transmission fluid ISUZU KB P190 2007 Workshop Manual PDF

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3886 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–100

Step Action Yes No

15 Using a multimeter, test between E-95 pin 10 and C-107 pin 9 for an

open circuit.

Did you find and correct the condition? Go to Step 19 —

16 Using a multimeter, test between E-95 pin 3 and C-96 pin 20 for a

short to ground.

Did you find and correct the condition? Go to Step 19 Go to Step 20

17 Using a multimeter, test between E-95 pin 3 and C-96 pin 20 for an

open circuit.

Did you find and correct the condition? Go to Step 19 Go to Step 20

18 Replace the TCM, refer to 7C4 Automatic Transmission – 4L60E –

On-vehicle Servicing.

Did you complete the replacement? Go to Step 19 —

19 Perform the following procedure to verify the repair:

1 On Tech 2 select: Diagnostic Trouble Codes / Clear Engine & Transmission

DTCs.

2 Follow the instructions on Tech 2 and clear any DTCs.

3 On Tech 2 select: Data Display / 2-3 Shift Data.

4 Drive the vehicle in D4 and ensure the following conditions are met::

• The TCM commands the Shift Solenoid B On and the

Shift Solenoid A Circuit status parameter displays Okay.

• The TCM commands the Shift Solenoid B Off and the

Shift Solenoid A Circuit status parameter displays Okay.

• All conditions are met for 5 seconds.

5 On Tech 2 select:

Diagnostic Trouble Codes / Read DTC Information.

Has DTC P0976 set? Go to Step 2 Go to Step 20

20 On Tech 2 select:

Diagnostic Trouble Codes / Read DTC Information.

Does Tech 2 display any DTCs you have not diagnosed? Refer to

4.8 Diagnostic Trouble Code List System OK

When all diagnosis and repairs are completed, check the

system for correct operation.

4.31 DTC P0977 – 2-3 Shift Solenoid Control

Circuit High Voltage

DTC Description

This diagnostic procedure supports DTC P0977 2-3 Shift Solenoid (SS) Control Circuit High Voltage.

Circuit Description

The 2-3 shift solenoid (SS) valve controls the fluid flow acting on the 2-3 shift valves. The solenoid is a normally-open

exhaust valve. W ith the 1-2 SS valve, the 2-3 SS valve allows four different shifting combinations. The solenoid attaches

to the control valve body within the transmission. The 2-3 SS valve receives voltage through the ignition voltage circuit.

The transmission control module (TCM) controls the solenoid by providing the ground path on the 2-3 SS valve control

circuit.

When the TCM detects a continuous short to voltage in the 2-3 shift solenoid valve control circuit, then DTC P0977 sets.

DTC P0977 is a type A DTC.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3889 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–103

Step Action Yes No

6 Using a multimeter, test between E-95 pin 3 and C-96 pin 30 for a

short to voltage.

Did you find and correct the condition? Go to Step 8 Go to Step 7

7 Replace the TCM, refer to 7C4 Automatic Transmission – 4L60E –

On-vehicle Servicing

Did you complete the replacement? Go to Step 8 —

8 Perform the following procedure to verify the repair:

1 On Tech 2 select: Diagnostic Trouble Codes / Clear Engine & Transmission

DTCs.

2 Follow the instructions on Tech 2 and clear any DTCs.

3 On Tech 2 select: Data Display / 2-3 Shift Data.

4 Drive the vehicle in D4 and ensure the following conditions are met::

• The TCM commands the Shift Solenoid B On and the

Shift Solenoid B Circuit status parameter displays Okay.

• The TCM commands the Shift Solenoid B Off and the

Shift Solenoid B Circuit status parameter displays Okay.

• All conditions are met for 5 seconds.

4 On Tech 2 select:

Diagnostic Trouble Codes / Read DTC Information.

Has DTC P0977 set? Go to Step 2 Go to Step 9

9 On Tech 2 select:

Diagnostic Trouble Codes / Read DTC Information.

