JAGUAR X308 1998 2.G Workshop Manual

X308 1998 2.G

JAGUAR

JAGUAR

https://www.carmanualsonline.info/img/21/7640/w960_7640-0.png

JAGUAR X308 1998 2.G Workshop Manual

Trending: check transmission fluid, door control module, center console, front bearing, Amp, power steering fluid, seat motor fuse

Page 1301 of 2490

With EM007 and EM046 disconnected, measure the

resistance in turn; 1

EM007/005 and EM046/002 2

EM007/001 and EM046/003 3

EM007/029 and EM046/007 4

EM007/004 and EM046/011 5

EM007/051 and EM046/015 6

Is the resistance < 0.5 OHM?

Yes GO to D8

No Inspect harness / connectors EM007 and EM046 for damage,

corrosion, bent / pushed back pins. Repair as necessary and

test the system for normal operation.

D8: CHECK FOR PRESSURE REGULATOR SHORT TO B+

Page 1302 of 2490

With EM007 and EM046 disconnected, measure the

resistance between EM007/005 and EM007/026 1

Repeat for EM007/001 and EM007/026 2

EM007/029 and EM007/026 3

EM007/004 and EM007/026 4

EM007/051 and EM007/026 5

Is the resistance > 10 MOHM?

Yes GO to D9

No Inspect harness / connectors EM007 and EM046 for damage,

corrosion, bent / pushed back pins. Repair as necessary and

test the system for normal operation.

D9: CHECK HARNESS SHORT TO GROUND

Page 1303 of 2490

With EM007 and EM046 disconnected, measure the

resistance between EM007/005 and EM008R 1

Repeat for EM007/001 and EM008R 2

EM007/029 and EM008R 3

EM007/004 and EM008R 4

EM007/051 and EM008R 5

Is the resistance > 10 MOHM?

Yes GO to D10

No Inspect harness / connectors EM007 for damage, corrosion,

bent / pushed back pins. Repa ir as necessary and test the

system for normal operation.

D10: CHECK FOR SHORT TO IGNITION

Page 1304 of 2490

With EM007 and EM046 disconnected, measure the

resistance between EM007/005 and EM007/054

Repeat for

1

EM007/001 and EM007/054 2

EM007/029 and EM007/054 3

EM007/004 and EM007/054 4

EM007/051 and EM007/054 5

Is the resistance > 10 MOHM?

Yes Reconnect EM046

GO to D11

No Inspect harness / connectors EM007 for damage, corrosion,

bent / pushed back pins. Repa ir as necessary and test the

system for normal operation.

