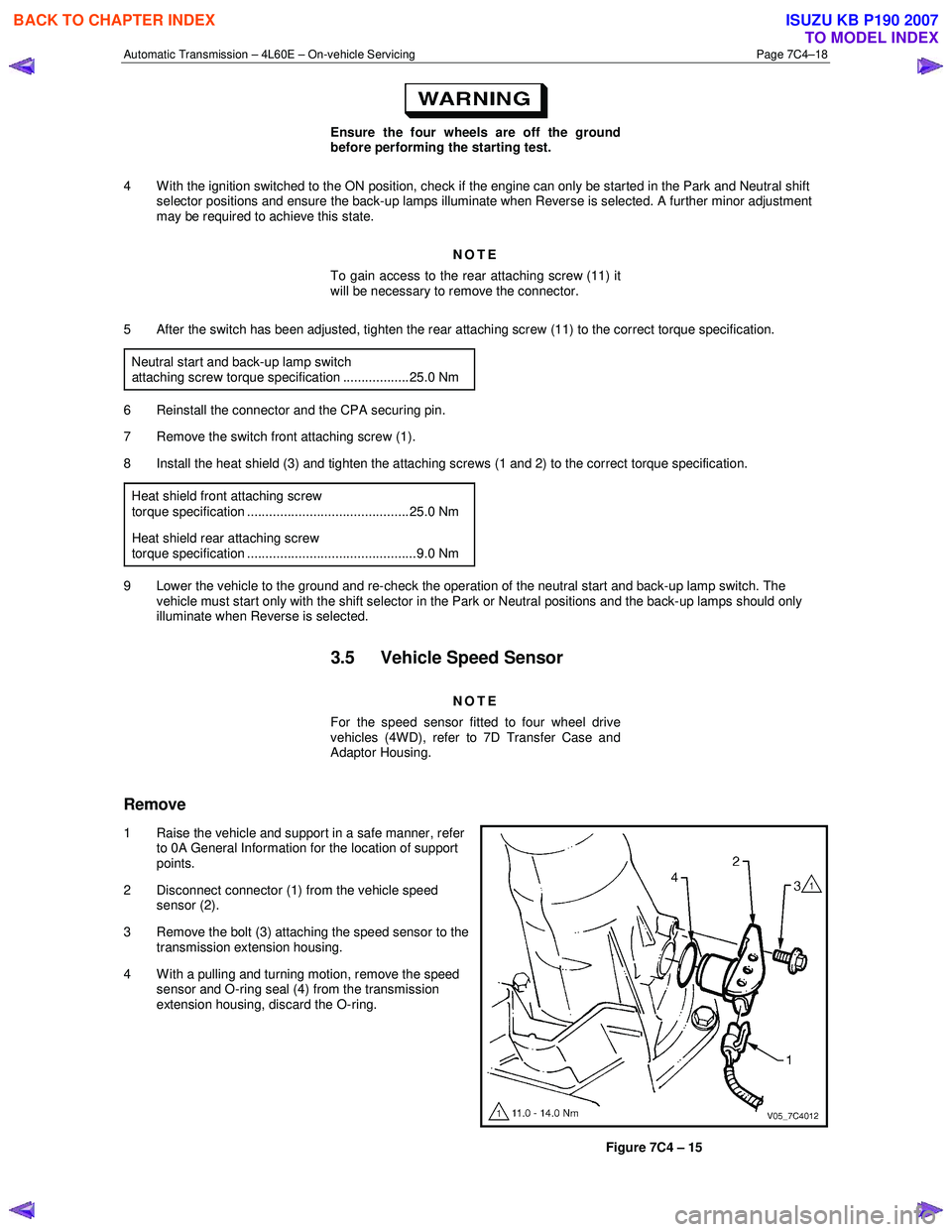

Remove

1 Raise the vehicle and support in a safe manner, refer

to 0A General Information for the location of support

points.

2 Disconnect connector (1) from the vehicle speed sensor (2).

3 Remove the bolt (3) attaching the speed sensor to the transmission extension housing.

4 With a pulling and turning motion, remove the speed sensor and O-ring seal (4) from the transmission

extension housing, discard the O-ring.

Figure 7C4 – 15

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3932 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–19

Reinstall

1 Lubricate a new O-ring seal with petroleum jelly and install it to the vehicle speed sensor.

2 Install the speed sensor to the transmission extension housing.

3 Install the attaching bolt and tighten to the correct torque specification.

Vehicle speed sensor attaching bolt

torque specification ............................................ 12.0 Nm

4 Connect the connector to the speed sensor.

5 Lower the vehicle to the ground.

3.6 Manual Shaft Oil Seal

Replace

NOTE

This procedure requires the use of special tool

No. AU583.

