Suspension JAGUAR X308 1998 2.G Owners Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 312 of 2490

REFE

R to

Specification

- /

F r

ont Brake Disc Runout Check

- V

eh

icles With: Brembo Brakes

/

F

ront Brake Disc Runout Check

- V

e

hicles Without: Brembo Brakes

in this

section.

Yes GO to B5

.

No

GO to B6

.

B5: CHECK VEHICLE

FOR A HISTORY OF BRAKE VIBRATION PROBLEMS

Chec

k to se

e if the vehicle has recently been

repaired for brake vibration problems by the

installation of new front brake discs and pads.

1

Has vehicl

e has recently been repaired for brake vibrat

ion problems by the installation of new front brake

discs and pads.

Yes INSTALL new front wheel hubs

REFER to Section 204

-01 Fron

t Suspension

.

INST ALL new fr

ont brake disc

s and front brake pads

REFER to Section 206

-03 Fr

ont Disc Brake

.

TEST the system for normal

operation.

No INSTALL front brake discs and front brake pads

REFER to Section 206

-03 Fr

ont Disc Brake

.

CHECK for excessiv

e brake disc runout

REFER to Front Brake Disc Runout Check

- Veh

icles With: Brembo Brakes

/

F

ront Brake Disc Runout Check

- V

e

hicles Without: Brembo Brakes

in this

section.

If excessive brake disc runout exis ts INSTALL new front wheel hubs

REFER to Section 204

-01 Fron

t Suspension

.

TEST the system for normal

operation.

B

6:

CHECK THE REAR BRAKE PADS AND REAR BRAKE DISCS

Chec

k

the condition of the rear brake pads and rear brake discs.

1

D

o

es excessive brake disc runout or br

ake disc thickness variation exist?

REFER to Specification

- /

Rear B

rake Disc Runout Check

- Ve

hicles Without: Brembo Brakes

/

Rear

Brake Disc Runout Check

- Veh

icles With: Brembo Brakes

in this

section.

Yes INSTALL rear brake discs and rear brake pads

REFER to Section 206

-04

Rear Disc Brake

.

CHECK for excessiv

e brake disc runout.

REFER to Rear Brake Disc Runout Check

- Veh

icles With: Brembo Brakes

/

Rear

Brake Disc Runout Check

- V

e

hicles Without: Brembo Brakes

in this

section.

If excessive brake disc runout exists INSTALL ne w rear wheel hubs. TEST the system for normal

operation.

No REPEAT road test and re-check for a vi bration concern. If vibration exists GO to B3

.

PINPOINT TEST

C : THE BRAKES PULL OR DRIFT

TE

S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

C1

:

ROAD TEST VEHICLE

Road test th

e veh

icle and apply the brake pedal.

1

D

o

es the vehicle pull or drift?

Yes GO to C2

.

No

Vehicle is OK.

C2:

INS

PECT TIRE PRESSURE

Check f

or ex

cessive tire wear

or incorrect pressures.

1

Are the ti

res at the correct pressure and in good condition?

Yes GO to C3

.

No

AD

JUST the tire pressures or IN

STALL new tires if excessively wo rn. TEST the system for normal

operation.

C3 : CH

ECK CALIPERS

Check the fr

on

t caliper pistons for binding, leakin

g or sticking. For additional information, refer

toSection 206

-03 Fr

ont Disc Brake

. Check the rear cal

i

per pistons for

binding, leaking or sticking. For

additional information, refer toSection 206

-04

Rear Disc Brake

.

1

Page 313 of 2490

Do t

he disc brake caliper pistons

and pins bind, leak or stick?

Yes INSTALL new calipers as necessary. TE ST the system for normal operation.

No GO to C4

.

C4: INSPECT BR

AKE DISCS

Check the brake discs fo

r excess

ive damage, thickness variatio n or runout. For additional

information, refer to General Procedures in this section.

1

D

oes excessive damage or runout exist?

Yes INSTALL new brake discs and brak e pads as necessary. TEST the system for normal operation.

No GO to C5

.

C5: INSPECT THE FRONT HU

B AND WHEEL BEARING ASSEMBLY

Check the fr

ont hub and wheel bearing assembly.

For additional information, refer toSection 204

-00

Su

spension System

- General

Information

. 1

Are th

e wheel bearings OK?

Yes GO to C6

.

No

INSTALL new wheel bearings. For additional inform ation, refer toSection 204

-01

Front Suspension

.

TEST the system

for normal operation.

C

6: CHECK SUSPENSION BUSHES AND BALL JOINTS.

Chec

k all suspension bu

shes and ball joints.

1

Are th

e suspension bushes and ball joints OK?

Yes Vehicle is OK.

No INSTALL new front suspension bushes and ball joints as required. For additional information, refer

toSection 204

-01

Front Suspension

. INSTALL n

ew rear suspension bush

es and ball joints as required.

For additional informat ion, refer toSection 204

-0

2 Rear Suspension

.

P

INPOINT TEST D : THE PEDAL FEELS SPONGY

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

D

1: CHECK FOR SPONGY PEDAL (ENGINE OFF)

Check f

or a firm brake pedal.

1

Is th

e brake pedal effort an

d brake pedal travel normal?

Yes Vehicle is OK.