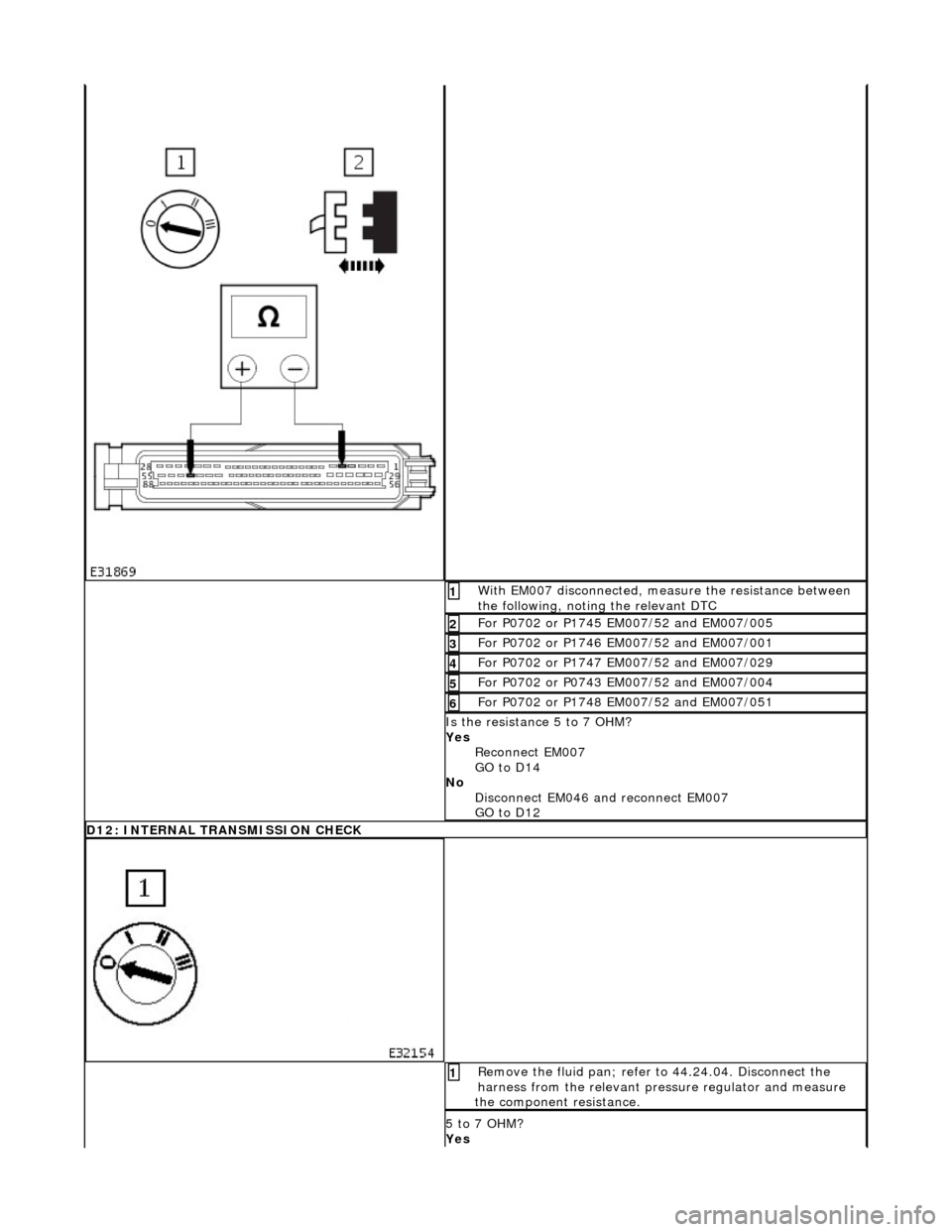

D11: CHECK INTERNAL HARNESS AND COMPON ENT CONTINUITY - PRESSURE REGULATORS

Page 1305 of 2490

With EM007 disconnected, measure the resistance between

the following, noting the relevant DTC 1

For P0702 or P1745 EM007/52 and EM007/005 2

For P0702 or P1746 EM007/52 and EM007/001 3

For P0702 or P1747 EM007/52 and EM007/029 4

For P0702 or P0743 EM007/52 and EM007/004 5

For P0702 or P1748 EM007/52 and EM007/051 6

Is the resistance 5 to 7 OHM?

Yes Reconnect EM007

GO to D14

No Disconnect EM046 and reconnect EM007

GO to D12

D12: INTERNAL TRANSMISSION CHECK

Remove the fluid pan; refer to 44.24.04. Disconnect the

harness from the relevant pres sure regulator and measure

the component resistance. 1

5 to 7 OHM?

Yes

Page 1306 of 2490

Pinpoint test E: P1720 (P0721)

GO to D13

No Renew the pressure regulator; refer to 44.15.51.

D13: INTERNAL TRANSMISSION HARNESS CHECK

Measure the resistance from transmission internal harness

multiplug to the relevant pr essure regulator connector 1

Is the resistance < 0.5 OHM?

Yes

GO to D14

No Renew the internal harnes s; refer to 44.15.35.

D14: END

Cycle the ignition ON - (OFF for 2 minutes) - ON, start the

engine and run >1600 rpm 1

Has the fault code cleared?

Yes

STOP

No Contact Jaguar Service

PINPOINT TEST E : P1720 (P0721)

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

E1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present.

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to E2

E2: CHECK HARNESS +VE CONTIN UITY (OUTPUT SPEED SENSOR)

Page 1307 of 2490

With EM007 and EM046 disconnected, measure the

resistance between EM046/001 and EM007/016 1

Is the resistance < 0.5 OHM?

Yes Reconnect EM046

GO to E3

No Inspect harness / connectors EM007 and EM046 for damage,

corrosion, bent / pushed back pins. Repair as necessary and

test the system for normal operation.

E3: CHECK HARNESS -VE CONTINUITY (OUTPUT SPEED SENSOR)

Page 1308 of 2490

With EM007 and EM046 disconnected, measure the

resistance between EM046/010 and EM007/044 1

Is the resistance < 0.5 OHM?

Yes GO to E4

No Inspect harness / connectors EM007 and EM046 for damage,

corrosion, bent / pushed back pins. Repair as necessary and

test the system for normal operation.

E4: CHECK OUTPUT SPEED SENSOR COIL CONTINUITY

Page 1309 of 2490

With, EM007 disconnected, measure the sensor value

between EM007/016 and EM007/044 1

Is the resistance between 280 and 1200 OHM?

Yes GO to E5

No Renew the output speed sensor.

