body JAGUAR X308 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 169 of 2490

Rear Suspension - Axle B

ump Stop

Re

moval and Installation

Remov

al

CAUTI

ON: Replacement of

nuts and bolts: Various thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

I

nstallation

1.

R

aise rear of vehicle and support

on stands. Refer to Section

100-02.

2. Remove appropriate road wheel. Refer to Section 100-02.

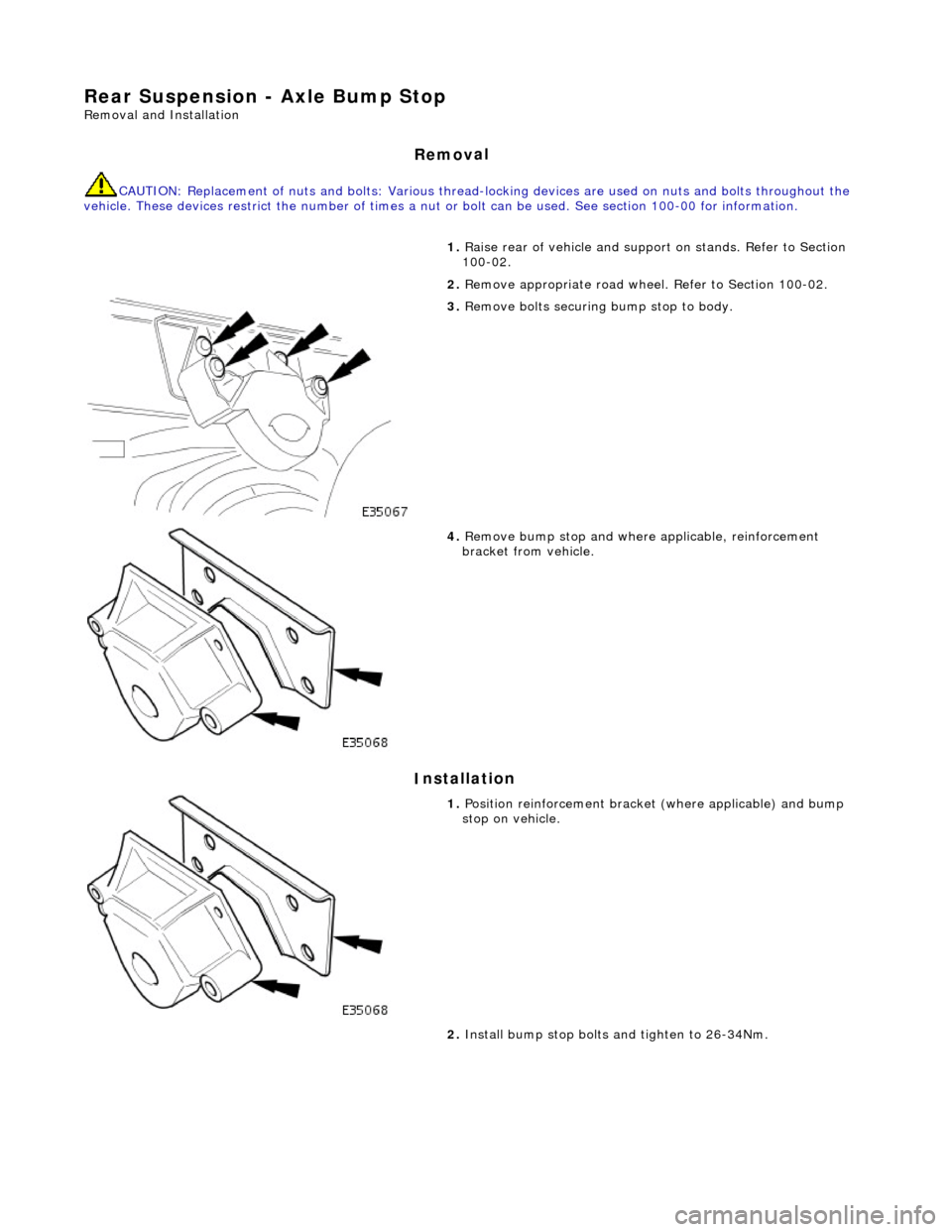

3. Remove bolts securing bump stop to body.

4. Remove bu

mp stop and where applicable, reinforcement

bracket from vehicle.

