Neutral switch ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4848 of 6020

7D-18 TRANSFER CASE

Transfer Disassembly

RTW 67DLF000101

Legend

(1) Transfer Case Speedometer Bushing, Plate and Driven Gear

(2) Companion Flange, O-ring and Nut

(8)

(M/T: MUA, MUX, A/T: JR405E, AW 30-40LE)

(3) Stoneguard (9) Speed sensor (M/T: AR-5, A/T: 4L60-E)

(4) Detent Plug, Spring and Detent Ball (10) Transfer Actuator (Diesel Engine)

(5) 2-4 Switch ASM (11) Transfer Actuator (Gasoline Engine)

(6) Switch Bracket (12) Breather Hose

(7) Neutral Switch ASM (13) Heat Protector (Gasoline Engine)

Removal

1. Remove the stoneguard.

2. Remove the drain plug from the transfer case to drain

the oil.

3. Remove the parts listed below.

• Speedometer bushing, plate, and speedomete

r

driven gear (M/T: MUA, MUX, A/T: JR405E,

AW 30-40LE)

• Speed sensor (M/T: AR-5, A/T: 4L60-E)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4849 of 6020

TRANSFER CASE 7D-19

• Breather hose (Between the transfer case and the

transfer actuator assembly)

• Transfer actuator assembly

• Switch bracket

• 2-4 switch assembly (Gray harness cover)

• Neutral switch assembly (Black harness cover)

• Detent plugs, detent springs, and detent balls (2

parts each)

