Joint JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1674 of 2490

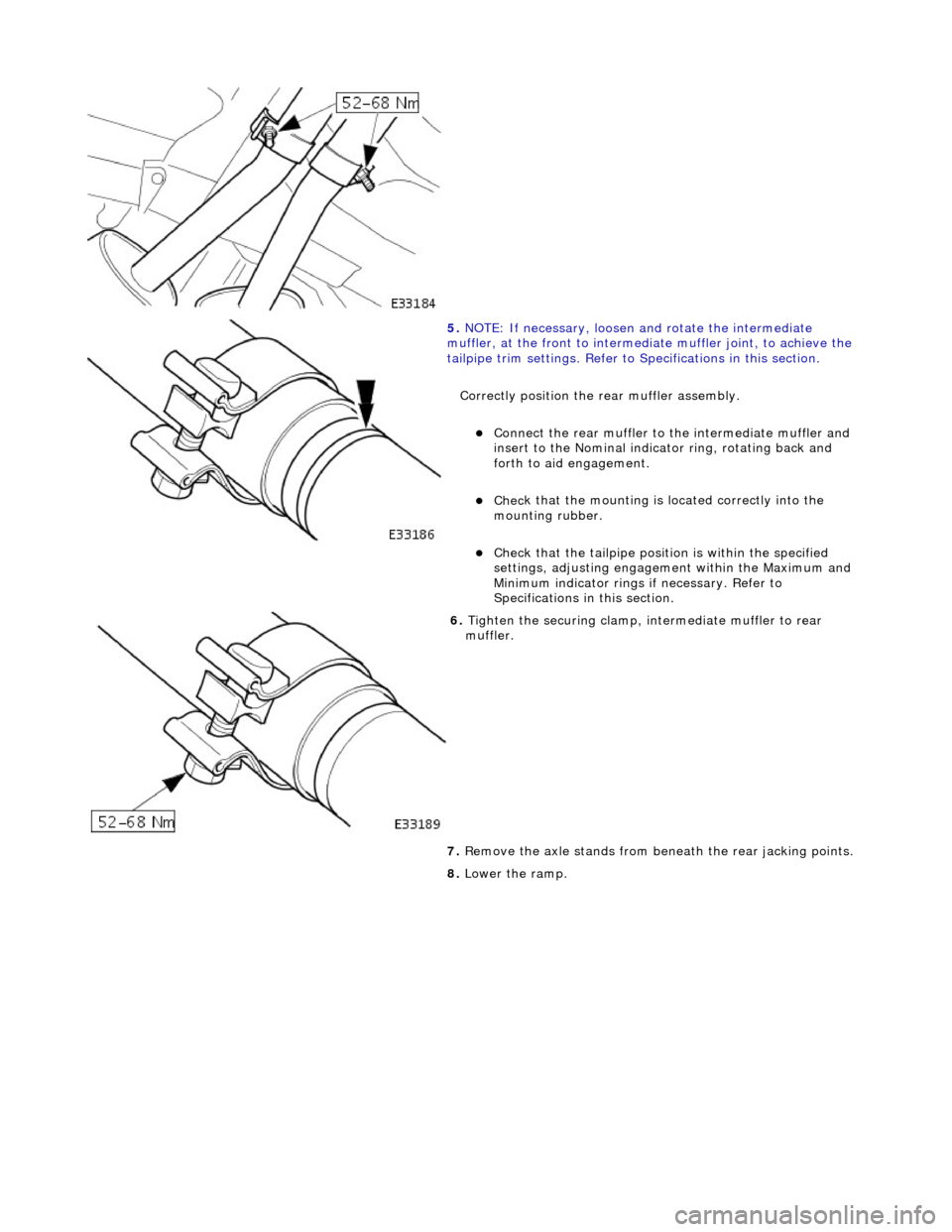

5.

NO TE

: If necessary, loosen and rotate the intermediate

muffler, at the front to intermediate muffler joint, to achieve the

tailpipe trim settings. Refer to Specifications in this section.

Correctly position the rear muffler assembly.

Connect the rear muffl

er to the intermediate muffler and

insert to the Nominal indicator ring, rotating back and

forth to aid engagement.

Chec k

that the mounting is located correctly into the

mounting rubber.

