automatic transmission ISUZU KB P190 2007 Workshop Manual PDF

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3313 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–35

Checks Actions

Fuel System

• Check the fuel system for the following fault conditions. Refer to 6C Fuel System

– V6.

− restricted fuel filter,

− incorrect fuel pressure, and

− contaminated fuel.

• Check the operation of the fuel injectors. Refer to 6C1-3 Engine Management –

V6 – Service Operations.

• Perform the fuel injector balance test, refer to 6.3 Fuel Injector Balance

Test in this Section.

• Check the items that cause an engine to run rich.

Ignition System

• Inspect for moisture or corrosion around the spark plug and ignition coil area.

• Test the ignition coil voltage output. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

• Remove and inspect the spark plugs. Refer to 6C1-3 Engine Management –V6 –

Service Operations.

NOTE

If the spark plugs are fouled, determine the cause of the fouling before

replacing the spark plugs. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

• Check for loose ignition coil grounds.

Engine Mechanical

• Parasitic load on the engine such as the following:

• automatic transmission fault condition, or

• a belt driven accessory fault condition.

• Check for the following engine fault conditions. Refer to 6A1 Engine Mechanical –

V6.

• low compression, or

• worn valve train components.

When all diagnosis and repairs are completed, check the system for correct operation.

5.13 Surges / Chuggles

Description

W ith the accelerator pedal in a steady position, the vehicle speeds up and slows down or the engine power fluctuates.

Checks Actions

Preliminary Perform the preliminary checks. Refer to 4.3 Preliminary Checks in this Section.

Sensor / System

• Using Tech 2, check the heated oxygen sensor (HO2s) operating parameters.

The HO2s should respond quickly to different throttle positions.

• Test the resistance of the crankshaft position (CKP) sensor. The CKP sensor

resistance must be 700 – 1,200 Ω at all temperatures.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3314 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–36

Checks Actions

Fuel System

• Check the fuel system for the following fault conditions. Refer to 6C Fuel System

– V6.

• restricted fuel filter,

• incorrect fuel pressure, and

• contaminated fuel.

• Check the operation of the fuel injectors. Refer to 6C1-3 Engine Management –

V6 – Service Operations.

• Perform the fuel injector balance test, refer to 6.3 Fuel Injector Balance

Test in this Section.

• Check the items that cause an engine to run rich.

• Check for fault conditions that can cause an engine to run lean.

Ignition System

• Inspect for moisture or corrosion around the spark plug / ignition coil area.

• Test the ignition coil voltage output. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

• Remove and inspect the spark plugs. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

NOTE

If the spark plugs are fouled, determine the cause of the fouling before

replacing the spark plugs. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

• Check for loose ignition coil ground circuit.

Additional Checks

• Check the torque converter clutch (TCC) operation. A TCC that applies too soon

can cause engine detonation, which will trigger spark retard activity. Refer to 7C2

Automatic Transmission – 4L60E – Electrical Diagnosis.

• Test the A/C clutch for correct operation. Refer to 2A Heater and Air-conditioning.

• Check the evaporative emission (EVAP) canister purge solenoid for the following

conditions: Refer to 6C1-3 Engine Management – V6 – Service Operations.

− stuck open condition, and

− charcoal contamination.

• Check the exhaust system for possible restrictions. Refer to 6F Exhaust System –

V6.

• Electromagnetic interference (EMI) on the crankshaft position (CKP) sensor can

cause an engine misfire condition.

Using Tech 2, monitor the engine speed parameter. A sudden increase in the engine speed parameters without moving the throttle position indicates that an

Electromagnetic Interference fault may be present.

W iring harness routing which may be positioned very close to a high voltage or high current device such as the following may induce EMI:

• secondary ignition components, or

• motors and generators.

When all diagnosis and repairs are completed, check the system for correct operation.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3324 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–46

6.5 Alcohol / Contaminants in Fuel

Diagnosis

Description

W ater contamination in the fuel system may cause driveability conditions such as hesitation, stalling, no start, or

misfires in one or more cylinders. W ater may collect near a single fuel injector at the lowest point in the fuel rail, and

cause a misfire in that cylinder. If the fuel system is contaminated with water, inspect the fuel system components for

rust, or deterioration.

