engine oil JAGUAR X308 1998 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 521 of 2490

Engine System - General Infor

mation - Engine

Description an

d Operation

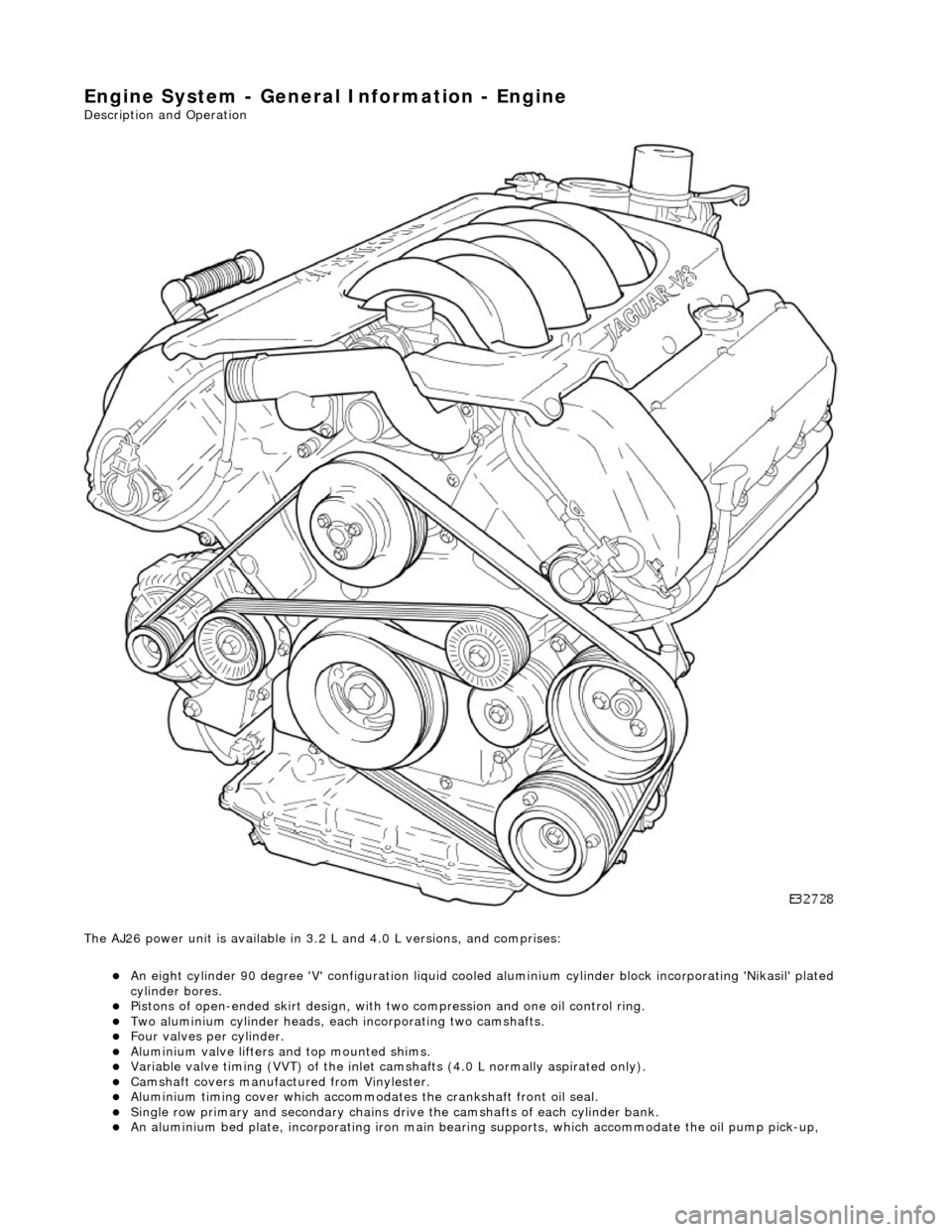

The AJ26 power unit is available in 3.2 L and 4.0 L versions, and comprises:

An eight cylinder 9

0 degree 'V' config

uration liquid cooled aluminium cylinder block incorporating 'Nikasil' plated

cylinder bores.

Pi

stons of open-ended skirt design, with

two compression and one oil control ring.

Two al

uminium cylinder heads, each

incorporating two camshafts.

F

our valves per cylinder.

Al

uminium valve lifters and top mounted shims.

Vari

able valve timing (VVT) of the inlet camshafts (4.0 L normally aspirated only).

Camshaft

covers manufactured from Vinylester.

Al

uminium timing cover which accommodat

es the crankshaft front oil seal.

Sin

gle row primary and secondary chains dr

ive the camshafts of each cylinder bank.

An alu

minium bed pl

ate, incorporating iron main bearing supports, which accomm odate the oil pump pick-up,

Page 522 of 2490

diverter val

ve (if fitted) and oil filter.

Main

bearings

which are grooved in the upper positions and plain in

the lower positions. They are manufactured from

aluminium / tin material.

A c

rankshaft with under

cuts and rolled fillets for extra strength.

Fracture

-split connecting rods in sintered-forged steel.

Brackets

bolted to the front of

the cylinder

block are used to mo unt all accessories.

A sin

gle, seven ribbed vee belt

drives the accessories.

