lower JAGUAR X308 1998 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 66 of 2490

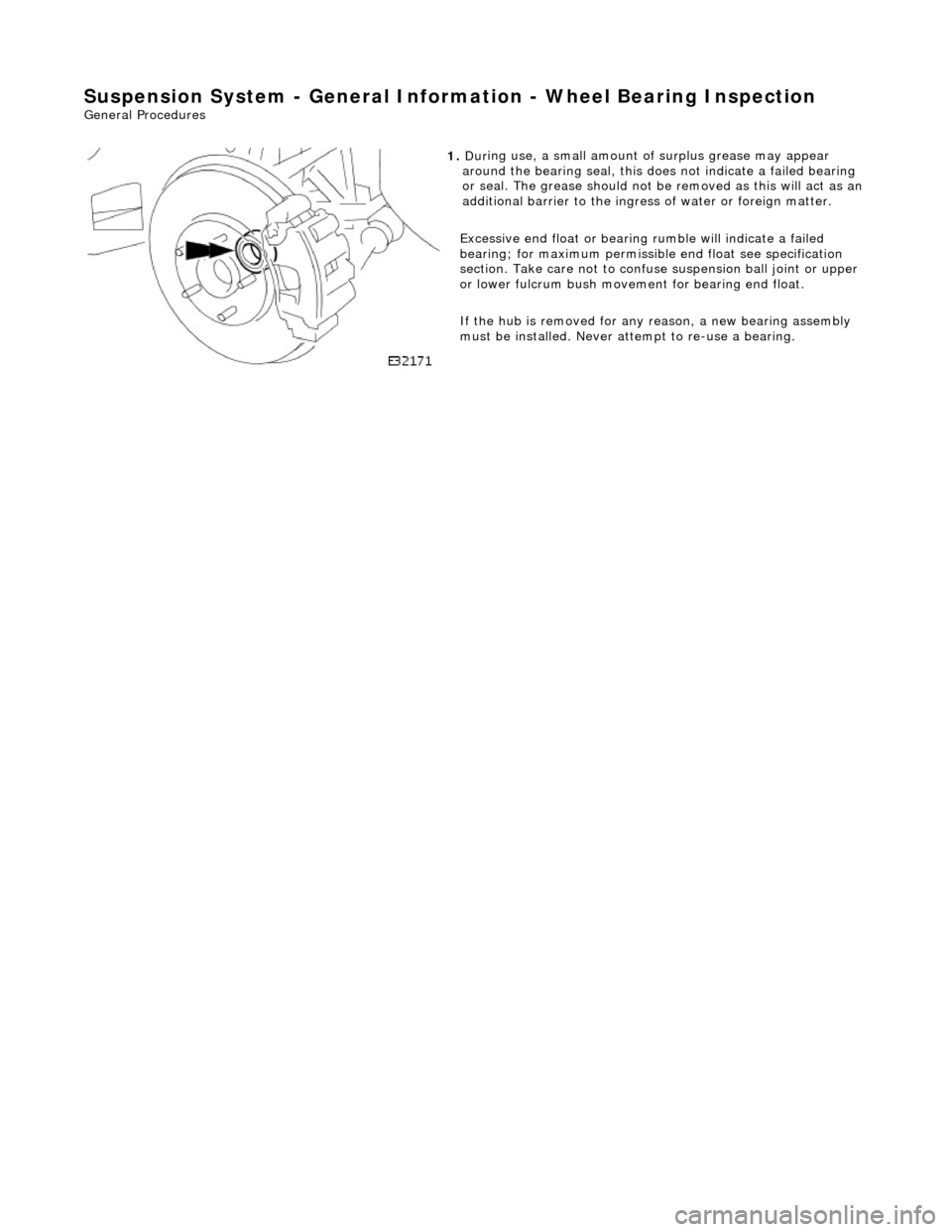

Suspension System - General Information - Wheel Bearing Inspection

Gene

ral Procedures

1.

Dur

ing use, a small amount of surplus grease may appear

around the bearing seal, this does not indicate a failed bearing

or seal. The grease should not be removed as this will act as an

additional barrier to the ingress of water or foreign matter.

Excessive end float or bearing ru mble will indicate a failed

bearing; for maximum permissibl e end float see specification

section. Take care not to confuse suspension ball joint or upper

or lower fulcrum bu sh movement for bearing end float.

If the hub is removed for any reason, a new bearing assembly

must be installed. Never at tempt to re-use a bearing.