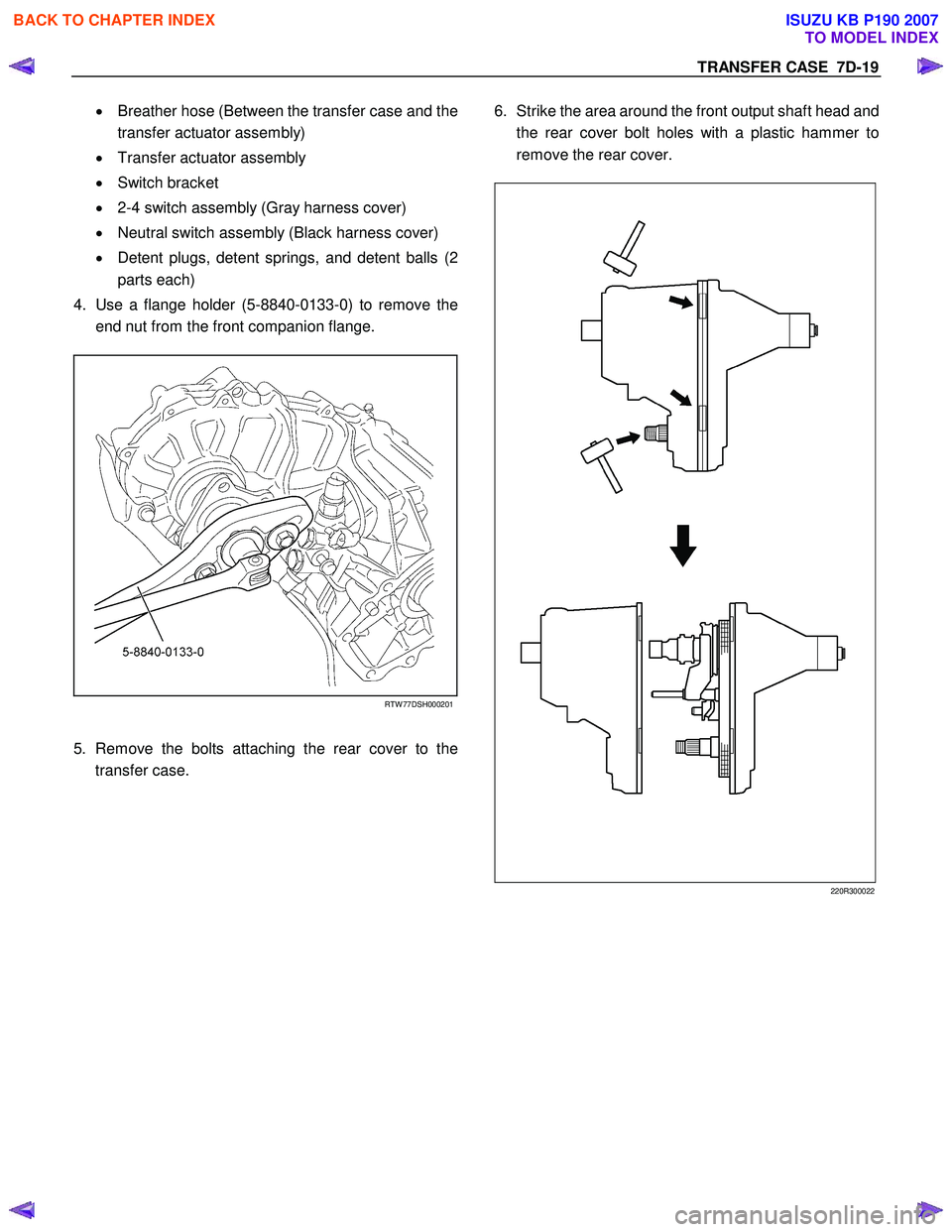

4. Use a flange holder (5-8840-0133-0) to remove the

end nut from the front companion flange.

RTW 77DSH000201

5. Remove the bolts attaching the rear cover to the

transfer case.

6. Strike the area around the front output shaft head and

the rear cover bolt holes with a plastic hammer to

remove the rear cover.

220R300022

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4857 of 6020

TRANSFER CASE 7D-27

Inspection and Repair

1. Make the necessary repair or parts replacement if

wear, damage or any other abnormal conditions are

found during inspection.

2. W ash all parts thoroughly in clean solvent. Be sure all

old lubricant, metallic particles, dirt, or foreign material

are removed from the surfaces of every part. Appl

y

compressed air to each oil feed port and channel in

each case half to remove any obstructions or cleaning

solvent residue.

Inspection and Repair (Transfer Case

Assembly)

W hen wear, damage, or any other defects are observed

during the inspection, the part or parts must be repaired

or replaced. W ash all the parts with clean detergent, and

check that old oil, metallic particles, dirt, or foreign

materials are completely removed. Blow the air into oil

holes and grooves to remove foreign materials or

residual detergent.

Chain

• Check whether the face that contacts the sprocket is

free from excessive wear or damage. If defects are

observed, replace the part.

• If the chain interference mark is found on the inside

wall of the transfer cover or the chain is so slack that a

skipped engagement occurs between the chain and

sprocket, replace the chain.

Sprocket

• Check whether the sprocket tooth surface is

excessively worn or damaged, and there is evidence

of burrs, chipping, wear, or damage on the gear

spline. Remove minor flaws or scratches with oil

stone. If excessive wear or damage is observed,

replace the part.

• If excessive wear or damage is observed on the

sprocket inside sliding surface, replace the part.

Gear

• Check whether the gear tooth surface is excessively

worn or damaged, and there is evidence of burrs,

chipping, wear, or damage on the gear spline.

• Remove minor flaws or scratches with oil stone. I

f

excessive wear or damage is observed, replace the

part.

