ignition JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1502 of 2490

The performance mode pushbutton:

Is mounted on the 'J' gate surround. This 'push-on push-off' swit ch selects Normal or Sport mode ( push-on for Sport) Is illuminated when Sport mode is selected. Is hard-wired to the transmission control module.

With 'Normal' selected the transmissi on will start off in 2 nd gear with kickdown to 1 st being available.

'Sport' mode allows 1 st gear en gagement from rest and modifies values in the TCM shift point calculations to provide higher

upshift speeds and enhanced availability of downshifts.

Kickdown Switch

The kickdown switch:

Is floor mounted under th e accelerator pedal. Is operated by pressing the pedal beyond the full throttle position. Provides maximum acceleration on driver demand, by signalling the TCM to select the lowest gear to give maximum

wheel torque.

Gear selector interlock solenoid:

Prevents the gear selector lever from being moved from P , unless the ignition switch is in position II, and the brake

pedal is depressed.

Is controlled by an output from the BPM

Park position switch:

Is hard-wired to the BPM Detects when the gear selector lever is moved to the Park position

Page 1508 of 2490

Automatic Transmission/Transaxle External Contro ls - 4.0L SC V8 - AJ26 -

Brake Shift Interlock Actuator Manual Override

General Procedures

1. To override the gearshift interlock:

1. Unscrew the release catch blanking plug.

2. Insert the ignition key into the aperture, depress the release catch and simultan eously move the gear

selector lever from the Park position. The lever will

only move approximately 25 mm with the key

inserted.

3. Remove the ignition key and replace the blanking plug.

Page 1520 of 2490

moving the set position of either the gear selector lever or the selector lever on the transmission casing.

3. Tighten to 22-28 Nm.

4. Verify the 'N' setting.

6. Check that all released connec tors are safely insulated and

connect the vehicle battery.

7. Switch ON the ignition.

8. Adjust the position of the linear switch so that the selector 'N'

position graphic illuminates. Ti ghten the four screws to 0,7-1

Nm.

9. Move the gear selector to 'R' to confirm that the 'R' position

graphic illuminates.

10. Check that the engine will start when the gear selector is in

the 'N' and 'P' positions, bu t not in any other position.

11. Move the gear selector to 'N'.

12. Switch OFF the ignition.

13. Disconnect the battery.

14. Install the console assembly, operation 76.25.01.

15. Install the console finisher veneer panel, operation 76.47.26.

16. Install the J-gate surround, operation 76.25.24.

17. Perform the Battery Reconnection Procedure described in

Operation 86.15.15.