1. Position reinforcemen t brac

ket (where a

pplicable) and bump

stop on vehicle.

2. Install bump stop bolts and tighten to 26-34Nm.

Page 172 of 2490

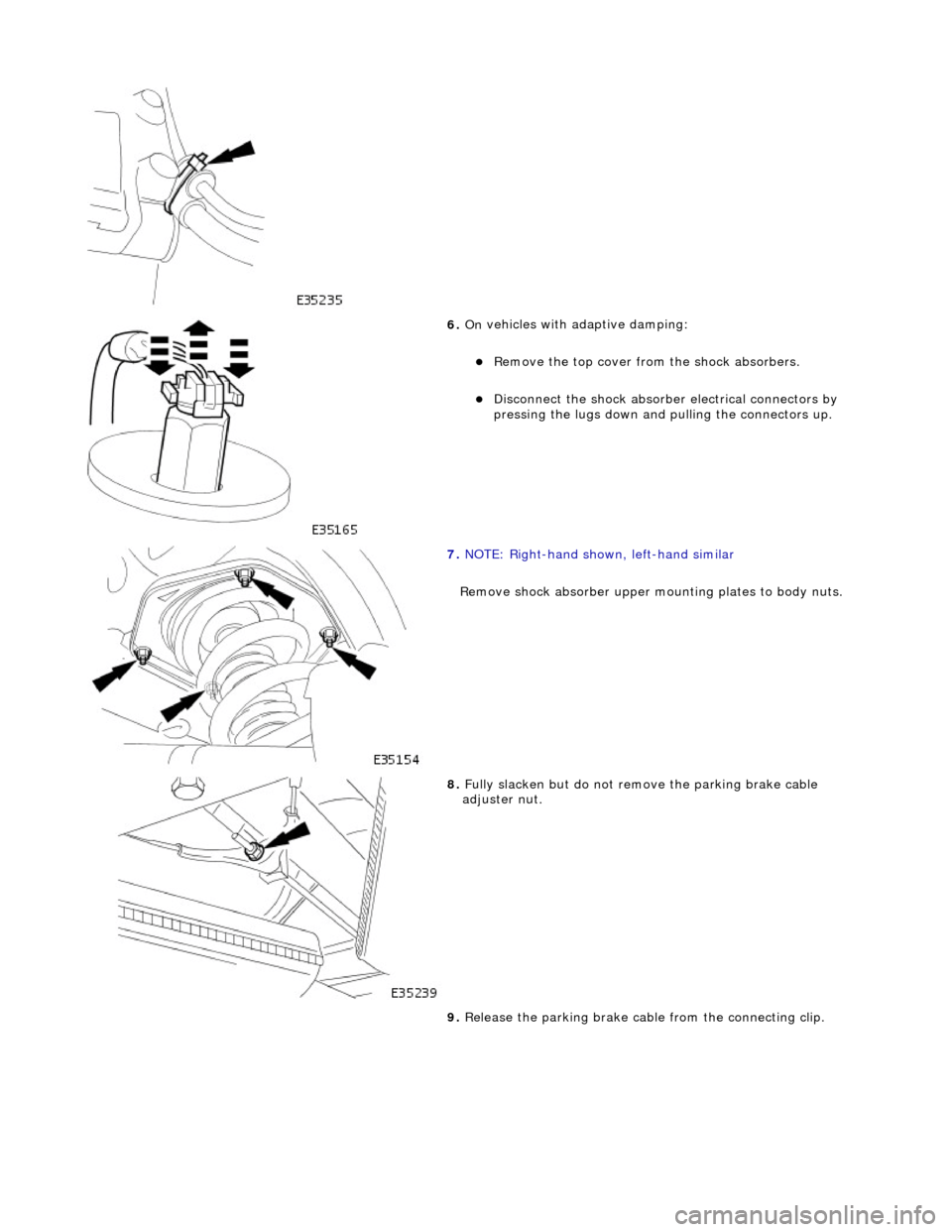

6. On

vehicles with adaptive damping:

R

e

move the top cover from

the shock absorbers.

