vvt JAGUAR X308 1998 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 541 of 2490

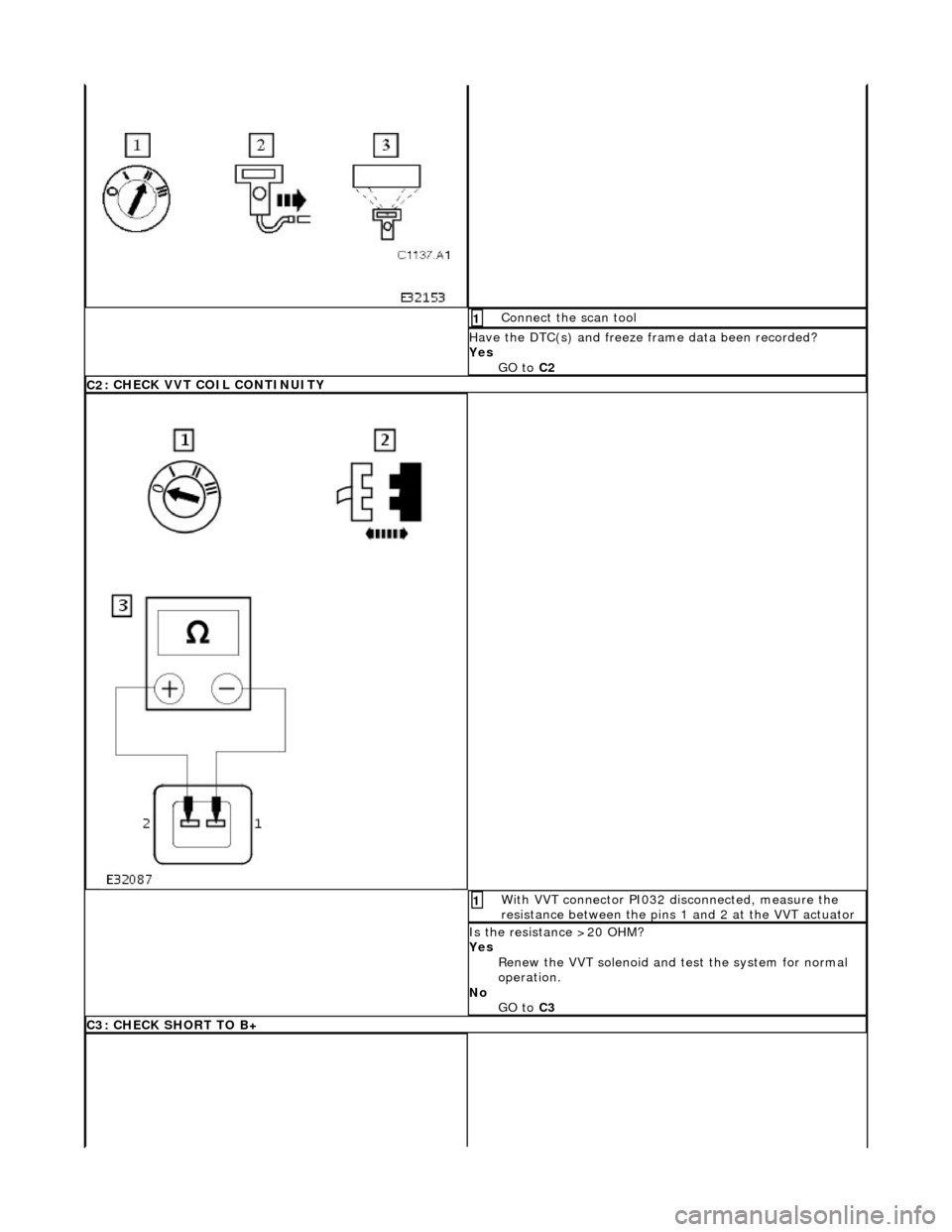

Conne

ct the scan tool

1

Have the DTC(s) and fr

eeze

frame data been recorded?

Yes GO to C2

C2

: CHECK VVT COIL CONTINUITY

Wi

th VVT connector PI032 disconnected, measure the

resistance between the pins 1 and 2 at the VVT actuator

1

I

s the resistance >20 OHM?

Yes Renew the VVT solenoid and te st the system for normal

operation.

