JAGUAR X308 1998 2.G Workshop Manual

X308 1998 2.G

JAGUAR

JAGUAR

https://www.carmanualsonline.info/img/21/7640/w960_7640-0.png

JAGUAR X308 1998 2.G Workshop Manual

Page 1313 of 2490

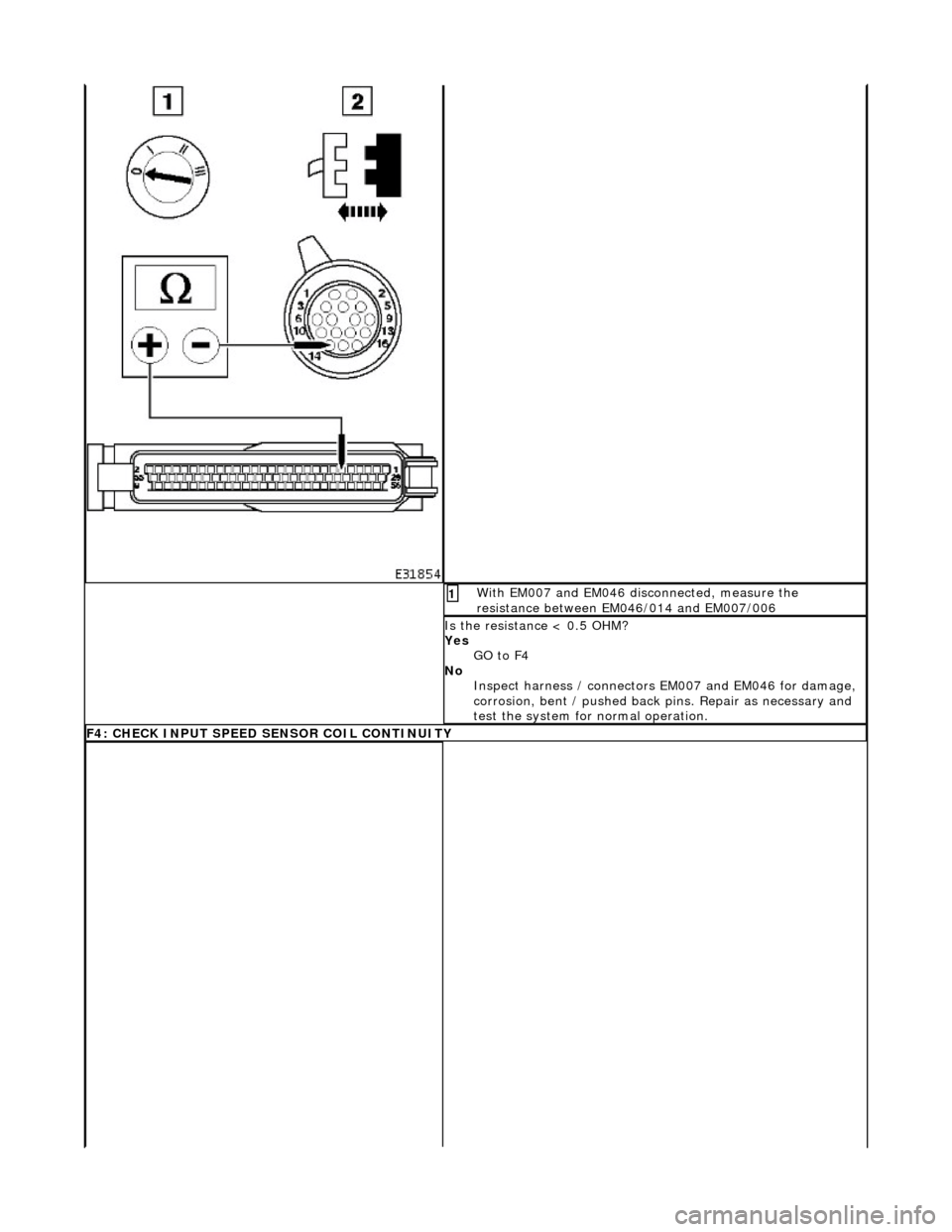

With EM007 and EM046 disconnected, measure the

resistance between EM046/014 and EM007/006 1

Is the resistance < 0.5 OHM?

Yes GO to F4

No Inspect harness / connectors EM007 and EM046 for damage,

corrosion, bent / pushed back pins. Repair as necessary and

test the system for normal operation.

F4: CHECK INPUT SPEED SENSOR COIL CONTINUITY

Page 1314 of 2490

With, EM007 disconnected, measure the sensor value

between EM007/042 and EM007/014 1

Is the resistance between 280 and 1200 OHM?