Alcohol (e.g. Ethanol) concentrations more than 10% in the fuel can be detrimental to fuel system components. Alcohol

contamination may cause fuel system corrosion, deterioration of rubber components, and subsequent fuel filter

restriction. Fuel contaminated with alcohol may cause driveability conditions such as hesitation, lack of power, stalling,

or no start. Some types of alcohol are more detrimental to fuel system components than others.

Alcohol in Fuel Testing Procedure

NOTE

The procedures detailed are not intended to be

accurate but rather, indicative of a contamination

situation.

The fuel sample should be drawn from the bottom of the tank so that any water present in the tank will be detected. The

sample should be bright and clear. If alcohol contamination is suspected, then use the following procedure to test the

fuel quality.

• Using a 100 ml graduated cylinder with 1 ml marks, fill the cylinder with fuel to the 90 ml mark.

• Add 10 ml of water to bring the total fluid volume to 100 ml and install a stopper.

• Shake the cylinder vigorously for 10 – 15 seconds.

• Carefully loosen the stopper to release the pressure.

• Re-install the stopper and shake the cylinder vigorously again for 10 – 15 seconds.

• Put the cylinder on a level surface for approximately 5 minutes to allow adequate liquid separation.

If alcohol is present in the fuel, the volume of the lower layer, that now contains both alcohol and water, will be more

than 10 ml. For example, if the volume of the lower layer is increased to 15 ml, this indicates at least 5 percent alcohol in

the fuel. The actual amount of alcohol may be somewhat more because this procedure does not extract all of the

alcohol from the fuel. To obtain an accurate determination of the amount of alcohol contamination in a given fuel sample,

then professional analysis should be sought.

Particulate Contaminants in Fuel Testing Procedure

The fuel sample should be drawn from the bottom of the tank so that any contaminants present in the tank will be

detected. The sample should be bright and clear. If the sample appears cloudy or contaminated with water as indicated

by a water layer at the bottom of the sample, use the following procedure to diagnose the fuel.

• Using an approved fuel container, draw approximately 0.5 litre of fuel.

• Place the cylinder on a level surface for approximately 5 minutes to allow settling of the particulate contamination.

Particulate contamination will show up in various shapes and colours. Sand will typically be identified by a white or light

brown crystals. Rubber will appear as black and irregular particles. If particles are found, clean the entire fuel system

thoroughly. Refer to 6C Fuel System – V6.

6.6 Crankshaft Position (CKP) System

Variation Learn Procedure

Description

The crankshaft position system variation learn feature is carried out automatically on the HFV6 engine under decel with

fuel cut. The road speed and duration of the self-learn process varies with different vehicle equipment levels such as

transmission, final drive ratio etc.

The variation learn procedure cannot be over-written, nor can it be accessed with Tech 2.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3439 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–161

Conditions for Clearing the DTC

DTC P0700 – Malfunction Indicator Request from TCM is a Type A DTCs. Refer to 1.4 Diagnostic Trouble Codes in

this Section, for action taken when a Type A DTC sets and conditions for clearing Type A DTCs.

Additional Information

• Refer to 6C1-1 Engine Management – V6 – General Information for details of the ECM operation.

• For an intermittent fault condition, refer to 5.2 Intermittent Fault Conditions in this Section.

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Secion, for the system wiring

diagram and connector charts.

DTC P0700 Diagnostic Table

Step Action Yes No

1 Has the Diagnostic System Check been performed?

Go to Step 2 Refer to

4.4 Diagnostic

System Check in this Section

2 1 Switch off the ignition for 30 seconds.

2 Operate the vehicle within the conditions for running the DTC.

3 Using Tech 2, select the DTC display function.

Does DTC P0700 fail this ignition cycle? Go to Step 3 Refer to Additional

Information in this DTC

3 Are other powertrain DTCs also set?

Go to the

appropriate DTC

Table in this Section Refer to 7C2

Automatic

Transmission –

4L60E – Electrical Diagnosis

When all diagnosis and repairs are completed, check the system for correct operation.

7.41 DTC P0704

DTC Descriptor

This diagnostic procedure supports DTC P0704 – Clutch Switch Input Circuit Malfunction.