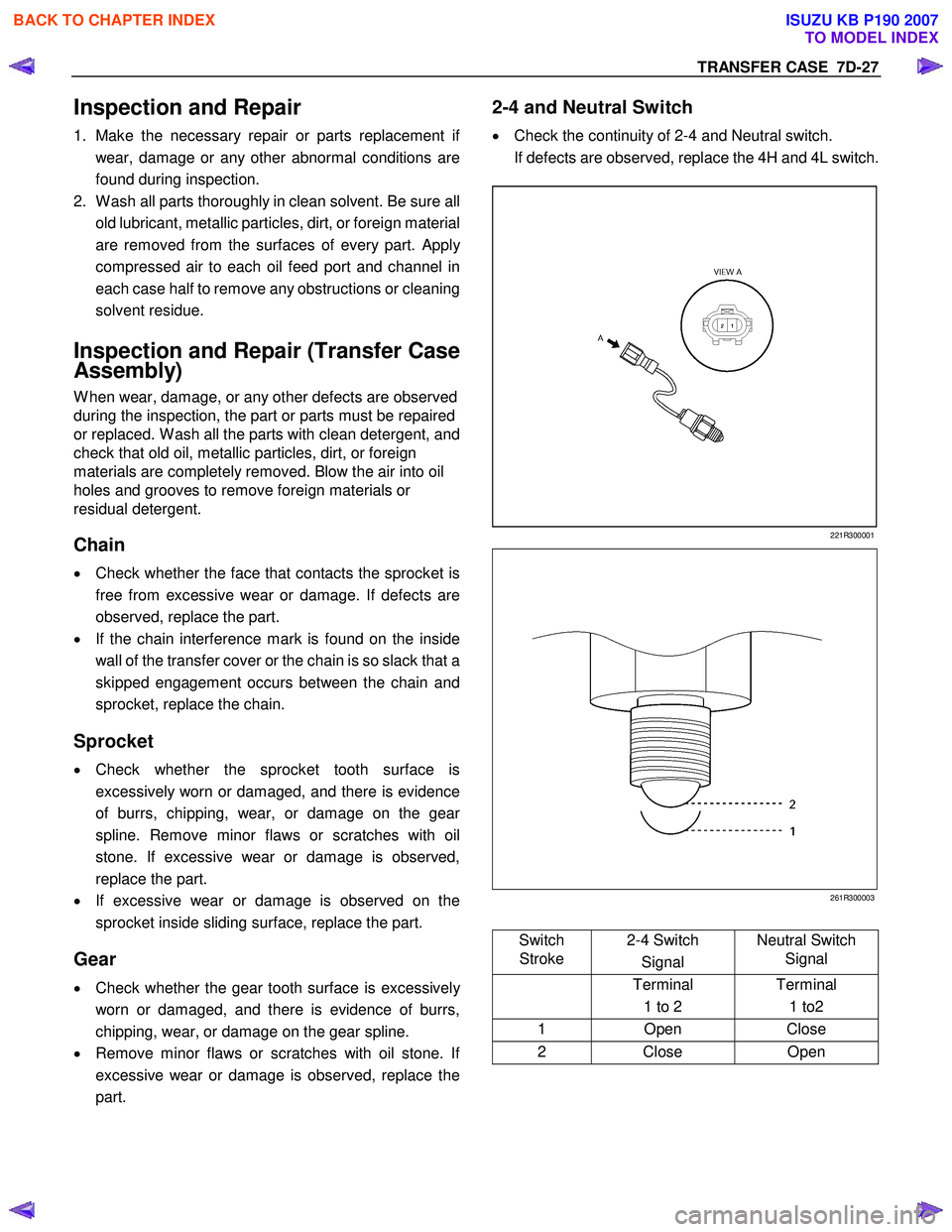

2-4 and Neutral Switch

• Check the continuity of 2-4 and Neutral switch.

If defects are observed, replace the 4H and 4L switch.