Disc

onnect the shock absorber electrical connectors by

pressing the lugs down and pulling the connectors up.

7. NOTE : R

ight-hand shown, left-hand similar

Remove shock absorber upper mo unting plates to body nuts.

8. Fully slacken bu

t do not remove the parking brake cable

adjuster nut.

9. Release the parking brake cabl e from the connecting clip.

Page 174 of 2490

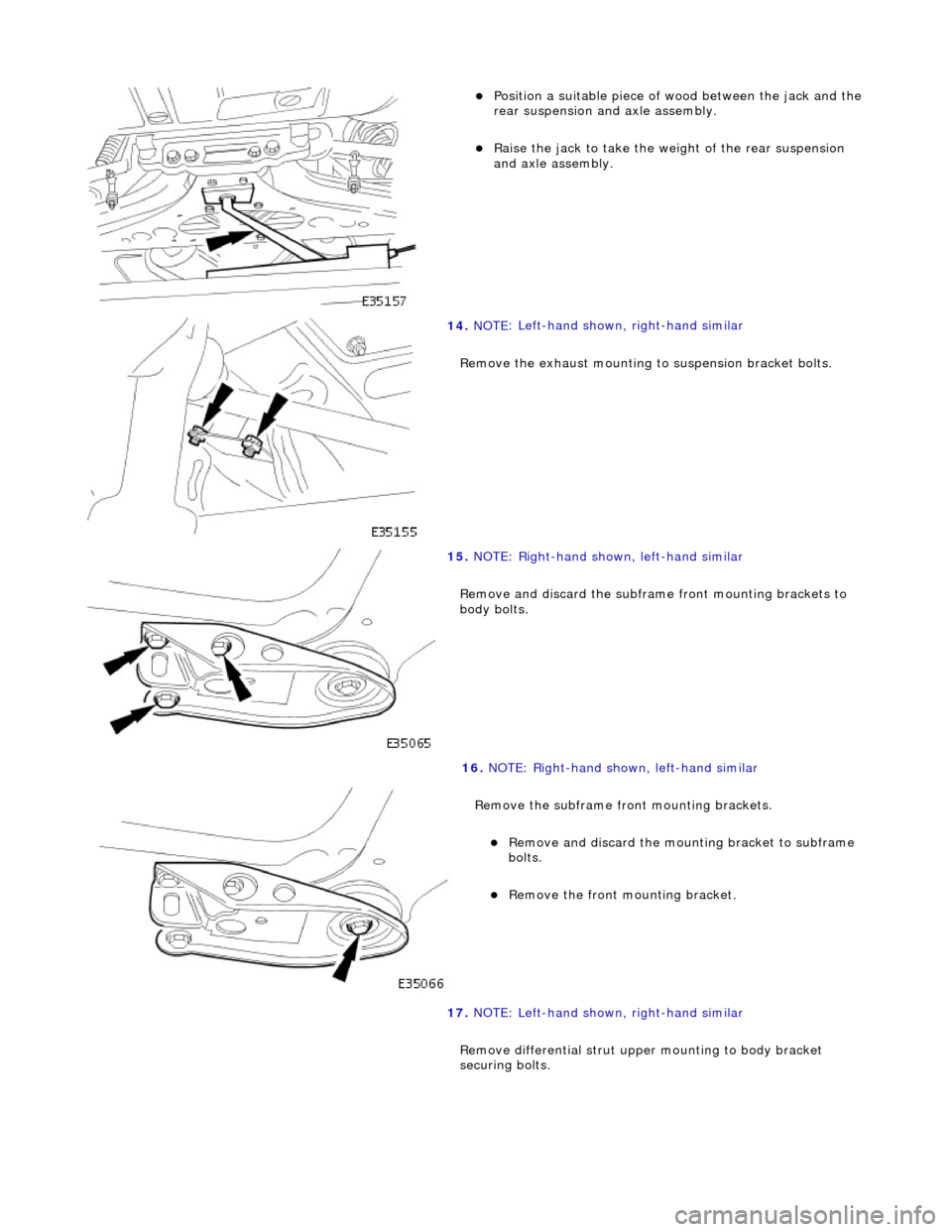

Position a suitable piece o

f wood between the jack and the

rear suspension and axle assembly.