Does Tech 2 display any DTCs you have not diagnosed? Refer to

4.8 Diagnostic Trouble Code List System OK

When all diagnosis and repairs are completed, check the

system for correct operation.

4.32 DTC P1810, P1815 and P1816 –

Transmission Fluid Pressure Position

Switch

DTC Description

This diagnostic procedure supports the following DTCs:

• DTC P1810 Transmission Fluid Pressure (TFP) Position Switch Circuit.

• DTC P1815 Transmission Fluid Pressure (TFP) Valve Position Switch – Start in W rong Range.

• DTC P1816 Transmission Fluid Pressure (TFP) Valve Position Switch Indicates Park/Neutral (P/N) with Drive Ratio.

Circuit Description

The automatic transmission fluid pressure (TFP) manual valve position switch consists of five pressure switches

(two normally-closed and three normally-open) and a transmission fluid temperature (TFT) sensor combined into one unit.

The combined unit mounts on the valve body. The transmission control module (TCM) supplies ignition voltage for each

range signal. By grounding one or more of these circuits through various combinations of the pressure switches, the

TCM detects which manual valve position you select. The TCM compares the actual voltage combination of the switches

to a TFP manual valve position switch combination chart stored in memory.

The TFP manual valve position switch cannot distinguish between park and neutral because the monitored valve body

pressures are identical. W ith the engine off and the ignition switch on, the TFP manual valve position switch indicates

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3891 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–105

• The TCM commands 4th gear.

• At the time of the first failure, the TCM records the operating conditions when the conditions for setting the DTC are

met. The TCM stores this information as a Failure Record.

• At the time of the second failure, the ECM records the operating conditions when the conditions for setting the DTC

are met. The ECM stores this information as a Freeze Frame.

• The TCM stores the DTC in TCM history during the second consecutive trip in which the conditions for setting the

DTC are met.

Conditions for Clearing the DTC

• The ECM turns off the MIL after the fourth consecutive drive trip in which the TCM does not send a MIL illumination

request.

• Tech 2 can clear the DTC.

• The TCM clears the DTC from TCM history if the vehicle completes 40 warm-up cycles without a non-emission

related diagnostic fault occurring.

• The TCM cancels the DTC default actions when the ignition is off long enough to power down the TCM.

Diagnostic Aids

• Refer to the 5.3 Transmission Fluid Pressure Manual Valve Position Switch Logic for the normal range signals

and the invalid combinations. On the table, LOW is 0 V, HI is ignition voltage.

• Sediment in the valve body may cause improper operation of the TFP manual valve position switch. If the presence

of sediment is suspected, clean the valve body and replace the TFP manual valve position switch.

Test Description

The following numbers refer to the step numbers in the diagnostic table:

3 Checks the indicated range signal to the selected manual valve position.

4-5 Checks for correct voltage from the TCM to the transmission inline 20-way connector.

6 Checks if there is a short between any of the signal circuits.

DTC P1810, P1815 and P1816 Diagnostic Table

Step Action Yes No

1 Has the Diagnostic System Check been performed?

Go to Step 2 Refer to

4.7 Diagnostic System Check

2 Inspect for correct transmission fluid level, refer to 7C4 Automatic

Transmission – 4L60E – On-vehicle Servicing.

Did you perform the fluid checking procedure? Go to Step 3 Refer to

7C4 Automatic

Transmission –

4L60E – On-vehicle Servicing

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3894 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–108

Step Action Yes No

13 On Tech 2 select:

Diagnostic Trouble Codes / Read DTC Information.

Does Tech 2 display any DTCs you have not diagnosed? Refer to

4.8 Diagnostic Trouble Code List System OK

When all diagnosis and repairs are completed, check the system for correct operation.

4.33 DTC P2763 – Torque Converter Clutch

Pressure Control Solenoid Control

Circuit High Voltage

DTC Description

This diagnostic procedure supports DTC P2763 Torque Converter Clutch (TCC) Pressure Control (PC) Solenoid Control

Circuit High Voltage.