No GO to C3

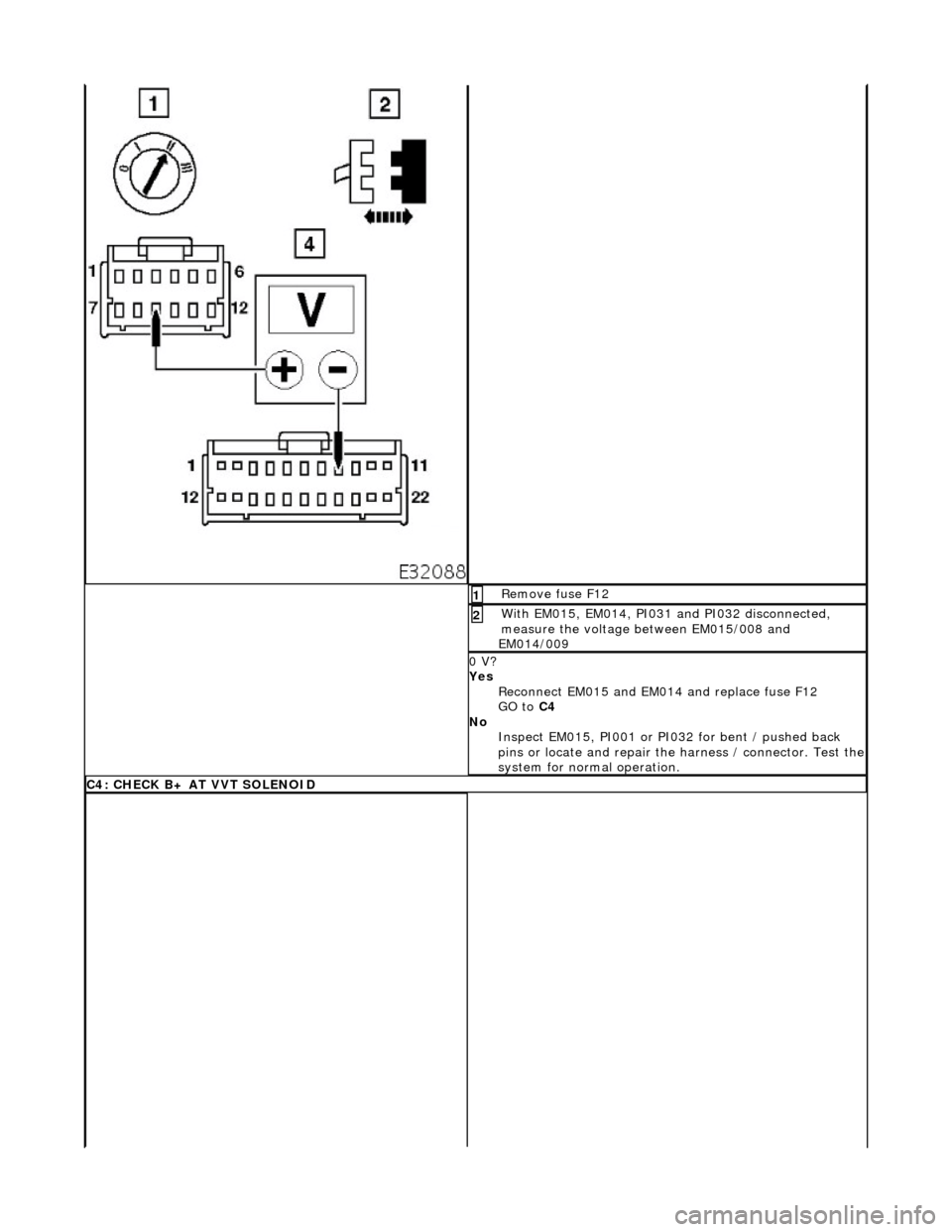

C3

: CHECK SHORT TO B+

Page 542 of 2490

Re

move fuse F12

1

W

i

th EM015, EM014, PI031 and PI032 disconnected,

measure the voltage between EM015/008 and

EM014/009

2

0 V?

Yes

Reconnect EM015 and EM0 14 and replace fuse F12

GO to C4

No Inspect EM015, PI001 or PI032 for bent / pushed back

pins or locate and repair the harness / connector. Test the

system for normal operation.