An au

tomatic belt tensioner for the front accessory drive,

incorporating a wear indicator.

An advanced en

gine management system inco

rporating electronic throttle control.

The un

it meets the requirements of the CARB OBDII USA legislation.

Ancillary Systems

The an

ci

llary systems, driven by the engine, each have a

detailed Description and Operation along with Diagnostic

Procedures, and Removal and Installation instructions ; refer to the following sections of this manual:

Power Steeri

ng Pump - Section 211-02

Ai

r Conditioning Compressor - Sectio

n 412-03

Engine

C

ooling Pump - Section 303-03

Generator

- Sectio

n 414-02

The drive belt, idler pulley and automatic tensioner are described in Section 303-05.

The engine starting system is described in Section 303-06.

En

gine Management and Emission Control System

Engine Control Modu

le (ECM)

Engine

management and exhaust emissions are controlled by the ECM, which has the

following main functions:

Fu

el injection

Idle

s

peed

Ignition Ev

aporative loss system

Engine

cooling fans Clim

ate control compressor clutch demand

The microprocessor within the ECM receiv es signals from various sensors and other modules and uses a pre-determined

program to compute engine management functions.

Adaptive functions are incorporated in the ECM to cater for co ntinuous adjustments to its computations to suit prevailing

conditions. Because the system also controls emissions to suit all modes, neither CO levels nor idle speed require service

attention or adjustment, except if an error should occur.

On Board Diagnostics are controlled by the ECM with the continuous monitoring of incoming signals and the subsequent

verification against what the module expects to 'see'. Should a si gnal be incorrect or missing, the ECM will substitute a fixed

value to provide the 'limp home mode' and alert the driver of the problem. Fixed values may be adopted for:

Transmission oil

temperature

Mechanica

l

guar

d position

Throttle blade angle Camshaft position

Inta

k

e air temperature

Diagnostic trouble codes (DTC), including OBD II codes, are stored in the ECM memo ry and can be read by an appropriate

retrieval tool.

Should either the ECM or TCM fa il, ensure that the control housing cooling fan is operating correctly. Failure of the cooling

fan MUST be rectified before renewing a control module and details of a fa n failure should accompany a returned control

module.

Page 528 of 2490

Speed an

d load

Coo

l

ant temperature

Ti

me el

apsed from start up

Cl

osed l

oop fuelling

Determination of the vapour concentration is made by stepped opening of the EVAP valve and subsequent monitoring of the

fuelling correction. This function is performed prior to purging, so that at the onse t of purging the EVAP valve can be set to

the optimum position. Should the ECM be unable to determine the concentration before purging, a default value is

employed, which is then modified whilst purging is in progress.

When the purging process is operational th e ECM modifies the basic fuelling calculation to maintain the correct air / fuel

ratio.

Purging is inhibited during fuel cut-off and stability / traction control intervention.

Coolant Temperature Sen

sor

Th

e

sensor outputs a voltage to the ECM which decreases as temperature increases.

Cooling Fans

In response to engi

ne coolant temperat

u

re and climate control system demand, the ECM will energize the cooling fans.

Climate Control Compressor

The E

C

M will allow the compressor clutch to be engaged if th

e engine temperature and load demand are normal. Should the

driver require maximum engine powe r or the coolant temperature be high, the request will be denied.

Cranking Signal

The ECM reacts to a signal fr

om th

e Body Processor Module (BPM) when the starter motor relay is energi

zed. This signal is

used to trigger starting, fu el and ignition strategies.

Engine Speed and Cranksh

aft Position

Engine

speed and cran

k position are moni

tored by a sensor which is mounted on the cylinder block (flywheel housing)

behind the crankshaft drive plat e. It indicates rotational speed to the ECM in the form of 12 pulses per crank revolution.

Engine speed is used for synchronization of fuel an d ignition systems, as well as other functions.

Camshaft Position

The ca

mshaft position sensor is mounted at

the rear of Bank 2 cylinder head on the inlet side and provides one signal every

720 degrees of crankshaft rotation. The signal, in conjunction with the signal from the crankshaft position sensor, indicates

to the ECM that the piston of cylinder 1A is approaching TDC on the compression stroke.

Variable Valve

Timing (Where Fitted)

By energi

si

ng a solenoid to allow the pass

age of pressurized oil on each of the inle t camshaft drives, the ECM can vary by a

single stepped amount, the relati ve timing of the inlet valves.

Ign

ition

Ignit

i

on spark is produced by

individual on-plug coil units.

There are two ignition amplifiers; module #1 drives coils 1A, 2B, 3B and 4A, whilst module #2 drives coils 1B, 2A, 3A and

4B. The ECM controls the amplifiers.