Circuit Description

The clutch pedal switch disengages the cruise control when the clutch is depressed, in much the same way that the

brake pedal switch is used to disengage the cruise control feature.

The cruise control cancel switch is normally closed when the clutch pedal is at rest, opening when the pedal is pressed.

Activation of this switch removes the signal to the ECM which will then deactivate the cruise control.

Conditions for Running the DTC

Runs continuously when the ignition is switched and the engine is running.

Conditions for Setting the DTC

The ECM detects 15 gear changes with less than three clutch switch inputs.

NOTE

The ECM determines that a gear change has

been performed by the engine speed / vehicle

speed ratio.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3441 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–163

7 Test the control circuit of the cruise control clutch switch, which failed

for a high resistance, open circuit, short to ground or short to voltage

fault condition. Refer to 8A Electrical - Body and Chassis for

information on electrical fault diagnosis.

W as any fault found and rectified? Go to Step 9 Go to Step 8

8 Replace the ECM. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

W as the repair completed? Go to Step 9 —

9 1 Using Tech 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Does DTC P0704 fail this ignition cycle? Go to Step 2 Go to Step 11

10 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? Go to the

appropriate DTC

Table in this Section System OK

When all diagnosis and repairs are completed, check the system for correct operation.

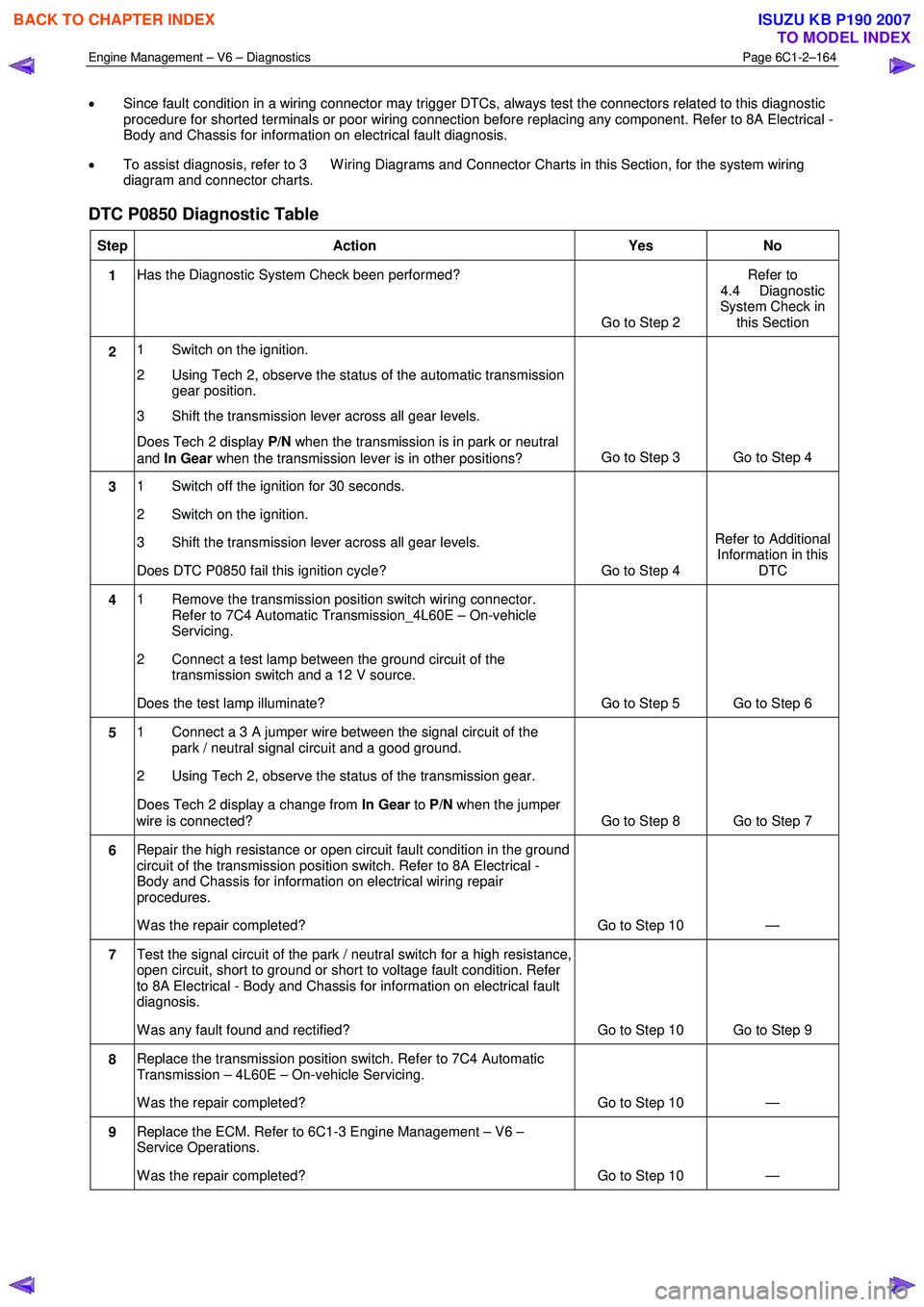

7.42 DTC P0850

DTC Descriptor

This diagnostic procedure supports DTC P0850 – Park / Neutral Signal Circuit Incorrect Signal.

Circuit Description

The Park / Neutral (P / N) switch is a part of the automatic transmission gear selector position switch assembly.

The P / N switch is a normally open switch that closes when the transmission is shifted to Park or Neutral position. The

ECM applies a reference 12 V to the signal circuit of the P / N switch when it is open. W hen the transmission is shifted

to the Park or Neutral position, the P / N switch closes and pulls the P/ N switch signal circuit to ground.

DTC P0850 sets when the ECM detects a fault condition in the P / N switch circuit.

Conditions for Running the DTC

DTC P0850 runs continuously when the ignition voltage is 10.0 – 16.0 V.

Conditions for Setting the DTC