1 Raise the vehicle and support in a safe manner, refer to 0A General Information for the location of support points.

2 Remove the neutral start and back-up lamp switch, refer to 3.4 Neutral Start and Back-up Lamp Switch.

3 Assemble the seal remover, Tool No. AU583-3 (1) by installing the remover nut, Tool No. AU583-4 (2) with

its threaded inner diameter closest to the hexagonal

head of the seal remover tool. Install the nut up to the

hexagonal head.

4 Install the assembled seal remover tool over the manual shaft (3) engaging the tapered thread end (4)

into the seal.

Do not over tighten the seal remover tool in

the seal.

5 Rotate the hexagonal head of the seal remover tool clockwise, until the thread grips the steel shell of the

seal.

Figure 7C4 – 16

6 W hile holding the hexagonal head of the seal remover tool (1) rotate the remover nut (2) clockwise, until it

contacts the transmission case.

7 Continue rotating the remover nut until the seal is pulled into the remover nut cavity.

8 Remove and discard the seal.

Figure 7C4 – 17

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3933 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–20

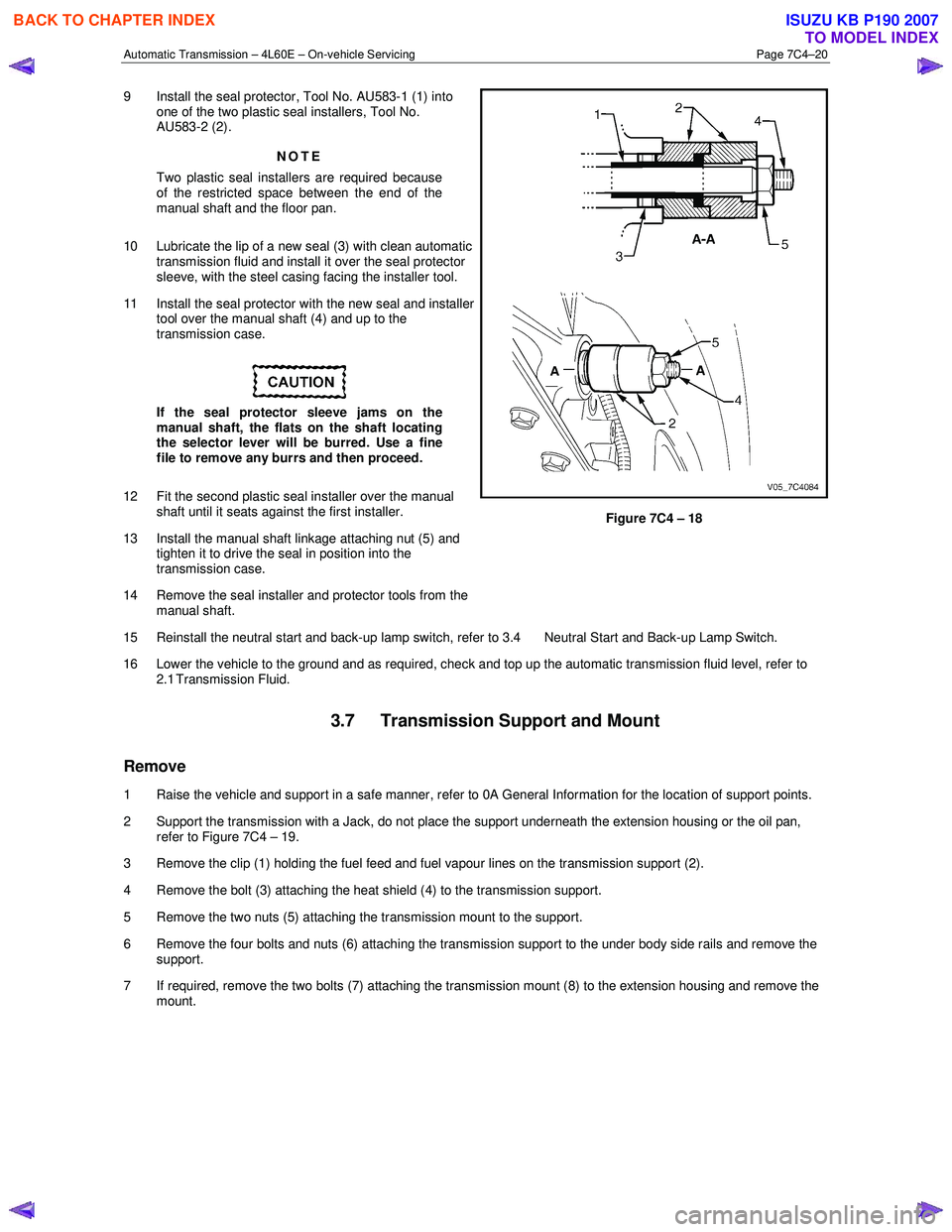

9 Install the seal protector, Tool No. AU583-1 (1) into

one of the two plastic seal installers, Tool No.

AU583-2 (2).

NOTE

Two plastic seal installers are required because

of the restricted space between the end of the

manual shaft and the floor pan.

10 Lubricate the lip of a new seal (3) with clean automatic transmission fluid and install it over the seal protector

sleeve, with the steel casing facing the installer tool.

11 Install the seal protector with the new seal and installer tool over the manual shaft (4) and up to the

transmission case.

If the seal protector sleeve jams on the

manual shaft, the flats on the shaft locating

the selector lever will be burred. Use a fine

file to remove any burrs and then proceed.

12 Fit the second plastic seal installer over the manual shaft until it seats against the first installer.

13 Install the manual shaft linkage attaching nut (5) and tighten it to drive the seal in position into the

transmission case.

14 Remove the seal installer and protector tools from the manual shaft.

Figure 7C4 – 18

15 Reinstall the neutral start and back-up lamp switch, refer to 3.4 Neutral Start and Back-up Lamp Switch.

16 Lower the vehicle to the ground and as required, check and top up the automatic transmission fluid level, refer to 2.1 Transmission Fluid.

3.7 Transmission Support and Mount

Remove

1 Raise the vehicle and support in a safe manner, refer to 0A General Information for the location of support points.

2 Support the transmission with a Jack, do not place the support underneath the extension housing or the oil pan, refer to Figure 7C4 – 19.