Circuit Description

The torque converter clutch pulse width modulation (TCC PW M) solenoid valve controls the fluid acting on the converter

clutch valve. The converter clutch valve controls the TCC application and release. The solenoid attaches to the control

valve body within the transmission. The solenoid receives voltage through ignition voltage circuit. The transmission

control module (TCM) controls the solenoid by providing a ground path on the TCC PW M solenoid valve control circuit.

Current flows through the solenoid coil according to the duty cycle, percentage of on and off time. The TCC PWM

solenoid valve provides a smooth engagement of the TCC by operating during a duty cycle percent of on time.

When the TCM detects a continuous short to voltage in the TCC PW M solenoid valve control circuit, then DTC P2763

sets. DTC P2763 is a type A DTC.

Refer to 2 W iring Diagrams and Connector Chart to aid in diagnosis.

Conditions for Running the DTC

• The system voltage is 8 – 18 V.

• The engine speed is 500 r.p.m. for 5 seconds.

Conditions for Setting the DTC

DTC P2763 sets if the TCM commands the solenoid on and the voltage feedback remains high, battery voltage.

Action Taken When the DTC Sets

• The TCM requests the ECM to illuminate the MIL during the second consecutive trip in which the conditions for

setting the DTC are met.

• The TCM commands maximum line pressure.

• The TCM freezes transmission adaptive functions.

• The TCM inhibits TCC engagement.

• The TCM inhibits 4th gear if in hot mode.

• At the time of the first failure, the TCM records the operating conditions when the conditions for setting the DTC are

met. The TCM stores this information as a Failure Record.

• At the time of the second failure, the ECM records the operating conditions when the conditions for setting the DTC

are met. The ECM stores this information as a Freeze Frame.

• The TCM stores DTC P2763 in TCM history during the second consecutive trip in which the conditions for setting

the DTC are met.

Conditions for Clearing the DTC

• The ECM turns off the MIL after the fourth consecutive drive trip in which the TCM does not send a MIL illumination

request.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3897 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–111

4.34 DTC P2764 – Torque Converter Clutch

Pressure Control Solenoid Control

Circuit Low Voltage

DTC Description

This diagnostic procedure supports DTC P2764 Torque Converter Clutch (TCC) Pressure Control (PC) Solenoid Control

Circuit Low Voltage.

Circuit Description

The torque converter clutch pulse width modulation (TCC PW M) solenoid valve controls the fluid acting on the converter

clutch valve. The converter clutch valve controls the TCC application and release. The solenoid attaches to the control

valve body within the transmission. The solenoid receives voltage through ignition voltage circuit. The transmission

control module (TCM) controls the solenoid by providing a ground path on the TCC PW M solenoid valve control circuit.

Current flows through the solenoid coil according to the duty cycle, percentage of on and off time. The TCC PWM

solenoid valve provides a smooth engagement of the TCC by operating during a duty cycle percent of on time.

W hen the TCM detects a continuous open or short to ground in the TCC PW M solenoid valve control circuit, then

DTC P2764 sets. DTC P2764 is a type A DTC.

Refer to 2 W iring Diagrams and Connector Chart to aid in diagnosis.

Conditions for Running the DTC

• The system voltage is 8 – 18 V.

• The engine speed is 500 r.p.m. for 5 seconds.

Conditions for Setting the DTC

DTC P2764 sets when either of the following conditions occurs for 5 seconds:

• The TCM detects an open in the TCC PWM shift solenoid valve circuit when the TCC PW M is commanded on.

• The TCM detects a short to ground in the TCC PWM shift solenoid valve circuit when the TCC PWM is

commanded on.

Action Taken When the DTC Sets

• The TCM requests the ECM to illuminate the MIL during the second consecutive trip in which the Conditions for

Setting the DTC are met.

• The TCM commands maximum line pressure.

• The TCM freezes transmission adaptive functions.

