body JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1161 of 2490

E

vaporative Emissions - Evaporative Emissions

D

iagnosis and Testing

Prelim

inary Inspection

1.

1. Vis

ually inspect for obvious signs of mechanical or electrical damage.

V

isual Inspection Chart

2.

2. If

an obvious cause for an observed or

reported concern is found, correct th e cause (if possible) before proceeding

to the next step.

3. 3. If the concern is not visually evident, verify the symptom and proceed with diagnosis, using the Jaguar approved

diagnostic system, where available.

4. 4. Where K-Line or Vacutec equipment is available, it should be used as an aid to diagnosis. The equipment must be

capable of testing to the 0.020 thou standard (2001 MY on).

Diagnostic Drive Cycles

Following th

e setting of a DTC, the appropriate repairs must

be carried out, and the normal operation of the system

checked. This will be done by performing a series of drive cycles which will enable the vehicle to operate the evaporative

emissions system as a function check. For details of the drive cycles,

REFER to Section 303

-1

4 Electronic Engine Controls

.

ECM adapt

ations.

Diagnostic Trouble Code

(D

TC) index/Symptom Chart

1.

1. Wh

ere the Jaguar approved diagnostic sy

stem is available, complete the S93 report before clearing any or all fault

codes from the vehicle.

• NOTE: If a DTC cannot be cleared, then there is a permanent fault present that flag s again as soon as it is cleared. (The

exception to this is P1260, which will only clear following an ignition OFF/ON cycle after rectification).

2. 2. If the cause is not visually evident and the Jaguar approv ed diagnostic system is not available, use a fault code

reader to retrieve the fault codes be fore proceeding to the Diagnostic Trou ble Code (DTC) Index Chart, or the

Symptom Chart if no DTCs are set.

3. 3. Using the Jaguar approved diagnostic system where available, and a scan tool where not, check the freeze frame

data for information on the conditions applicable when the fault was flagged. The format of this will vary,

depending on the tool used, but can pr ovide information useful to the technician in diagnosing the fault.

CAUTION: When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit,

part number 3548-1358-00.

• NOTE: When performing electrical voltag e or resistance tests, always use a digital multimeter (DMM) accurate to 3

decimal places, and with an up-t o-date calibration certificate. When testing resistance, always take the resistance of the

DMM leads into account.

• NOTE: Check and rectify basic faults before beginning diagnostic ro utines involving pinpoint tests.

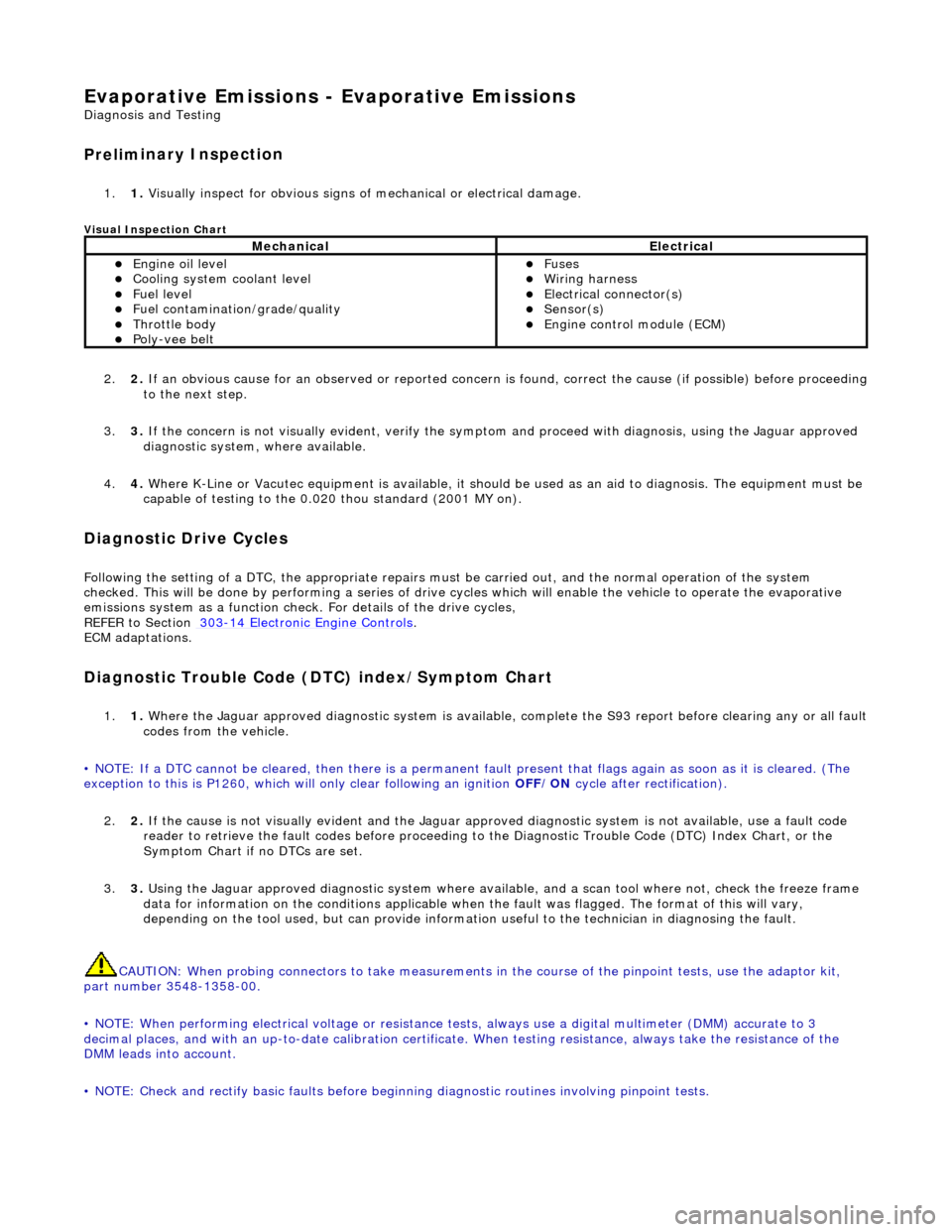

MechanicalElectrical

Engi

ne oil level

Coo

ling system coolant level

Fue

l level

Fuel contaminatio

n

/grade/quality

Throttle body Poly

-vee belt

F

uses

W

iring harness

E

lectrical connector(s)