Page 1535 of 2490

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to A2

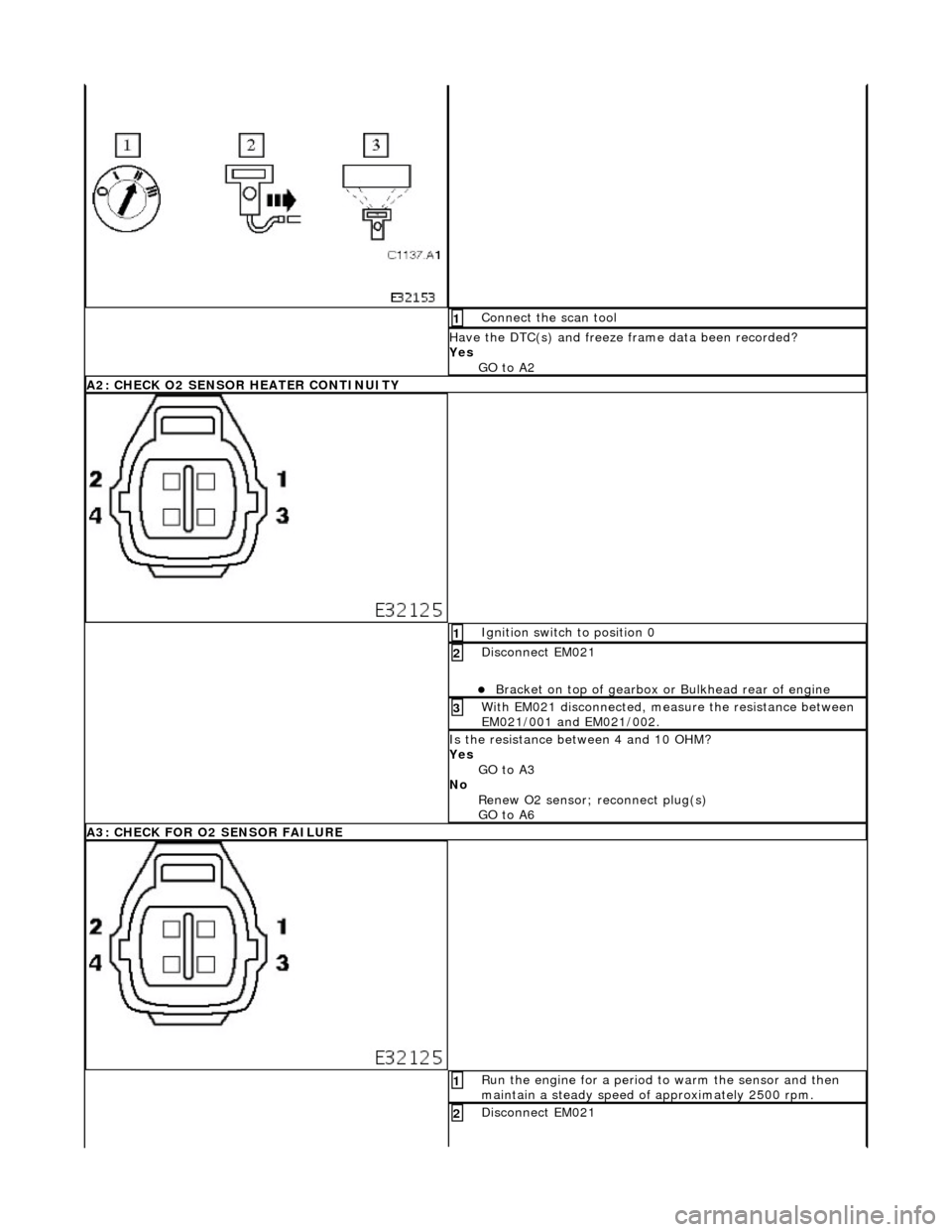

A2: CHECK O2 SENSOR HEATER CONTINUITY

Ignition switch to position 0 1

Disconnect EM021

Bracket on top of gearbox or Bulkhead rear of engine

2

With EM021 disconnected, measure the resistance between

EM021/001 and EM021/002. 3

Is the resistance between 4 and 10 OHM?

Yes

GO to A3

No Renew O2 sensor; reconnect plug(s)

GO to A6

A3: CHECK FOR O2 SENSOR FAILURE

Run the engine for a period to warm the sensor and then

maintain a steady speed of approximately 2500 rpm. 1

Disconnect EM021 2

Page 1542 of 2490

Ignition switch to position 0 1

Disconnect EM010 and EM012

Inside ECM housing

2

Ignition switch to position II 3

Measure the voltage between EM010/023 and EM012/015 4

Is the voltage 0 (zero) V?

Yes GO to A15

No Inspect harness / connectors EM010, EM012, and EM021 for

corrosion, damaged / pushed back pins. Repair as required

and reconnect plug(s).

