engine coolant ISUZU KB P190 2007 Workshop Manual Online

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1314 of 6020

6E-280 Engine Control System (4JH1)

EGR Solenid Valve Replacement

Removal Procedure 1. Disconenct the negative battery cable.

2. Disconnect a EGR solenoid valve harness connector.

3. Disconnect two hoses from the EGR solenoid valve.

4. Loosen two bolts and remove the EGR solenoid valve from the bracket.

Installation Procedure

1. Tighten the purge solenoid by tow bolts.

2. Connect a connector to the EGR solenoid valve.

3. Connect two hoses to the EGR solenoid valve.

4. Connect the negative battery cable.

Engine Coolant Temperature (ECT) Sensor

Replacement

1. Removal Procedure

2. Disconnect the negative battery cable.

3. Drain enough engine coolant so that the coolant level will be below the ECT sensor.

4. Disconnect connector from the ECT sensor.

5. Loosen and remove the ECT sensor from the thermostat housing.

Notice: Cool down the engine before above procedures

are carried out.

Installation Procedure

1.

Apply sealer to threads of screw at the ECT

sensor.

2. Tighten the ECT sensor with specified tightening torque.

Tightening Torque • Bolt: 13 N.m (1.3 kgf.m)

3. Connect a ECT sensor connector to the ECT sensor.

4. Fill the engine coolant.

5. Connect the negative battery cable.

Notice: Verify no engine coolant leaking from the

sensor threads after replacement.

Mass Air Flow (MAF) / Intake Air

Temperature (IAT) Sensor Replacement

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect a MAF & IAT sensor connector from the MAF & IAT sensor assembly.

3. Loosen the clips and remove the MAF & IAT sensor assembly from the intake duct housing.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1319 of 6020

Engine Control System (4JH1) 6E-285

Crankshaft Position (CKP) Sensor

RTW 06ESH000101

RTW 66ESH001401

Legend

1. Crankshaft Position (CKP) Sensor

2. Flywheel

3. Slit

The crankshaft position (CKP) sensor is located on top

of the flywheel housing. There are 4 slits spaced 90 °

on the flywheel circumference. The CKP sensor is a

magnetic coil type sensor , which generates an AC

signal voltage based on the crankshaft rotational speed.

The ECM monitors both the CKP sensor and injection

pump camshaft position (CMP) sensor signals to

ensure they correlate with each other.

The following waveform aids to diagnose when there is

an oscilloscope or equivalent.

Engine Coolant Temperature (ECT) Sensor

- Amplitudes of CKP sensor signal (CH1) increase as engine speed increases.

- Each waveform cycle shorten as the engine speed increases.

Terminal: 90 (CH1), 91 (CH2) (+) / GND (-)

Scale: 10V/div 2ms/div

Condition: Approximately 1000RPM

CH1

0V

CH2 0V

RTW 66ESH001501

Legend

1. Engine Coolant Temperature (ECT) Sensor

The engine coolant temperature (ECT) sensor is

installed to the thermostat housing. The ECT sensor is

a variable resistor. The ECT sensor measures the

temperature of the engine coolant. The engine control

module (ECM) supplies 5 volts to the ECT signal circuit

and a ground for the ECT low reference circuit. W hen

the ECT sensor is cold, the sensor resistance is high.

W hen the engine coolant temperature increases, the

sensor resistance decreases. W ith high senso

r

resistance, the ECM detects a high voltage on the ECT

signal circuit. W ith lower sensor resistance, the ECM

detects a lower voltage on the ECT signal circuit.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1320 of 6020

6E-286 Engine Control System (4JH1)