Sens

or(s)

Engine

control module (ECM)

Page 1167 of 2490

E

vaporative Emissions - Evap

orative Emission Canister

Re

moval and Installation

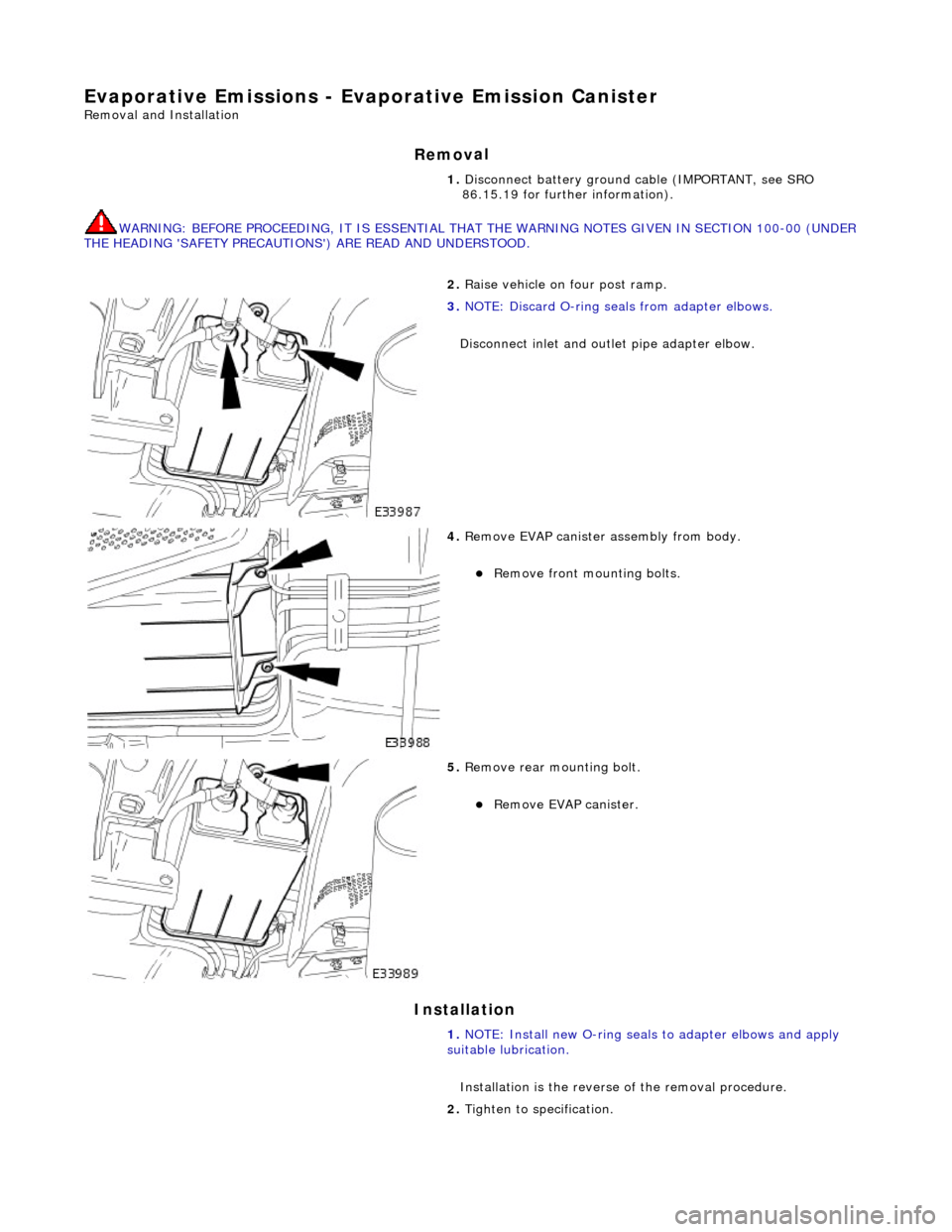

Remov

al

WARNING: B

EFORE PROCEEDING, IT IS ESSENTIAL THAT

THE WARNING NOTES GIVEN IN SECTION 100-00 (UNDER

THE HEADING 'SAFETY PRECAUTION S') ARE READ AND UNDERSTOOD.

I

nstallation

1.

Disc

onnect battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. R

aise vehicle on four post ramp.

3. N

OTE: Discard O-ring se

als from adapter elbows.

Disconnect inlet and outl et pipe adapter elbow.

4. R

emove EVAP canister assembly from body.

R

emove front mounting bolts.

5. Re

move rear mounting bolt.

Re

move EVAP canister.

1. NOTE: Install new O-ring seals to adapter elbows and apply

suitable lubrication.

Installation is th e reverse of the removal procedure.

2. Tighten to specification.

Page 1178 of 2490

Throttle Position (TP) Sensor

Location

P

arts List

sen

d

s the ECM a signal indica

ting throttle plate angle

is

the main input to the ECM from the driver

i

s

a dual Hall effect devi

ce mounted on the motor en d of the throttle body

Two additional sensors are attached to the throttle body to provide additional feedback to the ECM: a mechanical guard

position sensor and an accelerator pedal position sensor.