C4 :

CHECK B+ AT VVT SOLENOID

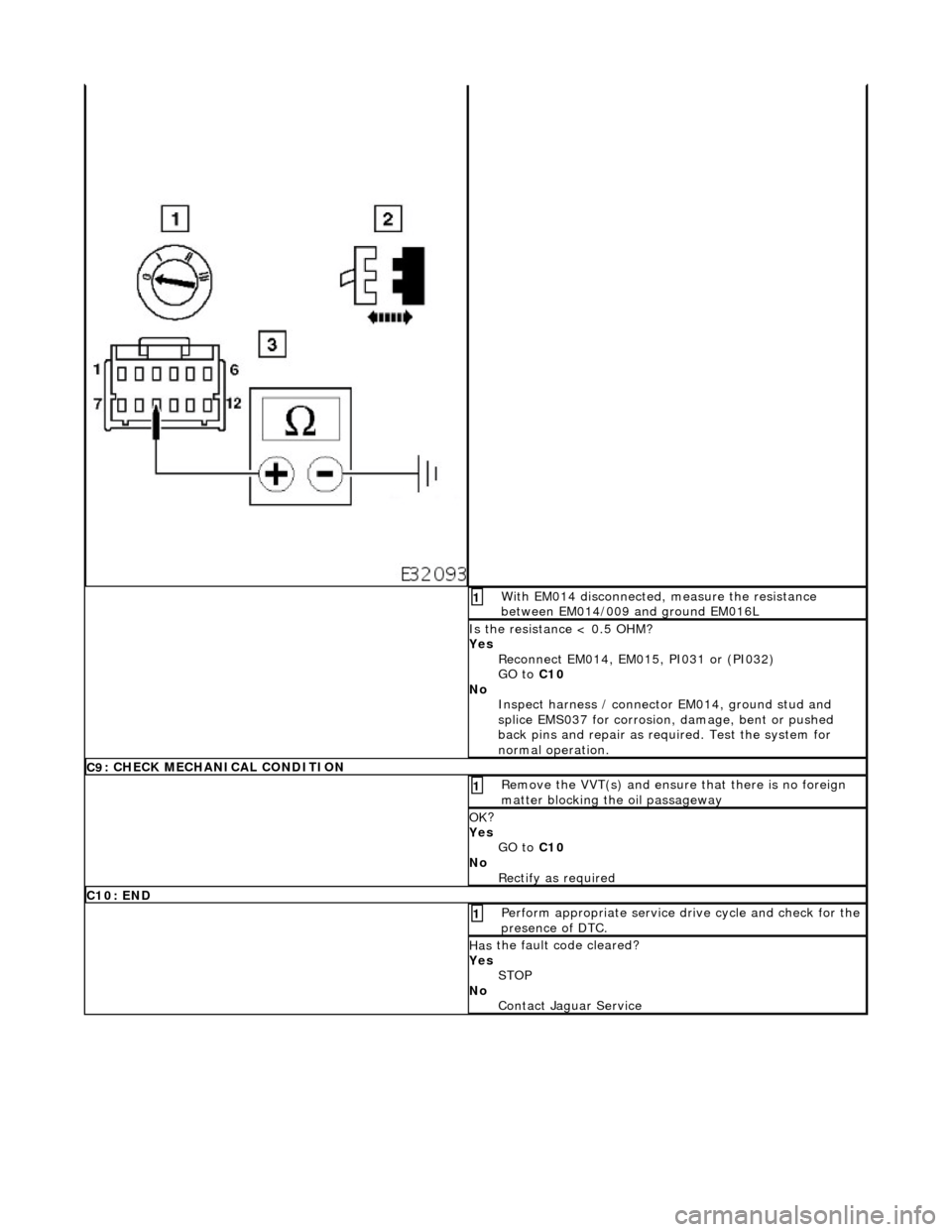

Page 547 of 2490

W

ith EM014 disconnected, measure the resistance

between EM014/009 and ground EM016L

1

I

s the resistance < 0.5 OHM?

Yes Reconnect EM014, EM015, PI031 or (PI032)

GO to C10

No Inspect harness / connector EM014, ground stud and

splice EMS037 for corrosion, damage, bent or pushed

back pins and repair as required. Test the system for

normal operation.

C9

: CHECK MECHANICAL CONDITION

R

emove the VVT(s) and ensure

that there is no foreign

matter blocking the oil passageway

1

OK

?

Yes GO to C10

No Rectify as required

C

10: END

Perform

appropriate service drive cycle and check for the

presence of DTC.