Page 531 of 2490

En

gine - Engine

D

iagnosis and Testing

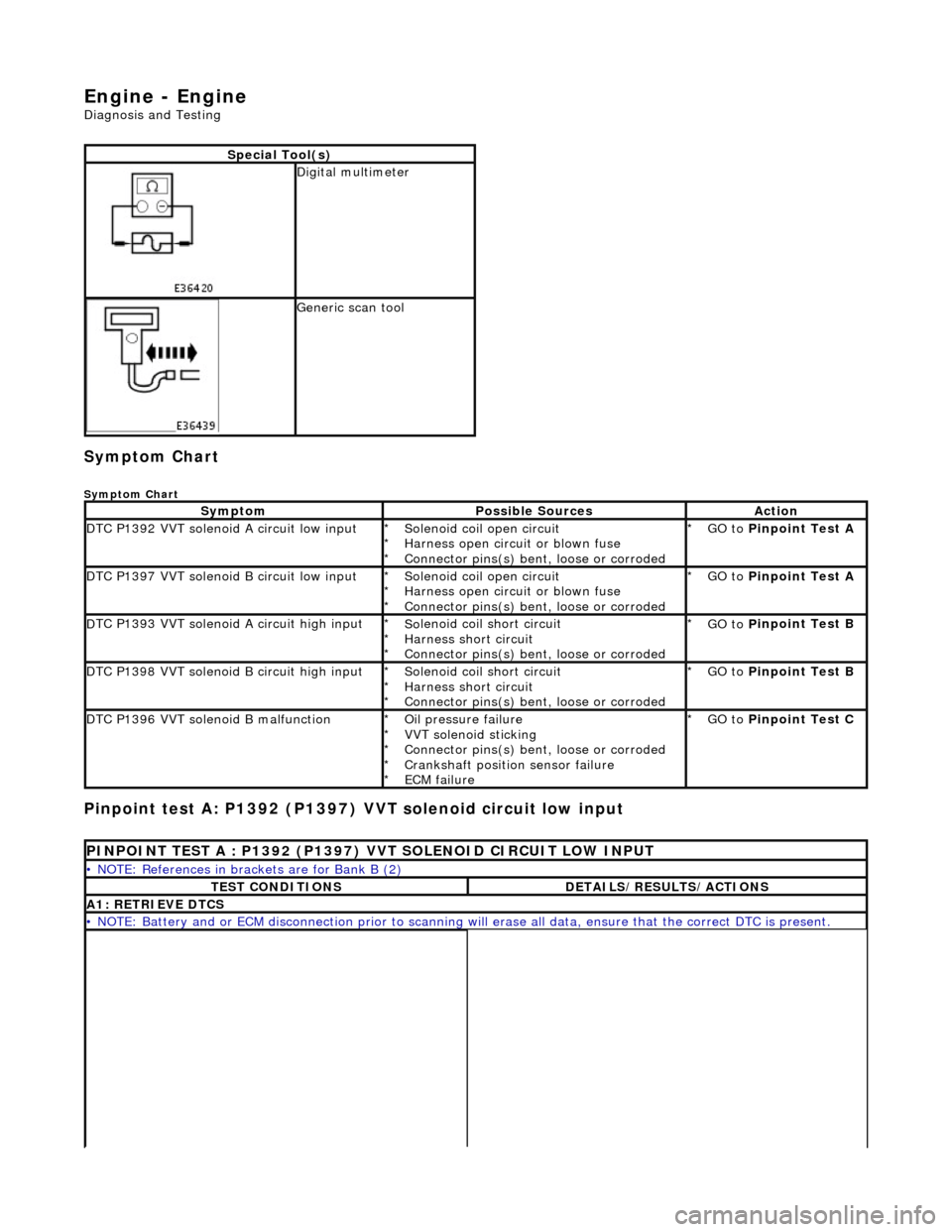

Sym

ptom Chart

Sy

mptom Chart

Pinp

oint test A: P1392 (P1397)

VVT solenoid circuit low input

S

pecial Tool(s)

D

igital multimeter

Generi

c scan tool

Sy

mptom

Possib

le Sources

Acti

on

D

TC P1392 VVT solenoid A circuit low input

So

lenoid coil open circuit

Harness open circuit or blown fuse

Connector pins(s) bent , loose or corroded

*

*

*

GO to

P

inpoint Test A

*

D

TC P1397 VVT solenoid B circuit low input

So

lenoid coil open circuit

Harness open circuit or blown fuse

Connector pins(s) bent , loose or corroded

*

*

*

GO to

P

inpoint Test A

*

D

TC P1393 VVT solenoid A circuit high input

So

lenoid coil short circuit

Harness short circuit

Connector pins(s) bent , loose or corroded

*

*

*

GO to

P

inpoint Test B

*

D

TC P1398 VVT solenoid B circuit high input

So

lenoid coil short circuit

Harness short circuit

Connector pins(s) bent , loose or corroded

*

*

*

GO to

P

inpoint Test B

*

D

TC P1396 VVT solenoid B malfunction

O

il pressure failure

VVT solenoid sticking

Connector pins(s) bent , loose or corroded

Crankshaft position sensor failure

ECM failure

*

*

*

*

*

GO to

P

inpoint Test C

*

P

INPOINT TEST A : P1392 (P1397) VVT SOLENOID CIRCUIT LOW INPUT

•

NOTE: References in brac

kets are for Bank B (2)

T

EST CONDITIONS

D

ETAILS/RESULTS/ACTIONS

A1

: RETRIEVE DTCS

•

NOTE: Battery and or ECM disconnection prior to scanning wi

ll erase all data, ensure that the correct DTC is present.