Cam s

haft Position (CMP) Sensor

sen

d

s the ECM a signal indicating camshaft po

sition for fuel synchronization purposes

is

a variable reluctance device mounted on bank 2 cylinder side face

generates a signal when the ri

ng

fitted to the bank 2 inlet

camshaft passes the sensor

Cranksha

ft Position (CKP) Sensor

i

s

a variable reluctance device

mounted on the engine oil pan

Ite

m

Par

t

Number

De

scr

iption

1—Acce

le

rator pedal and mechanic

al guard position sensors

2—Throttle

(blade)

position sensor

Page 1189 of 2490

E

lectronic Engine Controls -

Electronic Engine Controls

D

iagnosis and Testing

I

nspection and Verification

1.

1. Veri

fy the customer concern.

2. 2. Confirm which, if any, warning li ghts and/or messages were displayed on the instrument cluster.

• NOTE: If any warning lights and/or me ssages were displayed when the fault occurred, refer to the Driver Information

table for DTCs associated with the display, then to the DTC index table for possible sources and actions. Some warnings will

appear to clear when the ignition is cycl ed. This is often because the warning has flagged as a resu lt of one of the vehicle's

on-board diagnostic routines having run to detect the fault. If the same routine is not run when the ignition is switched ON,

the warning will not reflag until the routine does run. See the DTC summaries for drive cycle routines.

3. 3. Visually inspect for obvious signs of mechanical or electrical damage.

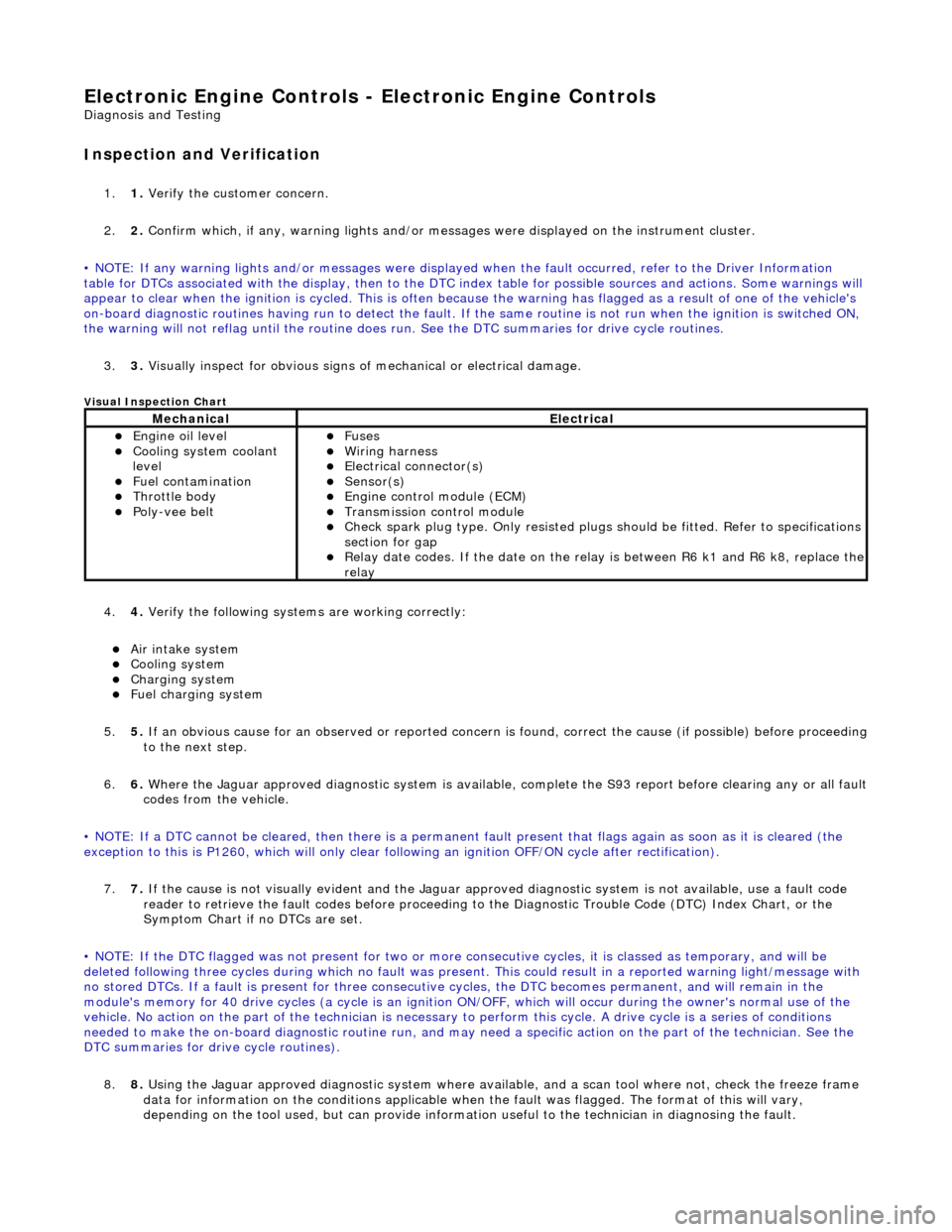

V

isual Inspection Chart

4.

4. Veri

fy the following syst

ems are working correctly:

Air in

take system

Coo

ling system

Charging system

F

uel charging system

5. 5. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding

to the next step.

6. 6. Where the Jaguar approved diagnostic sy stem is available, complete the S93 report before clearing any or all fault

codes from the vehicle.

• NOTE: If a DTC cannot be cleared, then there is a permanent fault present that flag s again as soon as it is cleared (the

exception to this is P1260, which will only clear following an ignition OFF/ON cycle after rectification).

7. 7. If the cause is not visually evident and the Jaguar approv ed diagnostic system is not available, use a fault code

reader to retrieve the fault codes be fore proceeding to the Diagnostic Trou ble Code (DTC) Index Chart, or the

Symptom Chart if no DTCs are set.