No GO to D2

.

D2:

CHECK BRAKE PEDAL RESERVE (ENGINE OFF)

Pump th

e brake pedal 10 times and

hold on the final application.

1

Does th

e brake pedal feel fi

rm on final application?

Yes GO to D3

.

No

BLEED the brake system. For additional information, re fer to General Procedures in this section. TEST

the system for normal operation.

D3:

CHECK BRAKE PEDAL RESERVE (ENGINE ON)

Engine is

idle.

1

Apply the brake pedal ligh

tl

y three or four times.

2

W

ait 15 seconds for the vacuum to recover.

3

Push down on

the brake pedal until it stops moving

downward or an increased resistance to the brake

pedal travel occurs.

4

Hol

d the brake pedal in the applied position while increasing the engine speed to 2000 revs/min.

5

Re

lease the accelerator pedal.

6

Does th

e brake pedal move downward as

the engine speed returns to idle?

Yes GO to D4

.

No

CHECK the vacuum to brake booster. For additional information, refer toSection 206

-0

7 Power Brake

Actuation.

Page 317 of 2490

Yes

Vehicle is OK.

No GO to J2

.

J

2: CHECK BRAKE FLUID LEVEL

Check the brake master cyli

nder reservoir fluid level.

1

Is the fl

uid level OK?

Yes GO to J3

.

No

CHECK brake master cylinder reservoir sealing points. For additional information, refer to Brake

Master Cylinder in this section. ADD brake fl uid and BLEED the brake system. For additional

information, refer to General Proc edures in this section. TEST the system for normal operation.

REPEAT road test if necessary.

J

3: CHECK BRAKE PEDAL RESERVE

Engine is

idle.

1

Apply the brake pedal ligh

tl

y three or four times.

2

W

ait 15 seconds for the vacuum to replenish.

3

Push down on

the brake pedal until it stops moving

downward or an increased resistance to the brake

pedal travel occurs.

4

Hol

d the brake pedal in the applied position while increasing the engine speed to 2000 revs/min.

5

Re

lease the accelerator pedal.

6

Does th

e brake pedal move downward as

the engine speed returns to idle?

Yes GO to J4

.

No

CHECK the vacuum to the brake booster. Fo r additional information, refer toSection 206

-0

7 Power

Brake Ac

tuation

.

J

4: CHECK THE FRONT HUB AND BEARING ASSEMBLY

Check the fr

ont hub and bearing assembly. Fo

r additional information, refer toSection 204

-01

Front

Suspe

nsion

. 1

Are th

e front wheel bearings loose?

Yes INSTALL a new front wheel bearin g if damaged. For additional information, refer toSection 204

-01

F

ront Suspension

. TEST

the system for normal operation.

No CHECK the front brake discs for thickness variances. For additional information, refer to General

Procedures in this section.

PINPO

INT TEST K : SLOW OR INCOMPLETE BRAKE PEDAL RETURN

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

K1: C

HECK FOR BRAKE PEDAL RETURN

Ru

n the engine at fast idle while

making several brake applications.

1

Pull the

brake pedal rearward with approximately 44.5 N (10lb) force.

2

Relea

se the brake pedal and measure

the distance to the toe board.

3

Make a hard brake

application.

4

Relea

se the brake pedal and measure the brake

pedal to toe board distance. The brake pedal

should return to its original position.

5

Does th

e brake pedal return

to its original position?

Yes Vehicle is OK.

No GO to K2

.

K

2: CHECK FOR BRAKE PEDAL BINDING

Check the brake pedal to make

s

ure it is operating freely.

1

Is th

e brake pedal operating freely?

Yes INSTALL a new brake booster. For addi tional information, refer toSection 206

-0

7 Power Brake

Actuation. TEST

the system for normal operation.

No REPAIR or INSTALL new brake pedal. TE ST the system for normal operation.

Page 346 of 2490

2.

Remove paper backing from pads to reveal adhesive

shim. Install brake pads, insert clip located on back of

inner pad into caliper piston.

3. Inst al

l caliper housing to caliper carrier.

Align hou

s

ing to carrier.

1. Install and tighten guide pins to 25-30 Nm.

2. Install dust covers.

3. Install anti-rattle spring.

4. NOTE : Th

e brake hose must only be installed with the vehicle's

body supported and the suspension hanging.

Install and tighten brake hose to caliper housing to 10-14 Nm.

5. NO

TE: Make sure the brake

hose does not twist when

tightening the hose lock-nut.

Connect brake hose to brake tube.

1. Position hose thread through bracket.

2. Install and tighten locking nut. Refer to Specifications, section 206-03.

3. Install and tighten brake- tube union nut. Refer to

Specifications, section 206-03.

6. Remove special tool from brake pedal.

7. Fit wheels. Refer to section 204-04.

8. NOTE: Make sure the brake hose is routed correctly.

Remove stands and lower vehicl e. Refer to section 100-02.

9. Bleed brake hydraulic system. See operation 70.25.03.

Page 350 of 2490

2.

Po

sition anti-rattle spring.

