air control JAGUAR X308 1998 2.G Owners Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1220 of 2490

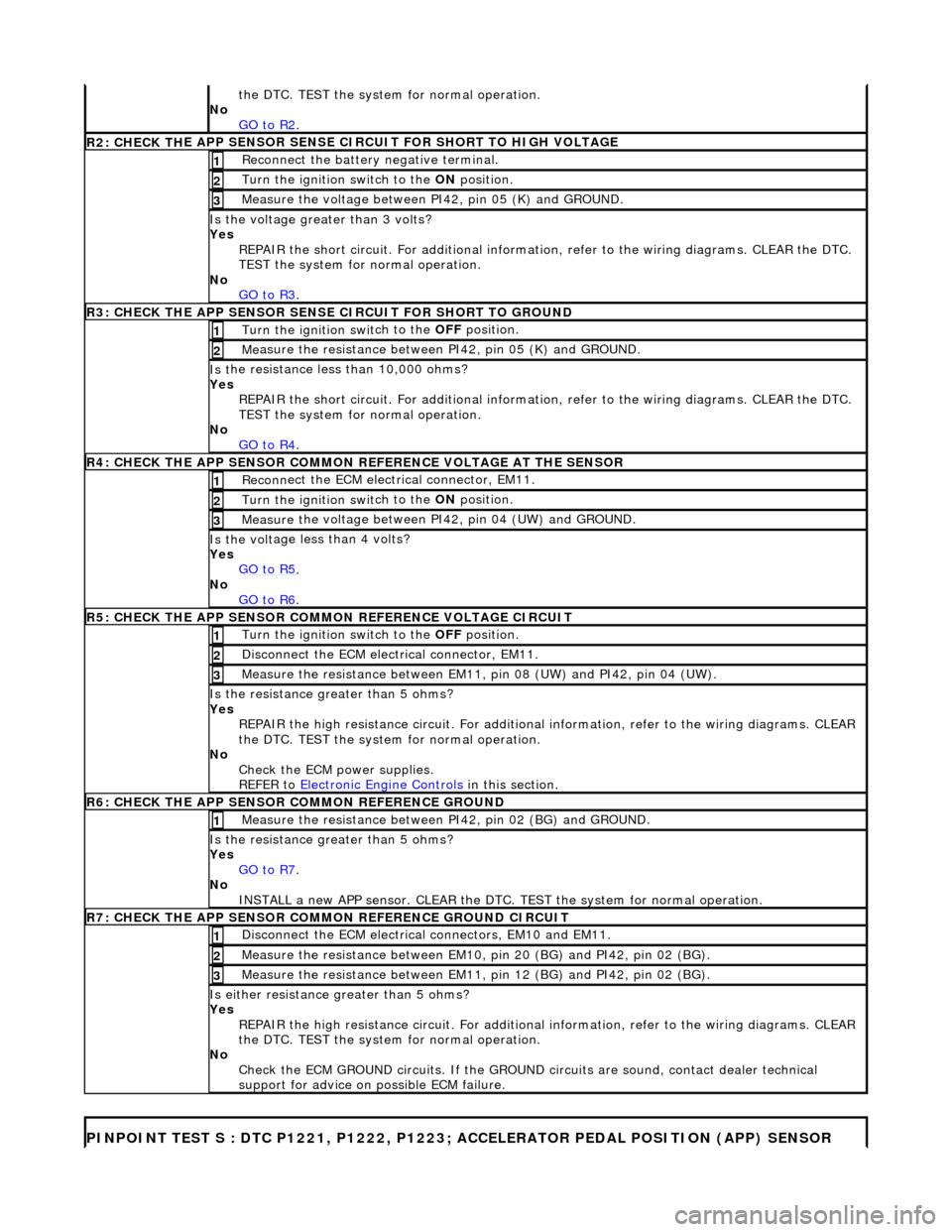

the DT

C. TEST the system for normal operation.

No GO to R2

.

R2: CHECK TH

E APP SENSOR SENSE CIRCUIT FOR SHORT TO HIGH VOLTAGE

R

e

connect the battery negative terminal.

1

Turn the ignition swi

t

ch to the ON

position.

2

Me

asure the voltage between PI42, pin 05 (K) and GROUND.

3

Is th

e volt

age greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to R3

.

R3: CHECK THE APP SENSOR SENS

E CIRCUIT FOR SHORT TO GROUND

Turn the ignition swi

t

ch to the OFF

position.

1

Me

asure the resistance between PI42, pin 05 (K) and GROUND.

2

Is

t

he resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to R4

.

R4: CHECK THE APP SENSOR COM

MON

REFERENCE VOLTAGE AT THE SENSOR

Reconn

ect the ECM electrical connector, EM11.

1

Turn the ignition swi

t

ch to the ON

position.

2

Measure t

he voltage between PI42, pin 04 (UW) and GROUND.

3

Is th

e volt

age less than 4 volts?

Yes GO to R5

.

No

GO to R6

.

R5: CHECK THE APP SENSOR COM

M

ON REFERENCE VOLTAGE CIRCUIT

Turn the ignition swit

ch to the OFF

position.

1

Di

sconnect the ECM electrical connector, EM11.

2

Measure t

he resistance between EM11,

pin 08 (UW) and PI42, pin 04 (UW).

3

Is the res

istance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No Check the ECM power supplies.

REFER to Electronic Engine Controls

in this

section.

R6: CHECK THE APP

SENSOR COM

MON REFERENCE GROUND

Meas

ure t

he resistance between PI42, pin 02 (BG) and GROUND.

1

Is th

e res

istance greater than 5 ohms?