DTC P0850 sets when the ECM detects one of the following fault conditions:

• The P / N switch signal circuit is pulled to ground for 100 seconds while the TCM sends a signal that the

transmission is in gear.

• The P / N switch signal circuit is 12 V for 100 seconds while the TCM sends a signal the transmission is in park or

neutral.

Conditions for Clearing the DTC

DTC P0850 is a Type ‘C’ DTC. Refer to 1.4 Diagnostic Trouble Codes in this Section, for action taken when Type ‘C’

DTCs set and conditions for clearing Type ‘C’ DTCs.

Additional Information

• The ECM uses the transmission range data to enable engine cranking when DTC P0850 sets.

• For an intermittent fault condition, refer to 5.2 Intermittent Fault Conditions in this Section.

• Refer to 6C1-1 Engine Management – V6 – General Information for details of the park / neutral switch operation.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3442 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–164

• Since fault condition in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

DTC P0850 Diagnostic Table

Step Action Yes No

1 Has the Diagnostic System Check been performed?

Go to Step 2 Refer to

4.4 Diagnostic

System Check in this Section

2 1 Switch on the ignition.

2 Using Tech 2, observe the status of the automatic transmission gear position.

3 Shift the transmission lever across all gear levels.

Does Tech 2 display P/N when the transmission is in park or neutral

and In Gear when the transmission lever is in other positions? Go to Step 3 Go to Step 4

3

1 Switch off the ignition for 30 seconds.

2 Switch on the ignition.

3 Shift the transmission lever across all gear levels.

Does DTC P0850 fail this ignition cycle? Go to Step 4 Refer to Additional

Information in this DTC

4 1 Remove the transmission position switch wiring connector.

Refer to 7C4 Automatic Transmission_4L60E – On-vehicle

Servicing.

2 Connect a test lamp between the ground circuit of the transmission switch and a 12 V source.

Does the test lamp illuminate? Go to Step 5 Go to Step 6

5 1 Connect a 3 A jumper wire between the signal circuit of the

park / neutral signal circuit and a good ground.

2 Using Tech 2, observe the status of the transmission gear.

Does Tech 2 display a change from In Gear to P/N when the jumper

wire is connected? Go to Step 8 Go to Step 7

6 Repair the high resistance or open circuit fault condition in the ground

circuit of the transmission position switch. Refer to 8A Electrical -

Body and Chassis for information on electrical wiring repair

procedures.