3. Install pins.

4. Install 'R' clips.

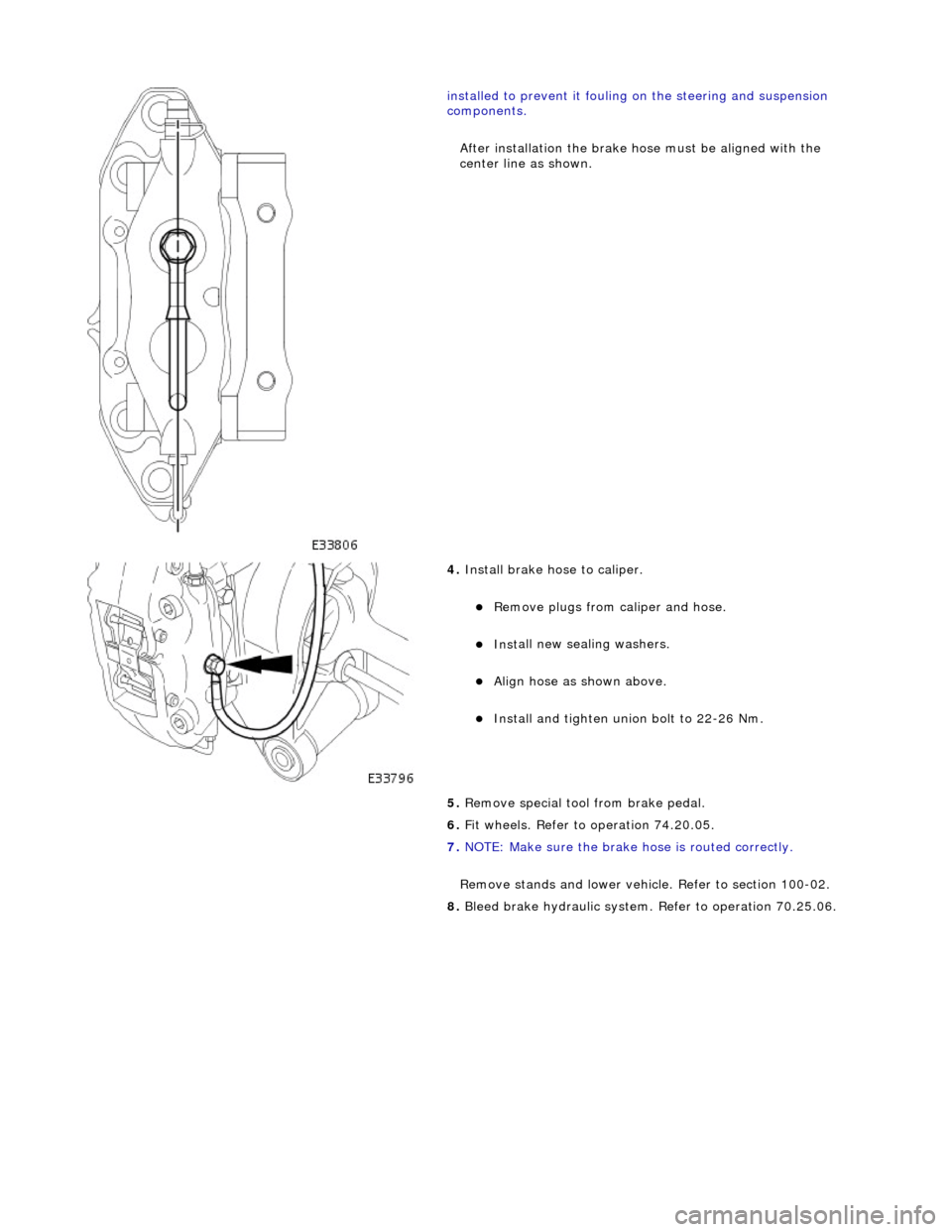

3. CAUTIO

N: The brake hose must

only be installed with the

vehicle's body supported and the suspension hanging.

Install brake hose to caliper.

Remove plugs f rom caliper and hose.

Instal

l new sealing washers.

Install and tigh

ten un

ion bolt to 22-26 Nm.

4.

NO

TE: Make sure the brake

hose does not twist when

tightening the hose lock-nut.

Connect brake hose to brake tube. 1. Position hose thread through bracket.

2. Install and tighten locking nut. Refer to Specifications, section 206-03.

3. Install and tighten brake- tube union nut. Refer to

Specifications, section 206-03.

5. Remove special tool from brake pedal.

6. Fit wheels. Refer to operation 74.20.05.

7. NOTE: Make sure the brake hose is routed correctly.

Remove stands and lower vehicl e. Refer to section 100-02.

8. Bleed brake hydraulic system. See operation 70.25.06.

Page 374 of 2490

In

stallation

11

. Remove brake

dust and clean

mating surfaces. See Warning

above.

1. Inst al

l caliper to hub carrier.

Install and tigh

ten bolts to 6

0 Nm.

2. CAUTI O

NS:

Retracting the caliper piston may cause the fluid reservoir

to over-flow. Remove brake flui d spillage immediately from paint

work with clean water.

Note the condition of the pi ns and replace if necessary.

Install brake pads. Refer to 70 .40.09 for anti-squeal grease

application.

Sl owly

retract caliper pistons.

1. Install pads.

2. Position anti-rattle spring.

3. Install pins - make sure pin collets are fully engaged

into caliper.