Rai s

e the jack to take the weight of the rear suspension

and axle assembly.

14 . NOTE

: Left-hand shown, right-hand similar

Remove the exhaust mounting to suspension bracket bolts.

15 . NOTE

: Right-hand shown, left-hand similar

Remove and discard the subframe front mounting brackets to

body bolts.

16 . NOTE

: Right-hand shown, left-hand similar

Remove the subframe front mounting brackets.

Remove an d discard the mount

ing bracket to subframe

bolts.

R e

move the front mounting bracket.

17. NOTE: Left-hand shown, right-hand similar

Remove differential strut upper mounting to body bracket

securing bolts.

Page 175 of 2490

I

nstallation

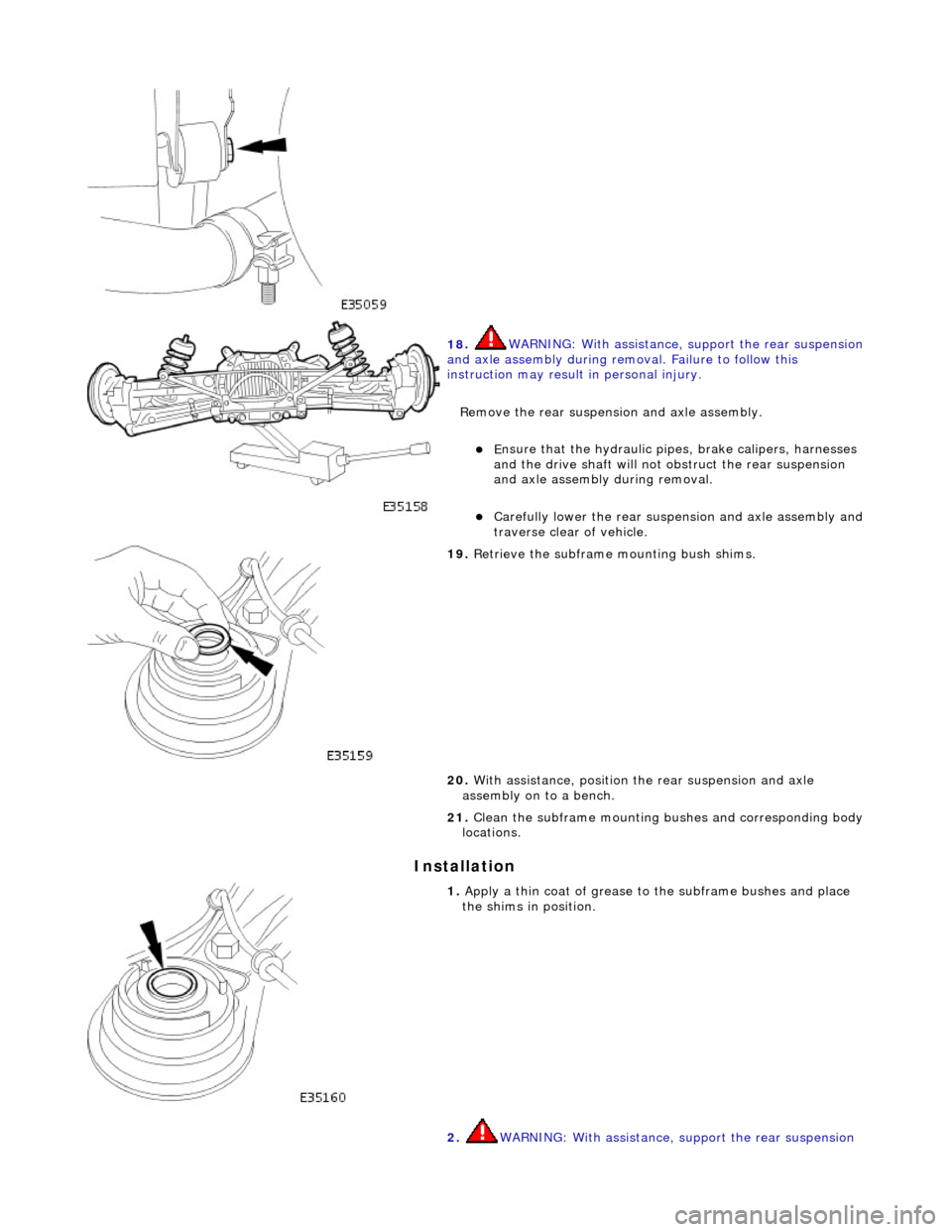

18

.