Page 548 of 2490

En

gine - Valve Clea

rance Adjustment

Gene

ral Procedures

S

p

ecial Tool(s)

Tappet adjustment

3

03-

540

Ai

r gun, fan nozzl

e

303-590

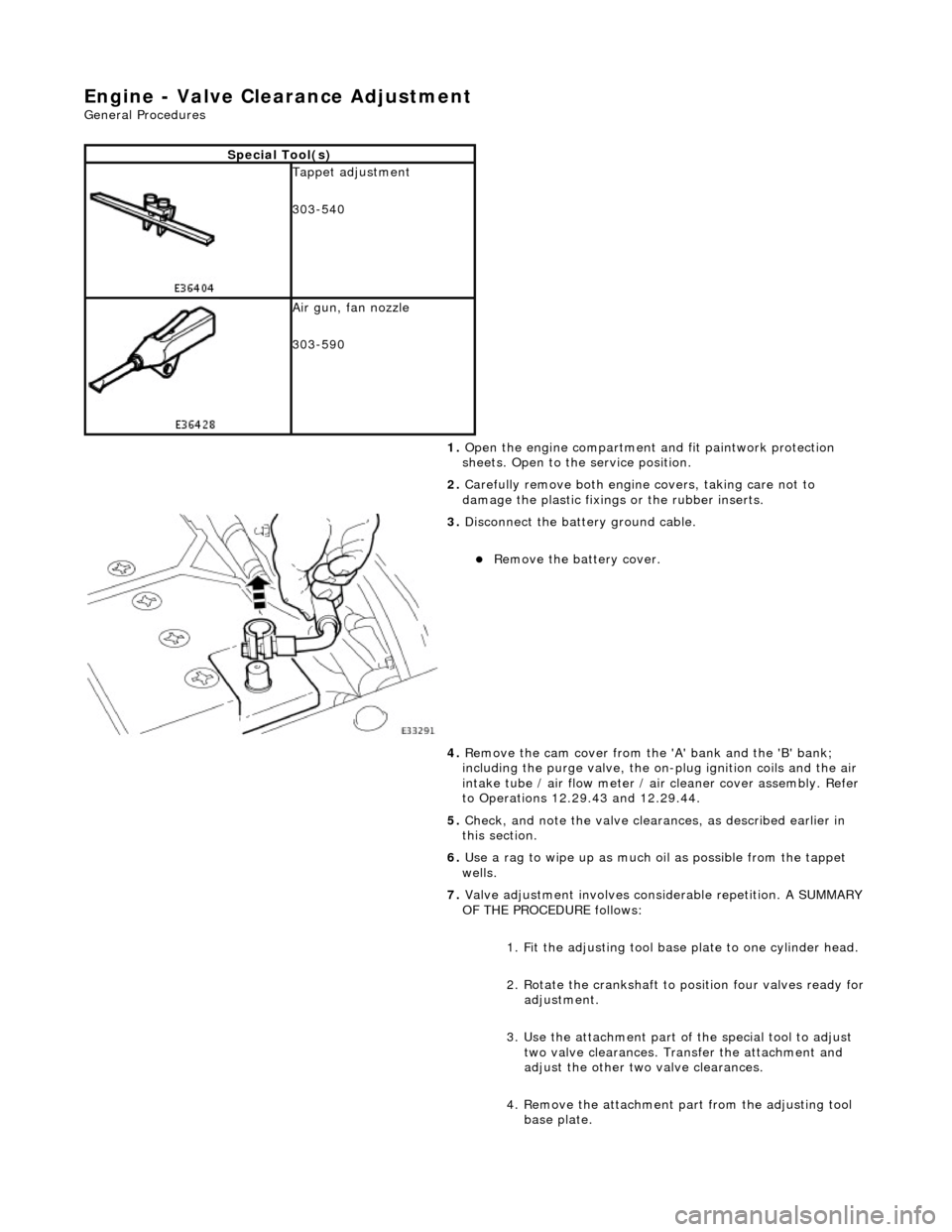

1. Open the engine compartment and fit paintwork protection

sheets. Open to the service position.

2. Carefully remove both engine covers, taking care not to

damage the plasti c fixings or the rubber inserts.

3. Disc

onnect the batt

ery ground cable.

Re

move the battery cover.

4. Remove the cam cover from the 'A' bank and the 'B' bank;

including the purge valve, the on-plug ignition coils and the air

intake tube / air flow meter / air cleaner cover assembly. Refer

to Operations 12.29.43 and 12.29.44.

5. Check, and note the valve cleara nces, as described earlier in

this section.

6. Use a rag to wipe up as much oil as possible from the tappet

wells.

7. Valve adjustment involves considerable repetition. A SUMMARY

OF THE PROCEDURE follows:

1. Fit the adjusting tool base plate to one cylinder head.

2. Rotate the crankshaft to position four valves ready for

adjustment.

3. Use the attachment part of the special tool to adjust two valve clearances. Transfer the attachment and

adjust the other two valve clearances.

4. Remove the attachment pa rt from the adjusting tool

base plate.