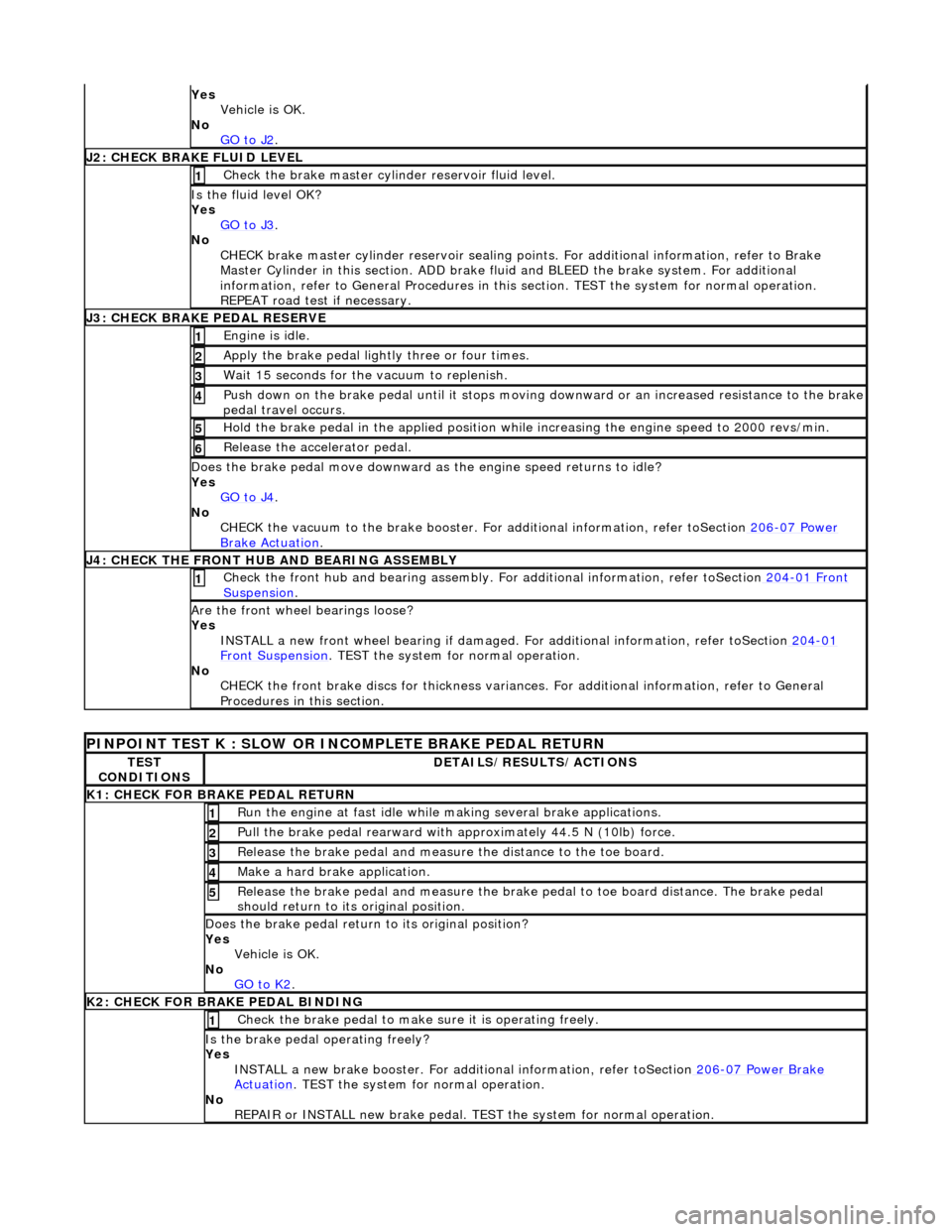

3. CAUTI O

NS:

The brake hose must only be installed with the vehicle's

body supported and the suspension hanging.

It is important that the brake hose is aligned correctly when

Page 375 of 2490

i

nstalled to prevent it fouling on the steering and suspension

components.

After installation the brake ho se must be aligned with the

center line as shown.

4. Install brake hose to

caliper.

Remove plugs f

rom caliper and hose.

Inst

all new sealing washers.

Align hos

e as shown above.

Install and tigh

ten union bolt to 22-26 Nm.

5. Remove special tool from brake pedal.

6. Fit wheels. Refer to operation 74.20.05.

7. NOTE: Make sure the brake hose is routed correctly.

Remove stands and lower vehicl e. Refer to section 100-02.

