JAGUAR X308 1998 2.G Workshop Manual

X308 1998 2.G

JAGUAR

JAGUAR

https://www.carmanualsonline.info/img/21/7640/w960_7640-0.png

JAGUAR X308 1998 2.G Workshop Manual

Page 1325 of 2490

With EM007 and EM046 disconnected, measure the resistance between EM046/001 and EM007/016 1

Is the resistance < 0.5 OHM?

Yes Reconnect EM046

GO to I6

No Inspect harness / connectors EM007 and EM046 for damage,

corrosion, bent / pushed back pins. Repair as necessary and

test the system for normal operation.

I6: CHECK HARNESS -VE CONTINUITY (OUTPUT SPEED SENSOR)

Page 1328 of 2490

With EM007 disconnected, measure the voltage between

EM007/016 and EM007/026 1

Repeat for EM007/026 and EM007/044 2

0V?

Yes GO to I9

No Inspect harness / connectors EM007 and EM046 for damage,

corrosion, bent / pushed back pins. Repair as necessary and

test the system for normal operation.

I9: CHECK HARNESS SHORT TO SCREEN

Page 1329 of 2490

With EM007 and EM046 disconnected, measure the insulation

resistance between EM007/016 and EM007/023 1

Repeat for EM007/044 and EM007/023 2

Is the resistance > 10 MOHM?

Yes GO to I10

No Inspect harness / connectors EM007 and EM046 for damage,

corrosion, bent / pushed back pins. Repair as necessary and

test the system for normal operation.

I10: CHECK HARNESS CORE TO CORE INSULATION

Page 1330 of 2490

Pinpoint test J: P1603, P1605, P1608

With EM007 and EM046 disconnected, measure the insulation

resistance between EM007/016 and EM007/044 1

Repeat for EM007/014 and EM007/042 2

Is the resistance > 10 MOHM?

Yes GO to I11

No Inspect harness / connectors EM007 and EM046 for damage,

corrosion, bent / pushed back pins. Repair as necessary and

test the system for normal operation.

I11: END

Perform appropriate service drive cycle and check for the

presence of DTC 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TEST J : P1603, P1605, P1608

• NOTE: It is important that J3 item 1 is carried out in order that system adaptions take place

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

J1: RETRIEVE DTCS

• NOTE: Following ECM power-down, the DTC will be lost and may only be disp layed when the ignition is energized

Page 1333 of 2490

Pinpoint test L: P0710

With EM007 and LS008 disconnected, measure the

resistance between EM007/054 and LS008/007 1

Repeat for EM007/055 and LS008/007 2

Is the resistance < 0.5 OHM?

Yes GO to K5

No Inspect harness / connector EM007, LS008, EM051, splice

EMS42 for damage, corrosion, bent / pushed back pins.

Repair as necessary and te st the system for normal

operation.

K5: END

Perform appropriate service drive cycle and check for the

presence of DTC. 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TEST L : P0710

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

L1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present.

Page 1339 of 2490

Automatic Transmission/Transaxle - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

- Electronic Pressure Control (EPC) Solenoid

In-vehicle Repair

Removal

1. Disconnect battery ground cable.

пЃ¬Remove the battery cover.

2. Raise the vehicle on a suitable lift.

2. WARNING: TRANSMISSION FLUID MAY CAUSE

SEVERE BURNS, ENSURE THAT ALL SAFETY PROCEDURES

ARE OBSERVED.

пЃ¬Carefully remove the drain plug and drain the

transmission fluid.

3. Remove the twenty-two fixings which secure the fluid pan .

пЃ¬Remove the fluid pan and all traces of gasket material.

4. Disconnect regulator / solenoid connectors.

5. Remove RH rear valve body securing screws.

Page 1349 of 2490

6. Remove the output speed sensor.

• NOTE: M6 fixing.

1. Remove the screw from the output speed sensor

securing bracket and pu ll the sensor clear.

пЃ¬Disconnect the harness multiplug.

7. Disconnect the five pressure regulator connectors and three

solenoid connectors.

8. Reposition the internal harness for access.

пЃ¬Release the internal harness from the retaining clips.

9. Drain the valve body.

1. Position a suitable drain tin below the valve body.

2. Slacken (do not remove) the twenty-two screws, valve body to transmission case.

пЃ¬Allow the fluid to drain.

10. Remove the valve body.

пЃ¬Remove five M6 X 30 screws, valve body to transmission

case.

пЃ¬Remove seventeen M6 X 60 screws, valve body to

transmission case.