1

Has

the fault code cleared?

Yes STOP

No Contact Jaguar Service

Page 565 of 2490

Engine - Crankshaft

Inner Sp

rocket4.0L NA V8 - AJ27

In-v

ehicle Repair

Remov

al

S

pecial Tool(s)

Camshaft setting

3

03 - 530

T

iming chain tensioning

303 - 532

Wedges, primary ch

ain

303 - 533

Cranksh

aft setting

303 - 531

1. Open the engine compartment and fit paintwork protection

sheets.

2. Set the engine compartment cover to the service access

position.

3. Di

sconnect the batt

ery ground cable.

R

emove the battery cover.

4. Remove the Timing Co ver. Refer to Operation 12.65.01 in this

Section.

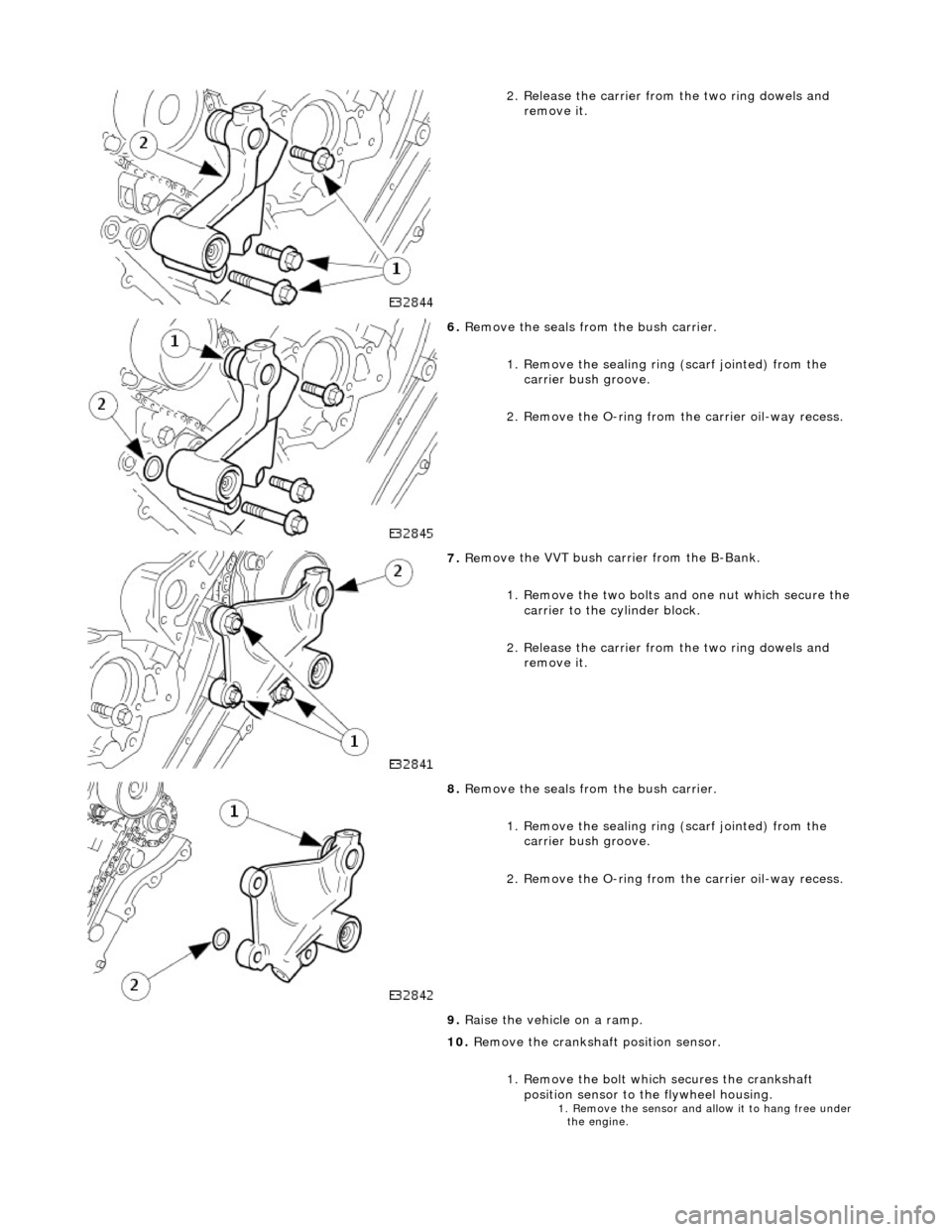

5. Remove the VVT bush carrier from the A-Bank.

1. Remove the three bolts which secure the carrier to the cylinder block.

Page 566 of 2490

2.