Yes GO to R7

.

No

INST

ALL a new APP sensor. CLEAR the DTC.

TEST the system for normal operation.

R7: CHECK THE APP SENSOR COM

MON REFERENCE GROUND CIRCUIT

D

i

sconnect the ECM electrical connectors, EM10 and EM11.

1

Measure t

he resistance between EM10,

pin 20 (BG) and PI42, pin 02 (BG).

2

Measure t

he resistance between EM11,

pin 12 (BG) and PI42, pin 02 (BG).

3

Is either resistance greater

than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No Check the ECM GROUND circuits. If the GROUND circuits are sound, contact dealer technical

support for advice on possible ECM failure.

PINPO

INT TEST S : DTC P1221, P1222, P1223;

ACCELERATOR PEDAL POSITION (APP) SENSOR

Page 1221 of 2490

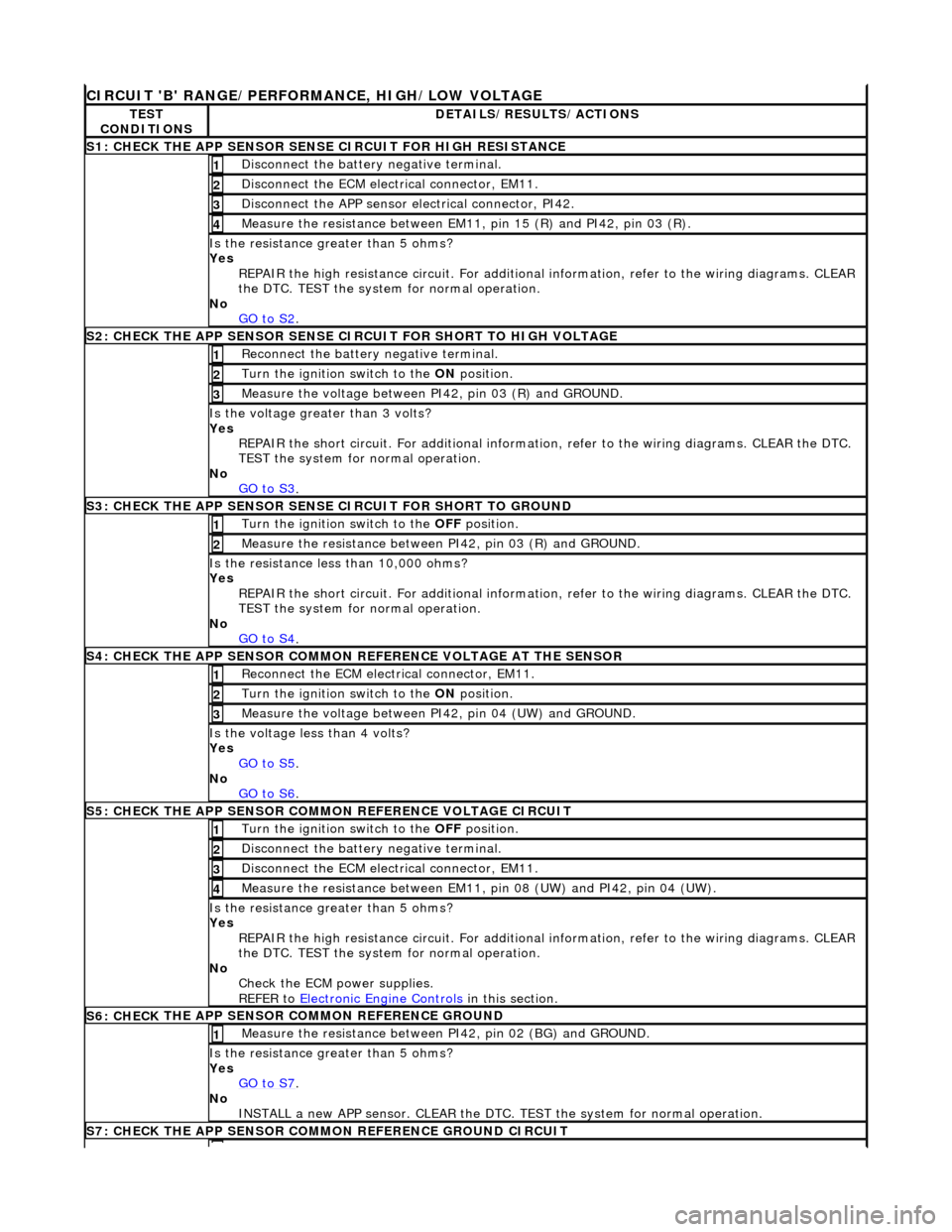

CIRCUI

T 'B' RANGE/PERFORMANCE, HIGH/LOW VOLTAGE

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

S1: CHECK

THE APP SENSOR SENSE CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

D

isconnect the ECM electrical connector, EM11.

2

Di

sconnect the APP sensor electrical connector, PI42.

3

Meas

ure the resistance between EM11, pin 15 (R) and PI42, pin 03 (R).

4

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to S2

.

S

2: CHECK THE APP SENSOR SENSE CIRCUIT FOR SHORT TO HIGH VOLTAGE

R

econnect the battery negative terminal.

1

Turn the ignition swi

tch to the ON

position.

2

M

easure the voltage between PI42, pin 03 (R) and GROUND.

3

Is th

e voltage greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to S3

.

S

3: CHECK THE APP SENSOR SENSE CIRCUIT FOR SHORT TO GROUND

Turn the ignition swi

tch to the OFF

position.

1

Meas

ure the resistance between PI42, pin 03 (R) and GROUND.