Page 67 of 2490

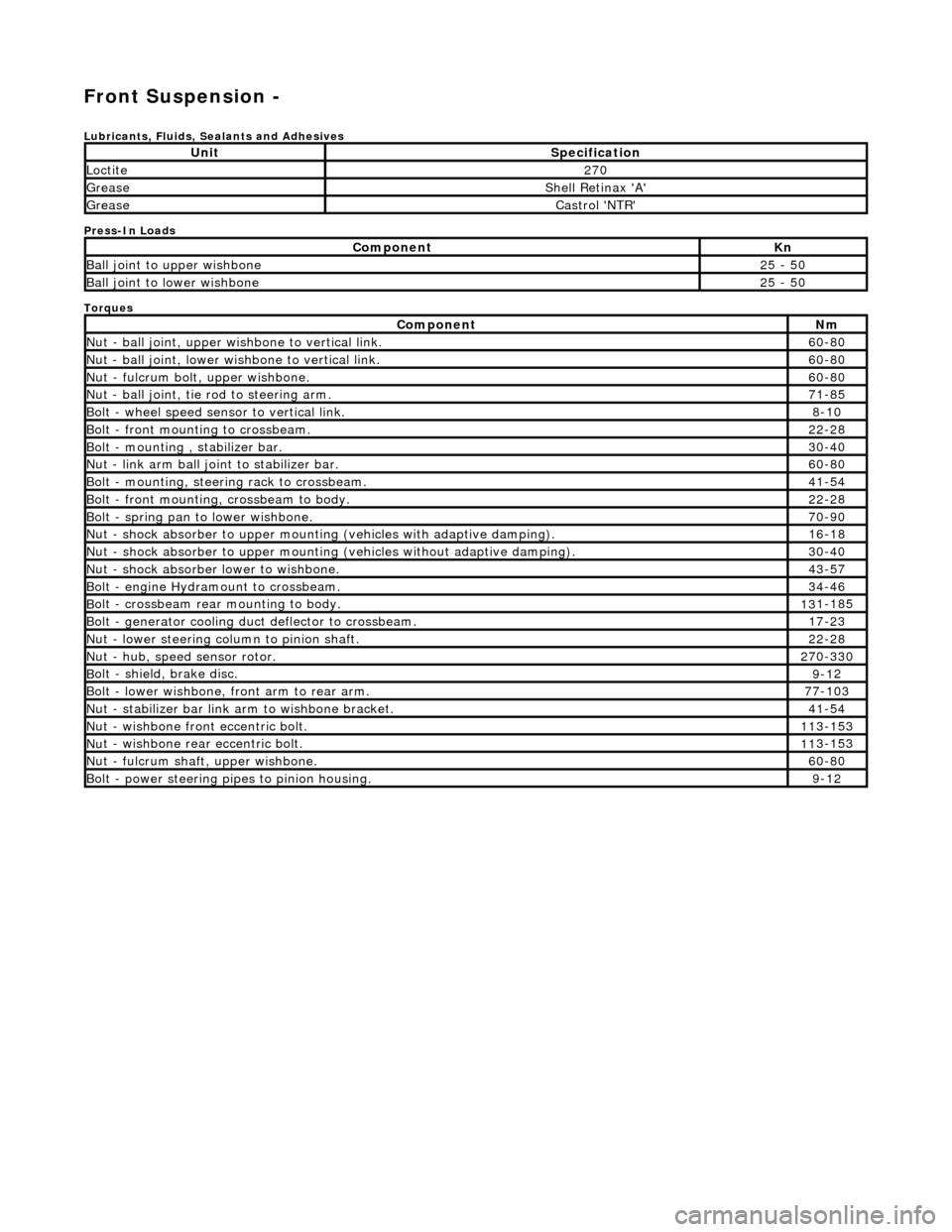

Front Suspension -

Lubri

cants, Fluids, Sealants and Adhesives

Press-In Loads

Torques

UnitS

pecification

Loctite27

0

Greas

e

Shell Retin

ax 'A'

Greas

e

Castro

l 'NTR'

Com

ponent

Kn

Ball join

t to upper wishbone

25

- 50

B

all joint to lower wishbone

25

- 50

Com

ponent

Nm

N

ut - ball joint, upper wishbone to vertical link.

60

-80

N

ut - ball joint, lower wishbone to vertical link.

60

-80

Nu

t - fulcrum bolt, upper wishbone.

60

-80

N

ut - ball joint, tie rod to steering arm.

71

-85

Bol

t - wheel speed sensor to vertical link.

8-1

0

Bol

t - front mounting to crossbeam.

22

-28

Bolt

- mounting , stabilizer bar.

30

-40

N

ut - link arm ball joint to stabilizer bar.

60

-80

Bolt

- mounting, steering rack to crossbeam.

41

-54

B

olt - front mounting, crossbeam to body.

22

-28

Bol

t - spring pan to lower wishbone.

