body JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1371 of 2490

Automatic Transmission/Transaxle - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

- Transmission Support Insulator

In-vehicle Repair

Removal

Installation

1. Raise the vehicle on a ramp to a suitable height for working on

the rear mounting.

2. Remove the bolt which secure s the engine rear mounting

rubber to the transmission.

3. Position a transmission jack under the transmission casing.

Take the weight of the transmission on the jack.

4. Remove the rear mounting rubber.

1. Slacken the four bolt s which secure the rear

crossmember to the vehicle floor.

2. Remove the two bolts which secure the mounting rubber to the crossmember.

3. Remove the mounting rubber.

1. Fit the mounting rubber assembly to position and tighten the

centre bolt to 30-40 Nm .

2. Tighten the crossmember to body bolts and the mounting

rubber to crossmember bolts to 22-28 Nm.

Page 1377 of 2490

16. Remove the engine rear mounting bracket.

1. Remove the engine rear mounting to bracket bolt.

2. Remove the mounting bracket to body bolts.

17. Detach the driveshaft from th e transmission drive flange.

If the transmission is to be refitted, mark the position of

the coupling to drive flange.

17. CAUTION: Under no circ umstances remove the

driveshaft to flexible coupling fixings.

Remove the transmission drive flange to flexible coupling

three fixings.

18. Lower the transmission unit by carefully releasing the engine

support beam and by loweri ng the transmission jack.