Page 1351 of 2490

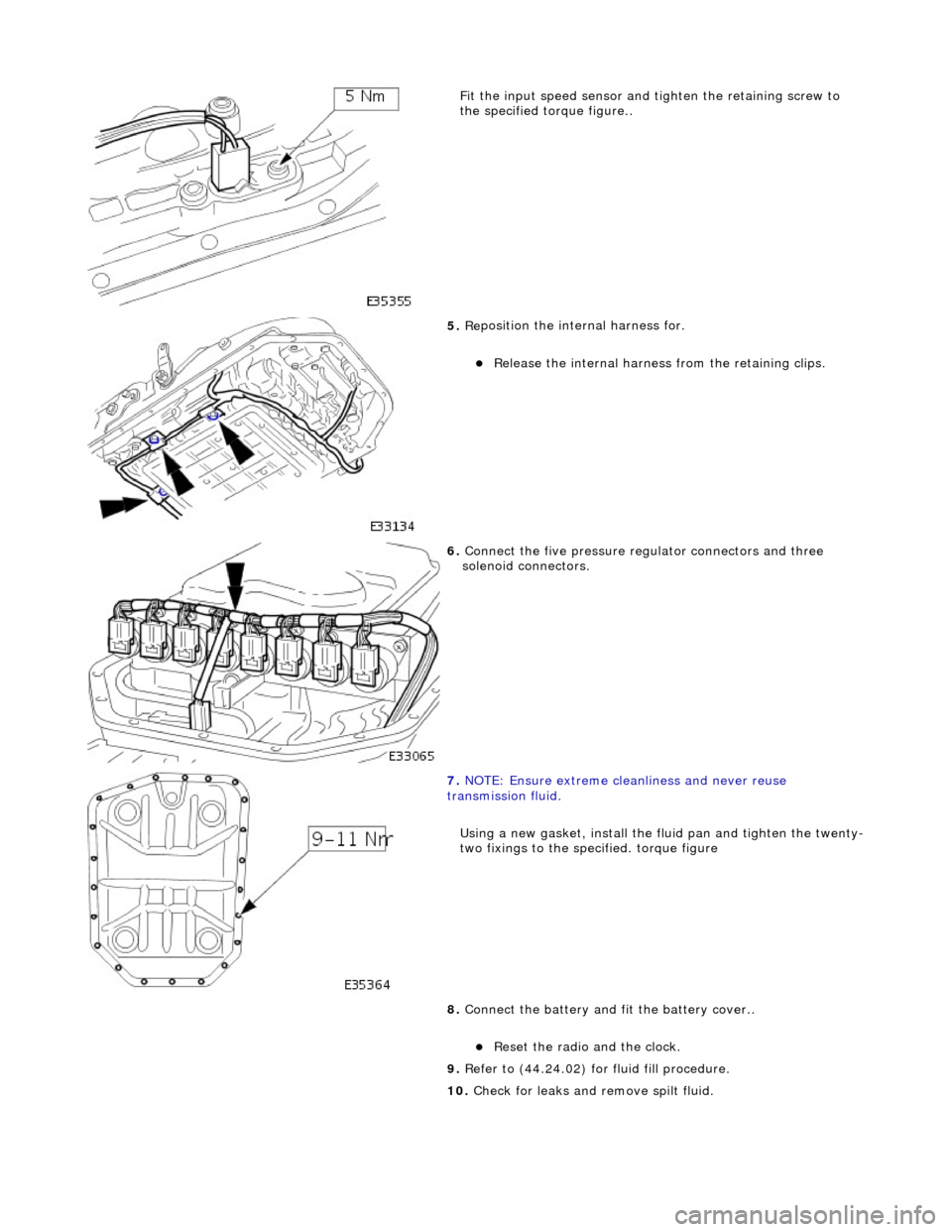

Fit the inpu

t speed sensor and

tighten the retaining screw to

the specified to rque figure..

5. Re

position the inte

rnal harness for.

пЃ¬R

elease the internal harness

from the retaining clips.

6. Connect

the five pressure re

gulator connectors and three

solenoid connectors.

7. N

OTE: Ensure extreme clea

nliness and never reuse

transmission fluid.

Using a new gasket, install the fl uid pan and tighten the twenty-

two fixings to the specified. torque figure

8. Connect the battery and fit the battery cover..

пЃ¬Reset th

e radio and the clock.

9. Refer to (44.24.02) for fluid fill procedure.

10. Check for leaks and remove spilt fluid.

Page 1354 of 2490

Automatic Transmission/Transaxle - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

- Shift Solenoids (SS)

In-vehicle Repair

Removal

1. Disconnect battery ground cable.

пЃ¬Remove the battery cover.

2. Raise the vehicle on a lift.

2. WARNING: TRANSMISSION FLUID MAY CAUSE

SEVERE BURNS, ENSURE THAT ALL SAFETY PROCEDURES

ARE OBSERVED.

пЃ¬Carefully remove the drain plug and drain the

transmission fluid.

3. Remove the twenty-two bolts which secure the fluid pan.

пЃ¬Remove the fluid pan and all tr aces of gasket material.

4. Disconnect the eight soleno id / regulator connectors.

5. Remove the RH rear valve body securing screws.

Page 1364 of 2490

Installation

9. Disconnect the eight soleno id / regulator connectors.

10. Release the internal harness from the retaining clips and

remove the harness.

1. Position the internal harness and fit it to the retaining clips.

2. Connect the eight solenoid / regulator harness connectors.