W as the repair completed? Go to Step 10 —

7 Test the signal circuit of the park / neutral switch for a high resistance,

open circuit, short to ground or short to voltage fault condition. Refer

to 8A Electrical - Body and Chassis for information on electrical fault

diagnosis.

W as any fault found and rectified? Go to Step 10 Go to Step 9

8 Replace the transmission position switch. Refer to 7C4 Automatic

Transmission – 4L60E – On-vehicle Servicing.

W as the repair completed? Go to Step 10 —

9 Replace the ECM. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

W as the repair completed? Go to Step 10 —

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3499 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–221

Step Action Yes No

2 1 Switch off the ignition for 30 seconds.

2 Operate the vehicle within the conditions for running the DTC.

3 Using Tech 2, select the DTC display function.

Does DTC U0101 fail this ignition cycle? Go to Step 3 Refer to Additional

Information in this DTC

3 Using Tech 2, attempt to communicate with the PIM.

Does the PIM failed to communicate? Refer to the 6E1

Powertrain Interface Module – V6 Go to Step 4

4 Are DTCs also set in the PIM? Refer to 6E1

Powertrain Interface Module – V6 Go to Step 5

5 Are DTCs that may trigger a fault condition in the serial data

communication circuit also set in the TCM? Refer to 7C2

Automatic

Transmission –

4L60E – Electrical Diagnosis Go to Step 6

6 Replace the TCM, refer to 7C4 Automatic Transmission – 4L60E –

On-vehicle Servicing.

W as the repair completed? Go to Step 7 —

7 1 Using Tech 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Does any of the serial data communication circuit – TCM DTCs fail

this ignition cycle? Go to Step 2 Go to Step 8

8 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? Go to the

appropriate DTC

Table in this Section System OK

When all diagnosis and repairs are completed, check the system for correct operation.

7.63 DTC U0155 or U0423

DTC Descriptors

This diagnostic procedure supports the following DTCs:

• DTC U0155 – CAN-Bus No Communication W ith Gateway

• DTC U0423 – CAN-Bus Invalid Data From Gateway

Circuit Description

The Engine Control Module (ECM) communicates directly with the control modules connected to the GM LAN serial data

communication circuit through the GM LAN protocol.

However, the immobiliser control unit (ICU) communicates with the ECM using the keyword 2000 protocol. Since the GM

LAN and keyword 2000 protocols are not compatible, a powertrain interface module (PIM) is integrated into the serial

data system to serve as a gateway. This gateway allows communication between the two protocols. Refer to 6E1

Powertrain Interface Module – V6 for further information on the GM LAN serial data communication circuit

A PIM serial data communication circuit DTC sets if the ECM detects an invalid signal from the PIM.

Conditions for Running the DTC

DTCs U0155 and U0423 run continuously when the following conditions are met:

• The engine is running.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3502 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–224