Page 550 of 2490

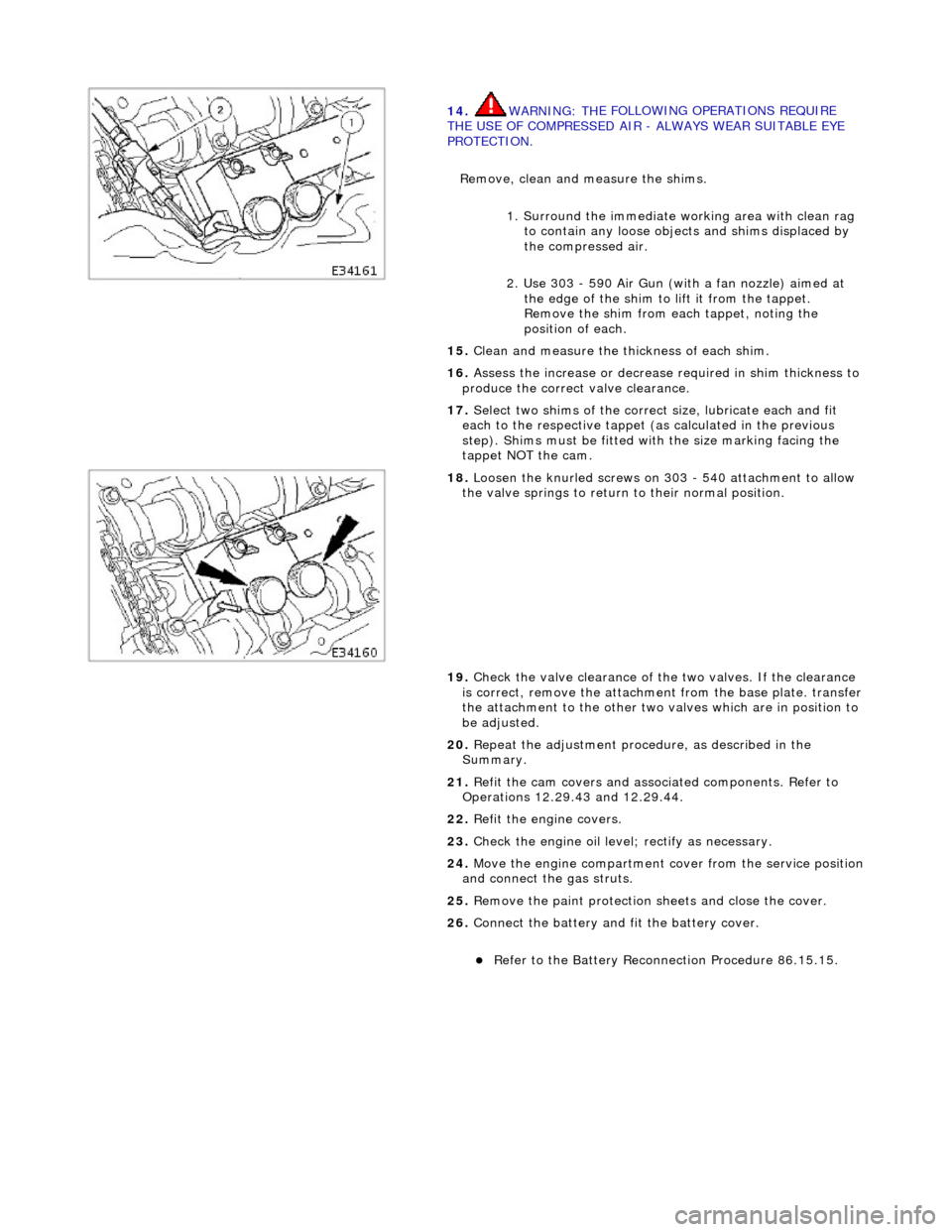

14

. WARNING: TH

E FOLLOWING OPERATIONS REQUIRE

THE USE OF COMPRESSED AIR - ALWAYS WEAR SUITABLE EYE

PROTECTION.

Remove, clean and measure the shims.

1. Surround the immediate wo rking area with clean rag

to contain any loose objects and shims displaced by

the compressed air.

2. Use 303 - 590 Air Gun (with a fan nozzle) aimed at the edge of the shim to lift it from the tappet.

Remove the shim from each tappet, noting the

position of each.

15 . Cl

ean and measure the thickness of each shim.

16. Assess the increase or decrease required in shim thickness to

produce the correct valve clearance.

17. Select two shims of the correct size, lubricate each and fit

each to the respective tappet (as calculated in the previous

step). Shims must be fitted with the size marking facing the

tappet NOT the cam.

18 . Loos

en the knurled screws on 303 - 540 attachment to allow

the valve springs to return to their normal position.

19. Check the valve clearance of the two valves. If the clearance

is correct, remove the attachment from the base plate. transfer

the attachment to the other two valves which are in position to

be adjusted.

20. Repeat the adjustment procedure, as described in the

Summary.

21. Refit the cam covers and associated components. Refer to

Operations 12.29.43 and 12.29.44.

22. Refit the engine covers.

23. Check the engine oil level; rectify as necessary.

24. Move the engine compartment cover from the service position

and connect the gas struts.

25. Remove the paint protection sheets and close the cover.

26. Connect the battery and fit the battery cover.

Refe

r to the Battery Reconnection Procedure 86.15.15.