Chec k

that the tailpi

pe position is wi thin the specified

settings, adjusting engageme nt within the Maximum and

Minimum indicator rings if necessary. Refer to

Specifications in this section.

6. Tigh te

n the securing clamp, in

termediate muffler to rear

muffler.

7. Remove the axle stands from be neath the rear jacking points.

8. Lower the ramp.

Page 1675 of 2490

Exhaust System - Intermediate Muffler LH4

.0L SC V8 - AJ26

Re

moval and Installation

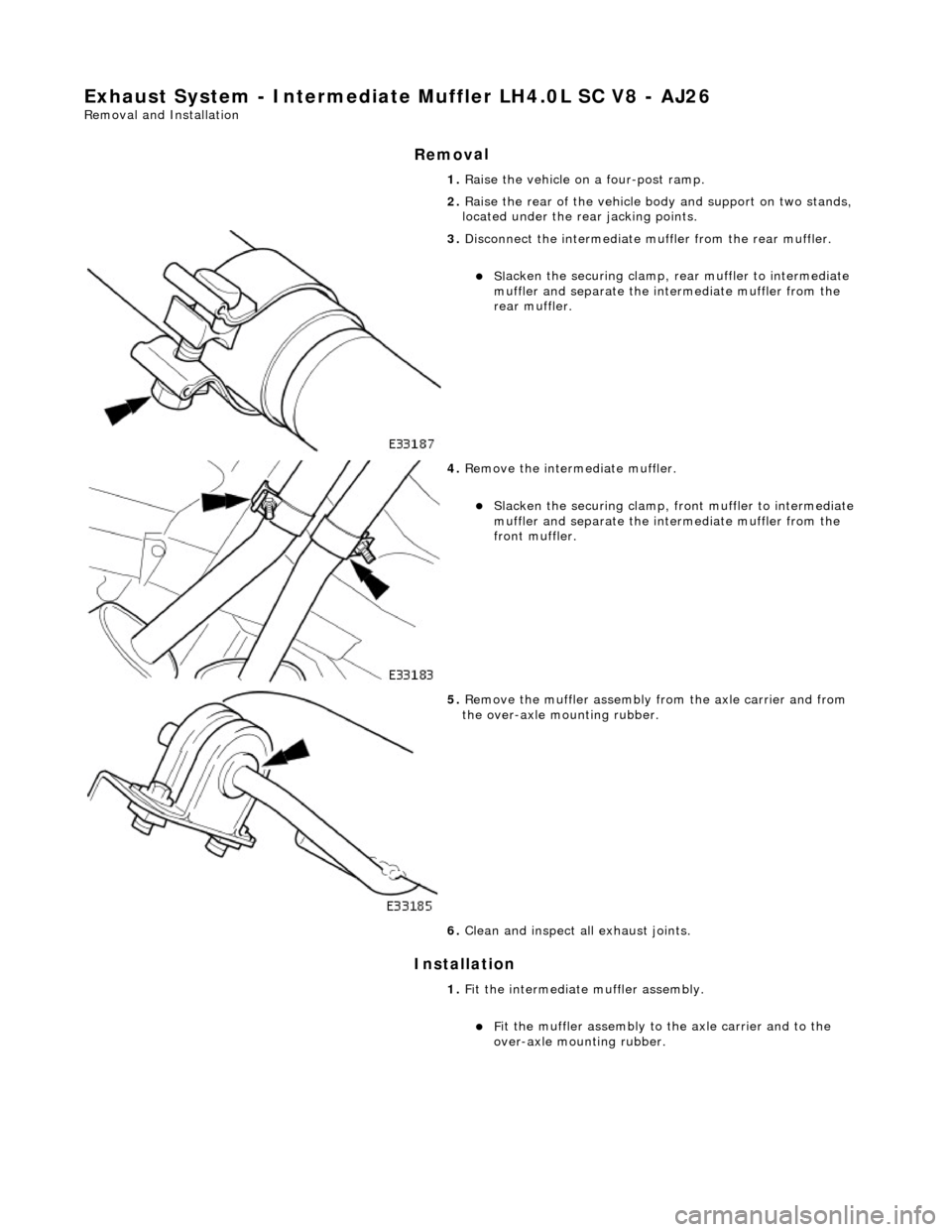

Remov

al

Installation

1. R

aise the vehicle on a four-post ramp.