19. Detach the gear selector cable from the transmission unit.

1. Remove the selector cable ball pin to selector lever nut.

2. Remove the selector cable to transmission casing bolts.

20. Disconnect the transmission harness multiplug.

1. Rotate the locking lever to release.

2. Disconnect the multiplug.

Page 1388 of 2490

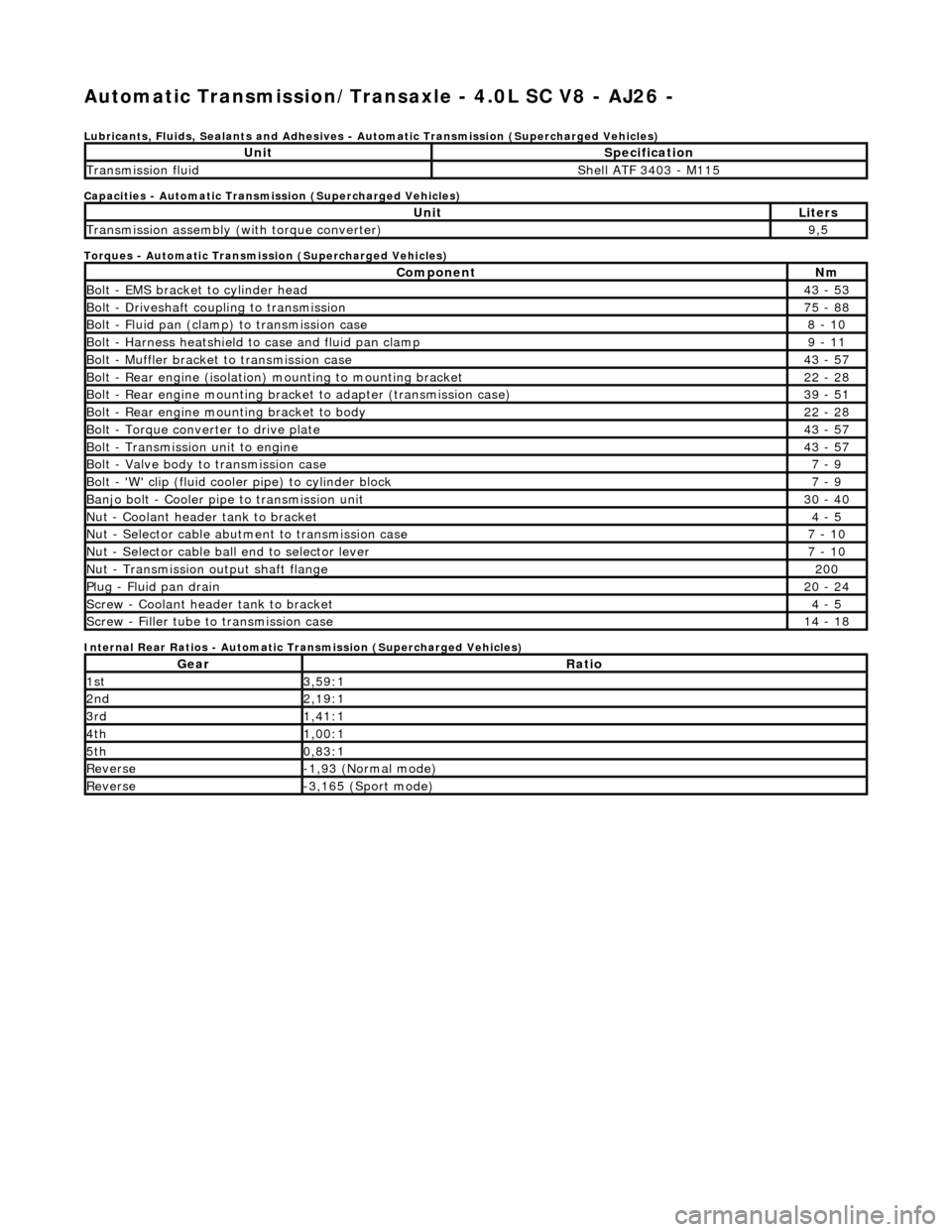

Automatic Transmission/Transaxle - 4.0L SC V8 - AJ26 -

Lubricants, Fluids, Sealants and Adhesives - Automatic Transmission (Supercharged Vehicles)

Capacities - Automatic Transmission (Supercharged Vehicles)

Torques - Automatic Transmission (Supercharged Vehicles)

Internal Rear Ratios - Automatic Transmission (Supercharged Vehicles)

UnitSpecification

Transmission fluidShell ATF 3403 - M115

UnitLiters

Transmission assembly (with torque converter)9,5

ComponentNm

Bolt - EMS bracket to cylinder head43 - 53

Bolt - Driveshaft coupling to transmission75 - 88

Bolt - Fluid pan (clamp) to transmission case8 - 10

Bolt - Harness heatshield to case and fluid pan clamp9 - 11

Bolt - Muffler bracket to transmission case43 - 57

Bolt - Rear engine (isolation) mounting to mounting bracket22 - 28

Bolt - Rear engine mounting brac ket to adapter (transmission case)39 - 51

Bolt - Rear engine mounting bracket to body22 - 28

Bolt - Torque converter to drive plate43 - 57

Bolt - Transmission unit to engine43 - 57

Bolt - Valve body to transmission case7 - 9

Bolt - 'W' clip (fluid cooler pipe) to cylinder block7 - 9

Banjo bolt - Cooler pipe to transmission unit30 - 40

Nut - Coolant header tank to bracket4 - 5

Nut - Selector cable abutment to transmission case7 - 10

Nut - Selector cable ball end to selector lever7 - 10

Nut - Transmission output shaft flange200

Plug - Fluid pan drain20 - 24

Screw - Coolant header tank to bracket4 - 5

Screw - Filler tube to transmission case14 - 18

GearRatio

1st3,59:1

2nd2,19:1

3rd1,41:1

4th1,00:1

5th0,83:1

Reverse-1,93 (Normal mode)

Reverse-3,165 (Sport mode)

Page 1401 of 2490

Pinpoint test A: P0740

DTC P0730 Incorrect gear ratioEngaged gear implausible / transmission

slipping Oil level low

Valve body assembly faulty

Transmission faulty

*

*

*

*GO to Pinpoint Test H *

DTC P0780 Shift malfunctionValve body assembly faulty

Transmission faulty

*

*GO to Pinpoint Test H *

PINPOINT TEST A : P0740

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

A1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi

ll erase all data, ensure that the correct DTC is present.