2

Is

the resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to S4

.

S4:

CHECK THE APP SENSOR COMMON REFERENCE VOLTAGE AT THE SENSOR

Re

connect the ECM electrical connector, EM11.

1

Turn the ignition swi

tch to the ON

position.

2

Meas

ure the voltage between PI42, pin 04 (UW) and GROUND.

3

Is th

e voltage less than 4 volts?

Yes GO to S5

.

No

GO to S6

.

S5: CHECK

THE APP SENSOR COMM

ON REFERENCE VOLTAGE CIRCUIT

Turn the ignition swi

tch to the OFF

position.

1

Di

sconnect the battery negative terminal.

2

D

isconnect the ECM electrical connector, EM11.

3

Meas

ure the resistance between EM11,

pin 08 (UW) and PI42, pin 04 (UW).

4

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No Check the ECM power supplies.

REFER to Electronic Engine Controls

in this section.

S6: CHECK

THE APP SENSOR COMMON REFERENCE GROUND

Meas

ure the resistance between PI42, pin 02 (BG) and GROUND.

1

Is th

e resistance greater than 5 ohms?

Yes GO to S7

.

No

INSTALL a new APP sensor. CLEAR the DTC. TEST the system for normal operation.

S7: CHECK

THE APP SENSOR COMM

ON REFERENCE GROUND CIRCUIT

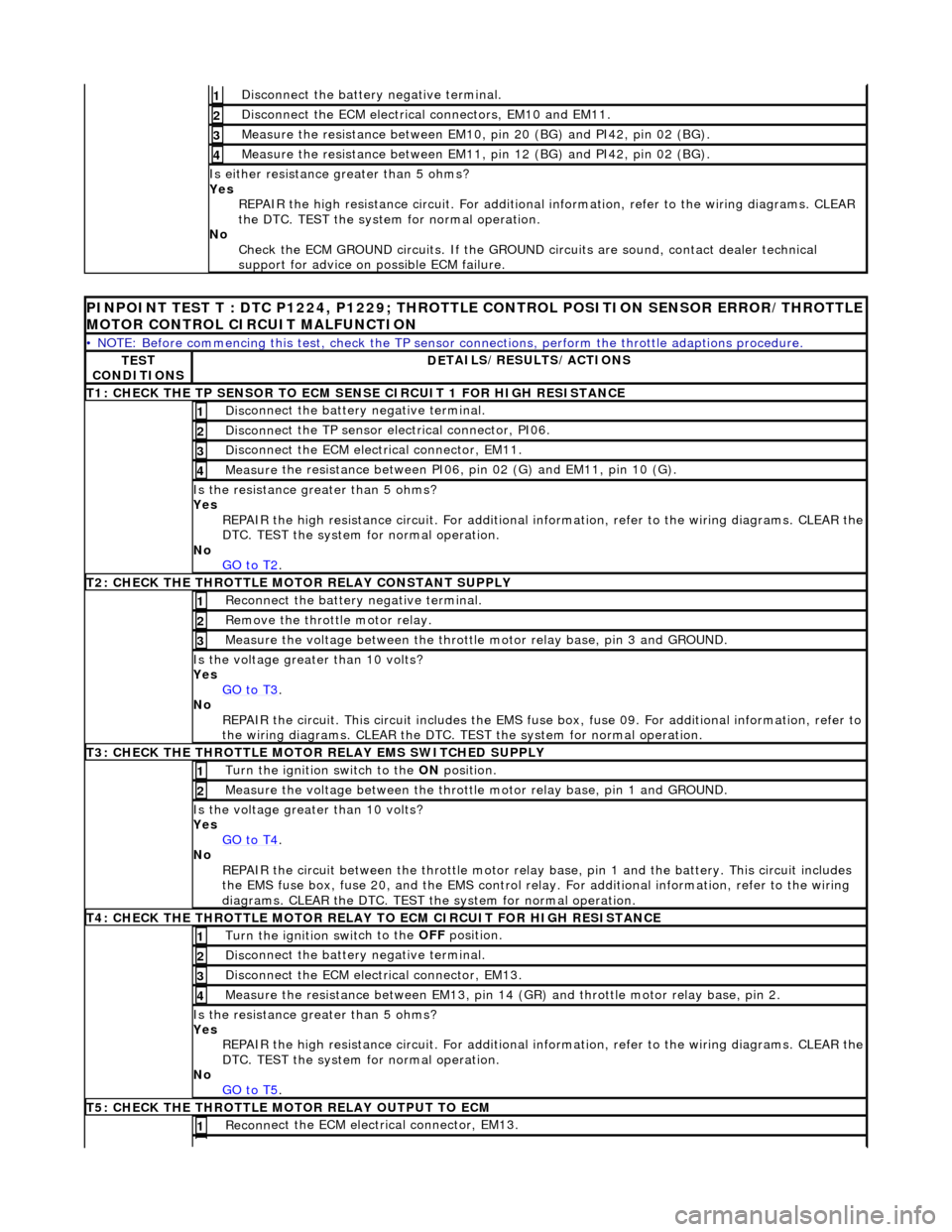

Page 1222 of 2490

Disc

onnect the battery negative terminal.

1

D

i

sconnect the ECM electrical connectors, EM10 and EM11.

2

Meas

ure t

he resistance between EM10,

pin 20 (BG) and PI42, pin 02 (BG).

3

Measure t

he resistance between EM11,

pin 12 (BG) and PI42, pin 02 (BG).

4

Is either resistance greater

than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No Check the ECM GROUND circuits. If the GROUND circuits are sound, contact dealer technical

support for advice on possible ECM failure.