2. Raise the rear of the vehicle bo dy and support on two stands,

located under the re ar jacking points.

3. Di

sconnect the intermediate

muffler from the rear muffler.

Sl

acken the securing clamp, re

ar muffler to intermediate

muffler and separate the in termediate muffler from the

rear muffler.

4. R

emove the intermediate muffler.

Sl

acken the securing clamp, front muffler to intermediate

muffler and separate the in termediate muffler from the

front muffler.

5. R

emove the muffler assembly

from the axle carrier and from

the over-axle mounting rubber.

6. Clean and inspect al l exhaust joints.

1. Fit the intermediate muffler assembly.

F

it the muffler assembly to the axle carrier and to the

over-axle mounting rubber.

Page 1676 of 2490

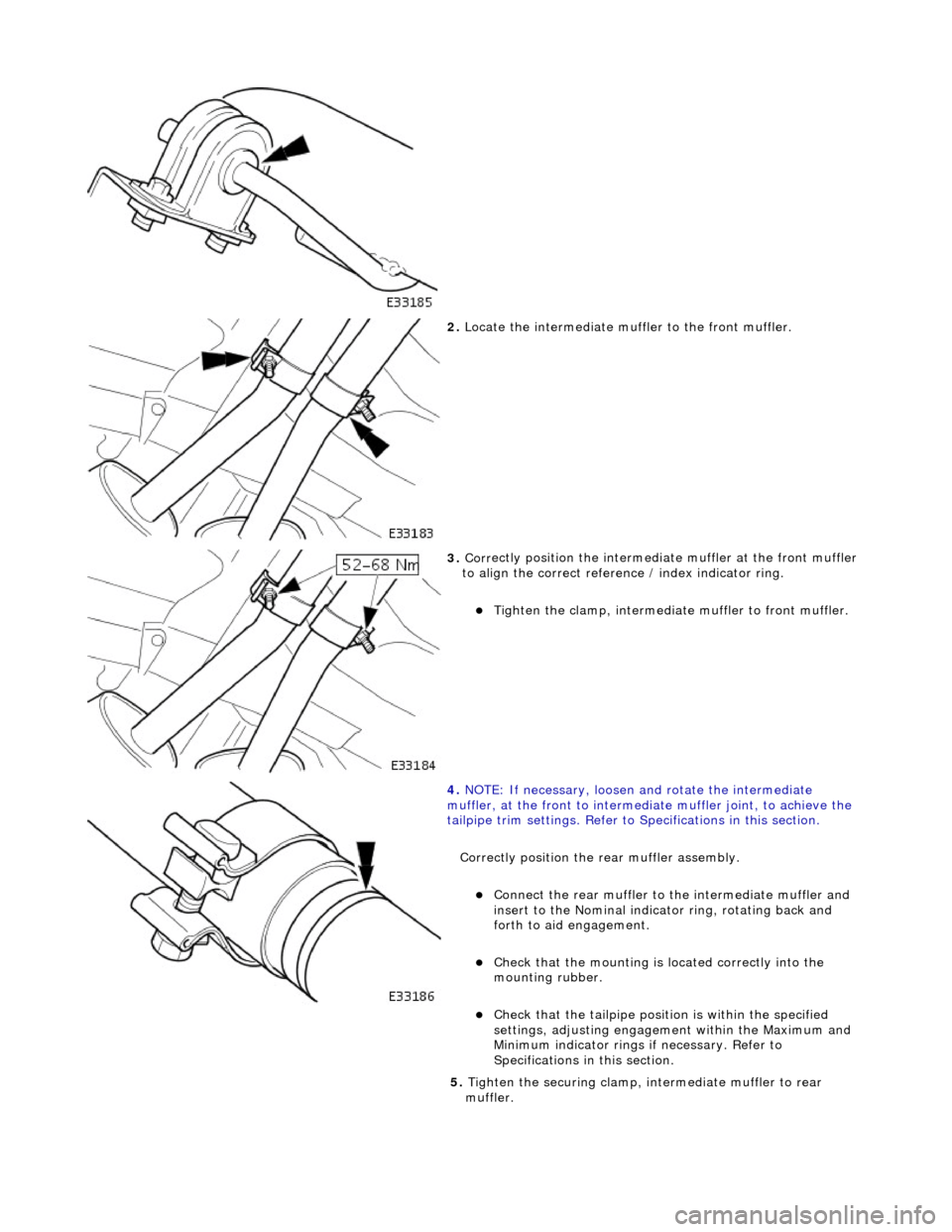

2. Locate the intermediate muffl er to the front muff

ler.