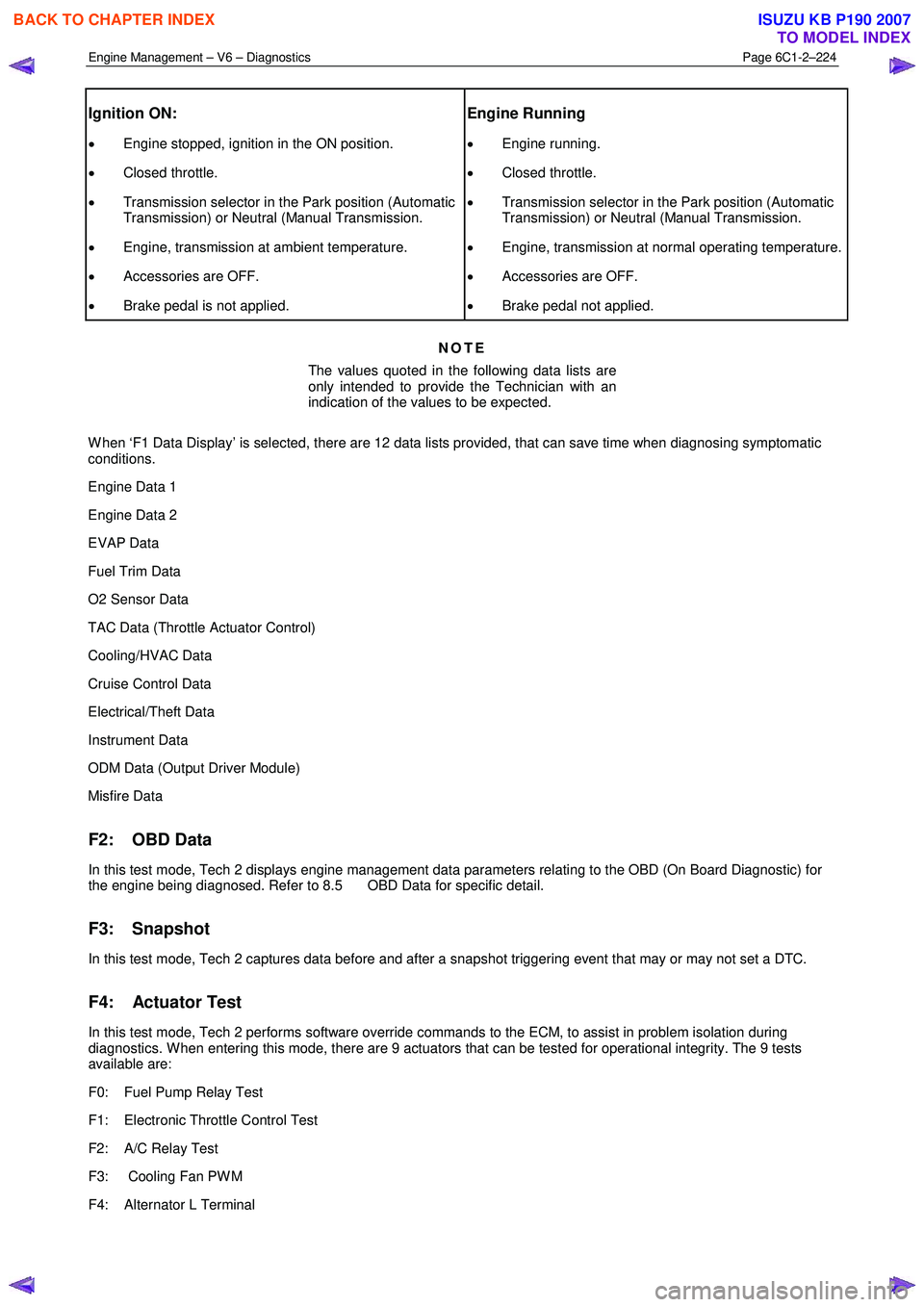

Ignition ON:

• Engine stopped, ignition in the ON position.

• Closed throttle.

• Transmission selector in the Park position (Automatic

Transmission) or Neutral (Manual Transmission.

• Engine, transmission at ambient temperature.

• Accessories are OFF.

• Brake pedal is not applied.

Engine Running

• Engine running.

• Closed throttle.

• Transmission selector in the Park position (Automatic

Transmission) or Neutral (Manual Transmission.

• Engine, transmission at normal operating temperature.

• Accessories are OFF.

• Brake pedal not applied.

NOTE

The values quoted in the following data lists are

only intended to provide the Technician with an

indication of the values to be expected.

W hen ‘F1 Data Display’ is selected, there are 12 data lists provided, that can save time when diagnosing symptomatic

conditions.

Engine Data 1

Engine Data 2

EVAP Data

Fuel Trim Data

O2 Sensor Data

TAC Data (Throttle Actuator Control)

Cooling/HVAC Data

Cruise Control Data

Electrical/Theft Data

Instrument Data

ODM Data (Output Driver Module)

Misfire Data

F2: OBD Data

In this test mode, Tech 2 displays engine management data parameters relating to the OBD (On Board Diagnostic) for

the engine being diagnosed. Refer to 8.5 OBD Data for specific detail.

F3: Snapshot

In this test mode, Tech 2 captures data before and after a snapshot triggering event that may or may not set a DTC.