PINPOINT TES

T T : DTC P1224, P1229; THROTTLE

CONTROL POSITION SENSOR ERROR/THROTTLE

MOTOR CONTROL CIRCUIT MALFUNCTION

•

NOTE: Before commencing this test, check the TP sensor

connections, perform the throttle adaptions procedure.

TES

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

T

1: CH

ECK THE TP SENSOR TO ECM SE

NSE CIRCUIT 1 FOR HIGH RESISTANCE

Disc

onnect the battery negative terminal.

1

Disc

onne

ct the TP sensor electrical connector, PI06.

2

D

i

sconnect the ECM electrical connector, EM11.

3

Me

asure

the resistance between PI06, pin 02 (G) and EM11, pin 10 (G).

4

Is th

e res

istance greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No GO to T2

.

T2

: CHECK THE THROTTLE MOTOR RELAY CONSTANT SUPPLY

R

e

connect the battery negative terminal.

1

R

e

move the thrott

le motor relay.

2

Measure t

he voltage between the throttle

motor relay base, pin 3 and GROUND.

3

Is the volt

age greater than 10 volts?

Yes GO to T3

.

No

R

EPAIR the circuit. This ci

rcuit includes the EMS fuse box, fuse 09. For addi tional information, refer to

the wiring diagrams. CLEAR the DTC. TE ST the system for normal operation.

T3

: CHECK THE THROTTLE MOTOR

RELAY EMS SWITCHED SUPPLY

Turn the ignition swit

ch to the

ON position.

1

Meas ure t

he voltage between the throttle

motor relay base, pin 1 and GROUND.

2

Is the volt

age greater than 10 volts?

Yes GO to T4

.

No

REP

AIR the circuit between the throttle motor relay

base, pin 1 and the battery. This circuit includes

the EMS fuse box, fuse 20, and the EMS control relay. For addition al information, refer to the wiring

diagrams. CLEAR the DTC. TEST th e system for normal operation.

T4

: CHECK THE THROTTLE MOTOR RELAY TO

ECM CIRCUIT FOR HIGH RESISTANCE

Turn the ignition swit

ch to the

OFF position.

1

Disc

onnect the battery negative terminal.

2

Di

sconnect the ECM electrical connector, EM13.

3

Measure t

he resistance between EM13, pin 14 (G

R) and throttle motor relay base, pin 2.

4

Is the res

istance greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No GO to T5

.

T5

: CHECK THE THROTTLE MOTOR RELAY OUTPUT TO ECM

Re

conn

ect the ECM electrical connector, EM13.

1

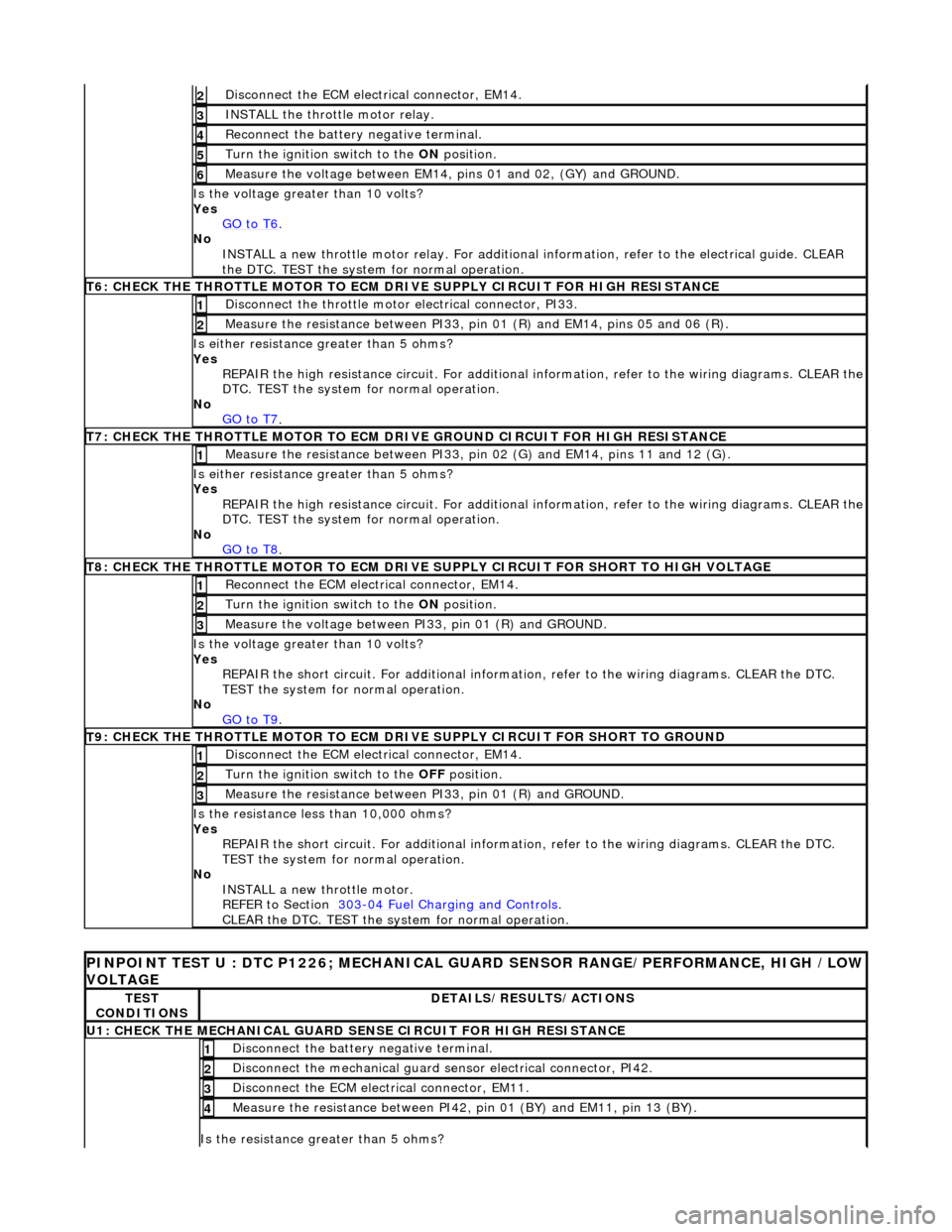

Page 1223 of 2490

D

isconnect the ECM electrical connector, EM14.