WARNING: With assistance, support the rear suspension

and axle assembly during remo val. Failure to follow this

instruction may result in personal injury.

Remove the rear suspensi on and axle assembly.

E

nsure that the hydr

aulic pipes, brake calipers, harnesses

and the drive shaft will not obstruct the rear suspension

and axle assembly during removal.

Carefull

y lower the rear suspen

sion and axle assembly and

traverse clear of vehicle.

19

.

Retrieve the subframe mounting bush shims.

20. With assistance, position th e rear suspension and axle

assembly on to a bench.

21. Clean the subframe mounting bushes and corresponding body

locations.

1. Apply a th

in coat of grease to the subframe bushes and place

the shims in position.

2. WARNING: With assistance, support the rear suspension

Page 177 of 2490

Inst

all new inner mounting bracket bolts.

Ti

ghten to 88-118 Nm.

8. NOTE

: Right-hand shown, left-hand similar

Tighten to 88-118 Nm.

9. NOTE

: Right-hand shown, left-hand similar

Install new different ial strut to body bracket bolts.

Tigh

ten to 68-92 Nm.

10. Lower and remove trolley jack.

11

.

Attach the drive shaft to the flexible coupling.

Align the marks previously pain

ted on drive shaft and

flexible coupling.

Inst

all new drive shaft coupling bolts and nuts.

12. Tighten to 76-88 Nm.

Page 182 of 2490

Withdraw th

e hub carrier and support on a block of wood.

9. CAUTIO

N: Note the position of

the shims during removal.

They must be returned to th eir original position during

installation.

Noting their positions, remove the shim from each end of the

pivot pin sleeve.

10 . WAR

NINGS:

ENSURE THE SPECIAL TOOLS ARE POSITIONED

DIAMETRICALLY OPPOSITE ON THE SPRING AND THE ARMS ARE

CORRECTLY SEATED .

WHEN COMPRESSING THE SPRING, TIGHTEN THE

SPECIAL-TOOL ADJUSTMENT BOLTS EVENLY.

Compress the spring.

Install and alig n th

e special

tools 204-179 diametrically

opposite on the spring.

Eve n

ly tighten the special tool tensioning bolts to

compress the spring.

11 . R

emove the shock absorber to

wishbone mounting nut and

bolt.

12. Remove the nuts securing th e shock absorber and spring

upper mounting to the body.