GO to A18

A15: CHECK FOR SHORT TO B+

Measure the voltage between EM010/023 and EM012/022 1

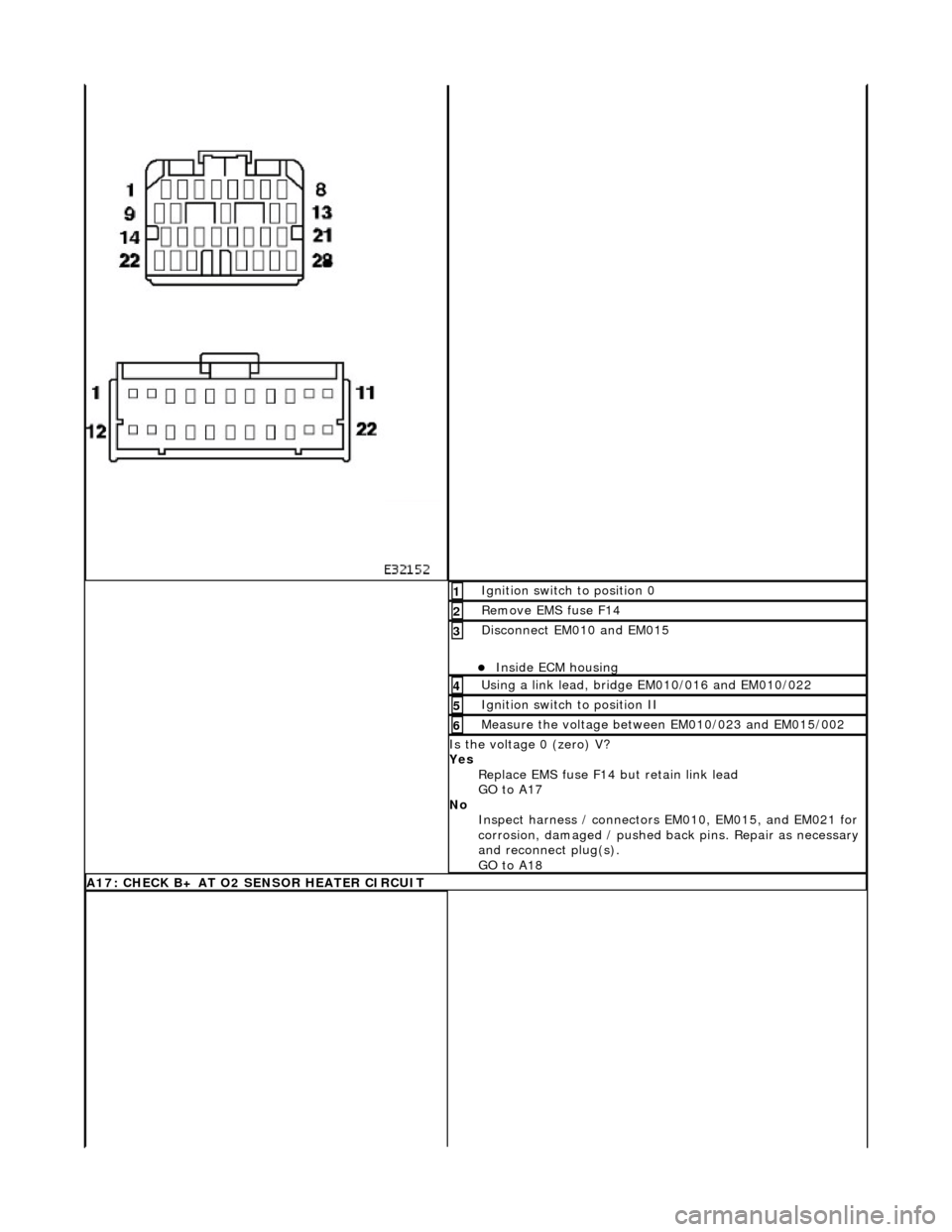

Page 1544 of 2490

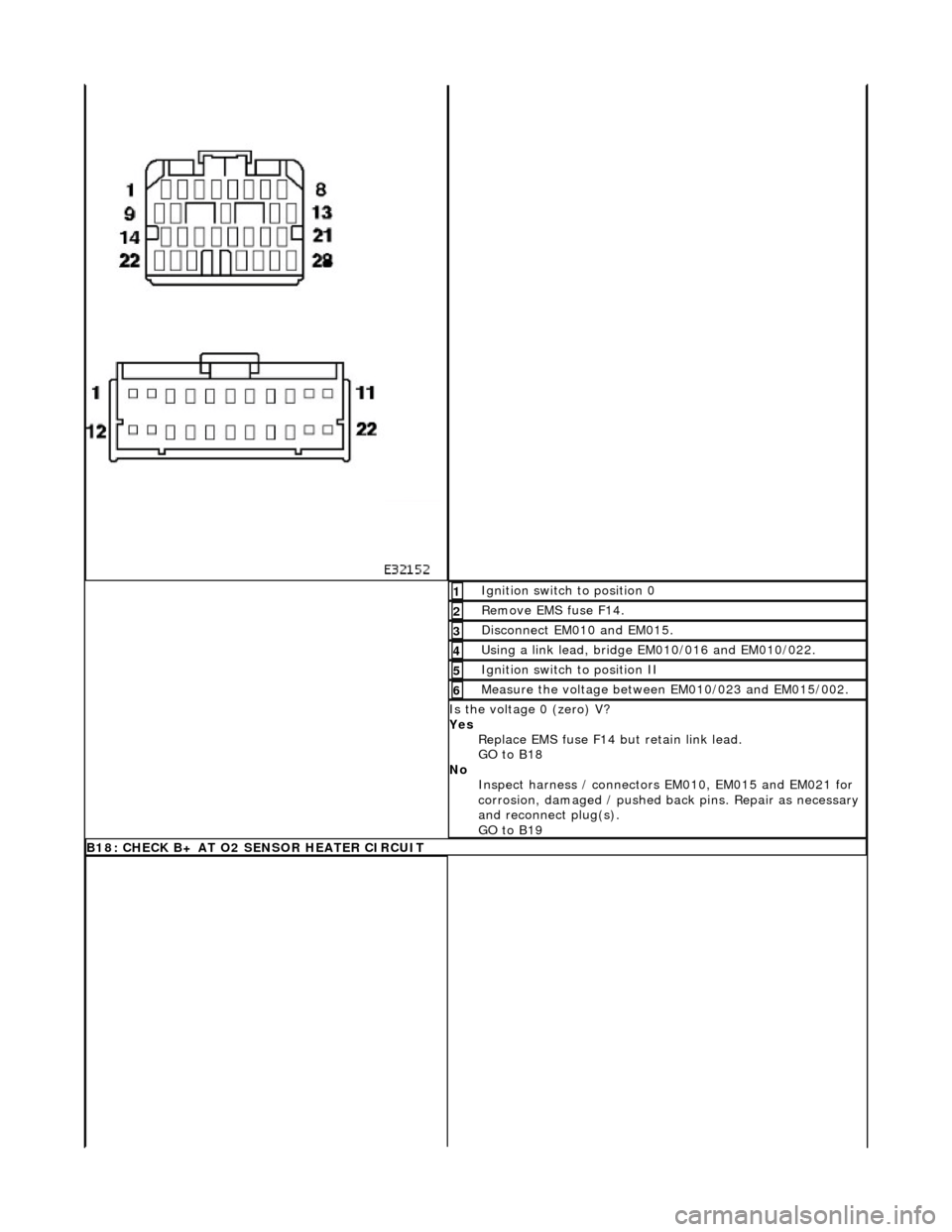

Ignition switch to position 0 1

Remove EMS fuse F14 2

Disconnect EM010 and EM015

Inside ECM housing

3

Using a link lead, bridge EM010/016 and EM010/022 4

Ignition switch to position II 5

Measure the voltage between EM010/023 and EM015/002 6

Is the voltage 0 (zero) V?

Yes Replace EMS fuse F14 but retain link lead

GO to A17

No Inspect harness / connectors EM010, EM015, and EM021 for

corrosion, damaged / pushed back pins. Repair as necessary

and reconnect plug(s).