2

IN

STALL the throttle motor relay.

3

R

econnect the battery negative terminal.

4

Turn the ignition swi

tch to the

ON position.

5

Measure the

voltage between EM14, pi

ns 01 and 02, (GY) and GROUND.

6

Is the vol

tage greater than 10 volts?

Yes GO to T6

.

No

INSTALL a new throttle motor relay. For additional information, refer to the electrical guide. CLEAR

the DTC. TEST the system for normal operation.

T

6: CHECK THE THROTTLE MOTOR TO ECM DRIVE SUPPLY CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the throttle motor electrical connector, PI33.

1

Meas

ure the resistance between PI33, pi

n 01 (R) and EM14, pins 05 and 06 (R).

2

Is either resi

stance

greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No GO to T7

.

T

7: CHECK THE THROTTLE MOTOR TO ECM DRIVE GROUND CIRCUIT FOR HIGH RESISTANCE

Meas

ure the resistance between PI33, pin

02 (G) and EM14, pins 11 and 12 (G).

1

Is either resi

stance

greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No GO to T8

.

T

8: CHECK THE THROTTLE MOTOR TO ECM DRIVE SU

PPLY CIRCUIT FOR SHORT TO HIGH VOLTAGE

Re

connect the ECM electrical connector, EM14.

1

Turn the ignition swi

tch to the

ON position.

2

M

easure the voltage between PI33, pin 01 (R) and GROUND.

3

Is the vol

tage greater than 10 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to T9

.

T

9: CHECK THE THROTTLE MOTOR TO ECM DRIVE SUPPLY CIRCUIT FOR SHORT TO GROUND

D

isconnect the ECM electrical connector, EM14.

1

Turn the ignition swi

tch to the

OFF position.

2

Meas

ure the resistance between PI33, pin 01 (R) and GROUND.

3

Is

the resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No INSTALL a new throttle motor.

REFER to Section 303

-0

4 Fuel Charging and Controls

.

CLEAR t

he DTC. TEST the system for normal operation.

P

INPOINT TEST U : DTC P1226; MECHANICAL

GUARD SENSOR RANGE/PERFORMANCE, HIGH /LOW

VOLTAGE

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

U1: CHECK T

HE MECHANICAL GUARD SENSE CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

Di

sconnect the mechanical guard sensor electrical connector, PI42.

2

D

isconnect the ECM electrical connector, EM11.

3

Me

asure the resistance between PI42, pin 01 (BY) and EM11, pin 13 (BY).

4

Is th

e resistance greater than 5 ohms?