Release the carrier from

the two ring dowels and

remove it.

6. Re

move the seals from the bush carrier.

1. Remove the sealing ring (scarf jointed) from the

carrier bush groove.

2. Remove the O-ring from the carrier oil-way recess.

7. Re

move the VVT bush carrier from the B-Bank.

1. Remove the two bolts and one nut which secure the carrier to the cylinder block.

2. Release the carrier from the two ring dowels and

remove it.

8. Re

move the seals from the bush carrier.

1. Remove the sealing ring (scarf jointed) from the

carrier bush groove.

2. Remove the O-ring from the carrier oil-way recess.

9. Raise the vehicle on a ramp.

10. Remove the crankshaft position sensor.

1. Remove the bolt which secures the crankshaft position sensor to the flywheel housing.

1. Re move

the sensor and allow it to hang free under

the engine.

Page 568 of 2490

18. L

oosen the bolt which secures

the VVT unit to the camshaft.

19 . Re

move the primary ch

ain tensioner bolts.

20 . R

emove the tensioner assembly.

1. Remove the tensioner.

2. Remove the tensioner back-plate.

21. Remove the chain tensioner blade.

1. Remove the pivot bolt which secures the tensioner blade.

2. Remove the tensioner blade.

Page 569 of 2490

22

.

Remove the chain from the VVT unit and from the crankshaft

pulley.

23

.

Remove the camshaft locking tool 303 - 530 and transfer it to

the B-Bank camshafts, aligning the shafts slightly as necessary.

24

.

Loosen the bolt which secures the sprocket to the camshaft.

25

.

Loosen the bolt which secures the VVT unit to the camshaft.