8. Bleed brake hydraulic system. Refer to operation 70.25.06.

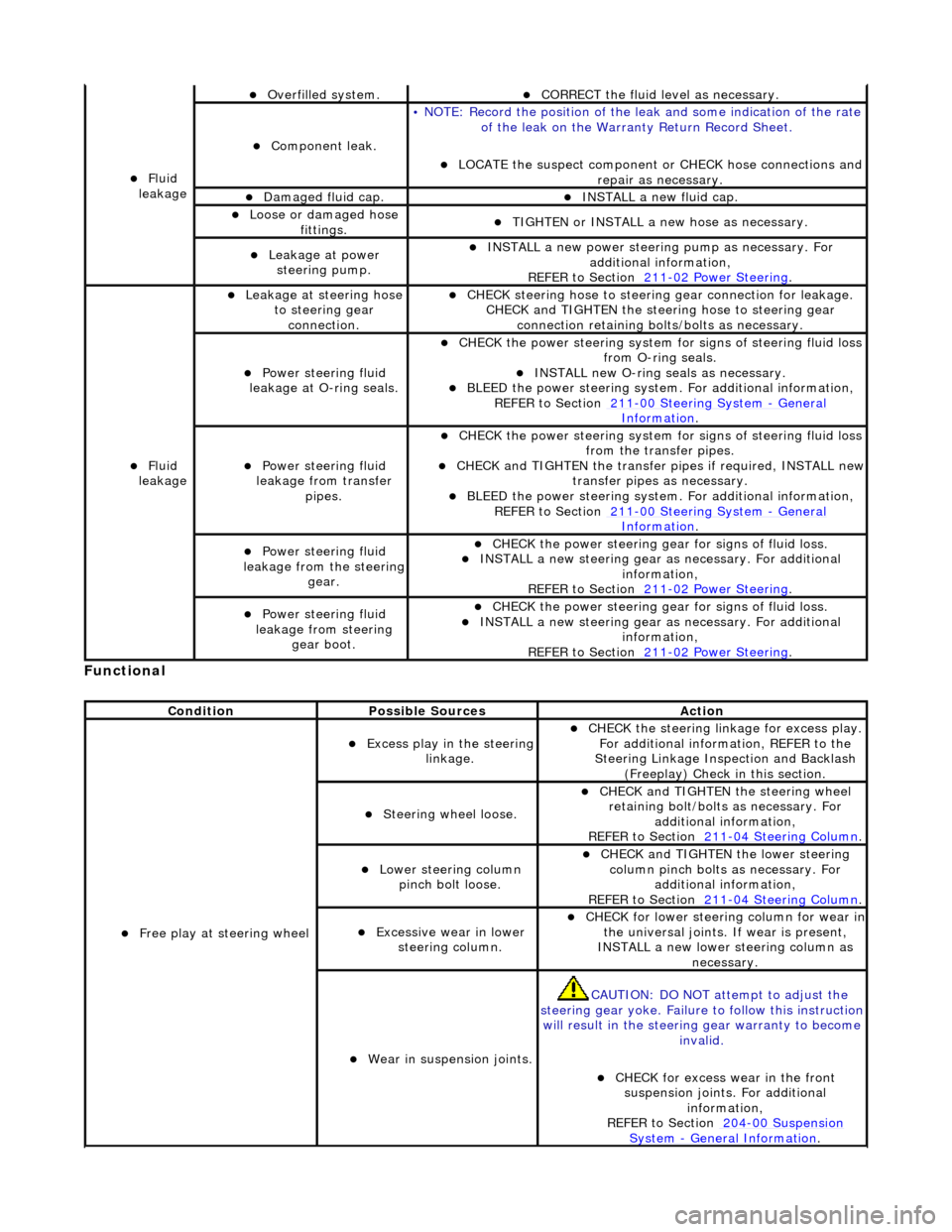

Page 459 of 2490

Function

al

Fl

uid

leakage

O

verfilled system.

CORRECT the

fluid leve

l as necessary.

Compon

ent leak.

•

NOTE: Record the position of the le

ak and some indication of the rate

of the leak on the Warra nty Return Record Sheet.

LOCATE

the suspect component or CHECK hose connections and

repair as necessary.

Damaged fluid cap. INST

ALL a new fluid cap.

Loose or damaged h

ose

fittings.

TI

GHTEN or INSTALL a new hose as necessary.

Leakage at

power

steering pump.

INST

ALL a new power steering

pump as necessary. For

additional information,

REFER to Section 211

-0

2 Power Steering

.

Fl

uid

leakage

Leakage

at steering hose

to steering gear connection.

CHECK

steering hose to

steering gear conn ection for leakage.

CHECK and TIGHTEN the steeri ng hose to steering gear

connection retaining bolt s/bolts as necessary.

Power steeri

ng fluid

leakage at O-ring seals.

CHECK

the power steering system fo

r signs of steering fluid loss

from O-ring seals.

INST

ALL new O-ring seals as necessary.

BLEE

D the power steering system.

For additional information,

REF

ER to Section 211

-0

0 Steering System

- Ge

neral

Informati

on

.

Power steeri

ng fluid

leakage from transfer pipes.

CHECK

the power steering system fo

r signs of steering fluid loss

from the transfer pipes.

CHECK

and TIGHTEN the transfer pipes if required, INSTALL new

transfer pipes as necessary.

BLEE

D the power steering system.

For additional information,

REF

ER to Section 211

-0

0 Steering System

- Ge

neral

Informati

on

.

Power steeri

ng fluid

leakage from the steering

gear.

CHECK

the power steering gear for signs of fluid loss.

INST

ALL a new steering gear as

necessary. For additional

information,

REFER to Section 211

-0

2 Power Steering

.

Power steeri

ng fluid

leakage from steering gear boot.

CHECK

the power steering gear for signs of fluid loss.

INST

ALL a new steering gear as

necessary. For additional

information,

REFER to Section 211

-0

2 Power Steering

.