• NOTE: If the DTC flagged was not present for two or more co nsecutive cycles, it is classed as temporary, and will be

deleted following three cycl es during which no fault was present. This could result in a reported wa rning light/message with

no stored DTCs. If a fault is present for three consecutive cycles, the DTC becomes permanent, and will remain in the

module's memory for 40 drive cycles (a cy cle is an ignition ON/OFF, which will occur during the owner's normal use of the

vehicle. No action on the part of the technician is necessary to perform this cycle. A drive cycle is a series of conditions

needed to make the on-board diagnostic ro utine run, and may need a specific action on the part of the technician. See the

DTC summaries for driv e cycle routines).

8. 8. Using the Jaguar approved diagnostic system where available, and a scan tool where not, check the freeze frame

data for information on the conditions applicable when the fault was flagged. The format of this will vary,

dependin

g o

n the tool used, but can provide information useful to the technician in dia

gnos

in

g th

e fault.

MechanicalElectrical

Engi

ne oil level

Coo

ling system coolant

level

Fuel contamination

Throttle body Poly

-vee belt

F

uses

W

iring harness

E

lectrical connector(s)

Sens

or(s)

Engine

control module (ECM)

Tran

smission control module

Check spark plu

g type. Only re

sisted plugs should be fitted. Refer to specifications

section for gap

Relay date codes.

If the date on the rela

y is between R6 k1 and R6 k8, replace the

relay

Page 1201 of 2490

leak

/blockage

EVAP valve failure

P0444Evaporati

ve emissions system

(EVAP) valve circuit open circuit

EVAP t

o ECM drive circuit open

circuit or high resistance

EVAP failu

re

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0445Evaporati

ve emissions system

(EVAP) valve circuit short circuit

E

VAP to ECM drive circuit short

circuit to ground

EVAP failu

re

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0447Cani

ster close valve (CCV) circuit

open circuit

CCV to ECM

drive circuit open

circuit, high resi stance or short

circuit to ground

EVAP failu

re

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0448Cani

ster close valve (CCV) circuit

short circuit

CCV to

ECM drive circuit short

circuit to high voltage

CCV failure

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0452F

uel tank pressure (FTP) sensor

circuit low voltage

FTP

sensor disconnected

FTP

sensor to ECM sense circuit

open circuit or short circuit to

ground

FTP sen

sor to ECM power supply

circuit open circuit or short circuit

to ground

F

TP sensor failure

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0453F

uel tank pressure (FTP) sensor

circuit high voltage

FTP

sensor to ECM signal ground

circuit open circuit

F

TP sensor to ECM wiring (supply,

sense, signal, ground) short circuit

to each other

FTP

sensor to ECM sense circuit

short circuit to high voltage

F

TP sensor failure

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0460Fue

l level sense signal

performance

Fue

l level sensor

to instrument

cluster circuits in termittent short or

open circuit

F

uel level sensor failure

Instrument cluster

faul

t (incorrect

fuel level data)

F

or fuel level sensor

circuit tests,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P0506Idl

e rpm lower than expected

Ai

r intake blockage

Acce

ssory drive overload

(defective/siezed component)

Thr

ottle valve stuck closed

Throttl

e assembly failure

Chec

k the air intake system.

REFER to Section 303

-1

2 Intake Air

Distribu

tion and Filtering

.

Check t

he accessory drive

components,

REFER to Section 303

-0

5 Accessory

Dr

ive

.

F

or throttle body information,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P0507Idle rpm

higher than expected

Inta

ke air leak between MAF

sensor and throttle

Inta

ke air leak between throttle

and engine

Engine

breather leak

Cruis

e (speed) control vacuum

failure

Thr

ottle valve stuck open

Throttl

e assembly failure

Chec

k the air intake system.

REFER to Section 303

-1

2 Intake Air

Distribu

tion and Filtering

.

Chec

k the engine breather system,

REFER to Section 303

-08

Engine

Emissi

on Control

.

F

or cruise (speed) control information,

REFER to Section 310

-03

Speed

Control.

F

or throttle body information,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P0560Vehicle voltage

malfunction

ECM battery

power supply open

circuit, high resistance

F

or ECM power supply circuit tests,

GO to Pinpoint Test AD.

.

P0566Cruise (speed) contr

ol

CANCEL

switch ON fault

Cru

ise (speed) control switches

internal steering wheel short circuit

to ground

For cru

ise (speed) control circuit tests,

REFER to Section 310

-03

Speed

Page 1203 of 2490

P1122Acce

lerator pedal position (APP)

sensor circuit 'A' low voltage

A

PP sensor to ECM sense circuit

'A' (sensor pin 5) open circuit or

high resistance

Sensor power su

pply fault

APP s

ensor failure

For APP

sensor circuit tests,GO to

Pinpoint Test R.

, andG

O to Pinpoint

Test S.

.

P1123Acce

lerator pedal position (APP)

sensor circuit 'A' high voltage

A

PP sensor to ECM sense circuit

'A' (sensor pin 5) short circuit to

high voltage

APP s

ensor failure

For APP

sensor circuit tests, GO to

Pinpoint Test R.

, and G

O to Pinpoint

Test S.

.

P1221Acce

lerator pedal position (APP)

sensor circuit 'B'

range/performance

A

PP sensor to ECM sense circuit

'B' (sensor pin 3) open circuit,

short circuit or high resistance

Sensor power su

pply fault

Sensor r

eference ground fault

APP s

ensor failure

For APP

sensor circuit tests,GO to

Pinpoint Test R.

, andG

O to Pinpoint

Test S.

.

P1222Acce

lerator pedal position (APP)

sensor circuit 'B' low voltage

A

PP sensor to ECM sense circuit

'B' (sensor pin 3) open circuit or

high resistance

Sensor power su

pply fault

APP s

ensor failure

For APP

sensor circuit tests,GO to

Pinpoint Test R.