3. Cor r

ectly position the intermedia

te muffler at the front muffler

to align the correct refere nce / index indicator ring.

Tighte

n the clamp, intermediate

muffler to front muffler.

4. NO TE

: If necessary, loosen and rotate the intermediate

muffler, at the front to intermediate muffler joint, to achieve the

tailpipe trim settings. Refer to Specifications in this section.

Correctly position the rear muffler assembly.

Connect the rear muffl

er to the intermediate muffler and

insert to the Nominal indicator ring, rotating back and

forth to aid engagement.

Chec k

that the mounting is located correctly into the

mounting rubber.

Chec k

that the tailpi

pe position is wi thin the specified

settings, adjusting engageme nt within the Maximum and

Minimum indicator rings if necessary. Refer to

Specifications in this section.

5. Tighten the securing clamp, in termediate muffler to rear

muffler.

Page 1679 of 2490

I

nstallation

7.

Clean and inspect al l e

xhaust joints.

1. Fi

t the intermediate muffler assembly.

F

it the muffler assembly to the axle carrier and to the

over-axle mounting rubber.

2. Locate the intermedi

ate muffl

er to the front muffler.

3. Cor

rectly position the front muffl

er in the catalytic converters

to align the correct reference / index indicator ring..

Tigh

ten the clamps (left-hand

and right-hand sides), front

muffler to catalytic converters.

4. Correctly position the intermedia te muffler at the front muffler

to align the correct reference / index indicator ring..

Tigh

ten the clamp, intermediate

mufflers to front muffler.