F4: Actuator Test

In this test mode, Tech 2 performs software override commands to the ECM, to assist in problem isolation during

diagnostics. W hen entering this mode, there are 9 actuators that can be tested for operational integrity. The 9 tests

available are:

F0: Fuel Pump Relay Test

F1: Electronic Throttle Control Test

F2: A/C Relay Test

F3: Cooling Fan PW M

F4: Alternator L Terminal

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3505 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–227

Knock Retard Cylinder 3 °CA 0 0

Knock Retard Cylinder 4 °CA 0 0

Knock Retard Cylinder 5 °CA 0 0

Knock Retard Cylinder 6 °CA 0 0

Ignition Accessory Signal Off / On On On

Ignition On Signal Off / On On On

Malfunction Indicator (MI) Off / On / Flashing On Off

Fuel Pump Relay Off / On Off On

Engine Control Ignition Relay Off / On On On

Engine Control Ignition Relay Feedback V 11.5 14.1

(1) Actual Gear -1- / -2- / -3- / -4- / -

5- / -P/N- / -R- / -Invalid- -P/N- -P/N-

Brake Lamp Switch

Inactive / Active Inactive Inactive

Reduced Engine Power Inactive / Active Inactive Inactive

DTC Set This Ignition No DTC / DTC Set No DTC No DTC

Vehicle Speed km/h 0 0

Engine Runtime h:m:s 00:00:00 00:05:20

(2) Clutch Pedal Switch Inactive / Active Inactive Inactive

(1) Automatic Transmission Only (2) Manual Transmission Only

Engine Data 2

Tech 2 Display

Units Displayed Ignition On Engine Running

Engine Speed RPM 0 751

Desired Engine Idle Speed RPM 830 750

Coolant Temperature °C 21 78

Cooling Fan On/Off Off On

Calculated ECT – Closed Loop Fuel Control (Engine

Coolant Temperature) °C 21 37

Calculated ECT – Thermostat Diagnosis (Engine

Coolant Temperature) °C 22 78

Intake Air Temperature

°C 31 27

Start Up ECT (Engine Coolant Temperature) °C 21 21

Start Up IAT (Intake Air Temperature) °C –48 30

Mass Air Flow Sensor V 1.00 1.3

Mass Air Flow g/s 0.00 5.47

Engine Load % 100 25

Volumetric Efficiency % 99 19

Power Enrichment No / Yes No No

Dec. Fuel Cutoff (Deceleration) Inactive / Active Inactive Inactive

Calculated Pedal Position % 0 0

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3506 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–228

Desired Throttle Position % 4 3

Calculated Throttle Position % 6 3

Barometric Pressure kPa 100 100

Barometric Pressure V 4.78 4.80

Loop Status B1S1 (Bank 1 Sensor 1) Open / Closed Open Closed

Loop Status B2S1 (Bank 2 Sensor 1) Open / Closed Open Closed

B1 Short Term Fuel Trim (Bank 1) % 0 –3

B1 LTFT Idle/Deceleration (Bank 1 Long Term Fuel

Trim) % 0 0

B1 LTFT Cruise/Acceleration (Bank 1 Long Term Fuel

Trim) % 0 0

B2 Short Term Fuel Trim (Bank 2)

% 0 –1

B2 LTFT Idle/Deceleration (Bank 2 Long Term Fuel

Trim) % 0 0

B2 LTFT Cruise/Acceleration (Bank 2 Long Term Fuel

Trim) % 0 0

Injection Time Cylinder 1

ms 0.0 2.5

Injection Time Cylinder 2 ms 0.0 2.5

Injection Time Cylinder 3 ms 0.0 2.5

Injection Time Cylinder 4 ms 0.0 2.5

Injection Time Cylinder 5 ms 0.0 2.5

Injection Time Cylinder 6 ms 0.0 2.5

Spark Advance °CA 0 12

Ignition Accessory Signal Off / On On On

Ignition On Signal Off / On On On

(1) Transmission Gear P-N / In Gear P-N P-N

(1) Actual Gear -1- / -2- / -3- / -4- / -

5- / -P/N- / -R- / -Invalid- -P/N- -P/N-

Fuel Pump Relay

Off / On Off On

A/C Relay (Air Conditioning) Off / On Off Off

(1) Transmission Gear Selector Signal Valid / Invalid Valid

Valid

Distance Since DTC Cleared km 0 0

Reduced Engine Power Inactive / Active Inactive Inactive

Vehicle Speed km/h 0 0

Engine Runtime h:m:s 00:00:00 00:09:20

(1) Automatic Transmission Only (2) Manual Transmission Only

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007