70

-90

N

ut - shock absorber to upper mounting

(vehicles with adaptive damping).

16

-18

Nu

t - shock absorber to upper mounting (vehicles without adaptive damping).

30

-40

N

ut - shock absorber lower to wishbone.

43

-57

B

olt - engine Hydramount to crossbeam.

34

-46

B

olt - crossbeam rear mounting to body.

13

1-185

Bol

t - generator cooling du

ct deflector to crossbeam.

17

-23

N

ut - lower steering column to pinion shaft.

22

-28

N

ut - hub, speed sensor rotor.

27

0-330

B

olt - shield, brake disc.

9-1

2

Bol

t - lower wishbone, front arm to rear arm.

77

-103

Nu

t - stabilizer bar link arm to wishbone bracket.

41

-54

N

ut - wishbone front

eccentric bolt.

11

3-153

Nu

t - wishbone rear

eccentric bolt.

11

3-153

N

ut - fulcrum shaft, upper wishbone.

60

-80

Bolt -

power steering pi

pes to pinion housing.

9-1

2

Page 69 of 2490

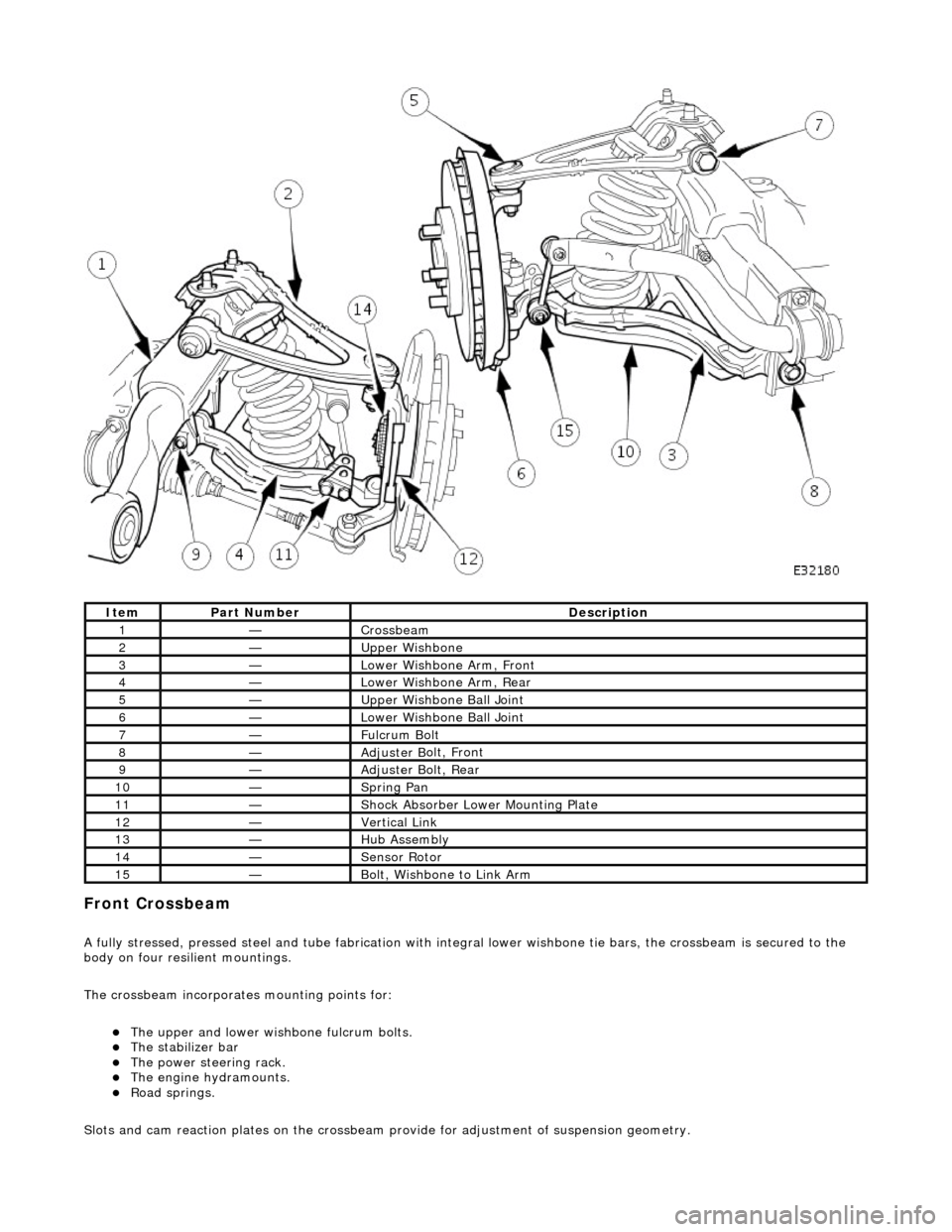

Front C

rossbeam

A

fully stressed, pressed steel and tube fa

brication with integral lower wishbone tie bars, the crossbeam is secured to the

body on four resilient mountings.