, andG

O to Pinpoint

Test S.

.

P1223Acce

lerator pedal position (APP)

sensor circuit 'B' high voltage

A

PP sensor to ECM sense circuit

'B' (sensor pin 3) short circuit to

high voltage

APP s

ensor failure

For APP

sensor circuit tests,GO to

Pinpoint Test R.

, andG

O to Pinpoint

Test S.

.

P1224Throttl

e control position error

Thro

ttle position adaptations not

performed after ba ttery disconnect

TP se

nsor disconnected

TP se

nsor to ECM sense circuits

open circuit, hi gh resistance

Throttl

e motor power relay failure

Throttl

e motor power relay to ECM

circuit fault

Throttl

e motor power relay power

supply open circuit

ECM ground circuit faul

t (relay coil

drive)

Th

rottle motor to ECM drive circuits

open circuit, short circuit, high

resistance

Throttl

e motor failure

Throttl

e assembly failure

Carry

out throttle adaptation

procedure. For TP sensor circuit

tests,GO to Pinpoint Test D.

, andG

O

to Pinpoint Test K.

. F

or throttle motor

circuit tests,GO to Pinpoint Test T.

.

F

or throttle body information,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P1226Mechanica

l guard sensor

range/performance

Mechanica

l guard sensor to ECM

sense circuit open circuit, short

circuit or high resistance

Sensor power su

pply fault

Sensor r

eference ground fault

Mechanica

l guard sensor failure

Mechanica

l guard actuator

seized/spring broken

For mech

anical guard circuit tests,GO

to Pinpoint Test U.

. F

or sensor power

supply circuit tests,GO to Pinpoint

Test V.

. F

or sensor ground circuit

tests,GO to Pinpoint Test W.

. For

throttle body i

nformation,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P1227Mechanica

l guard sensor circuit

low voltage

Mechanica

l guard sensor to ECM

sense circuit open circuit or high

resistance

Sensor power su

pply fault

Mechanica

l guard sensor failure

For mech

anical guard circuit tests,GO

to Pinpoint Test U.

. F

or sensor power

supply circuit tests,GO to Pinpoint

Test V.

. F

or throttle body

information,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P1228Mechanica

l guard sensor circuit

high voltage

Mechanica

l guard sensor to ECM

sense circuit short circuit to high

voltage

Mechanica

l guard sensor failure

For mech

anical guard circuit tests,GO

to Pinpoint Test U.

. F

or throttle body

information,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P1229Throttl

e motor control circuit

mallfunction

Throttl

e motor disconnected

Th

rottle motor to ECM drive circuits

short circuit or open circuit

Throttl

e motor failure

Fo

r throttle motor circuit tests,GO to

Pinpoint Test T.

.

P1230Fue

l pump relay malfunction.

NOTE. This DTC covers the S/C

system fuel pump 1

F

uel pump relay failure

F

uel pump to ECM circuit fault

F

uel pump relay coil power supply

F

or fuel pump relay circuit tests,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

Page 1204 of 2490

op

en circuit

ECM ground circuit faul

t (relay coil

drive)

P1235Vacuu m

switching valve (VSV) 1

circuit range/ performance

(mechanical guard position)

Vac u

um leak/blockage between the

throttle elbow and the throttle

vacuum actuator

Vacuu m

actuator failure

Mechanica

l

guard actuator

seized/spring broken

Carr y out mechanical checks

for

vacuum leak/blockag e, failed vacuum

actuator, and broken /siezed actuator

spring.

P1236Vacuu m

switching valve (VSV) 1

(vacuum) circuit failure

VSV 1 disconne cted

VSV 1 to ECM drive circu

i

t high

resistance, open circuit or short

circuit

VSV 1 powe r supply open

circuit

VSV 1 failu

r

e

For VSV tests,

REF

ER to Section 310

-03

Sp

eed

Control.

P1237Vacuu

m

switching valve (VSV) 2

(atmosphere) circuit failure

VSV 2 disconne cted

VSV 2 to ECM drive circu

i

t high

resistance, open circuit or short

circuit

VSV 2 power supply open

circuit

VSV 2 failu

r

e

For VSV tests,

REF

ER to Section 310

-03

Sp

eed

Control.

P1238Vacuu

m

switching valve (VSV) 3

(release) circuit failure

VSV 3 disconne cted

VSV 3 to ECM drive circu

i

t high

resistance, open circuit or short

circuit

VSV 3 powe r supply open

circuit

VSV 3 failu

r

e

For VSV tests,

REF

ER to Section 310

-03

Sp

eed

Control.

P1240Sensor r

e

fere

nce voltage

malfunction (throttle sensors, fuel

tank pressure se nsor) (ECM pins

EM10-21; EM11-8)

ECM t o

sensors reference voltage

short circuit to ground, short circuit

to high voltage, op en circuit, high

resistance

TP sensor , pedal position and

mechan

ical guard sensor(s), fuel

tank pressure sens or failure(s)

Fo

r sensor reference voltage circuit

tests,GO to Pinpoint Test V.

.

P1241Sensor re

ferenc

e voltage low

(throttle sensors, fuel tank

pressure sensor) (ECM pins EM10-

21; EM11-8)

ECM t o

sensors reference voltage

short circuit to ground

TP sensor , APP

and mechanical

guard sensor(s), fuel tank pressure

sensor failure(s)

F o

r sensor reference voltage circuit

tests,GO to Pinpoint Test V.

.

P1242Sensor re

ferenc

e voltage high

(throttle sensors, fuel tank

pressure sensor) (ECM pins EM10-

21; EM11-8)

ECM t o

sensors reference voltage

circuit open circuit, high resistance,

short circuit to high voltage

TP sensor , APP

and mechanical

guard sensor(s), fuel tank pressure

sensor failure(s)

F o

r sensor reference voltage circuit

tests,GO to Pinpoint Test V.