221R300001

261R300003

Switch

Stroke 2-4 Switch

Signal Neutral Switch

Signal

Terminal

1 to 2 Terminal

1 to2

1 Open Close

2 Close Open

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4869 of 6020

TRANSFER CASE 7D-39

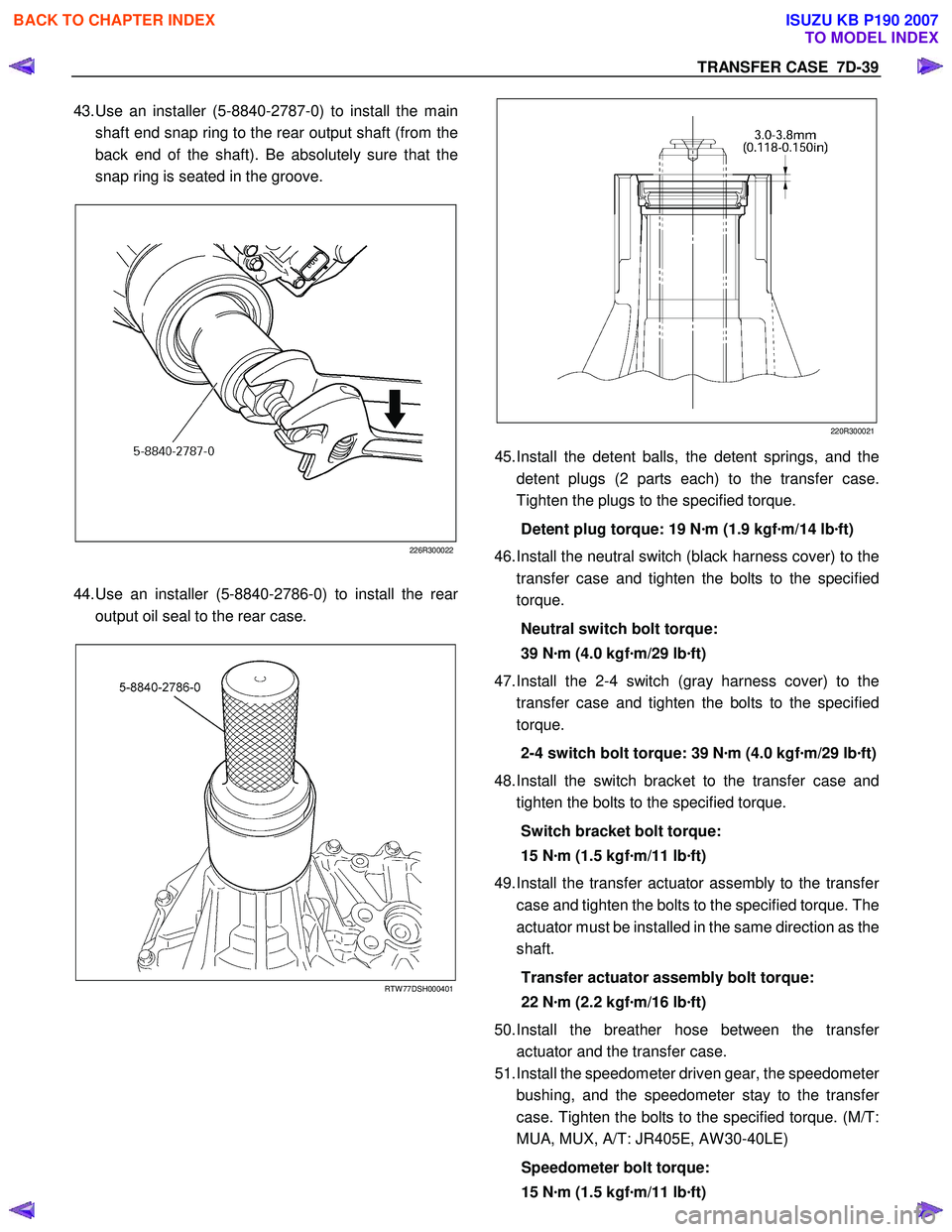

43. Use an installer (5-8840-2787-0) to install the main

shaft end snap ring to the rear output shaft (from the

back end of the shaft). Be absolutely sure that the

snap ring is seated in the groove.

226R300022

44. Use an installer (5-8840-2786-0) to install the rear

output oil seal to the rear case.

RTW 77DSH000401

220R300021

45.

Install the detent balls, the detent springs, and the

detent plugs (2 parts each) to the transfer case.

Tighten the plugs to the specified torque.

Detent plug torque: 19 N ·m (1.9 kgf ·m/14 lb ·ft)

46. Install the neutral switch (black harness cover) to the

transfer case and tighten the bolts to the specified

torque.

Neutral switch bolt torque:

39 N ·m (4.0 kgf ·m/29 lb ·ft)

47. Install the 2-4 switch (gray harness cover) to the

transfer case and tighten the bolts to the specified

torque.

2-4 switch bolt torque: 39 N ·m (4.0 kgf ·m/29 lb ·ft)

48. Install the switch bracket to the transfer case and

tighten the bolts to the specified torque.

Switch bracket bolt torque:

15 N ·m (1.5 kgf ·m/11 lb ·ft)

49. Install the transfer actuator assembly to the transfe

r

case and tighten the bolts to the specified torque. The

actuator must be installed in the same direction as the

shaft.

Transfer actuator assembly bolt torque:

22 N ·m (2.2 kgf ·m/16 lb ·ft)

50. Install the breather hose between the transfe

r

actuator and the transfer case.