• The TCM inhibits TCC engagement.

• The TCM inhibits 4th gear if in hot mode.

• At the time of the first failure, the TCM records the operating conditions when the conditions for setting the DTC are

met. The TCM stores this information as a Failure Record.

• At the time of the second failure, the ECM records the operating conditions when the conditions for setting the DTC

are met. The ECM stores this information as a Freeze Frame.

• The TCM stores DTC P2764 in TCM history during the second consecutive trip in which the conditions for setting

the DTC are met.

Conditions for Clearing the DTC

• The ECM turns off the MIL after the fourth consecutive drive trip in which the TCM does not send a MIL illumination

request.

• Tech 2 can clear the DTC.

• The TCM clears the DTC from TCM history if the vehicle completes 40 warm-up cycles without a non-emission

related diagnostic fault occurring.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3910 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–124

5 Electrical Specifications

5.1 Transmission Fluid Temperature (TFT)

Sensor Specifications

Temperature Minimum Resistance Normal Resistance Maximum Resistance Signal

°C Ω Ω Ω Volts

-40 90636 100707 110778 5.00

-30 47416 52684 57952 4.78

-20 25809 28677 31545 4.34

-10 14558 16176 17794 3.89

0 8481 9423 10365 3.45

10 5104 5671 6238 3.01

20 3164 3515 3867 2.56

30 2013 2237 2461 1.80

40 1313 1459 1605 1.10

50 876 973 1070 3.25

60 600 667 734 2.88

70 420 467 514 2.56

80 299 332 365 2.24

90 217 241 265 1.70

100 159 177 195 1.42

110 119 132 145 1.15

120 89.9 99.9 109.9 0.87

130 69.1 76.8 84.5 0.60

140 53.8 59.8 65.8 0.32

150 42.5 47.2 51.9 0.00

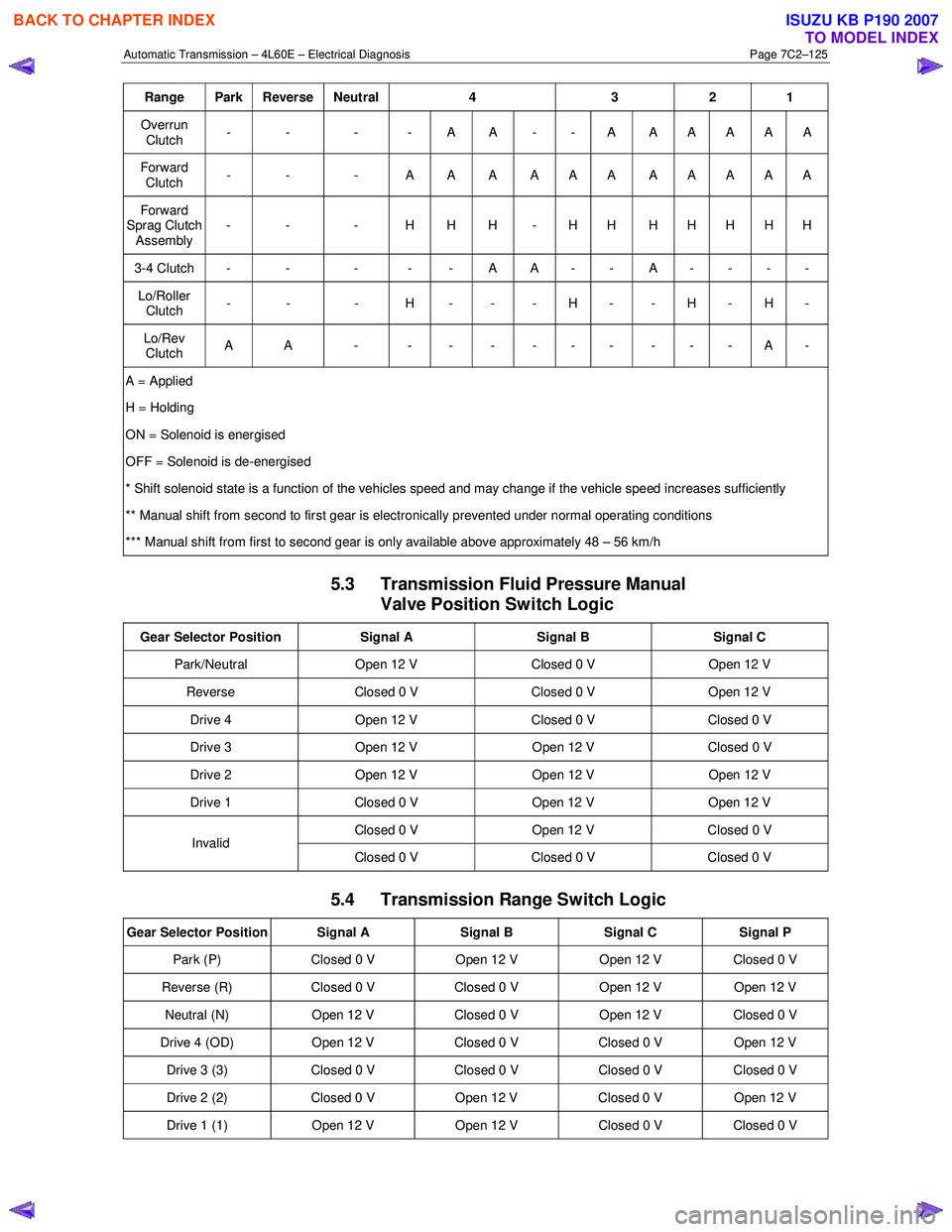

5.2 Range Reference

Range Park Reverse Neutral 4 3 2 1

Gear 1st 2nd3rd4th1st2nd3rd1st ** 2nd 1st2nd ***

Shift

Solenoid A (1-2 Shift

Solenoid) ON* ON* ON* ON OFF OFF ON ON OFF OFF ON OFF ON OFF

Shift

Solenoid B (2-3 Shift