The crossbeam incorporates mounting points for:

The u

pper and lower wish

bone fulcrum bolts.

The

stabilizer bar

The power steering rack. The engine h

ydramounts.

R

oad springs.

Slots and cam reaction pl ates on the crossbeam provide for ad justment of suspension geometry.

It

em

Par

t Number

De

scription

1—Cro

ssbeam

2—Upper

Wishbone

3—Lower Wi

shbone Arm, Front

4—Lower Wi

shbone Arm, Rear

5—Upper

Wishbone Ball Joint

6—Lower Wi

shbone Ball Joint

7—Ful

crum Bolt

8—Adjuster B

olt, Front

9—Adjuster B

olt, Rear

10—S

pring Pan

11—Shock Absorber Lower M

ounting Plate

12—Vertical Link

13—Hub Assembly

14—Sensor R

otor

15—B

olt, Wishbone to Link Arm

Page 70 of 2490

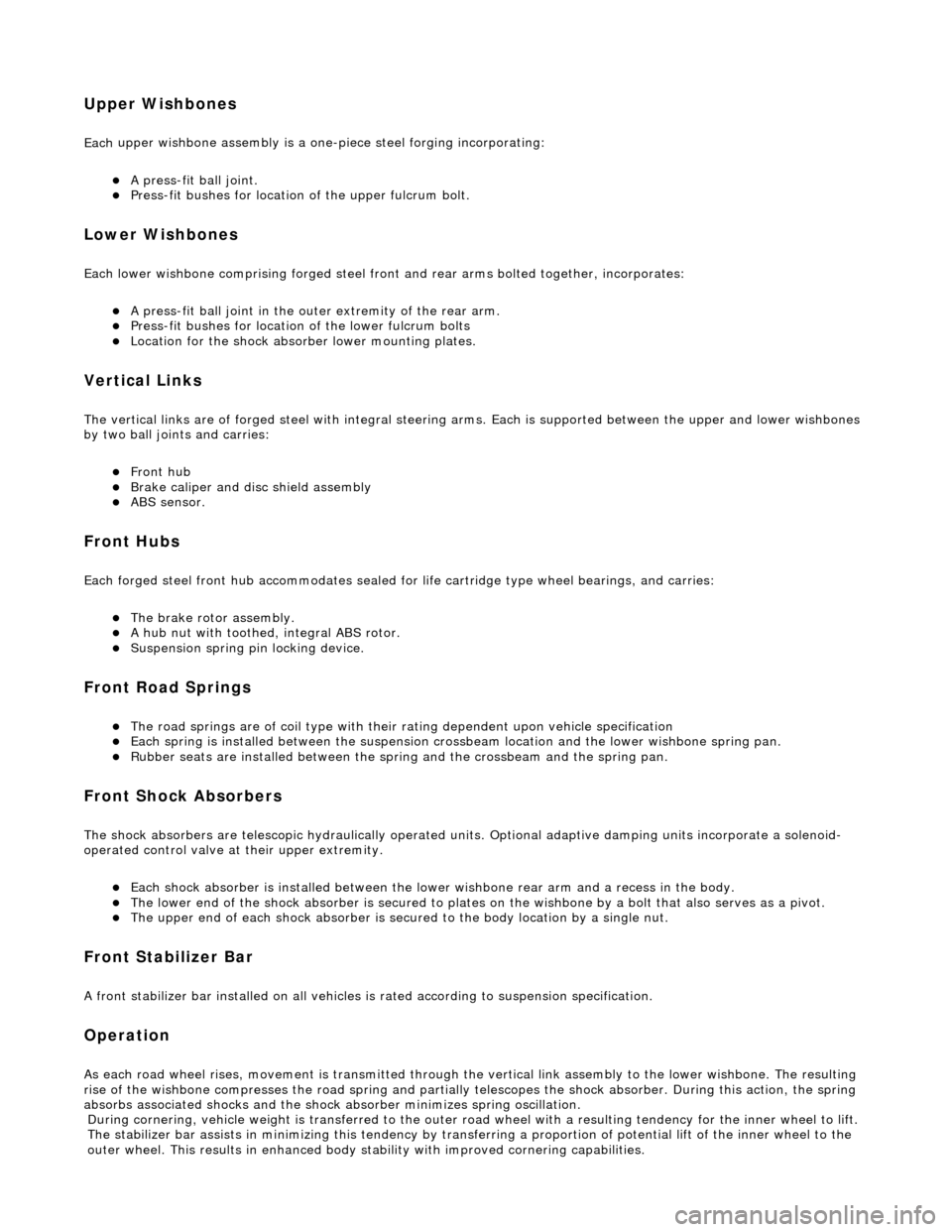

Upper

Wishbones

Each

upper wi

shbone assembly is a on

e-piece steel forging incorporating:

A pres

s-fit ball joint.