Cond

ition

Possib

le Sources

Acti

on

F

ree play at steering wheel

Exce

ss play in the steering

linkage.

CHECK

the steering linkage for excess play.

For additional information, REFER to the

Steering Linkage Inspection and Backlash (Freeplay) Check in this section.

S

teering wheel loose.

CHECK

and TIGHTEN the steering wheel

retaining bolt/bolts as necessary. For additional information,

REFER to Section 211

-0

4 Steering Column

.

Lower steeri

ng column

pinch bolt loose.

CHECK

and TIGHTEN the lower steering

column pinch bolts as necessary. For additional information,

REFER to Section 211

-0

4 Steering Column

.

Exce

ssive wear in lower

steering column.

CHECK

for lower steering column for wear in

the universal joints. If wear is present,

INSTALL a new lower steering column as necessary.

W

ear in suspension joints.

CAU

TION: DO NOT attempt to adjust the

steering gear yoke. Failure to follow this instruction

will result in the steering gear warranty to become

invalid.

CHECK

for excess wear in the front

suspension joints. For additional information,

REFER to Section 204

-00

Suspension

Sy

stem

- General

Information

.

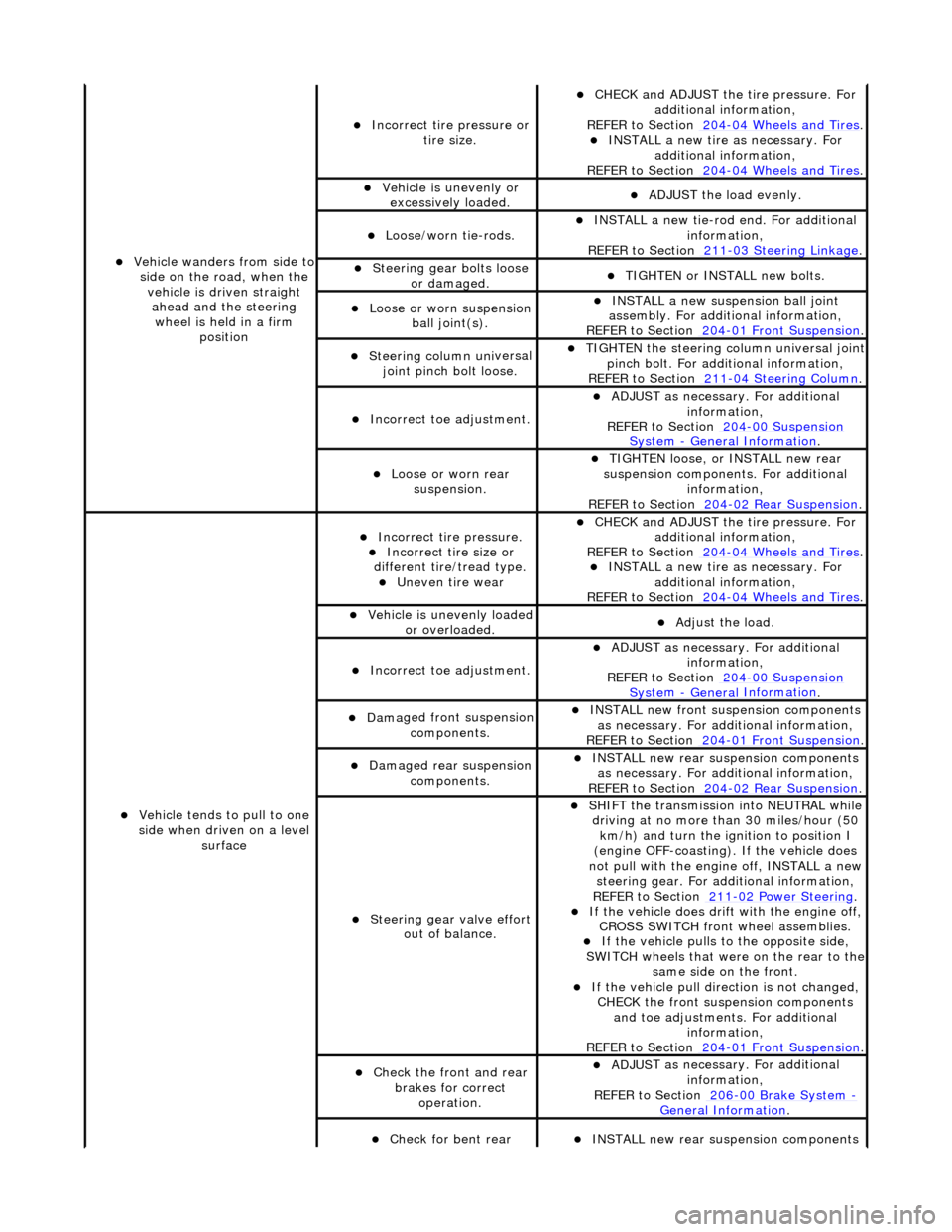

Page 460 of 2490

Vehicl

e wanders from side to

side on the road, when the vehicle is driven straight ahead and the steering wheel is held in a firm position

Incorrect ti re

pressure or

tire size.