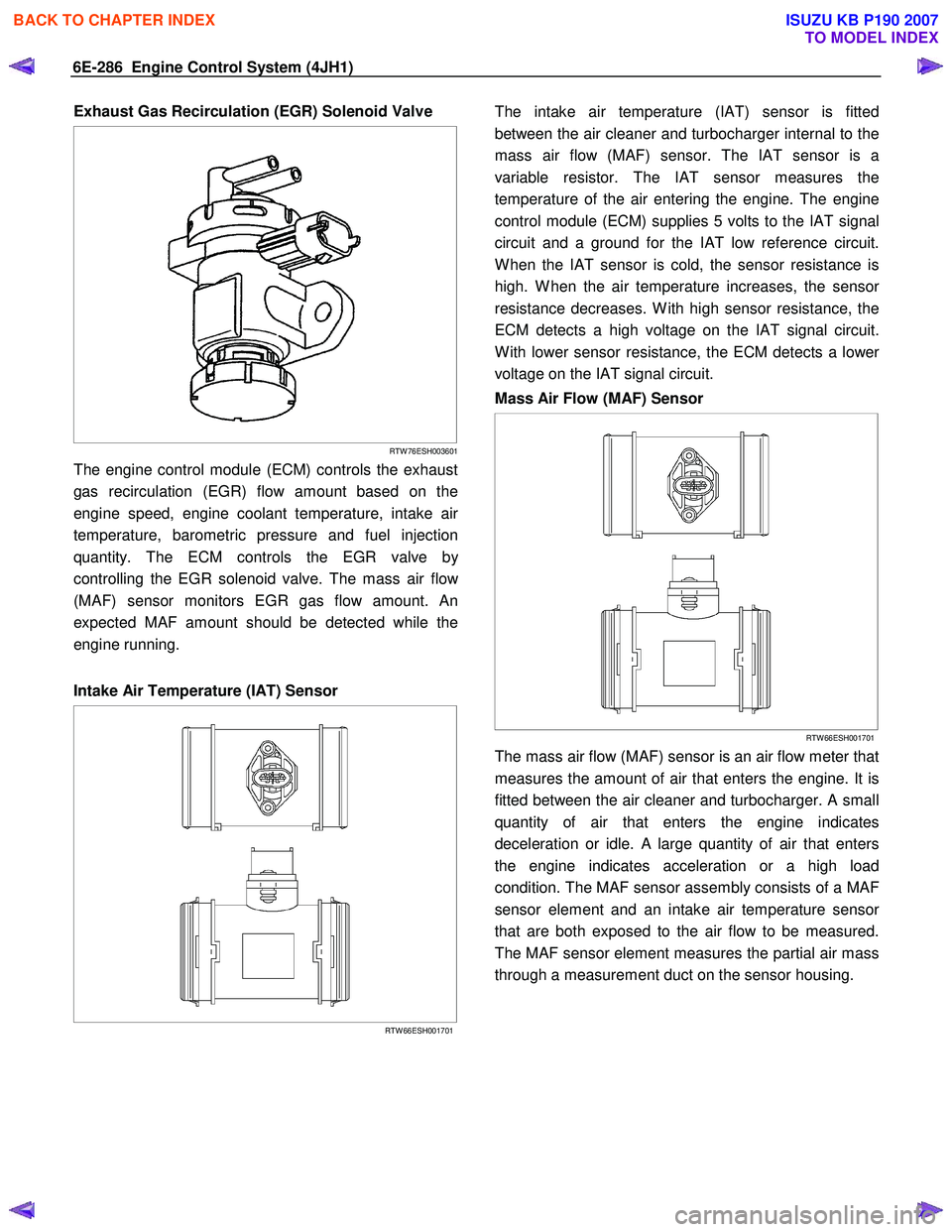

Exhaust Gas Recirculation (EGR) Solenoid Valve

RTW 76ESH003601

The engine control module (ECM) controls the exhaust

gas recirculation (EGR) flow amount based on the

engine speed, engine coolant temperature, intake ai

r

temperature, barometric pressure and fuel injection

quantity. The ECM controls the EGR valve b

y

controlling the EGR solenoid valve. The mass air flo

w

(MAF) sensor monitors EGR gas flow amount. An

expected MAF amount should be detected while the

engine running.

Intake Air Temperature (IAT) Sensor

RTW 66ESH001701

The intake air temperature (IAT) sensor is fitted

between the air cleaner and turbocharger internal to the

mass air flow (MAF) sensor. The IAT sensor is a

variable resistor. The IAT sensor measures the

temperature of the air entering the engine. The engine

control module (ECM) supplies 5 volts to the IAT signal

circuit and a ground for the IAT low reference circuit.

W hen the IAT sensor is cold, the sensor resistance is

high. W hen the air temperature increases, the senso

r

resistance decreases. W ith high sensor resistance, the

ECM detects a high voltage on the IAT signal circuit.

W ith lower sensor resistance, the ECM detects a lowe

r

voltage on the IAT signal circuit.

Mass Air Flow (MAF) Sensor

RTW 66ESH001701

The mass air flow (MAF) sensor is an air flow meter that

measures the amount of air that enters the engine. It is

fitted between the air cleaner and turbocharger. A small

quantity of air that enters the engine indicates

deceleration or idle. A large quantity of air that enters

the engine indicates acceleration or a high load

condition. The MAF sensor assembly consists of a MAF

sensor element and an intake air temperature senso

r

that are both exposed to the air flow to be measured.