Page 1231 of 2490

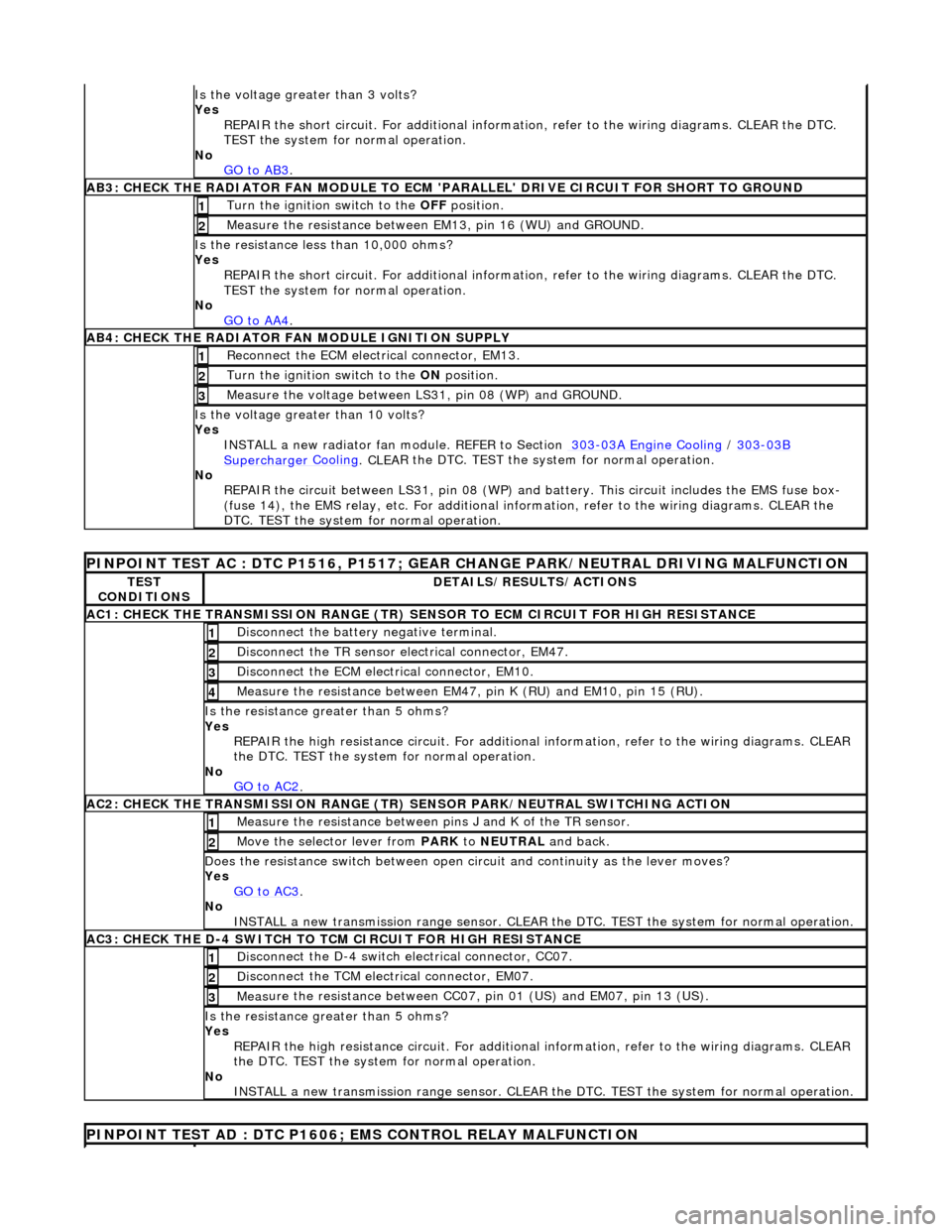

Is th

e voltage greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to AB3

.

AB3

: CHECK THE RADIATOR FAN MODULE TO ECM

'PARALLEL' DRIVE CIRCUIT FOR SHORT TO GROUND

Turn the ignition swi

tch to the OFF

position.

1

Meas

ure the resistance between EM13, pin 16 (WU) and GROUND.

2

Is

the resistance less than 10,000 ohms?

Yes

REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to AA4

.

AB4

: CHECK THE RADIATOR FAN MODULE IGNITION SUPPLY

Re

connect the ECM electrical connector, EM13.

1

Turn the ignition swi

tch to the ON

position.

2

Measure the

voltage between LS

31, pin 08 (WP) and GROUND.

3

Is the vol

tage greater than 10 volts?

Yes INSTALL a new radiator fan module. REFER to Section 303

-0

3A Engine Cooling

/

30

3

-03

B

Supercharger

Cooling

. CLEA

R the DTC. TEST the sy

stem for normal operation.

No REPAIR the circuit between LS31, pin 08 (WP) and battery. This circuit includes the EMS fuse box-

(fuse 14), the EMS relay, etc. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

P

INPOINT TEST AC : DTC P1516, P1517; GEAR

CHANGE PARK/NEUTRAL DRIVING MALFUNCTION

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

AC1: CH

ECK THE TRANSMISSION RANGE (TR) SE

NSOR TO ECM CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

Di

sconnect the TR sensor el

ectrical connector, EM47.

2

D

isconnect the ECM electrical connector, EM10.

3

Meas

ure the resistance between EM47, pin K (RU) and EM10, pin 15 (RU).

4

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to AC2

.

AC2: CH

ECK THE TRANSMISSION RANGE (TR)

SENSOR PARK/NEUTRAL SWITCHING ACTION

Meas

ure the resistance between pi

ns J and K of the TR sensor.

1

Mo

ve the selector lever from

PARK to NEUTRAL and back.

2

D

oes the resistance switch between open ci

rcuit and continuity as the lever moves?

Yes GO to AC3

.

No

INSTALL a new transmission range sensor. CLEAR th e DTC. TEST the system for normal operation.

AC3: CH

ECK THE D-4 SWITCH TO

TCM CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the D-4 switch electrical connector, CC07.

1

Di

sconnect the TCM electrical connector, EM07.

2

Meas

ure the resistance between CC07,

pin 01 (US) and EM07, pin 13 (US).

3

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No INSTALL a new transmission range sensor. CLEAR th e DTC. TEST the system for normal operation.

P

INPOINT TEST AD : DTC P1606;