Page 551 of 2490

E

ngine - Valve Clearance Check

Gen

eral Procedures

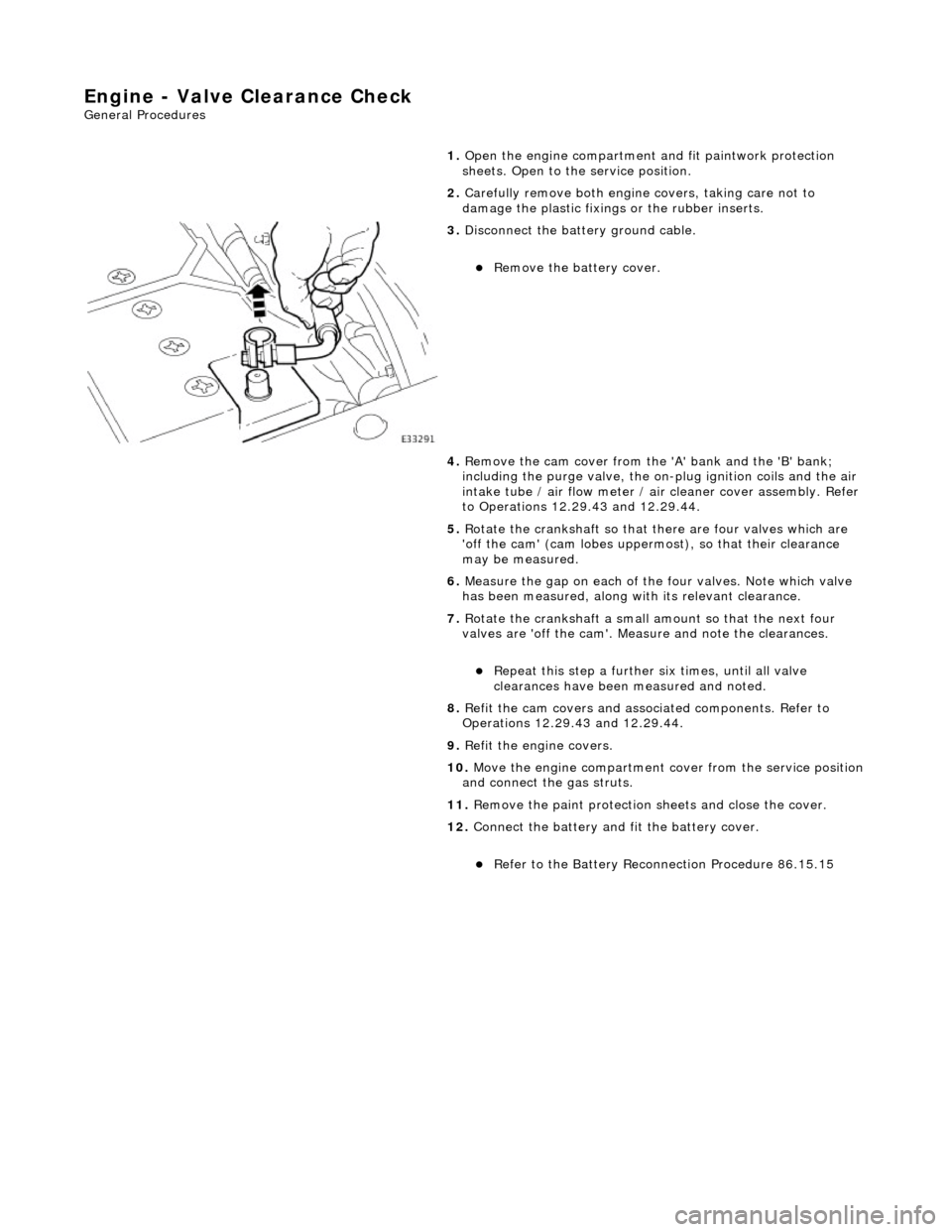

1.

Open the engine compartment and fit paintwork protection

sheets. Open to the service position.

2. Carefully remove both engine covers, taking care not to

damage the plasti c fixings or the rubber inserts.

3. Di

sconnect the batt

ery ground cable.

R

emove the battery cover.

4. Remove the cam cover from the 'A' bank and the 'B' bank;

including the purge valve, the on-plug ignition coils and the air

intake tube / air flow meter / air cleaner cover assembly. Refer

to Operations 12.29.43 and 12.29.44.

5. Rotate the crankshaft so that there are four valves which are

'off the cam' (cam lobes upperm ost), so that their clearance

may be measured.

6. Measure the gap on each of the four valves. Note which valve

has been measured, along with its relevant clearance.

7. Rotate the crankshaft a small am ount so that the next four

valves are 'off the cam'. Measure and note the clearances.

Re

peat this step

a further six times, until all valve

clearances have been measured and noted.

8. Refit the cam covers and associated components. Refer to

Operations 12.29.43 and 12.29.44.

9. Refit the engine covers.

10. Move the engine compartment cover from the service position

and connect the gas struts.