E5: CHECK FOR SHORT TO B+

With EM007 disconnected, measure the voltage between

EM007/015 and EM007/044 1

Repeat for EM007/016 and EM007/044 2

0V?

Yes GO to E6

No Inspect harness / connectors EM007 and EM046 for damage,

corrosion, bent / pushed back pins. Repair as necessary and

test the system for normal operation.

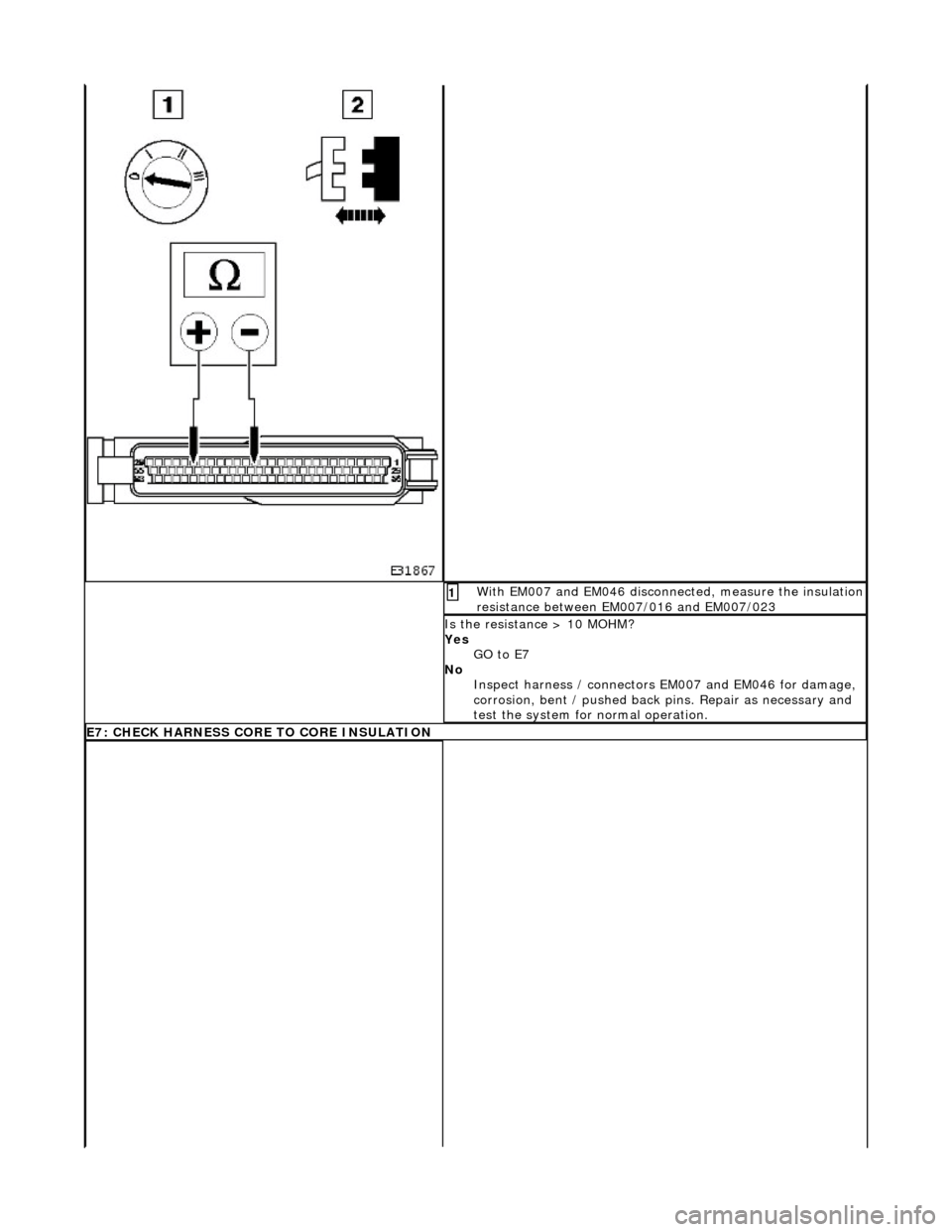

E6: CHECK HARNESS SHORT TO SCREEN

Page 1310 of 2490

With EM007 and EM046 disconnected, measure the insulation resistance between EM007/016 and EM007/023 1

Is the resistance > 10 MOHM?

Yes GO to E7

No Inspect harness / connectors EM007 and EM046 for damage,

corrosion, bent / pushed back pins. Repair as necessary and

test the system for normal operation.

E7: CHECK HARNESS CORE TO CORE INSULATION

Trending: heating, Adaptive fuse, nozzle, sensor, water pump, radio controls, wiring diagram