Solenoid) ON* ON* ON* ON ON OFF OFF ON ON OFF ON ON ON ON

2-4 Band - - - - A - A - A - - A - A

Reverse

Input Clutch - A - - - - - - - - - - - -

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3911 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–125

Range Park Reverse Neutral 4 3 2 1

Overrun

Clutch - - - - A A - - A A A A A A

Forward

Clutch - - - A A A A A A A A A A A

Forward

Sprag Clutch Assembly - - - H H H - H H H H H H H

3-4 Clutch - - - - - A A - - A - - - -

Lo/Roller

Clutch - - - H - - - H - - H - H -

Lo/Rev

Clutch A A - - - - - - - - - - A -

A = Applied

H = Holding

ON = Solenoid is energised

OFF = Solenoid is de-energised

* Shift solenoid state is a function of the vehicles speed and may change if the vehicle speed increases sufficiently

** Manual shift from second to first gear is electronically prevented under normal operating conditions

*** Manual shift from first to second gear is only available above approximately 48 – 56 km/h

5.3 Transmission Fluid Pressure Manual Valve Position Switch Logic

Gear Selector Position Signal A Signal B Signal C

Park/Neutral Open 12 V Closed 0 V Open 12 V

Reverse Closed 0 V Closed 0 V Open 12 V

Drive 4 Open 12 V Closed 0 V Closed 0 V

Drive 3 Open 12 V Open 12 V Closed 0 V

Drive 2 Open 12 V Open 12 V Open 12 V

Drive 1 Closed 0 V Open 12 V Open 12 V

Closed 0 V Open 12 V Closed 0 V Invalid

Closed 0 V Closed 0 V Closed 0 V

5.4 Transmission Range Switch Logic

Gear Selector Position Signal A Signal B Signal C Signal P

Park (P) Closed 0 V Open 12 V Open 12 V Closed 0 V

Reverse (R) Closed 0 V Closed 0 V Open 12 V Open 12 V

Neutral (N) Open 12 V Closed 0 V Open 12 V Closed 0 V

Drive 4 (OD) Open 12 V Closed 0 V Closed 0 V Open 12 V

Drive 3 (3) Closed 0 V Closed 0 V Closed 0 V Closed 0 V

Drive 2 (2) Closed 0 V Open 12 V Closed 0 V Open 12 V

Drive 1 (1) Open 12 V Open 12 V Closed 0 V Closed 0 V

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3912 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–126