EMS CONTROL RELAY MALFUNCTION

Page 1241 of 2490

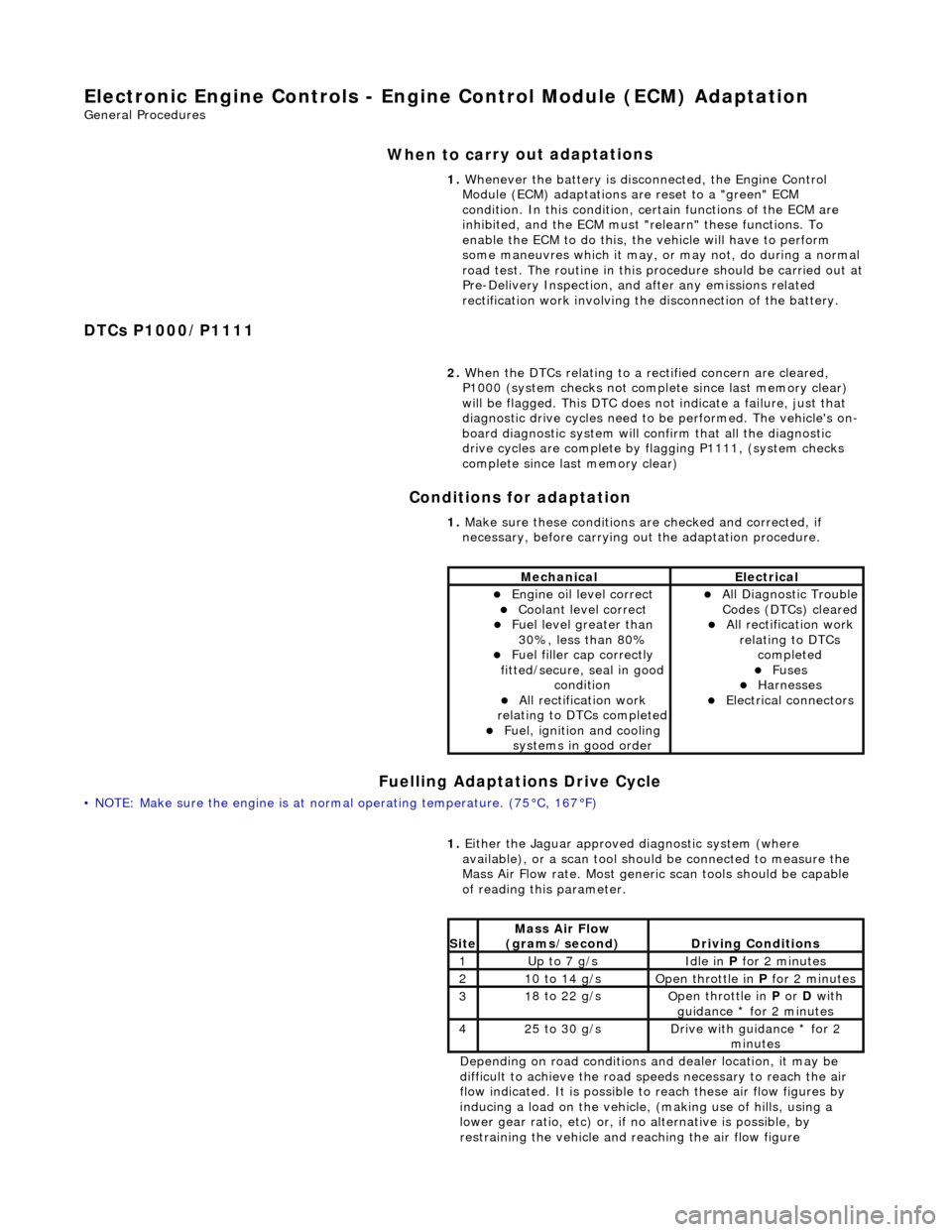

E

lectronic Engine Controls - Engine

Control Module (ECM) Adaptation

Gen

eral Procedures

When to car

ry out adaptations

DTCs P1000/P1111 Conditions for adaptation

Fuelling Adaptations Drive Cycle

•

NOTE: Make sure the engine is at normal operating

temperature. (75°C, 167°F) 1.

Whenever the battery is disconnected, the Engine Control

Module (ECM) adaptations are reset to a "green" ECM

condition. In this condition, certain functions of the ECM are

inhibited, and the ECM must "r elearn" these functions. To

enable the ECM to do this, the vehicle will have to perform

some maneuvres which it may, or may not, do during a normal

road test. The routine in this pr ocedure should be carried out at

Pre-Delivery Inspection, and after any emissions related

rectification work involving the disconnection of the battery.

2. When the DTCs relating to a rectified concern are cleared,

P1000 (system checks not complete since last memory clear)

will be flagged. This DTC does no t indicate a failure, just that

diagnostic drive cycles need to be performed. The vehicle's on-

board diagnostic system will confirm that all the diagnostic

drive cycles are complete by flagging P1111, (system checks

complete since last memory clear)

1. Make sure these conditions are checked and corrected, if

necessary, before carrying ou t the adaptation procedure.

MechanicalElectrical

Engi

ne oil level correct

Coo

lant level correct

F

uel level greater than

30%, less than 80%

F

uel filler cap correctly

fitted/secure, seal in good condition

Al

l rectification work

relating to DTCs completed

F

uel, ignition and cooling

systems in good order

Al

l Diagnostic Trouble

Codes (DTCs) cleared

Al

l rectification work

relating to DTCs completed

F

uses

Harnes

ses

E

lectrical connectors

1.

Either

the Jaguar approved diagnostic system (where

available), or a scan tool should be connected to measure the

Mass Air Flow rate. Most generi c scan tools should be capable

of reading this parameter.

Depending on road conditions and dealer location, it may be

difficult to achieve the road sp eeds necessary to reach the air

flow indicated. It is possible to reach these air flow figures by

inducing a load on the vehicle, (making use of hills, using a

lower gear ratio, etc) or, if no alternative is possible, by

restraining the vehicle and re aching the air flow figure

Si

te

Mass Air Flow

(gra

ms/second)

D

riving Conditions

1Up t

o 7 g/s

Idle

in

P for 2 minutes

21

0 to 14 g/s

O

pen throttle in

P for 2 minutes

31

8 to 22 g/s

O

pen throttle in

P or D with

guidance * for 2 minutes

42

5 to 30 g/s

D

rive with guidance * for 2

minutes

Page 1251 of 2490

E

lectronic Engine Controls - Inta

ke Air Temperature (IAT) Sensor

Re

moval and Installation

Remov

al

Installation

1.

Di

sconnect sensor connector at

rear of bank 1 charge air

cooler.

2. Re

move sensor.

Re

move sensor using a deep socket.

Discard sealin

g washer.