.

P1243Sensor re

ference ground

malfunction (throttle sensors, fuel

tank pressure sensor, ECT sensor,

IAT sensor, IAT sensor 2) (ECM

pins EM10-20; EM11-12)

ECM t o

sensors reference ground

circuit open circuit, high resistance

Throttle sensors, fuel

tank pressure

sensor, ECT sensor, IAT sensor,

IAT sensor 2 failures

F o

r sensor reference ground circuit

tests,GO to Pinpoint Test W.

.

P1245Engine crank signal low voltage Starter relay coi

l to ECM/BPM

circuit open circuit

For en gin

e crank circuit tests,GO to

Pinpoint Test X.

.

P1246Engine crank signal high voltage Starter relay coi

l to ECM/BPM

circuit short circuit to B+ voltage

B P

M failure

For en

gin

e crank circuit tests,GO to

Pinpoint Test X.

.

P1250Engine load

malfunction

Air in

take leak

Engine breath

er leak

TP sens

or circuit fault (DTC P0121)

Throttle

valve spring failure

Check air i

ntake system for leaks,

REFER to Section 303

-12

Intake Air

Distribution and Filterin

g

.

Check engi

ne breather system for

leaks,

REFER to Section 303

-08 En

gine

Emissi

on Control.

Se e

pinpoint test for P0121. For

throttle body information,

REFER to Section 303

-04 Fu

el

Charging and Con

t

rols

.

P1251Thr

o

ttle position malfunction

(engine off)

TP sensor to ECM wiri

ng open

circuit or high resistance

F o

r TP sensor circ

uit tests,GO to

Pinpoint Test D.

, andGO to Pinpoint

Page 1205 of 2490

TP se

nsor to ECM sensing circuits

('1' or '2') short circuit to high

voltage

TP sensor

failure

Throttl

e motor disconnected

Th

rottle motor to ECM drive circuits

short circuit or open circuit

Throttl

e motor failure

Throttl

e assembly failure

Test

K. . F

or throttle motor circuit

tests,GO to Pinpoint Test T.

. For

throttle body i

nformation,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

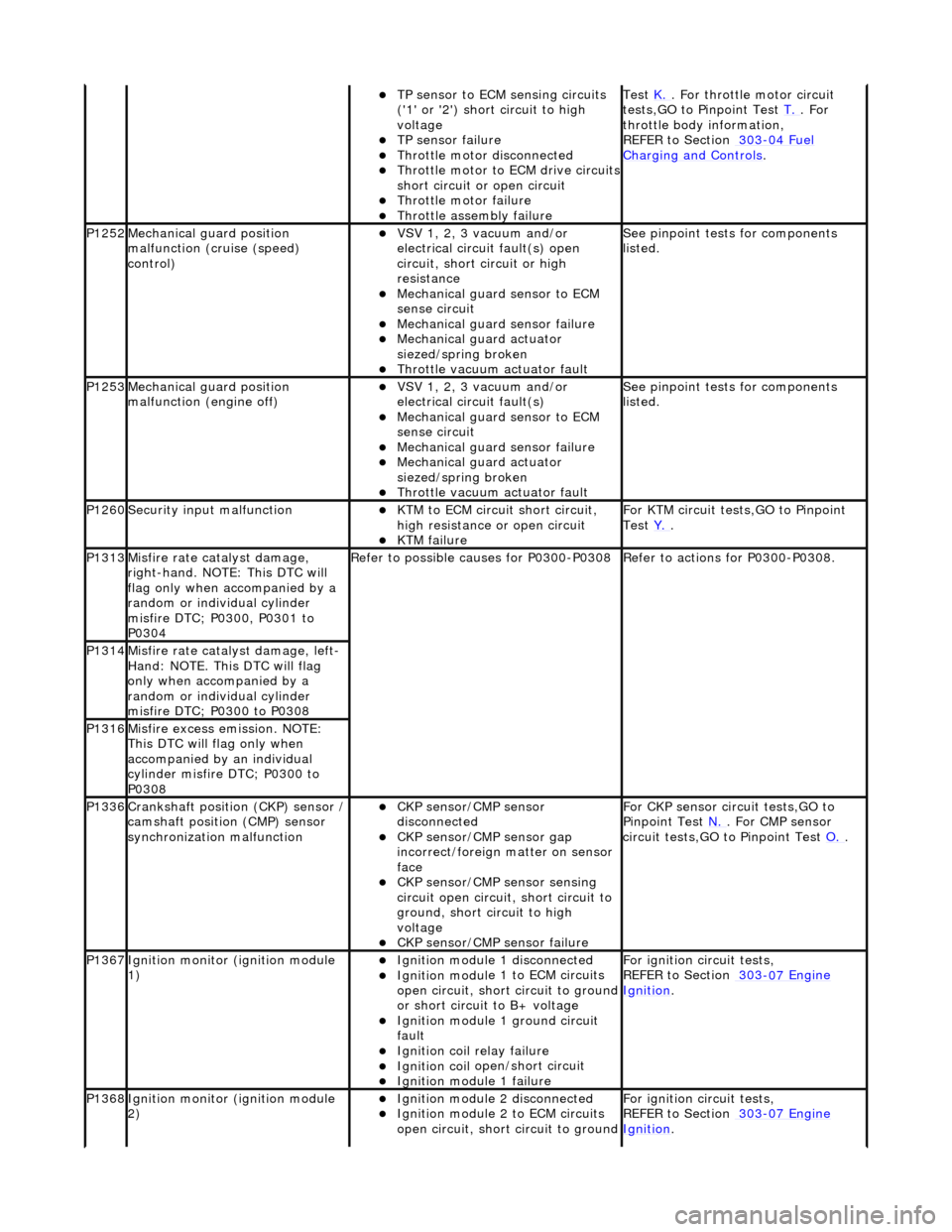

P1252Mec

hanical gu

ard position

malfunction (cruise (speed)

control)

VSV 1, 2, 3 v

acuum and/or

electrical circuit fault(s) open

circuit, short circuit or high

resistance

Mechanica

l guard sensor to ECM

sense circuit

Mechanica

l guard sensor failure

Mechanica

l guard actuator

siezed/spring broken

Throttl

e vacuum actuator fault

Se

e pinpoint tests for components

listed.