CHECK and ADJ

UST the tire pressure. For

additional information,

REFER to Section 204

-0 4

Wheels and Tires

. IN

ST

ALL a new tire as necessary. For

additional information,

REFER to Section 204

-0 4

Wheels and Tires

.

Vehi

cl

e is unevenly or

excessively loaded.

A D

JUST the load evenly.

Loose/worn ti

e-

rods.

INST

ALL a ne

w tie-rod

end. For additional

information,

REFER to Section 211

-0 3

Steering Linkage

.

Steeri

ng gear bolts loose

o

r damaged.

TIGHTE

N or INSTALL

new bolts.

Loose or worn suspensi

on

ball jo

int(s).

INST

ALL a ne

w suspension ball joint

assembly. For additional information,

REFER to Section 204

-01 Fron

t Suspension

.

Steeri

ng column uni

versal

joint pinch bolt loose.

TI G

HTEN the steering column universal joint

pinch bolt. For additi onal information,

REFER to Section 211

-0 4

Steering Column

.

Incorre

ct

toe adjustment.

ADJUS

T as necessary. For additional

information,

REFER to Section 204

-00 Sus

pension

Sy

ste

m

- General

Information

.

Loose or worn rear

susp

ension.

TIGHTEN

loose, or IN

STALL new rear

suspension components. For additional information,

REFER to Section 204

-0 2

Rear Suspension

.

Vehicle t

e

nds to pull to one

side when driven on a level surface

Incorrect ti

re pressure.

Incorrect

ti

re size or

different tire/tread type.

Uneven tire wear

CHECK and ADJ

UST the tire pressure. For

additional information,

REFER to Section 204

-0 4

Wheels and Tires

. IN

ST

ALL a new tire as necessary. For

additional information,

REFER to Section 204

-04

Wheels and Tires

.

Vehicl

e is unevenly loaded

or overloaded.

Adjust the load

.

Incorre

ct

toe adjustment.

ADJUS

T as necessary. For additional

information,

REFER to Section 204

-00 Sus

pension

Sy

ste

m

- General

Information

.

Dam

a

ged front suspension

components.

I N

STALL new front suspension components

as necessary. For addi tional information,

REFER to Section 204

-01 Fron

t Suspension

.

Damaged rear

suspen

sion

components.

INST ALL ne

w rear suspension components

as necessary. For addi tional information,

REFER to Section 204

-0 2

Rear Suspension

.

Steeri

ng gear val

ve effort

out of balance.

SHIF T the

transmission into NEUTRAL while

driving at no more than 30 miles/hour (50 km/h) and turn the ignition to position I

(engine OFF-coasting). If the vehicle does

not pull with the engine off, INSTALL a new steering gear. For additional information,

REF E

R to Section 211

-0

2

Power Steering

. If t

he

vehicle does drift with the engine off,

CROSS SWITCH front wheel assemblies.

If the

vehicle pulls to

the opposite side,

SWITCH wheels that were on the rear to the

same side on the front.

If the v

ehicle pull dire

ction is not changed,

CHECK the front susp ension components

and toe adjustments. For additional information,

REFER to Section 204

-01 Fron

t Suspension

.

Chec

k

the front and rear

brakes for correct operation.

ADJUS

T as necessary. For additional

information,

REFER to Section 206

-0 0

Brake System

-

General Informati on.