Press-fi

t bushes for location of the upper fulcrum bolt.

Lower Wishbones

Each l

o

wer wishbone comprising

forged steel front and rear arms bolted together, incorporates:

A p

ress-fit ball joint in the outer extremity of the rear arm.

Press-f

i

t bushes for location of the lower fulcrum bolts

Locati

on for the shock absor

b

er lower mounting plates.

Vertica l Links

The vertical

links are of forged steel

wi

th integral steering arms. Each is suppo rted between the upper and lower wishbones

by two ball joints and carries:

Front hub

Brake ca

liper and disc shield assembly

ABS se

nsor

.

Front Hub

s

Each f

o

rged steel front hub accommodates sealed for life cartridge

type wheel bearings, and carries:

The brake rotor assembl

y.

A

h

ub nut with toothed, integral ABS rotor.

Su

s

pension spring pi

n locking device.

Front Road

Springs

The road spri

ng

s are of coil type with their

rating dependent upon vehicle specification

Ea

ch spring is installed between the suspension crossbeam location and the lower wishbone spring pan.

Ru

bber seats ar

e installed betw

een the spring and the crossb eam and the spring pan.

Front Shock A

bsorbers

Th

e

shock absorbers are telescopic hydrau

lically operated units. Optional adaptive damping units incorporate a solenoid-

operated control valve at their upper extremity.

Each shoc

k absorber is installed between the lowe

r wishbone rear arm and a recess in the body.

The l

o

wer end of the shock absorber is se

cured to plates on the wishbone by a bolt that also serves as a pivot.

The u

pper en

d of each shock absorber is secured to the body location by a single nut.

Front Sta

b

ilizer Bar

A

front stabil

izer bar installed on all vehicles

is rated according to suspension specification.

Opera

tion

As each road wheel r

i

ses, move

ment is transmitted through the vertical link assembly to the lower wishbone. The resulting

rise of the wishbone compresses the road spring and partially telescopes the shock absorber. During this action, the spring

absorbs associated shocks and the shock absorber minimizes sprin

g os c

illation.

Du

ring cornering, vehicle weight

is transferred to the outer road wheel with a resulting tendency for the inner wheel to lift.

The stabilizer bar assists in minimizing this tendency by transf erring a proportion of potential lift of the inner wheel to the

outer wheel. This result s in enhanced body stability with improved corner ing capabilities.