11. Remove the paint protection sheets and close the cover.

12. Connect the battery and fit the battery cover.

Re

fer to the Battery Reconnection Procedure 86.15.15

Page 552 of 2490

Engine - Connecting Rod Bearings

In-vehic

le Repair

Remov

a

l

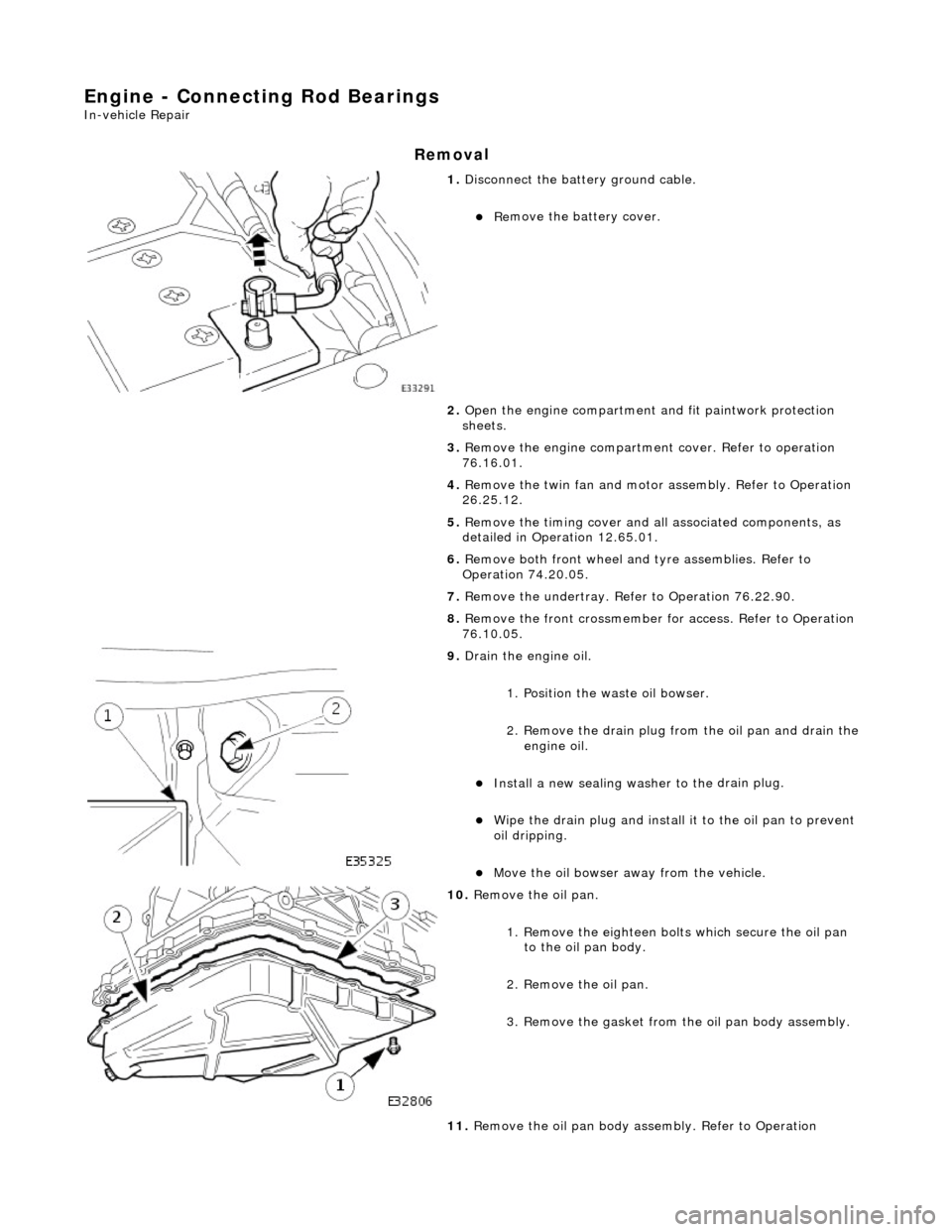

1.

Disc

onnect the batt

ery ground cable.

Re

move the battery cover.

2. Open the engine compartment and fit paintwork protection

sheets.

3. Remove the engine compartmen t cover. Refer to operation

76.16.01.

4. Remove the twin fan and motor assembly. Refer to Operation

26.25.12.

5. Remove the timing cover and al l associated components, as

detailed in Operation 12.65.01.

6. Remove both front wheel and tyre assemblies. Refer to

Operation 74.20.05.

7. Remove the undertray. Re fer to Operation 76.22.90.

8. Remove the front crossmember fo r access. Refer to Operation

76.10.05.

9. Drai

n the engine oil.

1. Position the waste oil bowser.

2. Remove the drain plug from the oil pan and drain the engine oil.

Install a new sealing wash er to the

drain plug.

Wipe the drain plug an

d

install

it to the oil pan to prevent

oil dripping.

Move the oil bowser away f

rom the vehicle.

10 . Re

move the oil pan.

1. Remove the eighteen bolt s which secure the oil pan

to the oil pan body.