51. Install the speedometer driven gear, the speedomete

r

bushing, and the speedometer stay to the transfe

r

case. Tighten the bolts to the specified torque. (M/T:

MUA, MUX, A/T: JR405E, AW 30-40LE)

Speedometer bolt torque:

15 N ·m (1.5 kgf ·m/11 lb ·ft)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4877 of 6020

TRANSFER CONTROL SYSTEM 7D1-3

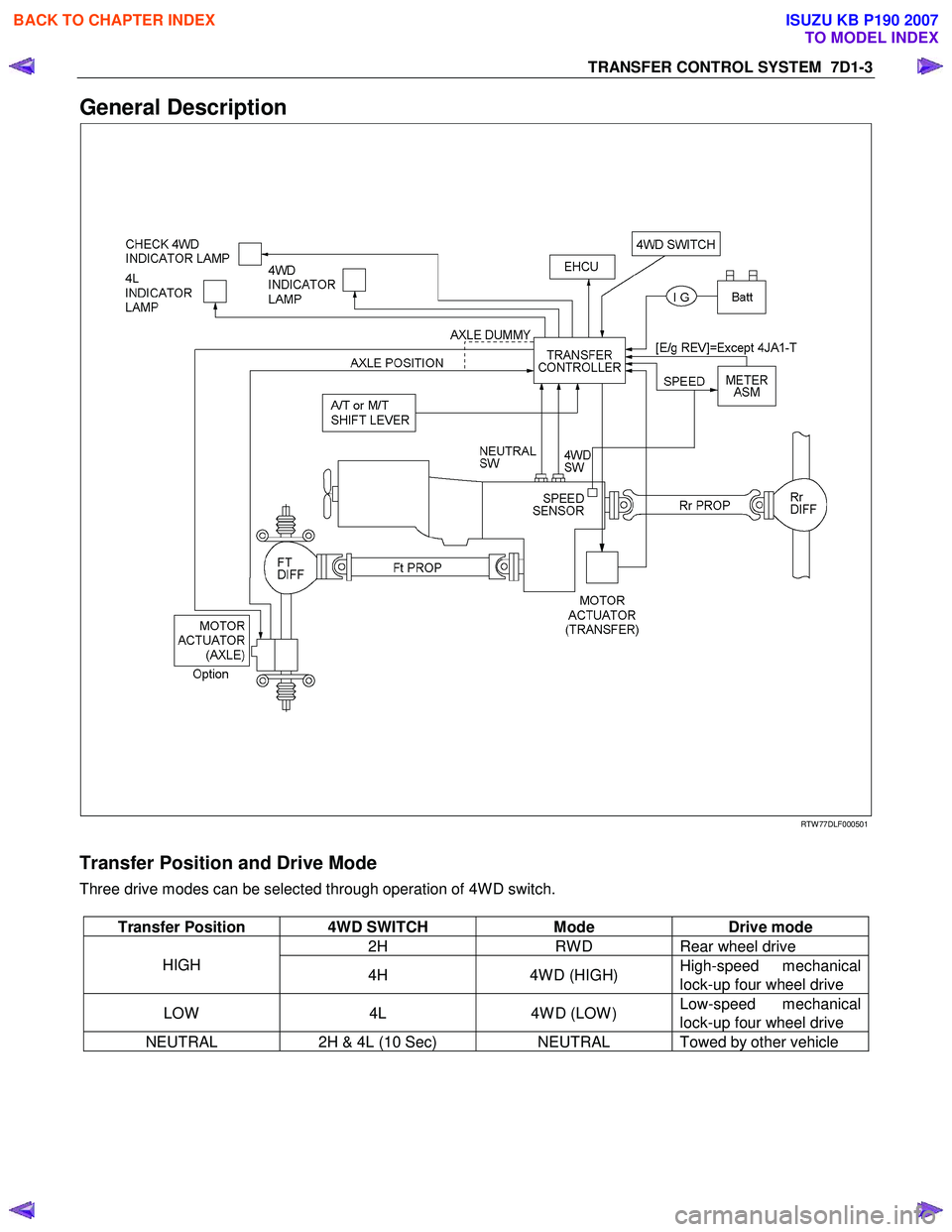

General Description

RTW 77DLF000501

Transfer Position and Drive Mode

Three drive modes can be selected through operation of 4W D switch.