Page 188 of 2490

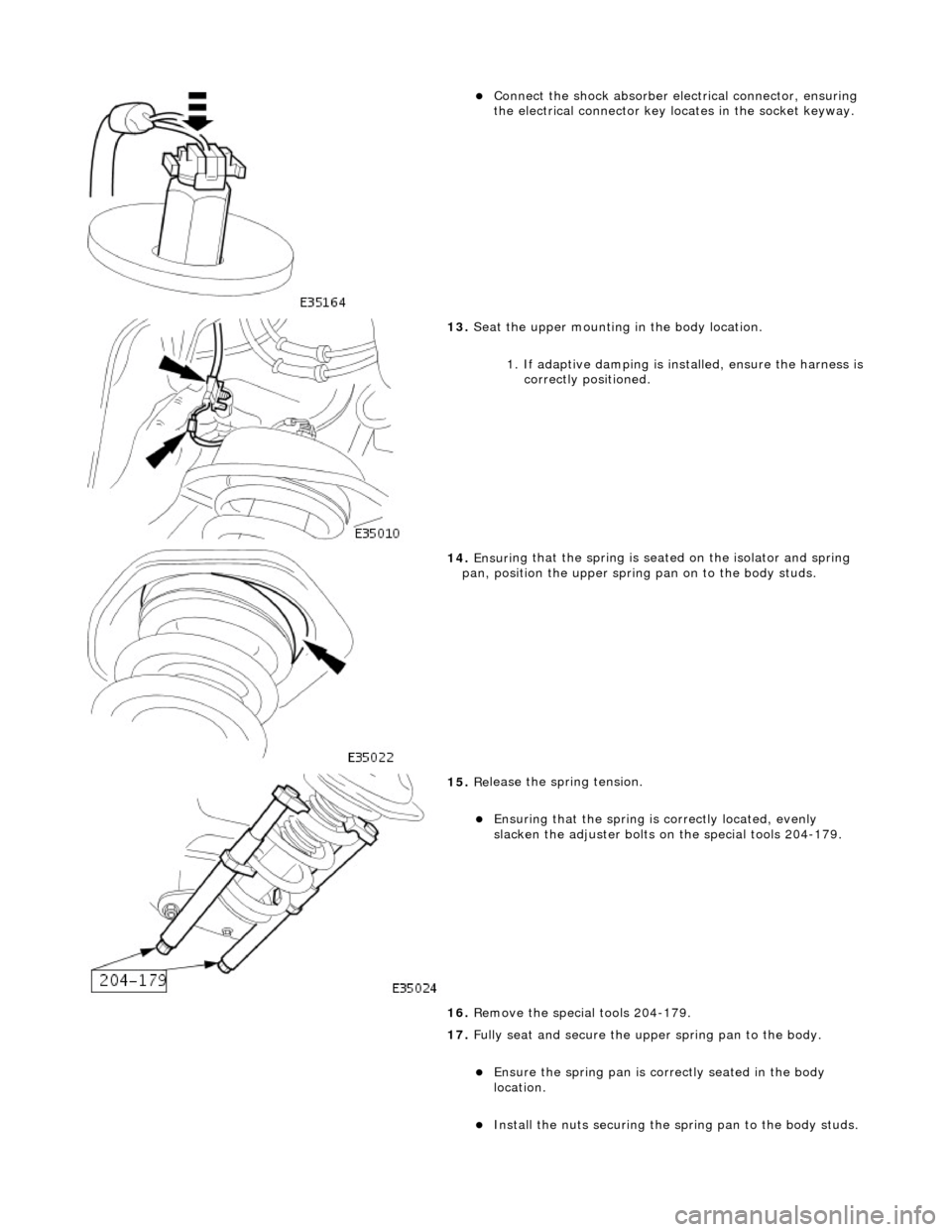

Connect

the shock absorber elec

trical connector, ensuring

the electrical connector key locates in the socket keyway.

13. Seat

the upper mounting in the body location.

1. If adaptive damping is installed, ensure the harness is

correctly positioned.

14 . Ensuri

ng that the spri

ng is seated on the isolator and spring

pan, position the u pper spring pan on to the body studs.

15 . Re

lease the spring tension.

Ensuri

ng that the spri

ng is

correctly located, evenly

slacken the adjuster bolts on the special tools 204-179.

16. Remove the special tools 204-179.

17. Fully seat and secure the u pper spring pan to the body.

Ensure the spring pan i

s correctly seated in the body

location.

Inst al

l the nuts securing the sp

ring pan to the body studs.

Page 197 of 2490

With

draw the hub carrier and support on a block of wood.

9. CAUTI

ON: Note the position of

the shims during removal.

They must be returned to th eir original position during

installation.

Noting their positions, remove the shim from each end of the

pivot pin sleeve.

10

.

WARNINGS:

ENSURE THE SPECIAL TOOLS ARE POSITIONED

DIAMETRICALLY OPPOSITE ON THE SPRING AND THE ARMS ARE

CORRECTLY SEATED .

WHEN COMPRESSING THE SPRING, TIGHTEN THE

SPECIAL-TOOL ADJUSTMENT BOLTS EVENLY.

Compress the spring.

Install and alig

n the special

tools 204-179 diametrically

opposite on the spring.

Eve

nly tighten the special tool tensioning bolts to

compress the spring.

11

.