5.5 Component Resistance

Component Pass/Thru Pins Resistance at 20°C Resistance at 100°C Resistance to Ground

(Case)

Shift Solenoid A (1-2

Shift Solenoid Valve) A, E 19 – 24

Ω 24 – 31 Ω Greater than 250 k Ω

Shift Solenoid B (2-3

Shift Solenoid Valve) B, E 19 – 24

Ω 24 – 31 Ω Greater than 250 k Ω

TCC Solenoid Valve T, E 21 – 26 Ω 26 – 33 Ω Greater than 250 k Ω

TCC PWM Solenoid

Valve U, E

10 – 11 Ω 13 – 15 Ω Greater than 250 k Ω

3-2 Shift Solenoid

Valve S, E 20 – 24

Ω 29 – 32 Ω Greater than 250 k Ω

Pressure Control

Solenoid Valve C, D

3 – 5 Ω 4 – 7 Ω Greater than 250 k Ω

*Transmission Fluid

Temperature (TFT) Sensor M, L

3088 – 3942 Ω 159.3 – 198.0 Ω Greater than 10 M Ω

Vehicle Speed Sensor A, B 1420Ω @ 25°C 2140 Ω @ 150°C Greater than 10 M Ω

*: The resistance of this device is necessarily temperature dependent and will therefore vary far more than any other

device. Refer to 5.1 Transmission Fluid Temperature (TFT) Sensor Specifications .

5.6 Shift Solenoid Valve State and Gear

Ratio

Gear 1-2 Shift Solenoid 2-3 Shift Solenoid Gear Ratio

1 ON ON 3.059:1

2 OFF ON 1.625:1

3 OFF OFF 1.000:1

4 ON OFF 0.696:1

5.7 Line Pressure

Pressure Control Solenoid Current (Amp) Approximate Line Pressure (PSI)

0.00 198 – 227

0.10 197 – 226

0.20 189 – 221

0.30 181 – 216

0.40 168 – 205

0.50 154 – 193

0.60 137 – 175

0.70 114 – 156

0.80 90 – 132

0.90 64 – 105

1.00 53 – 85

1.10 53 – 68

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3914 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–1

7C4

Automatic Transmission – 4L60E –

On-vehicle Servicing

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to General Information Warnings, Cautions and Notes for correct workshop practices with regard to safety and/or property damage.

1 General Information ............................................................................................................ ...................3

1.1 General Service Information ................................................................................................................................. 3

Description ............................................................................................................................................................. 3

Service Information ............................................................................................................ ................................... 3

1.2 WARNINGS, CAUTIONS and NOTES................................................................................................... ................. 3

Definition of WARNING, CAUTION and NOTE Statements ............................................................................. .... 3

WARNING Defined............................................................................................................................................. 4

CAUTION Defined .............................................................................................................................................. 4

NOTE Defined .................................................................................................................................................... 4

2 Maintenance Operations......................................................................................................... ...............5

2.1 Transmission Fluid ................................................................................................................................................ 5

Transmission Fluid Colour...................................................................................................... .............................. 5

Transmission Fluid Level ...................................................................................................................................... 5

2.2 Reverse Flush and Flow Rate Test ............................................................................................... ........................ 6

Reverse Flush ........................................................................................................................................................ 6

Flow Rate Test........................................................................................................................................................ 7

3 Service Operations ............................................................................................................. ....................8

3.1 Fluid Change and Filter Replacement ............................................................................................ ...................... 8