P1253Mec

hanical gu

ard position

malfunction (engine off)

VSV 1, 2, 3 v

acuum and/or

electrical circuit fault(s)

Mechanica

l guard sensor to ECM

sense circuit

Mechanica

l guard sensor failure

Mechanica

l guard actuator

siezed/spring broken

Throttl

e vacuum actuator fault

Se

e pinpoint tests for components

listed.

P1260Se

curity input malfunction

K

TM to ECM circuit short circuit,

high resistance or open circuit

KTM failu

re

F

or KTM circuit tests,GO to Pinpoint

Test Y.

.

P1313M

isfire rate catalyst damage,

right-hand. NOTE: This DTC will

flag only when accompanied by a

random or individual cylinder

misfire DTC; P0300, P0301 to

P0304

R

efer to possible causes for P0300-P0308

R

efer to actions for P0300-P0308.

P1314Mi

sfire rate catalyst damage, left-

Hand: NOTE. This DTC will flag

only when accompanied by a

random or individual cylinder

misfire DTC; P0300 to P0308

P1316M

isfire excess emission. NOTE:

This DTC will flag only when

accompanied by an individual

cylinder misfire DTC; P0300 to

P0308

P1336Cranksh

aft position

(CKP) sensor /

camshaft position (CMP) sensor

synchronization malfunction

CKP s

ensor/CMP sensor

disconnected

CKP sensor/CM

P sensor gap

incorrect/foreign matter on sensor

face

CKP s

ensor/CMP sensor sensing

circuit open circuit, short circuit to

ground, short circuit to high

voltage

CKP s

ensor/CMP sensor failure

F

or CKP sensor circ

uit tests,GO to

Pinpoint Test N.

. For CM

P sensor

circuit tests,GO to Pinpoint Test O.

.

P1367Ignit

ion monitor (ignition module

1)

Ignition modu

le

1 disconnected

Ignition modul

e 1 to ECM circuits

open circuit, short circuit to ground

or short circuit to B+ voltage

Ignition modul

e 1 ground circuit

fault

Ignition coil

relay failure

Ignition coil

open/short circuit

Ignition modul

e 1 failure

F

or ignition circuit tests,

REFER to Section 303

-07

Engine

Ignition.

P1368Ignit

ion monitor (ignition module

2)

Ignition modu

le

2 disconnected

Ignition modul

e 2 to ECM circuits

open circuit, short circuit to ground

F

or ignition circuit tests,

REFER to Section 303

-07

Engine

Ignition.