3 Remove the clip (1) holding the fuel feed and fuel vapour lines on the transmission support (2).

4 Remove the bolt (3) attaching the heat shield (4) to the transmission support.

5 Remove the two nuts (5) attaching the transmission mount to the support.

6 Remove the four bolts and nuts (6) attaching the transmission support to the under body side rails and remove the support.

7 If required, remove the two bolts (7) attaching the transmission mount (8) to the extension housing and remove the mount.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3956 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–43

If the verifier disc does not clip into place, the

quick-connect fitting is not engaged, rectify

as required.

10 As a security check, push and clip each verification disc into place over the quick-connect fittings. If difficulty is experienced, repeat the installation process until the verification disc can be clipped into place over the radiator

quick-connect fitting.

11 Snap the outlet cooler line (4) in the clip (5) of the radiator fan shroud.

12 Ensure the routeing of the cooler lines is correct and there is no fouling of the lines.

13 Tighten the screw attaching the cooler lines bracket to the correct torque specifications.

Transmission cooler lines bracket

attaching screw torque specification .................. 23.0 Nm

14 If required, top up the transmission fluid level (cold).

15 Start the engine and check for any fluid leak at the fittings. If a leak is found, stop the engine and rectify the leak.

16 Check and top up the transmission fluid to the correct level as required, refer to 2.1 Transmission Fluid.

3.18 Transmission Assembly

Remove

Disconnection of the battery affects certain

vehicle electronic systems. Refer to 6D1-3

Battery, before disconnecting the battery.

1 Disconnect the battery ground lead.

2 Raise the vehicle and support in a safe manner, refer to 0A General Information for the location of support points.

3 Remove the heat shield from the neutral start and back-up lamp switch, gently prise the selector cable from the transmission external manual shaft linkage and remove the selector cable from the bracket, refer to

3.3 Selector Cable Assembly.

4 Disconnect the harness connectors from the following:

a Vehicle speed sensor, refer to 3.5 Vehicle Speed Sensor.

b Neutral start and back-up switch, refer to 3.4 Neutral Start and Back-up Lamp Switch.

c For the following on four wheel drive vehicles (4W D), refer to 7D Transfer Case and Adaptor Housing:

• neutral switch,

• 2WD – 4WD shift actuator switch,

• speed sensor.

NOTE

If the battery is connected, avoid turning the

ignition switch to the ON position, as the transfer

case control module (TTCM) must first be

removed (memory to be cleared as Check 4W D

Indicator will light).