The MAF sensor element measures the partial air mass

through a measurement duct on the sensor housing.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1328 of 6020

6E-294 Engine Control System (4JH1)

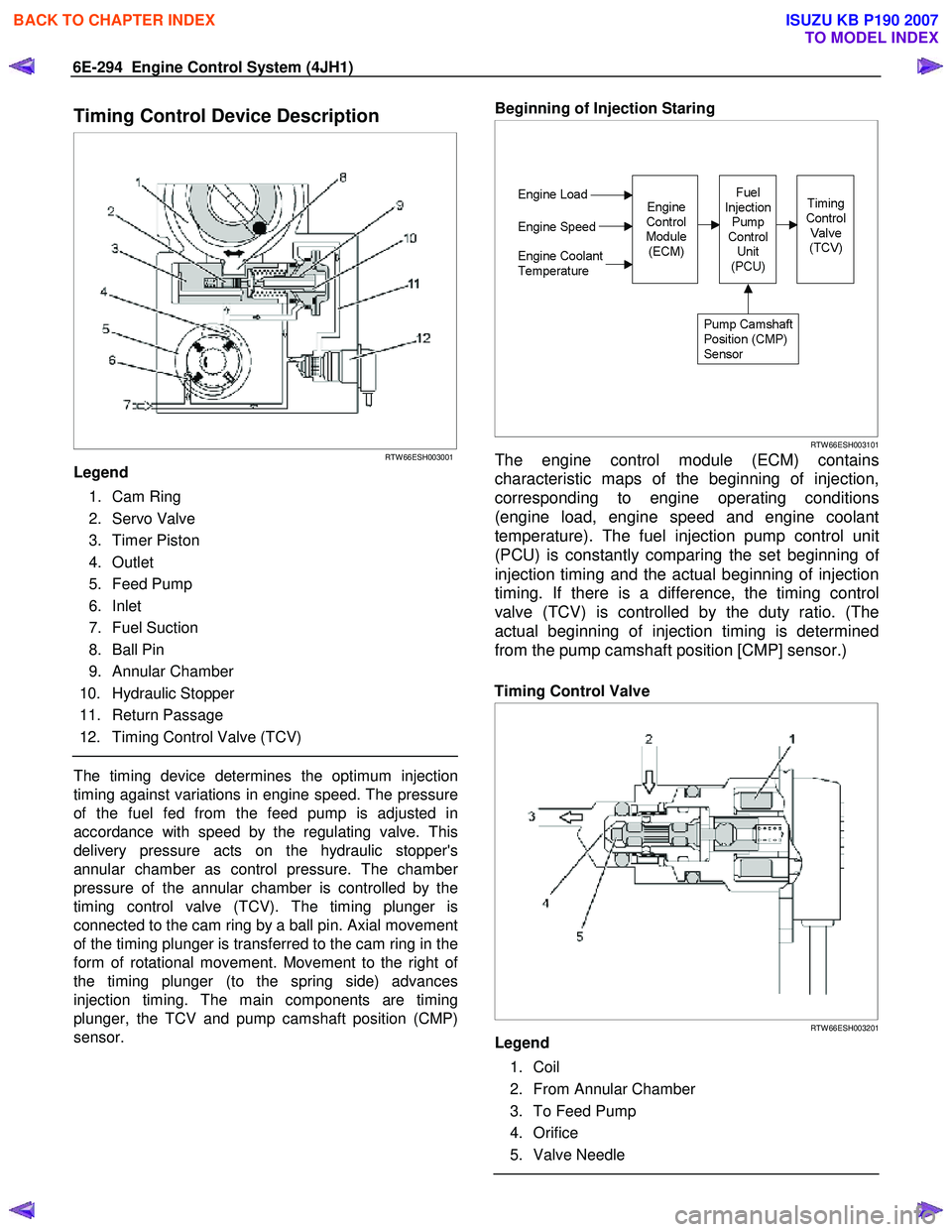

Timing Control Device Description

RTW 66ESH003001

Legend

1. Cam Ring

2. Servo Valve

3. Timer Piston

4. Outlet

5. Feed Pump

6. Inlet

7. Fuel Suction

8. Ball Pin

9. Annular Chamber

10. Hydraulic Stopper

11. Return Passage

12. Timing Control Valve (TCV)

The timing device determines the optimum injection

timing against variations in engine speed. The pressure

of the fuel fed from the feed pump is adjusted in

accordance with speed by the regulating valve. This

delivery pressure acts on the hydraulic stopper's

annular chamber as control pressure. The chambe

r

pressure of the annular chamber is controlled by the

timing control valve (TCV). The timing plunger is

connected to the cam ring by a ball pin. Axial movement

of the timing plunger is transferred to the cam ring in the

form of rotational movement. Movement to the right o

f

the timing plunger (to the spring side) advances

injection timing. The main components are timing

plunger, the TCV and pump camshaft position (CMP)

sensor.