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to A2

A2: CHECK TORQUE CONVERTER CLUTCH SOLENOID RESISTANCE

With, EM062 disconnected, measure the resistance between 1

Page 1412 of 2490

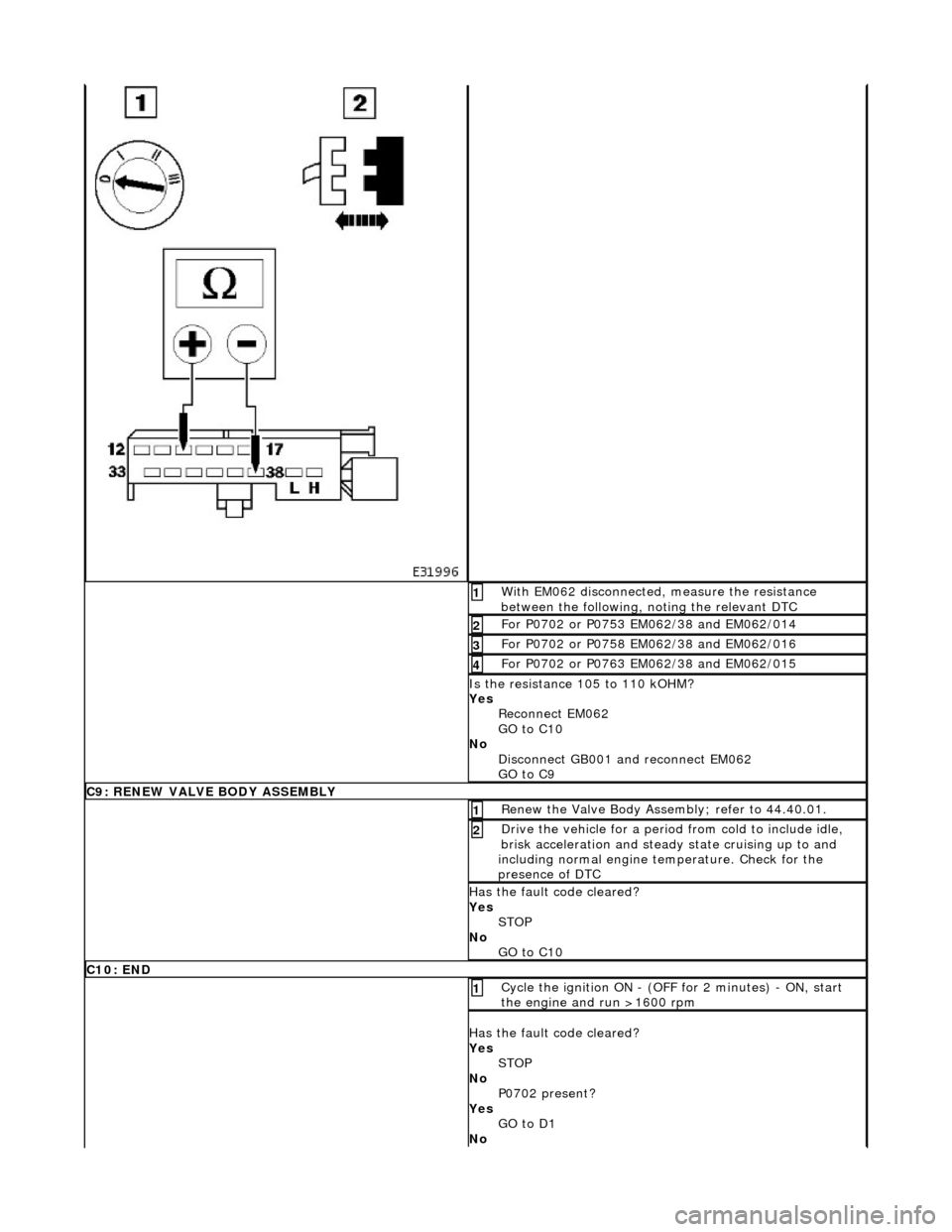

With EM062 disconnected, measure the resistance

between the following, noting the relevant DTC 1

For P0702 or P0753 EM062/38 and EM062/014 2

For P0702 or P0758 EM062/38 and EM062/016 3

For P0702 or P0763 EM062/38 and EM062/015 4

Is the resistance 105 to 110 kOHM?

Yes Reconnect EM062

GO to C10

No Disconnect GB001 and reconnect EM062

GO to C9

C9: RENEW VALVE BODY ASSEMBLY

Renew the Valve Body Assembly; refer to 44.40.01. 1

Drive the vehicle for a period from cold to include idle,

brisk acceleration and steady state cruising up to and

including normal engine temperature. Check for the

presence of DTC 2

Has the fault code cleared?