26. Remove the primary ch ain tensioner bolts.

Page 570 of 2490

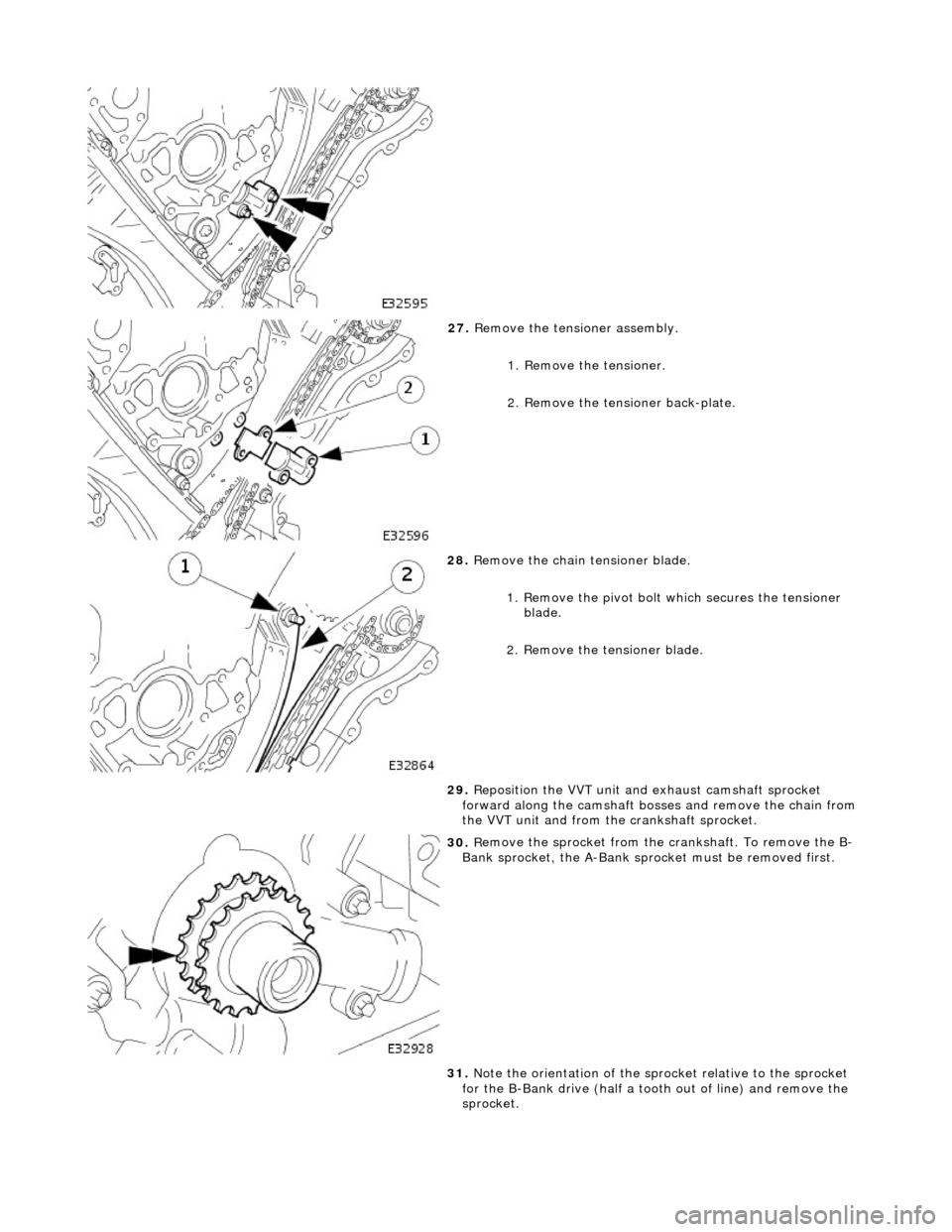

27. R

emove the tensioner assembly.

1. Remove the tensioner.

2. Remove the tensioner back-plate.

28. R

emove the chain tensioner blade.

1. Remove the pivot bolt which secures the tensioner blade.

2. Remove the tensioner blade.

29. Reposition the VVT unit and exhaust camshaft sprocket

forward along the camshaft bosses and remove the chain from

the VVT unit and from th e crankshaft sprocket.

30 . R

emove the sprocket from the

crankshaft. To remove the B-

Bank sprocket, the A-Bank spro cket must be removed first.

31. Note the orientation of the spro cket relative to the sprocket

for the B-Bank drive (half a toot h out of line) and remove the

sprocket.

Page 571 of 2490

I

nstallation

32

.

Clean and inspect all relevant components.

1. F

it the sprockets to the crankshaft.

Th

e teeth of the A-Bank and the B-Bank sprockets on the

crankshaft must be out of phas e with each other. If they

are in-phase after fitting, remove the A-Bank sprocket,

turn it on its vertical axis and refit it.

2. F

it the chain tensioning tool 303 - 532 to the exhaust camshaft

sprocket, B-Bank.

Re

position the sprocket (and

the VVT unit) for the most

advantageous position for use of the tool.

R

emove the tool.

3. R

efit the primary timing chain, B-Bank.

1. Fit the primary chain over the crankshaft sprocket and the VVT unit sprocket. There must be no slack on

the drive side of the primary chain and the VVT unit

must not be rotate d on the camshaft.

Sl

ide the VVT and exhaust sprocket fully rearwards onto

the respective camshafts.

4. Fit the primary chain tensioner blade.

1. Position the tensioner blade to the cylinder block.

Page 572 of 2490

2. Fi

t the retaining / pivot bolt and tighten it to 12 - 16

Nm.

5. Refi

t the primary chain tensione

r assembly. Refer to Operation

12.65.55 in this Section.

U s

e a wedge 303 - 533 (or two if required) between the

primary chain tensioner and te nsioner blade, to take up

the slack in the chain.

6. Tigh te

n the exhaust camshaft

sprocket securing bolt.

1. Fit the chain tensioner tool 303 - 532 to the sprocket holes.

1. Apply force to the to

ol in

an anti-clockwise direction

to tension the chain on its drive side.

2 .

Whilst applying the opposing force to the sprocket

and chain, tighten the sprock et securing bolt to 115 -

125 Nm.

7. Tigh te

n the VVT unit securing bolt.

1. Whilst still applying the opposing force to the

sprocket and chain (using 303 - 532), check that the

wedges are still in place, tighten the VVT unit

securing bolt to 115 - 125 Nm.

Re

move the chain tensioning

tool and the wedge(s).

8. Remove the camshaft locking tool 303 - 530 and transfer it to

the A-Bank camshafts, aligning the shafts slightly as necessary.