Beginning of Injection Staring

RTW 66ESH003101

The engine control module (ECM) contains

characteristic maps of the beginning of injection,

corresponding to engine operating conditions

(engine load, engine speed and engine coolant

temperature). The fuel injection pump control unit

(PCU) is constantly comparing the set beginning o

f

injection timing and the actual beginning of injection

timing. If there is a difference, the timing control

valve (TCV) is controlled by the duty ratio. (The

actual beginning of injection timing is determined

from the pump camshaft position [CMP] sensor.)

Timing Control Valve

RTW 66ESH003201

Legend

1. Coil

2. From Annular Chamber

3. To Feed Pump

4. Orifice

5. Valve Needle

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1331 of 6020

Engine Control System (4JH1) 6E-297

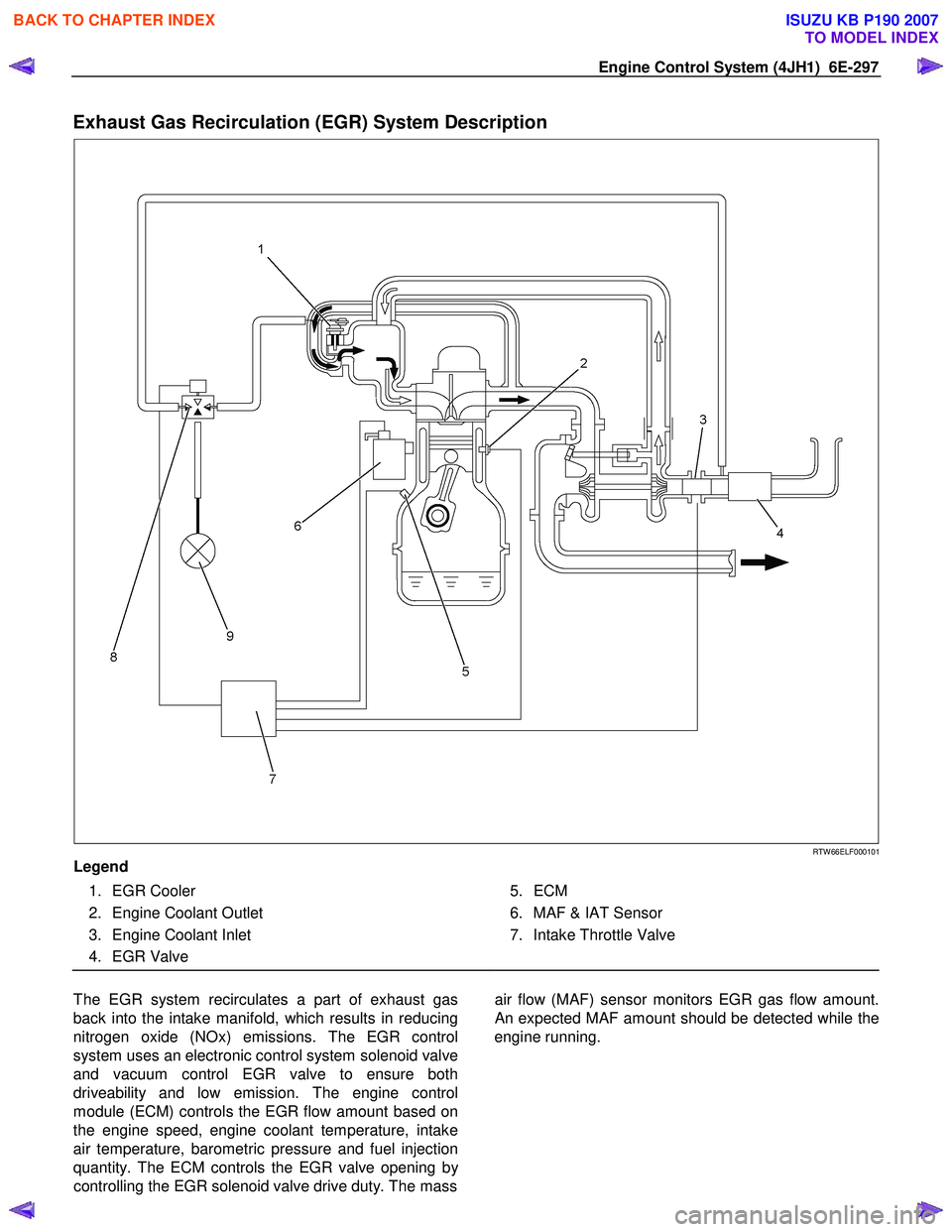

Exhaust Gas Recirculation (EGR) System Description

RTW 66ELF000101

Legend

1. EGR Cooler

2. Engine Coolant Outlet

3. Engine Coolant Inlet

4. EGR Valve

5. ECM

6. MAF & IAT Sensor

7. Intake Throttle Valve

The EGR system recirculates a part of exhaust gas

back into the intake manifold, which results in reducing

nitrogen oxide (NOx) emissions. The EGR control

system uses an electronic control system solenoid valve

and vacuum control EGR valve to ensure both

driveability and low emission. The engine control

module (ECM) controls the EGR flow amount based on

the engine speed, engine coolant temperature, intake

air temperature, barometric pressure and fuel injection

quantity. The ECM controls the EGR valve opening b

y

controlling the EGR solenoid valve drive duty. The mass

air flow (MAF) sensor monitors EGR gas flow amount.

An expected MAF amount should be detected while the

engine running.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1365 of 6020

ENGINE MECHANICAL (4JK1/4JJ1) 6A-5

EGR system

Based upon data, including water temperature, engine

speeds or engine loads, it is controlled via Engine

Control Module (ECM) to purify exhaust by recycling

part of it.

Its main components include an EGR valve, an EGR

cooler and various sensors.

Connecting rod cap bolt

The angular tightening method of the connecting rod

cap bolt further increases reliability and durability.

Fuel rail-type electronic control injection system

The fuel rail-type electronic control injection system is

composed of a fuel supply pump that sets the target

pressure of high-pressure fuel and supply it, a fuel rail