Yes GO to F5

No Renew the input speed sensor

F5: CHECK FOR SHORT TO B+

With EM007 disconnected, measure the voltage between

EM007/014 and EM007/026 1

Repeat for EM007/042 and EM007/026 2

0V?

Yes GO to F6

No Inspect harness / connectors EM007 and EM046 for damage,

corrosion, bent / pushed back pins. Repair as necessary and

test the system for normal operation.

F6: CHECK HARNESS SHORT TO SCREEN

Page 1315 of 2490

With EM007 and EM046 disconnected, measure the insulation resistance between EM007/042 and EM007/023 1

Is the resistance > 10 MOHM?

No 4 Repeat for EM007/014 and EM007/023

Yes GO to F7

No Inspect harness / connectors EM007 and EM046 for damage,

corrosion, bent / pushed back pins. Repair as necessary and

test the system for normal operation.

F7: CHECK HARNESS CORE TO CORE INSULATION

Page 1316 of 2490

Pinpoint test G: P1722

With EM007 and EM046 disconnected, measure the insulation resistance between EM007/014 and EM007/042 1

Is the resistance > 10 MOHM?

Yes GO to F8

No Inspect harness / connectors EM007 and EM046 for damage,

corrosion, bent / pushed back pins. Repair as necessary and

test the system for normal operation.

F8: END

Perform appropriate service drive cycle and check for the

presence of DTC. 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TEST G : P1722

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

G1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present.

Page 1317 of 2490

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to G2

G2: CHECK HARNESS +VE CONTIN UITY (OUTPUT SPEED SENSOR)

With EM007 and EM046 disconnected, measure the

resistance between EM046/001 and EM007/016 1

Is the resistance < 0.5 OHM?

Yes

Reconnect EM046

GO to G3

No Inspect harness / connectors EM007 and EM046 for damage,

corrosion, bent / pushed back pins. Repair as necessary and

test the system for normal operation.

G3: CHECK HARNESS -VE CONTINUITY (OUTPUT SPEED SENSOR)

Page 1318 of 2490

With EM007 and EM046 disconnected, measure the

resistance between EM046/010 and EM007/044 1

Is the resistance < 0.5 OHM?

Yes GO to G4

No Inspect harness / connectors EM007 and EM046 for damage,

corrosion, bent / pushed back pins. Repair as necessary and

test the system for normal operation.

G4: CHECK OUTPUT SPEED SENSOR COIL CONTINUITY

Page 1319 of 2490

With, EM007 disconnected, measure the sensor value

between EM007/016 and EM007/044 1

Is the resistance between 280 and 1200 OHM?

Yes GO to G5

No Renew the output speed sensor

G5: CHECK FOR SHORT TO B+

With EM007 disconnected, measure the voltage between

EM007/015 and EM007/044 1

Repeat for EM007/016 and EM007/044 2

0V?

Yes GO to G6

No Inspect harness / connectors EM007 and EM046 for damage,

corrosion, bent / pushed back pins. Repair as necessary and

test the system for normal operation.

G6: CHECK HARNESS SHORT TO SCREEN

Page 1320 of 2490

With EM007 and EM046 disconnected, measure the insulation resistance between EM007/016 and EM007/015 1

Is the resistance > 10 MOHM?

No 4 Repeat for EM007/015 and EM007/044

Yes GO to G7

No Inspect harness / connectors EM007 and EM046 for damage,

corrosion, bent / pushed back pins. Repair as necessary and

test the system for normal operation.

G7: CHECK HARNESS CORE TO CORE INSULATION

With EM007 and EM046 disconnected, measure the insulation resistance between EM007/016 and EM007/044 1

Is the resistance > 10 MOHM?

Yes GO to G8

No Inspect harness / connectors EM007 and EM046 for damage,

corrosion, bent / pushed back pins. Repair as necessary and

test the system for normal operation.

Page 1322 of 2490

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to I2

I2: CHECK HARNESS +VE CONTIN UITY (INPUT SPEED SENSOR)

With EM007 and EM046 disconnected, measure the resistance between EM046/005 and EM007/042 1

Is the resistance < 0.5 OHM?

Yes

Reconnect EM046

GO to I3

No Inspect harness / connectors EM007 and EM046 for damage,

corrosion, bent / pushed back pins. Repair as necessary and

test the system for normal operation.

I3: CHECK HARNESS -VE CONTINUITY (INPUT SPEED SENSOR)

Page 1323 of 2490

With EM007 and EM046 disconnected, measure the resistance between EM046/014 and EM007/006 1

Is the resistance < 0.5 OHM?

Yes GO to I4

No Inspect harness / connectors EM007 and EM046 for damage,

corrosion, bent / pushed back pins. Repair as necessary and

test the system for normal operation.

I4: CHECK INPUT SPEED SENSOR COIL CONTINUITY