5 Remove the following components: a Front and centre exhaust assemblies, refer to 6F Exhaust System.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3960 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–47

14 Reconnect the fuel and EVAP pipes three brackets and clips, refer to 6C Fuel System – V6.

15 Reinstall the following components:

a Starter motor, refer to 6D1-2 Starting System.

b Transmission support, refer to 3.7 Transmission Support and Mount.

c Front and centre exhaust assemblies, refer to 6F Exhaust System.

d Rear propeller shaft and for 4WD front propeller shaft, refer to 4A Propeller Shaft.

16 Reconnect the harness connectors to the following: a Vehicle speed sensor, refer to 3.5 Vehicle Speed Sensor.

b Neutral start and back-up switch, refer to 3.4 Neutral Start and Back-up Lamp Switch.

c For the following on 4W D vehicles, refer to 7D Transfer Case and Adaptor Housing:

• neutral switch,

• 2WD – 4WD shift actuator switch,

• speed sensor.

17 Reinstall the selector cable to the transmission external manual shaft linkage, secure the selector cable to the bracket and attach the heat shield to the neutral start and back-up lamp switch, refer to 3.3 Selector Cable

Assembly.

18 Perform a reverse flush of the cooler lines and a flow rate test, refer to 2.2 Reverse Flush and Flow Rate, if either of the following applies:

• the transmission fluid is contaminated,

• the transmission has been replaced,

• the torque converter has been replaced, or

• the transmission oil pump has been replaced.

19 Lower the vehicle to the ground.

20 If required, top up the transmission fluid level (cold).

21 Reconnect the battery ground lead.

22 Start the engine and check for any fluid leaking at the fittings. If a leak is found, stop the engine and rectify the leak.

23 Road test until the transmission has reached operating temperature. Re-check the fluid level and for any fluid leaks, refer to 2.1 Transmission Fluid.

3.19 Transmission Control Module

Remove

1 Ensure the ignition switch is in the OFF position.

2 Disconnect the connector (1) from the transmission control module (TCM) (2) as follows, refer to Figure 7C4 – 63: a remove the securing pin (3),

b press the locking tab and swing the lever (4) to free the connector,

c remove the connector.

3 Remove the four bolts (5) and nuts (6), then the TCM from the mounting bracket (7).

4 If required, remove the two nuts (8) and the mounting bracket from the firewall.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3975 of 6020

TRANSMISSION CONTROL SYSTEM (AW30–40LE) 7A2-9

TCM Voltage & Resistance Check Sheet

CHECK ITEM PIN No. VALUE NOTE

VIGN C-94: 6–1 VIGN Key “ON”

Backup Power Supply C-94: 24–1 +B (Always) Key “ON”

Neutral Start Switch P “P” Position VIGN Key “ON”

Except “P” 0V

Neutral Start Switch R C-95: 1–C-94: 1 “R” Position VIGN Key “ON”

Except “R” 0V

Neutral Start Switch N C-95: 8–C-94: 1 “N” Position VIGN Key “ON”

Except “N” 0V

Neutral Start Switch D C95: 7–C-94: 1 “D” Position VIGN Key “ON”

Except “D” 0V

Neutral Start Switch 2 C-95: 19–C-94: 1 “2” Position VIGN Key “ON”

Except “2” 0V

Neutral Start Switch 1 C-95: 18–C-94: 1 “1” Position VIGN Key “ON”

Except “1” 0V

Neutral Start Switch 3 C-95: 9–C-94: 1 “3” Position VIGN Key “ON”

Except “3” 0V

Power SW C-95: 13–C-94: 1 “ON” 0V Key “ON”

“OFF” VIGN

3rd Start SW C-95: 4–C-94: 1 “ON” 0V Key “ON”

“OFF” VIGN

Brake SW C-95: 22–C-94: 1 “ON” VIGN Key “ON”

“OFF” 0V

AT Oil Temperature

Sensor C-94: 11–12 20

°C/68 °F 4.6V Engine run.

155°C/311 °F 1.1V

4L Signal C-95: 21–C-94: 1 4L 0V Key “ON”

2H/4H VIGN

Diag SW C-95: 12–C-94: 1 “ON” VIGN Key “ON”

“OFF” 0V

Shift Solenoid A (S1) C-94: 16–1 P VIGN Engine run.

R VIGN

N VIGN

D–1 VIGN

D–2 VIGN

D–3 0V

D–4 0V

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007