1. Installation is a reversal of the removal procedure.

Page 1256 of 2490

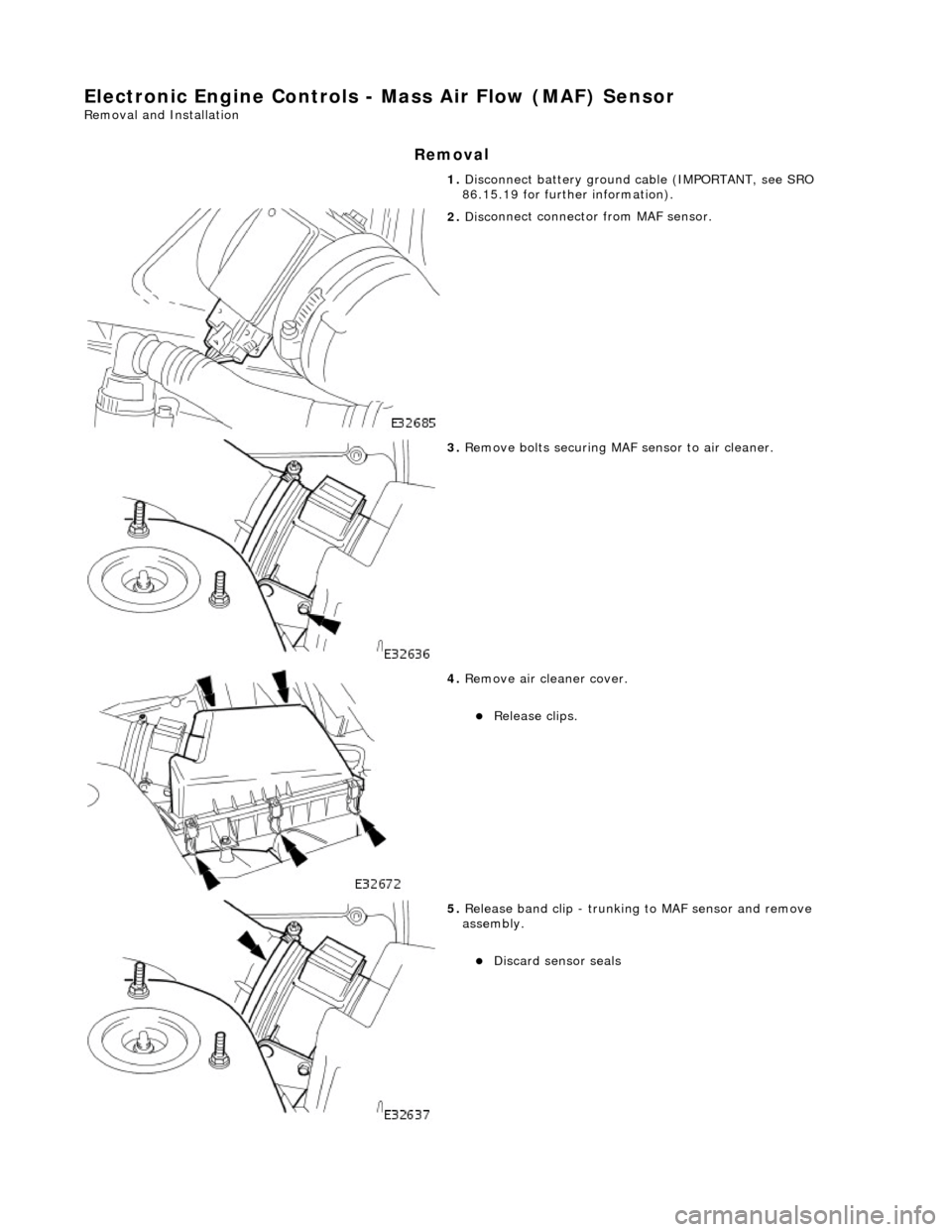

El

ectronic Engine Controls -

Mass Air Flow (MAF) Sensor

Remo

val and Installation

Remov

a

l

1.

Disc onne

ct battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. Disc

onnect connector from MAF sensor.

3. Re

move bolts securing MAF sensor to air cleaner.

4. Re

move air cleaner cover.

Re

lea

se clips.

5. Re

lease band clip - trunking to MAF sensor and remove

assembly.

Di sc

ard sensor seals

Page 1339 of 2490

Automatic Transmission/Transaxle - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

- Electronic Pressure Control (EPC) Solenoid

In-vehicle Repair

Removal

1. Disconnect battery ground cable.

Remove the battery cover.

2. Raise the vehicle on a suitable lift.

2. WARNING: TRANSMISSION FLUID MAY CAUSE

SEVERE BURNS, ENSURE THAT ALL SAFETY PROCEDURES

ARE OBSERVED.

Carefully remove the drain plug and drain the

transmission fluid.

3. Remove the twenty-two fixings which secure the fluid pan .

Remove the fluid pan and all traces of gasket material.

4. Disconnect regulator / solenoid connectors.

5. Remove RH rear valve body securing screws.

Page 1348 of 2490

Automatic Transmission/Transaxle - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

- Main Control Valve Body

In-vehicle Repair

Removal

1. Disconnect battery ground cable.

Remove the battery cover.

2. Raise the vehicle for access.

2. WARNING: TRANSMISSION FLUID MAY CAUSE

SEVERE BURNS, ENSURE THAT ALL SAFETY PROCEDURES

ARE OBSERVED.

Carefully remove the drain plug and drain the

transmission fluid.

3. Remove the twenty-two bolts which secure the fluid pan.

Remove the fluid pan and all tr aces of gasket material.

4. Remove the fluid filter, (44.24.07).

5. Remove the input speed sensor.

• NOTE: M5 fixing.

1. Remove the screw from the input speed sensor securing bracket and pu ll the sensor clear.

Disconnect the harness multiplug.