Page 72 of 2490

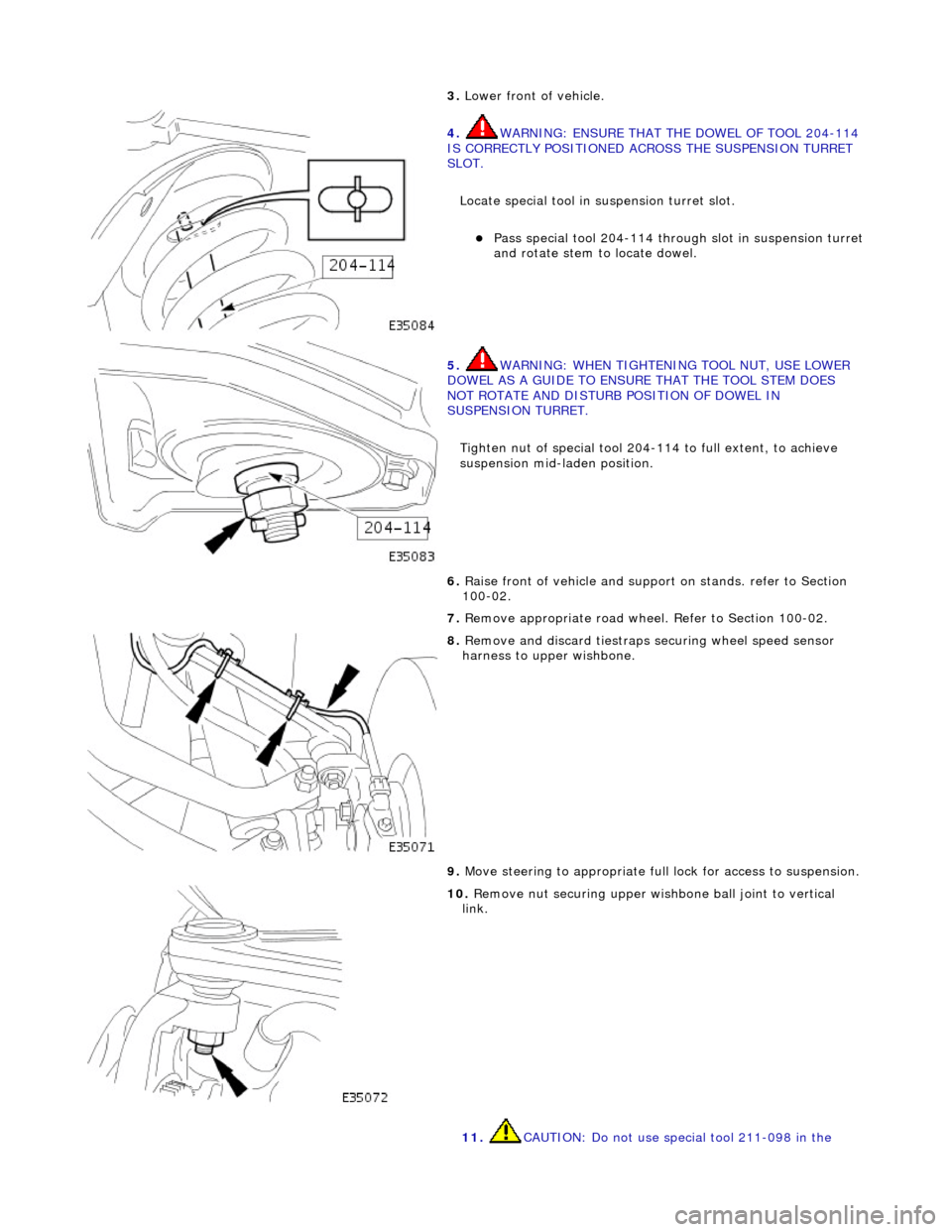

3. Lower front of vehicl

e.

4. W

A

RNING: ENSURE THAT THE DOWEL OF TOOL 204-114

IS CORRECTLY POSITIONED ACROSS THE SUSPENSION TURRET

SLOT.

Locate special tool in suspension turret slot.

Pas s

special tool 204-114 thro

ugh slot in suspension turret

and rotate stem to locate dowel.

5. WARNING: WHE N

TIGHTENING

TOOL NUT, USE LOWER

DOWEL AS A GUIDE TO ENSURE THAT THE TOOL STEM DOES

NOT ROTATE AND DISTURB POSITION OF DOWEL IN

SUSPENSION TURRET.

Tighten nut of special tool 204-114 to full extent, to achieve

suspension mid-laden position.

6. Ra

ise front of vehicle and support

on stands. refer to Section

100-02.

7. Remove appropriate road wheel. Refer to Section 100-02.

8. Remove an d discard tiestraps se

curing wheel speed sensor

harness to upper wishbone.

9. Move steering to appropriate full lock for access to suspension.

10 . R

emove nut securing upper wish

bone ball joint to vertical

link.

11. CAUTION: Do not use special tool 211-098 in the

Page 73 of 2490

f

ollowing procedure as this will

damage the ball joint gaiter.

Release wishbone ball joint from vertical link.

1. Install special tool 204-192 on upper wishbone ball joint.

2. Tighten bolt of special tool to release ball joint

taper from vertical link.

12. Remove special tool from ball joint.

13

.

Lift upper wishbone to withdraw ball joint from vertical link.

14

.

To prevent damage to lower ball joint, secure vertical link to

road spring using strong wire.

15

.

Remove upper wishbone fulcrum nut and bolt and withdraw

wishbone from vehicle.

16. Secure upper wishbone in a vise.

17. Using a hacksaw, partially cut through two diametrically

opposite segments of ball joint flange.