Remove ................................................................................................................................................................... 8

Reinstall .................................................................................................................................................................. 9

3.2 Shift Selector Assembly ...................................................................................................................................... 11

Remove ................................................................................................................................................................. 11

Reinstall ................................................................................................................................................................ 12

3.3 Selector Cable Assembly .................................................................................................................................... 14

Remove ................................................................................................................................................................. 15

Reinstall ................................................................................................................................................................ 15

3.4 Neutral Start and Back-up Lamp Switch ............................................................................................................ 16

Remove ................................................................................................................................................................. 16

Reinstall ................................................................................................................................................................ 17

Adjust .................................................................................................................................................................... 17

3.5 Vehicle Speed Sensor ......................................................................................................................................... 18

Remove ................................................................................................................................................................. 18

Reinstall ................................................................................................................................................................ 19

3.6 Manual Shaft Oil Seal .......................................................................................................................................... 19

Replace ................................................................................................................................................................. 19

3.7 Transmission Support and Mount ................................................................................................. ..................... 20

Remove ................................................................................................................................................................. 20

Reinstall ................................................................................................................................................................ 21

3.8 Extension Housing Oil Seal, RWD ...................................................................................................................... 22

Replace ................................................................................................................................................................. 22

3.9 Extension Housing and Rear Bush, RWD ........................................................................................... ............... 22

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3916 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–3

1 General Information

This Section describes the removal and reinstallation procedures of the four speed 4L60E hydra-matic automatic

transmission as well as the service operations which can be performed with the transmission still fitted to the vehicle.

1.1 General Service Information

Description

The shift selector mechanism is linked to the transmission manual shaft with a selector cable. A heat protector is fitted

over the neutral start and back-up switch and manual shaft select lever.

For rear wheel drive (RWD) vehicles an extension housing is fitted to the rear of the transmission case.

Four wheel drive (4W D) vehicles have an adaptor housing and transfer case fitted to the rear of the transmission case,

for description and service operation refer to 7D Transfer Case and Adaptor Housing.

The four speed 4L60E hydra-matic automatic transmission is fitted with a filler tube, a breather hose and a vent pipe for

hot fluid overflow.

The transmission fluid is driven through a cooler within the radiator via the cooler line/hose assemblies to maintain

normal operating temperature.

Service Information

Throughout the service operations within this

Section, when handling retaining clips, using

compressed air or cleaning fluids, wear safety

equipment to avoid personal injury.

Refer to 7C1 Automatic Transmission – 4L60E – General Information for the following:

• information relating to mechanical and electrical operations,

• abbreviations, transmission specifications, special tools and torque wrench specifications,

• servicing, cleaning and inspection procedure recommendations.

It is essential to read and understand the General Information, W arnings, Cautions and Service Notes contained in that

same Section, before any service operation is performed on the four speed 4L60E hydra-matic automatic transmission or

any associated components.

Failure to comply with the procedures and service notes can affect the reliable and efficient operation of this automatic

transmission.

1.2 WARNINGS, CAUTIONS and NOTES

This Section contains various W ARNINGS, CAUTIONS and NOTE statements that you must observe carefully to reduce

the risk of death or injury during service, repair procedures or vehicle operation. Incorrect service or repair procedures

may damage the vehicle or cause operational faults. W ARNINGS, CAUTION and NOTE statements are not exhaustive.

GM HOLDEN LTD can not possibly warn of all the potentially hazardous consequences of failure to follow these

instructions.

Definition of WARNING, CAUTION and NOTE Statements

Diagnosis and repair procedures in this Section contain both general and specific W ARNING, CAUTION and NOTE

statements. GM HOLDEN LTD is dedicated to the presentation of service information that helps the technician to

diagnose and repair the systems necessary for proper operation of the vehicle. Certain procedures may present a hazard

to the technician if they are not followed in the recommended manner. W ARNING, CAUTION and NOTE statements are

designed to help prevent these hazards from occurring, but not all hazards can be foreseen.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007