that measures such high-pressure fuel and a fuel

injector that turns it into a fine spray and injects it. Each

is controlled via ECM based upon various signals, while

injection timing or fuel injection quantity is controlled

under every possible driving condition.

Fuel injector

The fuel injector is a 6-hole nozzle that adjusts fuel

injection quantity or injection timing by opening o

r

closing an electromagnetic valve on the head of the fuel

injector.

ECM corrects the dispersion of fuel injection quantit

y

between fuel injector according to ID code data in

memory. At the replacement of fuel injector, ID code

data should be stored in ECM.

Fuel filter with sedimenter

It is a fuel filter with sedimenter that gets rid of water by

making use of the difference in specific gravity between

light oil and water, which comes with an indicator that

notifies you that it is filled with water.

Preheating system

The preheating system consists of the ECM, the glow

relay, glow plugs and the glow indicator lamp. The

preheating system is operated when the engine coolant

temperature is low, and makes the engine easy to start.

Lubrication system

It is an oil filter with full-flow bypass, which uses a

water-cool oil cooler and oil jet to cool the piston.

Functional inspection

Inspection/adjustment of valve clearance 1. Inspection of valve clearance

• Remove the fuel injector harness assembly.

• Remove the leak off hose.

• Remove the cylinder head cover.

• Rotate the crankshaft to make the No.1

cylinder meet the compression top dead cente

r

(TDC).

RTW 76ASH001301

Legend

1. TDC

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1373 of 6020

ENGINE MECHANICAL (4JK1/4JJ1) 6A-13

Main Data and specifications

Item Engine model 4JK1 Engine model 4JJ1

Type Diesel/4-cycle/water cooling-type in-line DOHC

Combustion chamber type Direct injection type

Cylinder liner type Liner less

Number of cylinders -cylinder

bore × strokes mm (in) 4-95.4 (3.76) × 87.4 (3.44) 4-95.4(3.76) × 104.9(4.13)

Displacement

cc (cu.in) 2499 (152) 2999 (183)

Compression ratio 18.3 17.5

Compression pressure MPa (psi)/rpm 3 (435)/200

Idling speed rpm 700 ± 25

Valve clearance Intake 0.15 (0.006) (cold)

mm (in) Exhaust 0.15 (0.006) (cold)

Ignition type Compressed ignition

Injection order 1 - 3 - 4 - 2

Lubricating system

Lubricating type Pressure delivery type

Oil pump type Gear type

Volume of lubricating oil L (qts) 8.0 (8.5)