Transfer Position 4WD SWITCH Mode Drive mode

2H RW D Rear wheel drive

HIGH

4H 4W D (HIGH) High-speed mechanical

lock-up four wheel drive

LOW 4L 4W D (LOW ) Low-speed mechanical

lock-up four wheel drive

NEUTRAL 2H & 4L (10 Sec) NEUTRAL Towed by other vehicle

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4878 of 6020

7D1-4 TRANSFER CONTROL SYSTEM

Summary of transfer control system

The transfer control system switches between the 2-wheel

drive (2H), 4-wheel drive high-speed (4H), 4-wheel drive low-

speed (4L), and neutral positions electrically when the driver

operates the switches.

This system has following functions.

1. Connection or disconnection of drive force distribution to the

front wheel front shaft (axle shaft). (The drive force

distribution to the front propeller is connected o

r

disconnected with the motor actuator.)

2. Try to repeat the connection or disconnection of the front wheel drive function as described above.

3. Option: Shift on the fly type only.

Instruction of connection or disconnection of the drive force transmission between the front wheel axle (axle shaft) and

front wheel. (The motor actuator connects or disconnects

the left front wheel and front wheel axle (axle shaft).)

4. Shifting of auxiliary transmission gears, connection o

r

disconnection of wheel and engine drive force (4H, 4L,

neutral).

5. Operation of the indicator on the instrument panel.

6. Transmission of the position signal to other controllers.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4880 of 6020

7D1-6 TRANSFER CONTROL SYSTEM

the 4×2 - 4 ×4 shift rod. W hen moving in 4 ×2 direction, a spring

standby mechanism is provided between the rod and sleeve so

that the rod is positioned at the 4 ×2 position, while the sleeve is

at the 4 ×4 position.

This mechanism is provided to protect the shift mechanism

from the force and to prevent movement of the sleeve

(torsional torque etc. of the drive system). By releasing the

preventive force, the sleeve can move to the 4 ×2 state by the

spring force.

Neutral switch

The neutral switch detects the movement of the shift rod

driving the high-low sleeve.

PUSH close is achieved with the PUSH close switch when the

shift rod is positioned between the High and the Low, at the

neutral state.

High-Low Sleeve & Arm

The spring standby mechanism is provided for the high-low

sleeve in both directions of the high-low shift rod. Therefore,

the rod position and the actual sleeve position may be offset in

some cases.

This system is provided to protect the shift mechanism from a

collision due to coincidence of the high and low phases of the

engaged splines. By giving rotational force to the preventing

phase coincidence, the splines are moved to the proper

engagement position by the spring force.

Shift actuator

The output shaft is rotated by the built-in motor and the transfer

position is switched.

Detection (limit) switches to detect the rotating angle of the

output shaft that is provided to the actuator at 4 positions.

These are connected to the transfer controller through the

vehicle harness to constantly transmit the actuator operating

angle and changes in its transfer status.

7B4-PDF2

4WD indicator (in meter panel)

This lamp indicates the following items:

Valve check

Drive condition (2W D-4W D)

Operating condition (2Hz: Actuator in operation, mechanism

standby)

Restrictions on operation (4Hz, including indication of

interrupted operation due

to excessive load)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4881 of 6020

TRANSFER CONTROL SYSTEM 7D1-7

7B4-PDF3

4L indicator (in meter panel)

This lamp indicates following items:

Valve check

Driving status (High-Low)

Operating status (2Hz: Actuator in operation, mechanism

standby)

Restrictions on operation (4Hz)

RTW 77DSH000601

Neutral indicator (in operation switch panel)

This LED indicates following items:

LED check

Driving status (Neutral)

Operating status (2Hz: Actuator in operation, mechanism

standby)

Restrictions on operation (4Hz)

7B4-PDF5

Check 4WD warning light (in meter panel)

This light indicates following items:

Valve check

Faulty actuator limit SW , and circuit related faults with the limit

switch

RTW 77DSH000501

4WD switch

Switch to transmit a switching command to the 2H, 4H,

Neutral, or 4L position.

It comprises 3 PUSH momentary switches. By pushing the 2H

and 4L switches for 10 seconds,

operation is changed to the neutral position.