GO to A18

A17: CHECK B+ AT O2 SENSOR HEATER CIRCUIT

Page 1546 of 2490

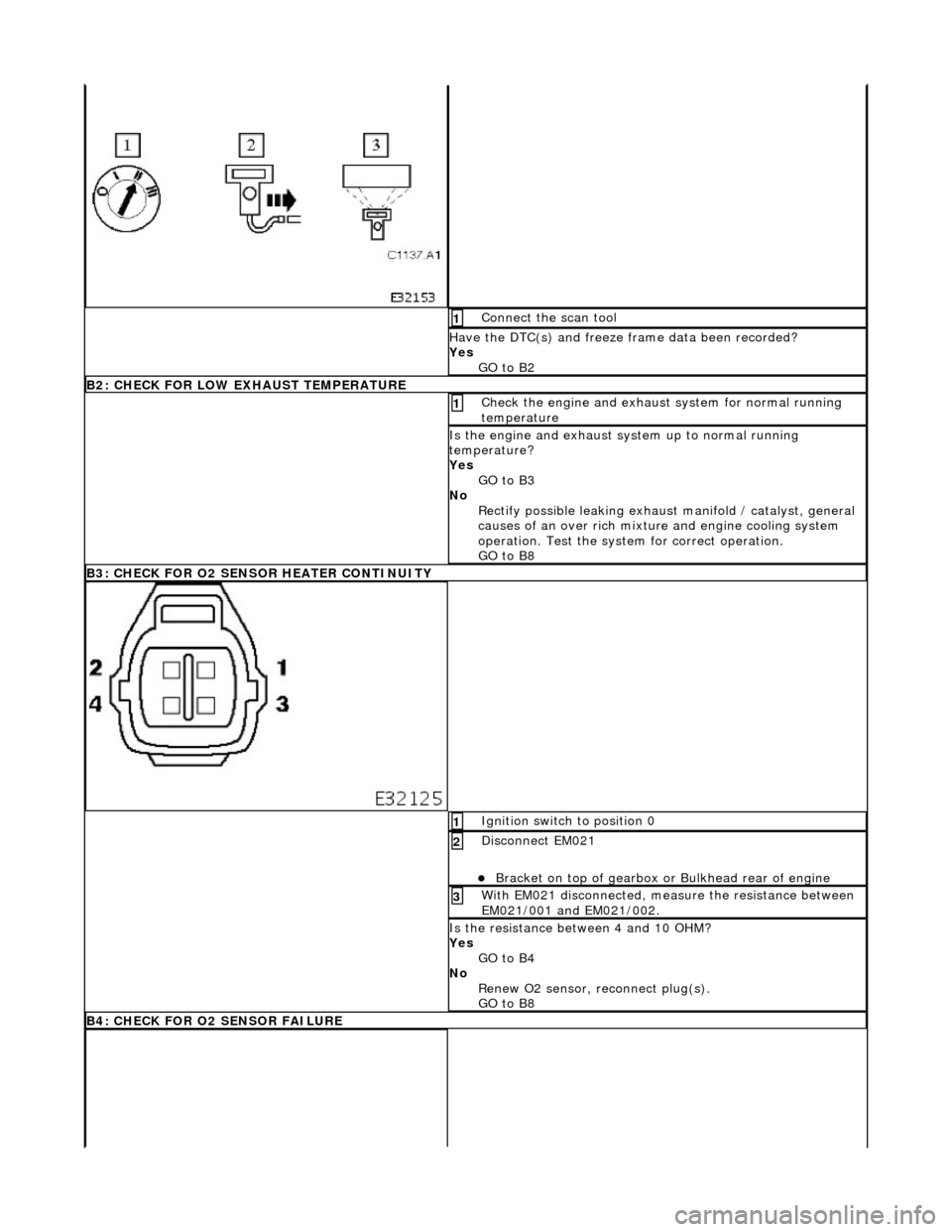

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to B2

B2: CHECK FOR LOW EX HAUST TEMPERATURE

Check the engine and exhaust system for normal running

temperature 1

Is the engine and exhaust sy stem up to normal running

temperature?

Yes GO to B3

No Rectify possible leaking exhaust manifold / catalyst, general

causes of an over rich mixture and engine cooling system

operation. Test the system for correct operation.

GO to B8

B3: CHECK FOR O2 SENS OR HEATER CONTINUITY

Ignition switch to position 0 1

Disconnect EM021

Bracket on top of gearbox or Bulkhead rear of engine

2

With EM021 disconnected, measure the resistance between

EM021/001 and EM021/002. 3

Is the resistance between 4 and 10 OHM?

Yes

GO to B4

No Renew O2 sensor, reconnect plug(s).

GO to B8

B4: CHECK FOR O2 SENSOR FAILURE

Page 1554 of 2490

Ignition switch to position 0 1

Disconnect EM010

Inside ECM housing

2

Disconnect EM012

Inside ECM housing

3

Ignition switch to position II 4

Measure the voltage between EM010/023 and EM012/015. 5

Is the voltage 0 (zero) V?

Yes GO to B16

No Inspect harness / connectors EM010, EM012 and EM021 for

corrosion, damaged / pushed back pins. Repair as necessary

and reconnect plug(s).

GO to B19

B16: CHECK FOR SHORT TO B+

Measure the voltage between EM010/023 and EM012/022 1

Page 1556 of 2490

Ignition switch to position 0 1

Remove EMS fuse F14. 2

Disconnect EM010 and EM015. 3

Using a link lead, bridge EM010/016 and EM010/022. 4

Ignition switch to position II 5

Measure the voltage between EM010/023 and EM015/002. 6

Is the voltage 0 (zero) V?

Yes Replace EMS fuse F14 but retain link lead.

GO to B18

No Inspect harness / connectors EM010, EM015 and EM021 for

corrosion, damaged / pushed back pins. Repair as necessary

and reconnect plug(s).