Page 77 of 2490

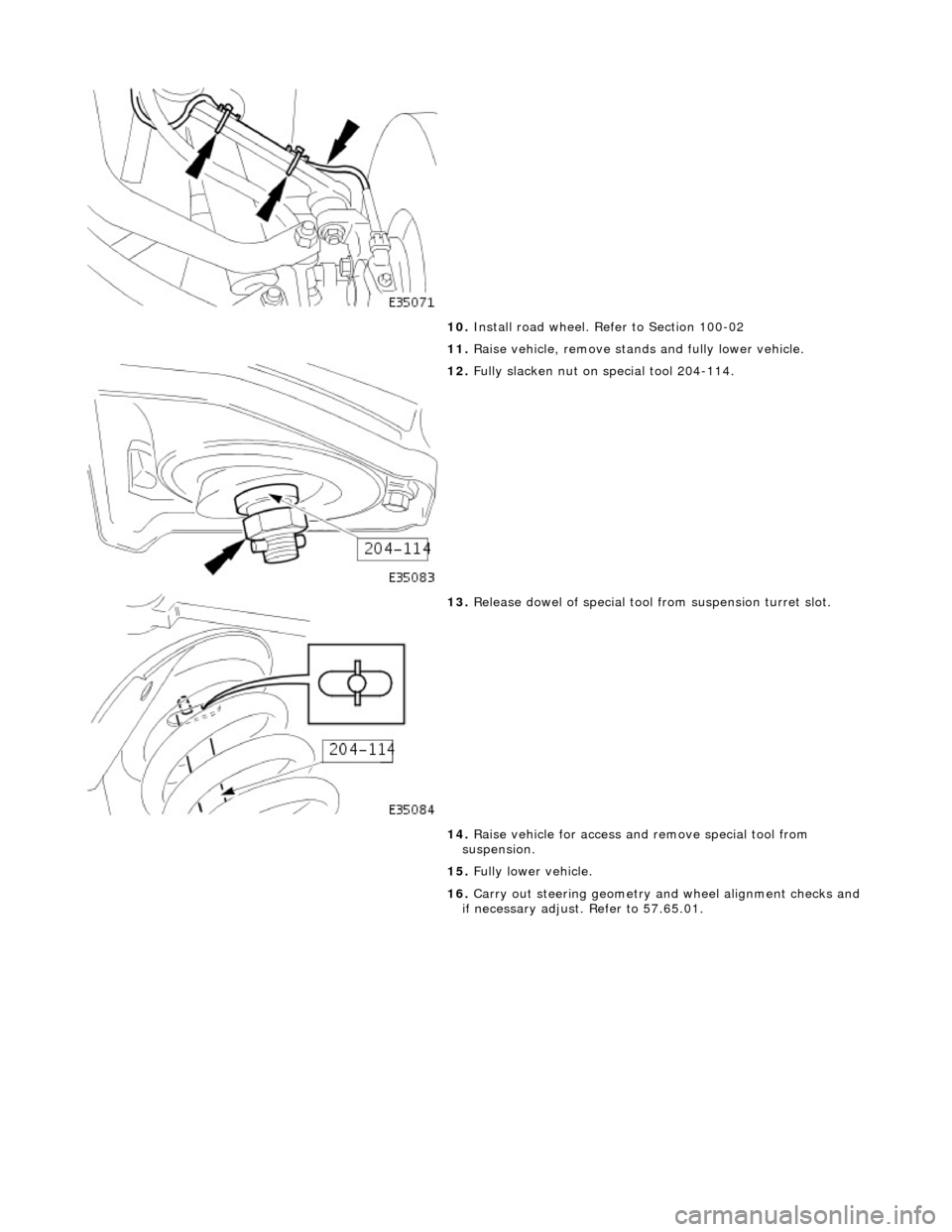

10

.

Install road wheel. Re fer to Section 100-02

11. Raise vehicle, remove stands and fully lower vehicle.

12

.

Fully slacken nut on special tool 204-114.

13

.

Release dowel of special tool from suspension turret slot.

14. Raise vehicle for access an d remove special tool from

suspension.

15. Fully lower vehicle.

16. Carry out steering geometry an d wheel alignment checks and

if necessary adjust. Refer to 57.65.01.

Page 78 of 2490

Front Suspension - Rear Lower Arm

Remo

val and Installation

Remov

a

l

CAUTI

O

N: Replacement of

nuts and bolts: Various thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt can be used. Refer to Section 100-00 for further

information.

S p

ecial Tool(s)

R

o

ad spring compressor

204-111 (JD115)

Taper separator

2

11-098 (JD 100)

Ball

Jo

int Taper Separator

204-192 (JD 219)

Bal l

joint splitter

204-293

1. Ra

ise front of vehicle and support on stands. Refer to Section

100-02.

2. Remove appropriate road wheel. Refer to Section 100-02.

3. CAUTIO

N: Do not suspend caliper from brake hose as

this will damage the hose.

Remove brake calipers from carriers. 1. Remove caliper spring clip.

2. Remove guide pin dust caps.

3. Slacken and withdraw guide pins.

4. Remove caliper from carrier and tie to suspension mounting bracket.

4. Ra

ise vehicle further to provid

e access for Special Tool 204-

Page 79 of 2490

1

11 and support on stands. Refer to Section 100-02.

5. Ins

tall Special Tool 204-111 in road spring.

Sl

acken tool adjuster to suit spring length.

Install adaptor

and thrust collar.

Posit

ion stem of tool in center of spring passing dowel

through slot in su spension turret.

6. R

otate stem of Special Tool to

position dowel across slot.