Oil filter type Full flow filter (cartridge type)

Oil cooling type Built-in-type, water cooling

Cooling system

Cooling type W ater cooling type

Radiator type Corrugated fin (pressure type)

W ater pump type Centrifugal, belt drive type

Thermostat type W ax-type units

Thermostat valve-opening temperature °C ( °F) 85 (185)

Volume of coolant L (qts) M/T8.7 (9.2) A/T 8.6 (9.1) (incl. radiator)

Fuel system

Injection pump type Fuel supply pump fuel rail type

Fuel injector type Electronic control injector

6-hole

Fuel pump type Into the fuel tank type

Charging system

Generator type AC type

Power output V-A 12 - 90

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1375 of 6020

ENGINE MECHANICAL (4JK1/4JJ1) 6A-15

Engine Assembly

Removal

1. Disconnect the negative battery cable.

2. Remove the engine hood.

3. Drain the coolant.

4. Remove the starter motor.

5. Remove the transmission assembly.

Refer to removal procedure for “TRANSMISSION” in this manual.

6. Disconnect the ECM harness connector.

7. Remove the ECM.

8. Remove the air cleaner. • Disconnect the MAF sensor harness connector.

• Remove the intake pipe with the lid of ai

r

cleaner box.

• Remove the air cleaner box.

RTW 76ASH000401

Legend

1. ECM Harness Connector

2. ECM

3. Air Cleaner Box

4. MAF Sensor Harness Connector

9. Remove the intake hose (intercooler - intake

throttle) (Standard output).

10. Remove the intake hose (turbocharger - intercooler) (Standard output).

Remove the harness connector.

RTW 56ASH004001

Legend

1. Intake Hose (intercooler - intake throttle)

2. Intake Hose (turbocharger - intercooler)

11. Remove the intercooler (High output).

• Disconnect the BARO sensor harness

connector (2).

• Remove the two intake hoses.

• Remove the intercooler (1).

RTW 76ASH000501

12. Remove the radiator upper hose.

13. Remove the engine harness clip (1).

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1378 of 6020

6A-18 ENGINE MECHANICAL (4JK1/4JJ1)

21.Install the intake hose (intercooler - intake throttle)

(Standard output).

RTW 56ASH004001

22.Install the intercooler (High output).

• Install the intercooler.

• Install the two intake hoses.

• Connect the BARO sensor harness connector.

23.Install the air cleaner.

• Install the intake pipe with the lid of air cleane

r

box.

• Install the air cleaner box.

• Connect the MAF sensor harness connector.

24.Install the ECM.

25.Connect the ECM harness connector.

26.Install the transmission assembly.

Refer to installation procedure fo

r

“TRANSMISSION”.

27.Install the starter motor.

Tightening torque: 94 N ⋅

⋅⋅

⋅

m (9.6kg ⋅

⋅⋅

⋅

m / 69 lb ft)

28.Replenish the coolant.

29.Install the engine hood.

Tightening torque: 10 N ⋅

⋅⋅

⋅

m (1.0kg ⋅

⋅⋅

⋅

m / 87 lb in)

30.Connect the negative battery cable.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1394 of 6020

6A-34 ENGINE MECHANICAL (4JK1/4JJ1)

Removal

1. Loosen the radiator drain plug to drain coolant.

2. Remove the engine cover.

3. Remove the intake hose from the intercooler and intake throttle.

4. Remove the intake hose from the turbocharge

r

and the intercooler.

5. Remove the air intake duct from the turbocharge

r

and the air cleaner.

6. Remove the EGR cooler.

Refer to “EGR Cooler” in EXHAUST SYSTEM Section.

7. Remove the oil feed pipe.

8. Remove the oil return pipe. • Loosen clamp (1) of A/T oil cooler pipe.

RTW 56ASH025101

9. Remove the water feed and return pipe.

RTW 56ASH005401

Legend

1. Oil Feed Pipe

2. EGR Cooler

3. W ater Feed Pipe

4. W ater Return Pipe

5. Oil Return Pipe

10. Remove the front exhaust pipe.

RTW 56ASH018301

Legend

1. Gasket

2. Front Exhaust Pipe (4 ×2 High Ride Suspention,

4 ×4)

3. Gasket

4. Front Exhaust Pipe (4 ×2 Except High Ride

Suspention)

11. Disconnect the front propeller shaft flange (1)

(Front Diff Side, 4 ×4 only).

RTW 76ASH002301

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007