GO to B19

B18: CHECK B+ AT O2 SENSOR HEATER CIRCUIT

Page 1558 of 2490

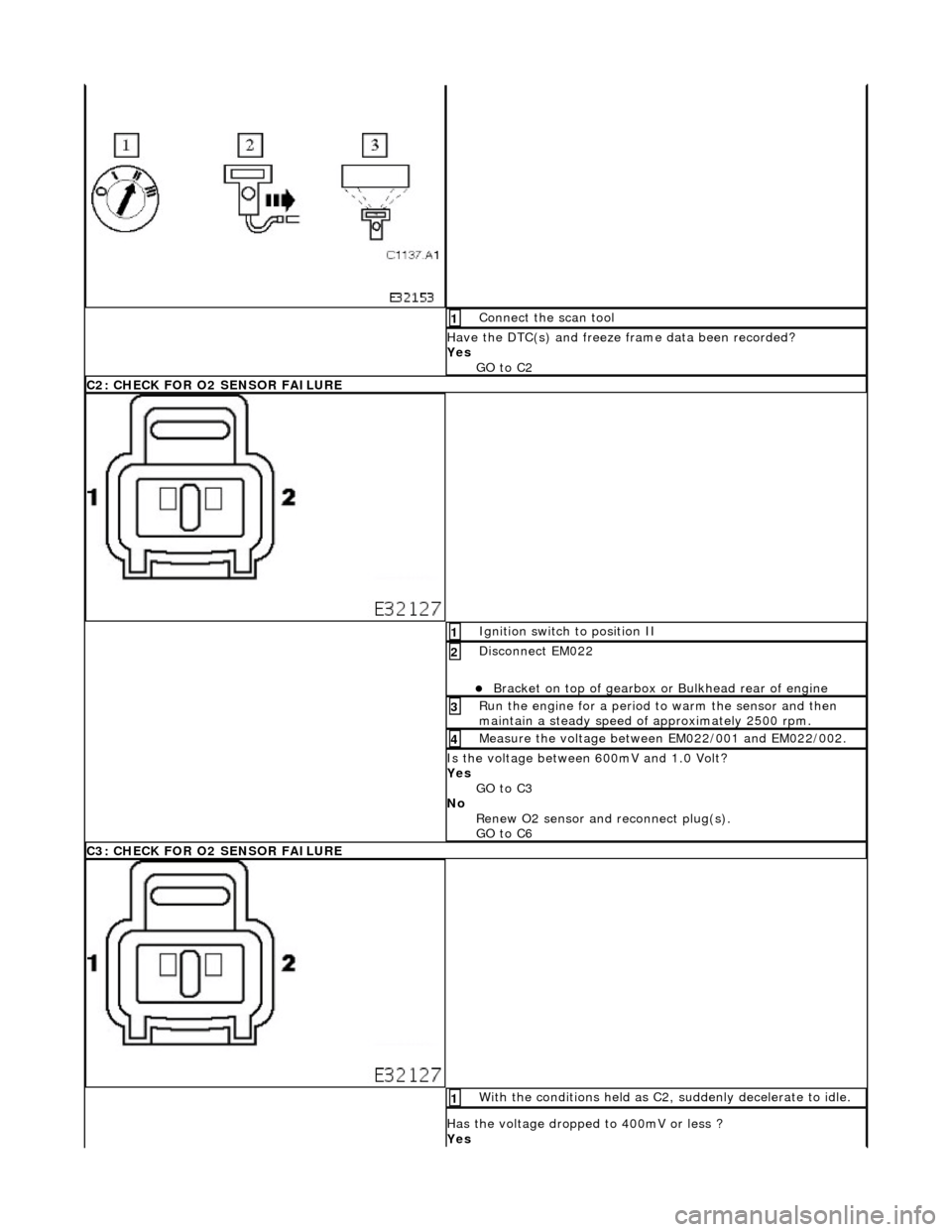

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to C2

C2: CHECK FOR O2 SENSOR FAILURE

Ignition switch to position II 1

Disconnect EM022

Bracket on top of gearbox or Bulkhead rear of engine

2

Run the engine for a period to warm the sensor and then

maintain a steady speed of approximately 2500 rpm. 3

Measure the voltage between EM022/001 and EM022/002. 4

Is the voltage between 600mV and 1.0 Volt?

Yes

GO to C3

No Renew O2 sensor and reconnect plug(s).

GO to C6

C3: CHECK FOR O2 SENSOR FAILURE

With the conditions held as C2, suddenly decelerate to idle. 1

Has the voltage dropped to 400mV or less ?

Yes