7. W

ARNING: WHEN TURNING TOOL ADJUSTER, ENSURE

THAT TOOL STEM DOES NOT ROTATE AND DISTURB POSITION

OF DOWEL IN SUSPENSION TURRET.

Rotate adjuster of Special Tool to tension spring.

8. R

emove spring pan to lower

wishbone securing bolts.

9. Rotate adjuster of Special Tool to release tension from spring.

Page 80 of 2490

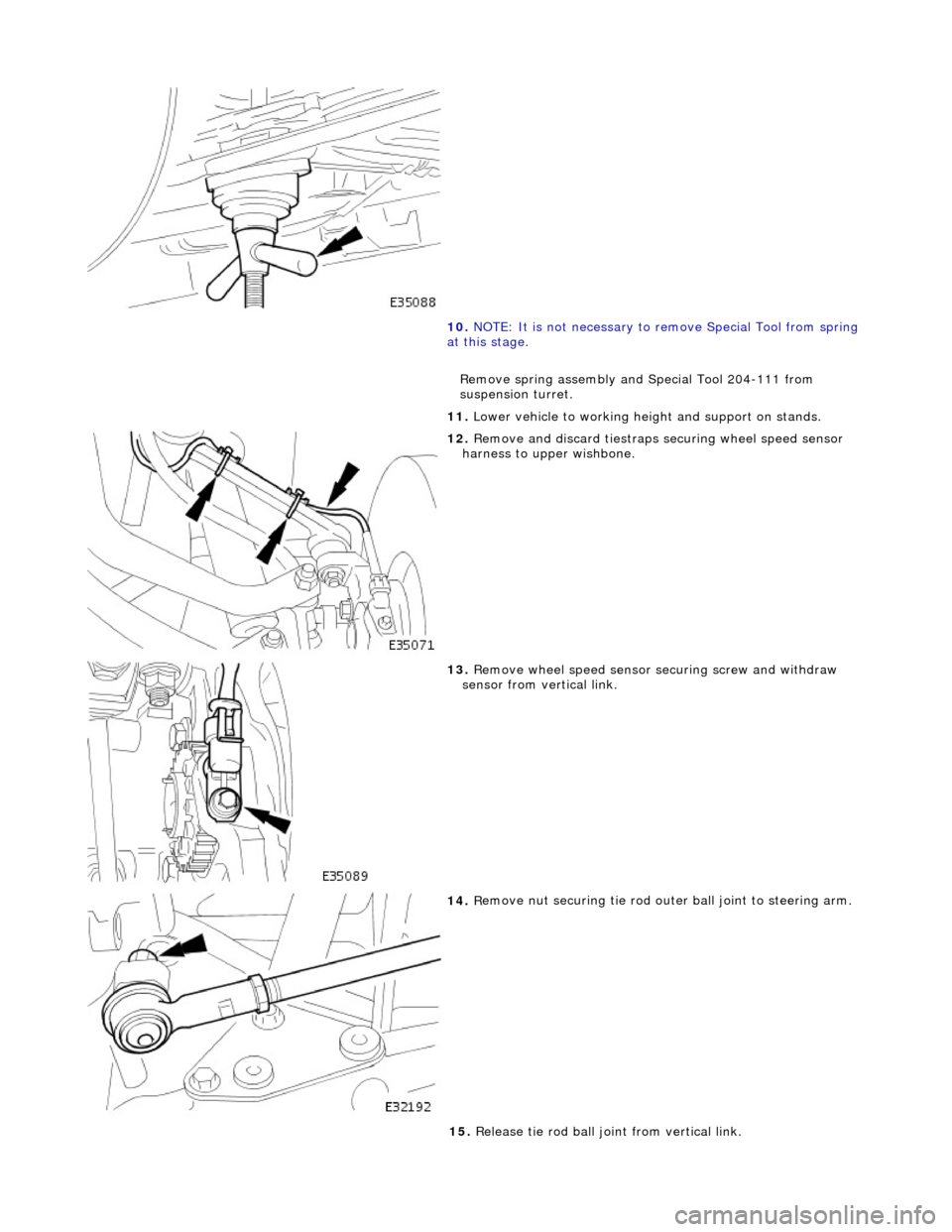

10. NOTE

: It is not necessary to re

move Special Tool from spring

at this stage.

Remove spring assembly and Special Tool 204-111 from

suspension turret.

11. Lower vehicle to working heig ht and support on stands.

12 . Remove an

d discard tiestraps

securing wheel speed sensor

harness to upper wishbone.

13 . R

emove wheel speed sensor se

curing screw and withdraw

sensor from vertical link.

14 . R

emove nut securing tie rod oute

r ball joint to steering arm.

15. Release tie rod ball joint from vertical link.