Page 1680 of 2490

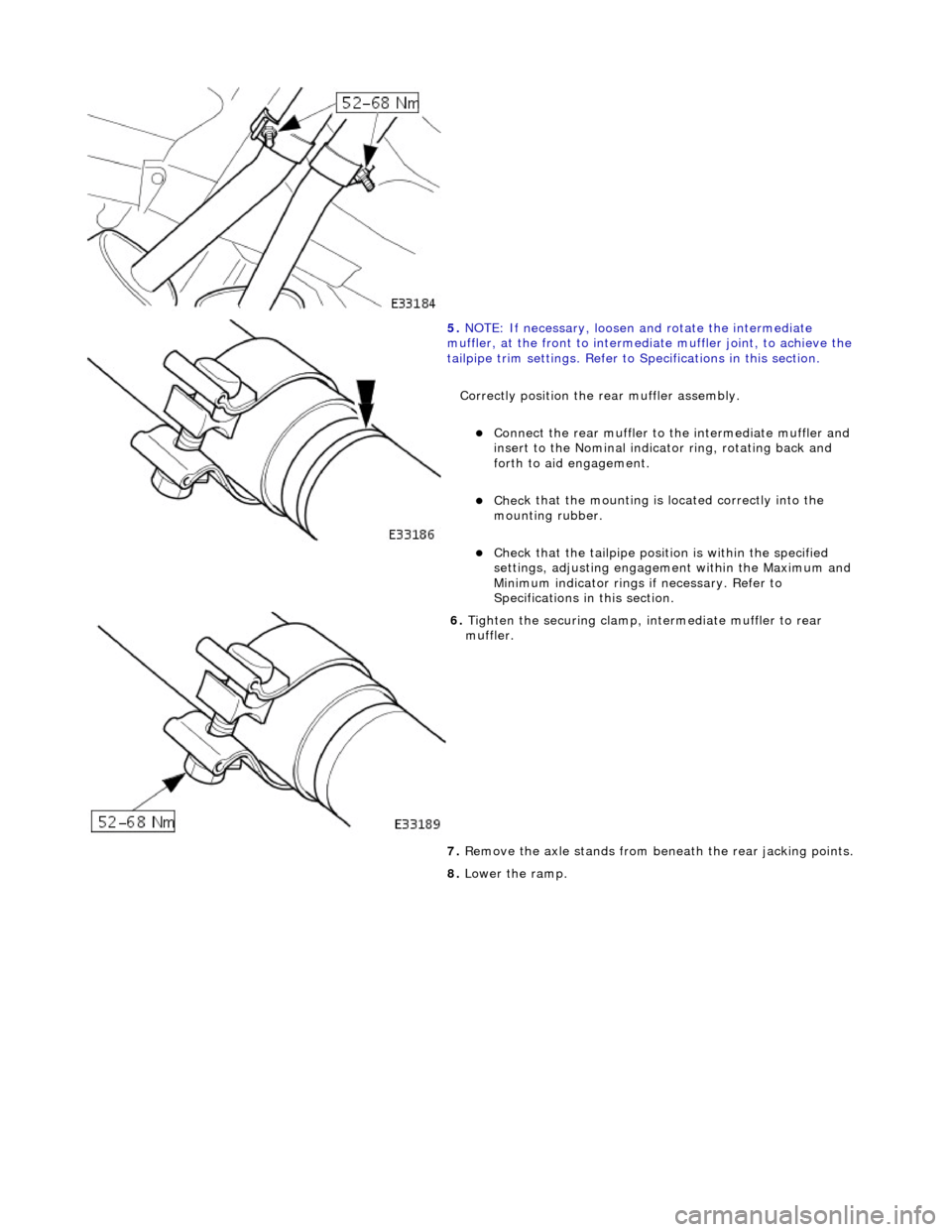

5.

NO TE

: If necessary, loosen and rotate the intermediate

muffler, at the front to intermediate muffler joint, to achieve the

tailpipe trim settings. Refer to Specifications in this section.

Correctly position the rear muffler assembly.

Connect the rear muffl

er to the intermediate muffler and

insert to the Nominal indicator ring, rotating back and

forth to aid engagement.

Chec k

that the mounting is located correctly into the

mounting rubber.

Chec k

that the tailpi

pe position is wi thin the specified

settings, adjusting engageme nt within the Maximum and

Minimum indicator rings if necessary. Refer to

Specifications in this section.

6. Tigh te

n the securing clamp, in

termediate muffler to rear

muffler.

7. Remove the axle stands from be neath the rear jacking points.

8. Lower the ramp.

Page 1681 of 2490

Exhaust System - Intermediate Muffler RH4

.0L SC V8 - AJ26

Re

moval and Installation

Remov

al

Installation

1. R

aise the vehicle on a four-post ramp.

2. Raise the rear of the vehicle bo dy and support on two stands,

located under the re ar jacking points.

3. Di

sconnect the intermediate

muffler from the rear muffler.

Sl

acken the securing clamp, re

ar muffler to intermediate

muffler and separate the in termediate muffler from the

rear muffler.

4. R

emove the intermediate muffler.

Sl

acken the securing clamp, front muffler to intermediate

muffler and separate the in termediate muffler from the

front muffler.

5. R

emove the muffler assembly

from the axle carrier and from

the over-axle mounting rubber.

6. Clean and inspect al l exhaust joints.

1. Fit the intermediate muffler assembly.

F

it the muffler assembly to the axle carrier and to the

over-axle mounting rubber.

Page 1682 of 2490

2. Locate the intermediate muffl er to the front muff

ler.

3. Cor r

ectly position the intermedia

te muffler at the front muffler

to align the correct refere nce / index indicator ring.

Tighte

n the clamp, intermediate

muffler to front muffler.

4. NO TE

: If necessary, loosen and rotate the intermediate

muffler, at the front to intermediate muffler joint, to achieve the

tailpipe trim settings. Refer to Specifications in this section.

Correctly position the rear muffler assembly.

Connect the rear muffl

er to the intermediate muffler and

insert to the Nominal indicator ring, rotating back and

forth to aid engagement.

Chec k

that the mounting is located correctly into the

mounting rubber.

Chec k

that the tailpi

pe position is wi thin the specified

settings, adjusting engageme nt within the Maximum and

Minimum indicator rings if necessary. Refer to

Specifications in this section.

5. Tighten the securing clamp, in termediate muffler to rear

muffler.

Page 1684 of 2490

Ex

haust System - Muff

ler and Tailpipe LH

Remo

val and Installation

Remov

a

l

Installation

1. Ra

ise the vehicle on a four-post ramp.