Yes STOP

No GO to C10

C10: END

Cycle the ignition ON - (OFF for 2 minutes) - ON, start

the engine and run >1600 rpm 1

Has the fault code cleared?

Yes STOP

No P0702 present?

Yes GO to D1

No

Page 1419 of 2490

Pinpoint test E: P0702

With EM062 disconnected, measure the resistance

between the following, noting the relevant DTC 1

For P0702 or P0748 EM062/38 and EM062/036 2

For P0702 or P1748 EM062/38 and EM062/037 3

Is the resistance 16 to 18 kOHM?

Yes Reconnect EM062

GO to D9

No Renew the Valve Body Assembly; refer to 44.40.01.

Drive the vehicle for a period from cold to include idle,

brisk acceleration and steady state cruising up to and

including normal engine temperature.

GO to D9

D9: END

Cycle the ignition ON - (OFF for 2 minutes) - ON, start

the engine and run >1600 rpm 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TEST E : P0702

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

E1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present.

Page 1427 of 2490

Pinpoint test H: P0730, P0780

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to G2

G2: RENEW TCM

Renew the TCM 1

Has the TCM been renewed?

Yes GO to G3

G3: END

• NOTE: The following step must be carried out in order that sy stem adaptions can take place.

Drive the vehicle for a period from cold to include idle, brisk

acceleration and steady state cruising up to and including

normal engine temperature. Check for the presence of DTC 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TEST H : P0730, P0780

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

H1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present.

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to H2

H2: RENEW VALVE BODY ASSEMBLY

Renew the valve body assembly 1

Drive the vehicle for a period from cold to include idle, brisk

acceleration and steady state cruising up to and including

normal engine temperature. Check for the presence of DTC 2

Has the fault code cleared?

Page 1433 of 2490

Automatic Transmission/Transaxle - 4.0L SC V8 - AJ26 - Extension

Housing Seal

In-vehicle Repair

Removal

Special Tool(s)

Oil seal replacer

307-378

Driveshaft wrench

205-053

1. Disconnect the battery ground lead.

2. Select N and choc the road wheels.

3. Remove the front muffler, re fer to Operation 30.10.18.

4. Remove the engine rear mounting bracket.

1. Support the transmission.

2. Remove the bolt, engine rear mounting to transmission.

3. Remove the four bolts which secure the mounting

cross member to the body.

5. Detach the driveshaft from th e transmission drive flange.

1. If the transmission is to be refitted, mark the position of the coupling relative to the drive flange.

5. CAUTION: Under no circ umstances remove the

driveshaft to flexible coupling fixings.

2. Remove the three bolts, tr ansmission drive flange to

flexible coupling.

6. Secure the driveshaft wrench 205 - 053 to the output shaft

flange.

Page 1436 of 2490

Automatic Transmission/Transaxle - 4.0L SC V8 - AJ26 - Main Control

Valve Body

In-vehicle Repair

Removal

• NOTE: This procedure will not remove re sidual fluid from the torque converter.

1. Disconnect the battery ground lead.

2. Raise the vehicle for access.

3. Remove the RH catalytic converter; refer to Operation

17.50.10.

4. Remove the harness heatshield lower fixing.

Remove the screw heatshield / fluid pan clamp.

5. Remove the harness heatshield.

Pull the heatshield from under the clip.

6. Disconnect the transmission link harness connector.

1. Release the locking lever.

7. Release the (transmission case mounted) female connector.

Remove the (center) retaining bolt.

Page 1437 of 2490

8. Drain the transmission fluid.

8. WARNING: TRANSMISSION FLUID MAY CAUSE

SEVERE BURNS, ENSURE THAT ALL SAFETY PROCEDURES

ARE OBSERVED AND THAT THE RECEPTACLE FOR WASTE

HAS SUFFICIENT CAPACITY.

Carefully remove the drain pl ug and discard the sealing

washer.

9. Remove the fluid pan; refer to Operation 44.24.05,

10. Remove the fluid filter.

Pull the filter squarely to disengage the pick-up 'O' ring

and location tang - there is NO mechanical retention.

11. Remove the selector detent leaf spring.

Remove the screw.

12. Remove the dowel - leaf spring to valve body.