2. Remove the oil pan.

3. Remove the gasket from the oil pan body assembly.

11. Remove the oil pan body a ssembly. Refer to Operation

Page 554 of 2490

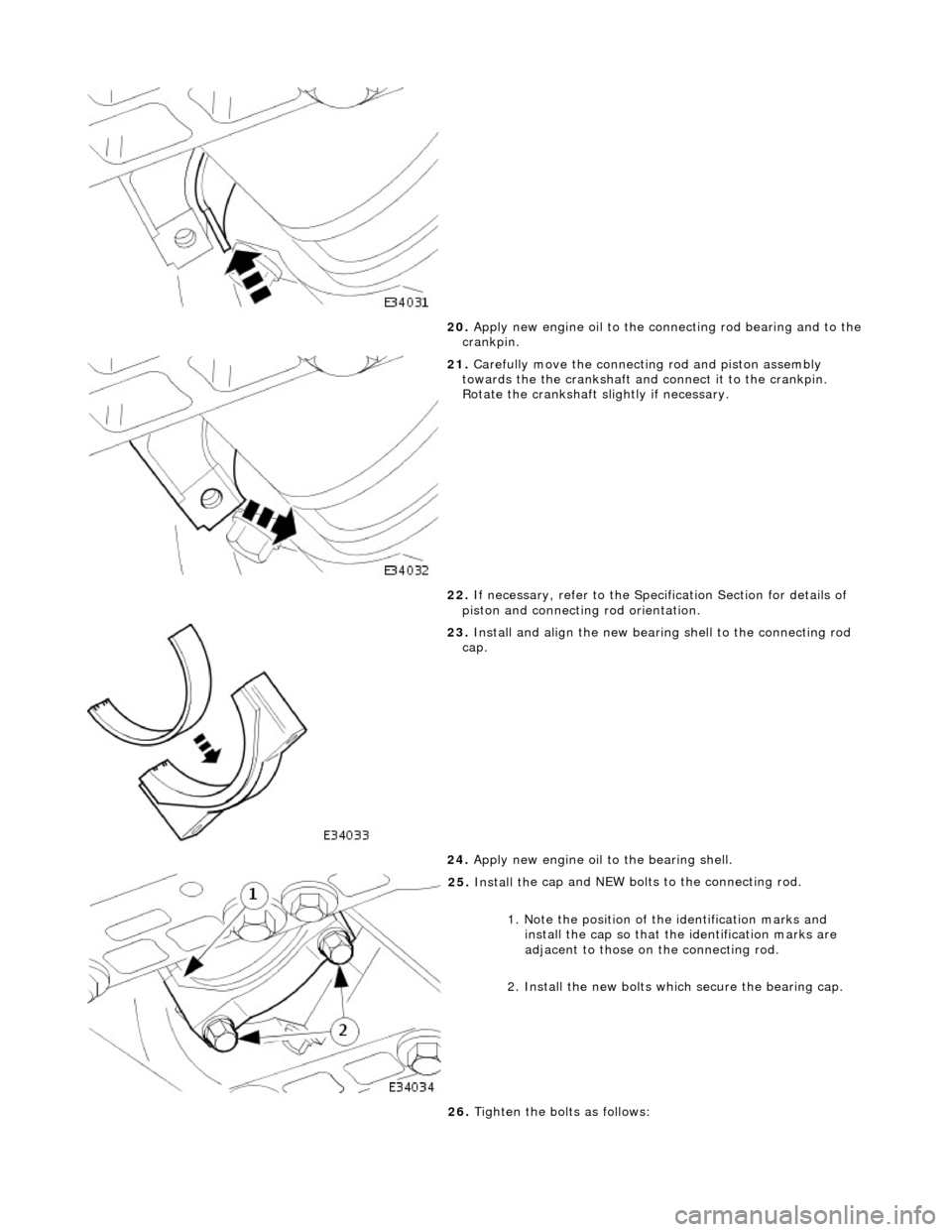

20. Apply new en

gine oil to the co

nnecting rod bearing and to the

crankpin.

21. Carefull

y move the connecting

rod and piston assembly

towards the the crankshaft and connect it to the crankpin.

Rotate the crankshaft slightly if necessary.

22. If necessary, refer to the Spec ification Section for details of

piston and connecting rod orientation.

23 . Install and alig

n the new bearin

g shell to the connecting rod

cap.

24. Apply new engine oil to the bearing shell.

25 . Install th

e cap and NEW bolts to the connecting rod.

1. Note the position of the identification marks and install the cap so that the identification marks are

adjacent to those on the connecting rod.

2. Install the new bolts whic h secure the bearing cap.

26. Tighten the bolts as follows:

Page 556 of 2490

5.

Install the front cros smember. Refer to Operat

ion 76.10.05.

6. Install the undert ray. Refer to Operation 76.22.90.

7. Install both front wheel and tyre assemblies. Refer to

Operation 74.20.05.

8. Install the timing cover and al l associated components, as

detailed in Operation 12.65.01.

9. Install the twin fan and motor assembly. Refer to Operation

26.25.12.

10. NOTE: When the engine is star ted from cold and run for a

short period only, before being swit ched off, a quantity of oil will

be 'hung up' within the engine because it is not up to operating

temperature.

Should the oil level subsequently be topped-up, the level could

become too high, causing oil burning.

Typically, 0.875 L is hung up.

Refill the engine with the correct specification engine oil.

11. Connect the battery and in stall the battery cover.

Refe

r to the Battery Reconnection Procedure 86.15.15.

12. Check the oil level and start th e engine. Check for leaks and

that the engine runs correctly.

13. Install the engine compartmen t cover. Refer to operation

76.16.01.

14. Remove the paintwork protection sheets and close the engine

compartment cover.