Check fo

r bent rear

INST

ALL ne

w rear suspension components

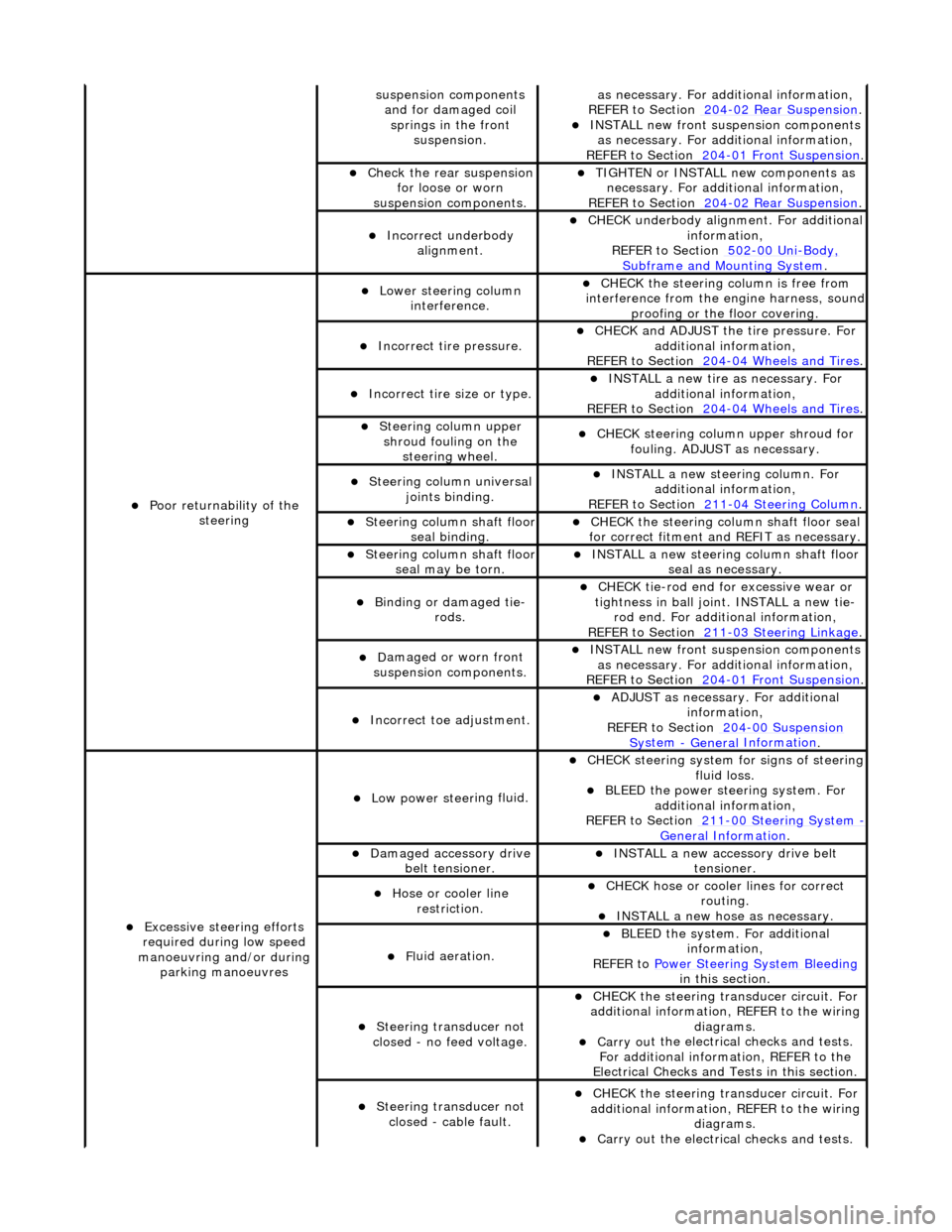

Page 461 of 2490

sus

pension components

and for damaged coil springs in the front suspension.

as necessary. For addi tional information,

REF

ER to Section 204

-0

2 Rear Suspension

. I

NSTALL new front suspension components

as necessary. For addi tional information,

REFER to Section 204

-01

Front Suspension

.

Chec

k the rear suspension

for loose or worn

suspension components.

TIGHTE

N or INSTALL new components as

necessary. For additi onal information,

REFER to Section 204

-0

2 Rear Suspension

.

Incorre

ct underbody

alignment.

CHECK

underbody alignment. For additional

information,

REFER to Section 502

-00

Uni

-Body, Subframe and M

ounting System

.

Poor r

eturnability of the

steering

Lower steeri

ng column

interference.

CHECK

the steering co

lumn is free from

interference from the en gine harness, sound

proofing or the floor covering.

Incorrect

tire pressure.

CHECK

and ADJUST the tire pressure. For

additional information,

REFER to Section 204

-0

4 Wheels and Tires

.

Incorrect

tire size or type.

IN

STALL a new tire as necessary. For

additional information,

REFER to Section 204

-0

4 Wheels and Tires

.

Steeri

ng column upper

shroud fouling on the steering wheel.

CHECK

steering column upper shroud for

fouling. ADJUST as necessary.

Steeri

ng column universal

joints binding.

IN

STALL a new steering column. For

additional information,

REFER to Section 211

-0

4 Steering Column

.

Steeri

ng column shaft floor

seal binding.

CHE

CK the steering column shaft floor seal

for correct fitm ent and REFIT as necessary.

Steeri

ng column shaft floor

seal may be torn.

IN

STALL a new steering column shaft floor

seal as necessary.

Bin

ding or damaged tie-

rods.

CHECK

tie-rod end for excessive wear or

tightness in ball joint. INSTALL a new tie- rod end. For additional information,

REFER to Section 211

-0

3 Steering Linkage

.

D

amaged or worn front

suspension components.

I

NSTALL new front suspension components

as necessary. For addi tional information,

REFER to Section 204

-01

Front Suspension

.

Incorre

ct toe adjustment.

AD

JUST as necessary. For additional

information,

REFER to Section 204

-00

Suspension

Sy

stem

- General

Information

.

Excessive steeri

ng efforts

required during low speed

manoeuvring and/or during parking manoeuvres

Low power steer

ing fluid.

CHE

CK steering system

for signs of steering

fluid loss.

BLEE

D the power steering system. For

additional information,

REFER to Section 211

-0

0 Steering System

- General Informati

on

.

Damaged accessory driv

e

belt tensioner.

INST

ALL a new accessory drive belt

tensioner.

Hose or cooler li

ne

restriction.

CHECK

hose or cooler lines for correct

routing.

INST

ALL a new hose as necessary.

Fl

uid aeration.

BLEE

D the system. For additional

information,

REFER to Power Steering System Bleeding

in t

his section.

Steeri

ng transducer not

closed - no feed voltage.

CHECK

the steering transducer circuit. For

additional information, REFER to the wiring diagrams.

Carry ou

t the electrical checks and tests.

For additional information, REFER to the

Electrical Checks and Tests in this section.

Steeri

ng transducer not

closed - cable fault.

CHECK

the steering transducer circuit. For

additional information, REFER to the wiring diagrams.

Carry ou

t the electrical checks and tests.