2. Slacken the securi

ng clamp, re

ar muffler to intermediate

muffler.

3. Re

move the rear muffler

and tailpipe assembly.

Separate the rear muffl er fr

om

the intermediate muffler.

Di

sengage the rear muffler mounting peg from the

mounting rubber.

R e

move the rear muffler asse

mbly. Rotate the assembly

back and forth to aid removal.

4. Clean the exhaust joints.

1. Fi

t the rear muffler and tailpipe assembly.

Connect

the rear muffl

er to the intermediate muffler and

insert to the Nominal indicator ring.

2. Position and align the rear mu ffler and tailpipe assembly.

Engage the peg with

the mounting rubber.

Chec

k

that the tailpi

pe position is wi thin the specified

settings, adjusting engageme nt within the Maximum and

Minimum indicator rings if necessary; refer to

Specifications in this section.

Page 1686 of 2490

Ex

haust System - Muff

ler and Tailpipe RH

Remo

val and Installation

Remov

a

l

Installation

1. Ra

ise the vehicle on a four-post ramp.

2. Slacken the securi

ng clamp, re

ar muffler to intermediate

muffler.

3. Re

move the rear muffler

and tailpipe assembly.

Separate the rear muffl er fr

om

the intermediate muffler.

Di

sengage the rear muffler mounting peg from the

mounting rubber.

R e

move the rear muffler asse

mbly. Rotate the assembly

back and forth to aid removal.

4. Clean the exhaust joints.

1. Fi

t the rear muffler and tailpipe assembly.

Connect

the rear muffl

er to the intermediate muffler and

insert to the Nominal indicator ring.

2. Position and align the rear mu ffler and tailpipe assembly.

Engage the peg with

the mounting rubber.

Chec

k

that the tailpi

pe position is wi thin the specified

settings, adjusting engageme nt within the Maximum and

Minimum indicator rings if necessary; refer to

Specifications in this section.