To shift from the neutral to another position, push another

switch for 10 seconds.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4886 of 6020

7D1-12 TRANSFER CONTROL SYSTEM

Functions of Switch and indicator Lamp

Transfer-related indicator lamp and switch function

Item 4WD

lamp 4L lamp Neutral

lamp Check

4WD

warning light 4WD

switch Actu ato r

detection (limit)

switches

LS1, LS2, LS3. and LS4

1 = on

2 = off Transfer

4WD

switch Transfer

neutral switch SOF

actuator switch Or

Axl e

dummy Remarks

2H Off Off Off Off No

operation 1,0,1,0 Open Open Open -----

4H start

of

operation Off Off Off Off 4H position

for 0.1

second 1,0,1,0 Open Open Open Switch

operation sensor

Start of

operation Blinking

(2HZ) Off Off Off No

operation 1,1,1,0

0,0,1,0

0,1,1,0

0,1,1,1 Open Open Open

2H to 4H

while

driving

During

operation

(Synchro) Blinking

(2HZ) Off Off Off No

operation 1,1,1,0

0,0,1,0

0,1,1,0

0,1,1,1 Open Open Open 2H to 4H

using

synchro and

retrial

During

operation (Axle

drive) Blinking

(2HZ) Off Off Off No

operation 0,0,1,1 Closed Open Open Axle drive

Axle

waiting Blinking

(2HZ) Off Off Off No

operation 0,0,1,1 Closed Open Open Axle drive

4H On Off Off Off No

operation 0,0,1,1 Closed Open Closed -----

4L start

of

operation On Off Off Off 4L position

for 0.1

second 0,0,1,1 Closed Open Closed Switch

operation sensor

Start of

operation On Blinking

(2HZ) Off Off No

operation 0,0,0,1

0,1,0,1 Closed Open Closed 4H to 4L

while

driving

During

operation (N) Off

Blinking

(2HZ) Off Off No

operation 0,0,0,1

0,1,0,1 Closed Closed Closed 4H to 4L

through neutral

During

operation (N) Off

Blinking

(2HZ) Off Off No

operation 0,1,0,0 Closed Closed Closed 4H to 4L

through neutral

During

operation (N) Off

Blinking

(2HZ) Off Off No

operation 1,1,0,0 Closed Closed Closed 4H to 4L

through neutral

4L

waiting On Blinking

(2HZ) Off Off No

operation 1,1,0,1 Closed Closed Closed 4H to 4L

while

waiting

4L On On Off Off No

operation 1,1,0,1 Closed Open Closed -----

4H start of

operation On Off Off Off 4H position

for 0.1

second 1,1,0,1 Closed Open Closed Switch

operation sensor

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4887 of 6020

TRANSFER CONTROL SYSTEM 7D1-13

Item 4WD

lamp 4L lamp Neutral

lamp Check

4WD

warning light 4WD

switch Actu ato r

detection (limit)

switches

LS1, LS2, LS3. and LS4

1 = on

2 = off Transfer

4WD

switch Transfer

neutral switch SOF

actuator switch Or

Axl e

dummy Remarks

During

operation On Blinking

(2HZ) Off Off No

operation 1,1,0,1 Closed Open Closed 4L to 4H

while

driving

During

operation (N) Off

Blinking

(2HZ) Off Off No

operation 1,1,0,0 Closed Closed Closed 4L to 4H

through neutral

During

operation Off Blinking

(2HZ) Off Off No

operation 0,1,0,1

0,0,0,1 Closed Closed Closed 4L to 4H

while

driving

4H

waiting Off Blinking

(2HZ) Off Off No

operation 0,0,1,1 Closed Closed Closed

4L to 4H

while

waiting

4H On Off Off Off No

operation 0,0,1,1 Closed Open Closed -----

2H start of

operation On Off Off Off 2H position

for 0.1

second 0,0,1,1 Closed Open Closed Switch

operation sensor

Start of

operation Blinking

(2HZ) Off Off Off No

operation 0,1,1,1

0,1,1,0

0,0,1,0

1,1,1,0 Closed Open Closed

2H to 4H

while

driving

During

operation (Axle) Blinking

(2HZ) Off Off Off No

operation 0,1,1,1

0,1,1,0

0,0,1,0

1,1,1,0 Open Open Closed Axle drive

Axle

waiting

Blinking

(2HZ) Off Off Off No

operation 1,0,1,0 Open Open Closed Axle

waiting

2H Off Off Off Off No

operation 1,0,1,0 Open Open Open -----

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007