Page 1207 of 2490

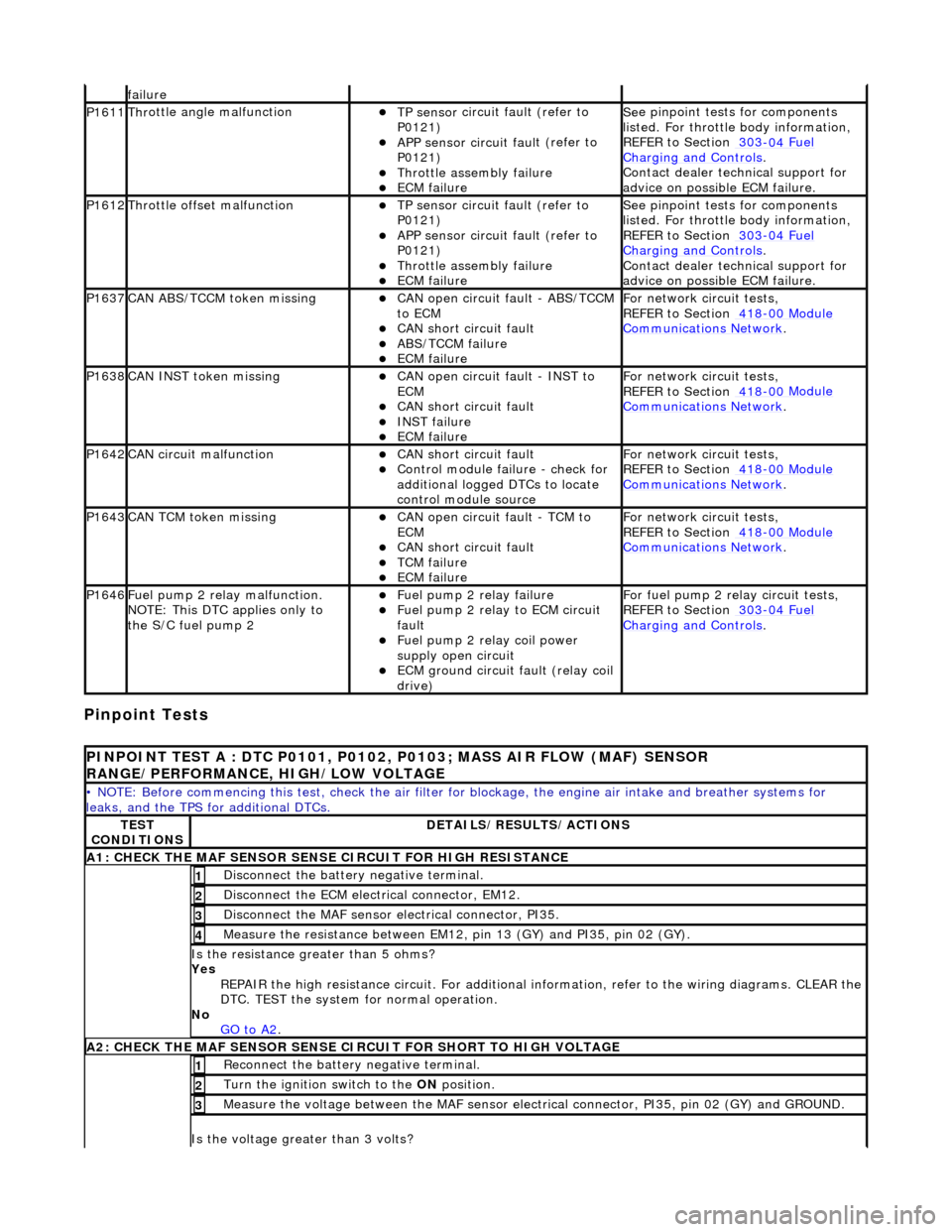

Pinpoint Tests

f

ailure

P1611Thr

ottle angle malfunction

TP sensor

circuit fault (refer to

P0121)

APP sensor circuit faul

t (refer to

P0121)

Throttl

e assembly failure

ECM failu

re

Se

e pinpoint tests for components

listed. For throttle body information,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

Contact deal

er technical support for

advice on possible ECM failure.

P1612Throttl

e offset malfunction

TP sensor

circuit fault (refer to

P0121)

APP sensor circuit faul

t (refer to

P0121)

Throttl

e assembly failure

ECM failu

re

Se

e pinpoint tests for components

listed. For throttle body information,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

Contact deal

er technical support for

advice on possible ECM failure.

P1637CAN AB

S/TCCM token missing

CAN

open circuit fault - ABS/TCCM

to ECM

CAN s

hort circuit fault

ABS/TCCM failu

re

ECM failu

re

F

or network circuit tests,

REFER to Section 418

-00

Module

Comm

unications Network

.

P1638CAN INST token missingCAN

open circuit fault - INST to

ECM

CAN s

hort circuit fault

INST

failure

ECM failu

re

F

or network circuit tests,

REFER to Section 418

-00

Module

Comm

unications Network

.

P1642CAN c

ircuit malfunction

CAN s

hort circuit fault

Control modul

e failure - check for

additional logged DTCs to locate

control module source

F

or network circuit tests,

REFER to Section 418

-00

Module

Comm

unications Network

.

P1643CAN TC

M token missing

CAN

open circuit fault - TCM to

ECM

CAN s

hort circuit fault

TCM failure

ECM failu

re

F

or network circuit tests,

REFER to Section 418

-00

Module

Comm

unications Network

.

P1646F

uel pump 2 relay malfunction.

NOTE: This DTC applies only to

the S/C fuel pump 2

F

uel pump 2 relay failure

F

uel pump 2 relay to ECM circuit

fault

F

uel pump 2 relay coil power

supply open circuit

ECM ground circuit faul

t (relay coil

drive)

F

or fuel pump 2 relay circuit tests,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P

INPOINT TEST A : DTC P0101, P0102, P0103; MASS AIR FLOW (MAF) SENSOR

RANGE/PERFORMANCE, HIGH/LOW VOLTAGE

•

NOTE: Before commencing this

test, check the air filter for blockage, the engine air inta ke and breather systems for

leaks, and the TPS for additional DTCs.

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

A1: CHECK

THE MAF SENSOR SENS

E CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

D

isconnect the ECM electrical connector, EM12.

2

Di

sconnect the MAF sensor electrical connector, PI35.

3

Meas

ure the resistance between EM12, pin 13 (GY) and PI35, pin 02 (GY).

4

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No GO to A2

.

A2: CHECK

THE MAF SENSOR SENSE CI

RCUIT FOR SHORT TO HIGH VOLTAGE

R

econnect the battery negative terminal.

1

Turn the ignition swi

tch to the ON

position.

2

M

easure the voltage between the MAF sensor electrical connector, PI35, pin 02 (GY) and GROUND.

3

Is th

e voltage greater than 3 volts?

Page 1243 of 2490

Drive Cycle for 40 thou leak test

Drive Cycle for 20 thou leak test (2001 my on only)

1. Make sure the "conditions

for ad

aptation" detailed at the start

of this section are met.

1. Avoiding high engine load s, drive the vehicle steadily

between 48 and 89 kph (30 and 55 mph) for 15 to 20

minutes after starting the engine. (Depending on the

amount of fuel vapor gene rated, the test may take

longer than this).

2. Where possible, avoid body roll to minimise fuel movement.

3. If the scan tool being used is able to read TIDs, check

TID 08 in mode 6. If the test has not completed, this

TID will display "0". Any other value indicates that

the test has successfully completed.

4. If the test has not completed, the drive cycle must be repeated.

5. If the scan tool being used is not able to read TIDs, the only way to confirm that the test has run is to

check for P1111 after running the 20 thou test, where

applicable.

1. This test needs to be completed within 50 minutes of starting

the engine from cold. It should be run following the 40 thou

test.

1. Continue driving the vehi cle steadily between 48 and

89 kph, (30 and 55 mph) avoiding high engine loads

for a further 15 minutes.

2. Avoiding excessive fuel movement, bring the vehicle to rest.

3. Allow to idle for two minutes.

4. Provided the vapor conditions are suitable, the test will complete.

5. If the scan tool being used is able to read TIDs, check

TID 06 in mode 6. If the test has not completed, this

TID will display "0". Any other value indicates that

the test has successfully completed.

6. If the test has not completed, the drive cycle must be repeated.

7. Check for DTCs. P1111 will be flagged if all monitors have run.

8. Leak check drive cycles will only normally be necessary if an Evaporative Emissions related DTC is

flagged.

9. Unless P1111 is required for the State inspection, fuelling adaptations will normally be all that is

required for the vehicle to adapt itself and complete