Page 1756 of 2490

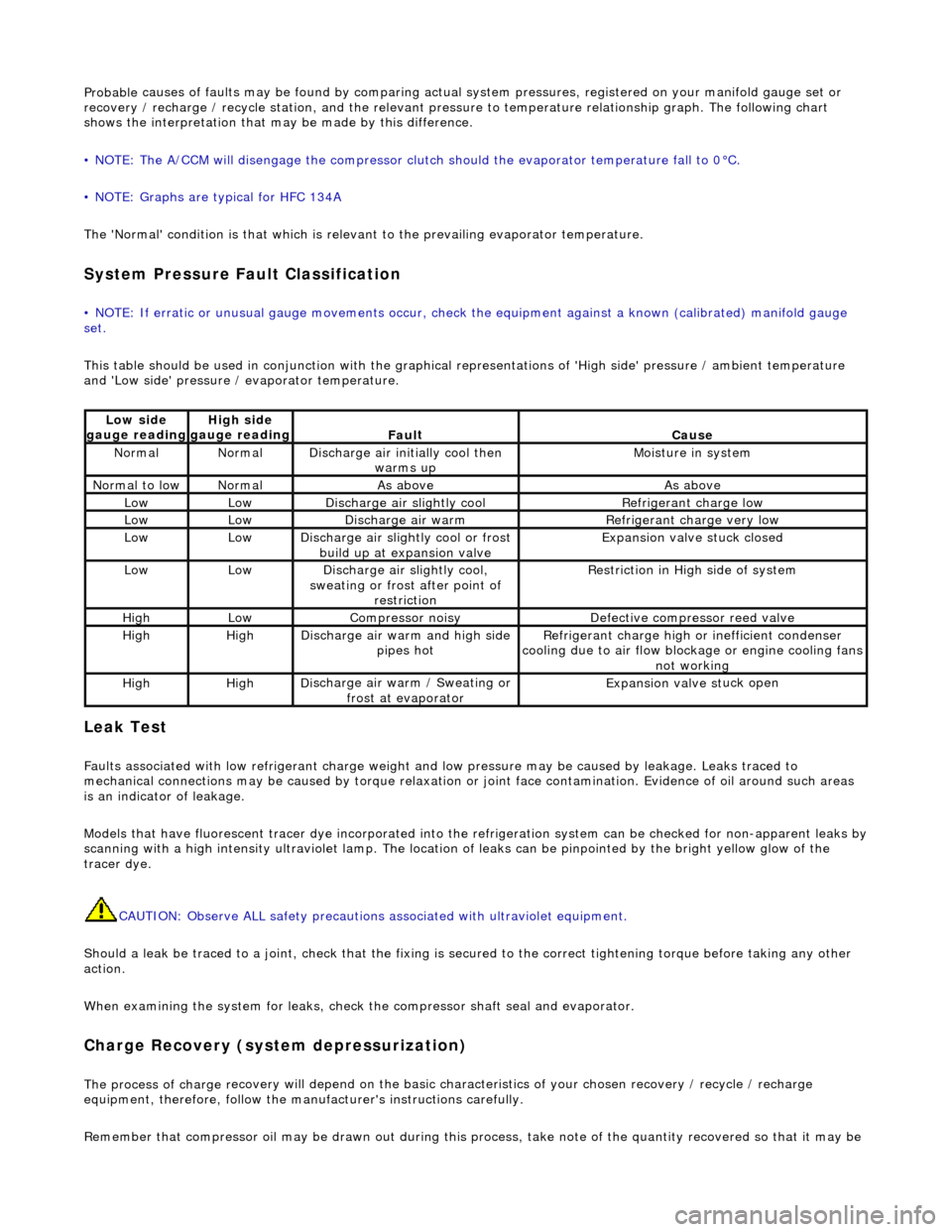

Probable

causes of faults may be found by comparing actual

system pressures, registered on your manifold gauge set or

recovery / recharge / recycle station, and the relevant pressure to temperature relationship graph. The following chart

shows the interpretation that ma y be made by this difference.

• NOTE: The A/CCM will disengage the compressor clutch should the evaporator temperature fall to 0°C.

• NOTE: Graphs are typical for HFC 134A

The 'Normal' condition is that which is relevant to the prevailing evaporator temperature.

System Pressure Fault Classification

• NOTE

: If erratic or unusual gauge move

ments occur, check the equipment against a known (calibrated) manifold gauge

set.

This table should be used in conjunction with the graphical representations of 'High side' pressure / ambient temperature

and 'Low side' pressure / evaporator temperature.

Leak

Test

F

a

ults associated with low re

frigerant charge weight and low pressure ma y be caused by leakage. Leaks traced to

mechanical connections may be caused by to rque relaxation or joint face contamination. Evidence of oil around such areas

is an indicator of leakage.

Models that have fluorescent tracer dye incorporated into the refrigeration system can be checke d for non-apparent leaks by

scanning with a high intensity ultraviolet lamp. The location of leaks can be pinpointed by the bright yellow glow of the

tracer dye.

CAUTION: Observe ALL safety precautions associated with ultraviolet equipment.

Should a leak be traced to a joint, check that the fixing is secured to the correct tightening torque before taking any other

action.

When examining the system for leaks, chec k the compressor shaft seal and evaporator.

Charge Re

covery (system depressurization)

The process of

charge r

ecovery will depe

nd on the basic characteristics of your chosen recovery / recycle / recharge

equipment, therefore, follow the manu facturer's instructions carefully.

Remember that compressor oil may be drawn out during this process, take note of the quantity recovered so that it may be

Lo

w side

gauge reading

High s i

de

gauge reading

Fau l

t

Cause

No

r

mal

No

r

mal

Di

sc

harge air initially cool then

warms up

Mois

ture in system

N

ormal

to low

No

r

mal

As aboveAs above

LowLowD

i

scharge air slightly cool

Ref

r

igerant charge low

LowLowDi

scharge air warm

Refr

igerant charge very low

LowLowDi

scharge air slightly cool or frost

build up at expansion valve

Expansion valve st

uck closed

LowLowDi

scharge air slightly cool,

sweating or frost after point of restriction

Restri

ction in High side of system

HighLowCompressor noisyDe

fe

ctive compressor reed valve

HighHighD

i

scharge air warm and high side

pipes hot

Refri

gerant charge high or inefficient condenser

cooling due to air flow blockage or engine cooling fans

not working

HighHighD i

scharge air warm / Sweating or

frost at evaporator

Expans ion valve st

uck open