Remove the shock absorber to wishbone mounting nut and

bolt.

12. Remove the nuts securing th e shock absorber and spring

upper mounting to the body.

Page 204 of 2490

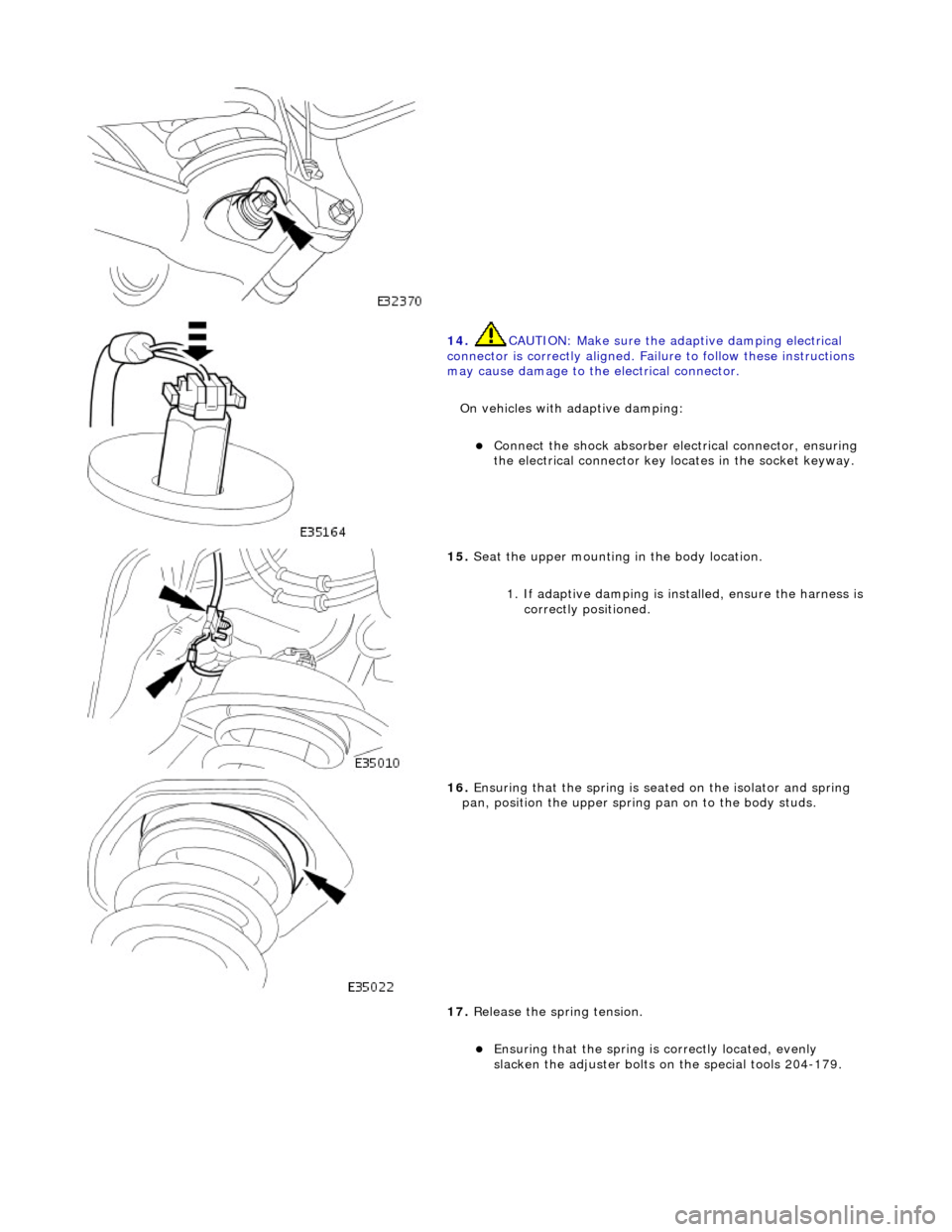

14. CAUTI

ON: Make sure the adaptive damping electrical

connector is correctly aligned. Failu re to follow these instructions

may cause damage to the electrical connector.

On vehicles with adaptive damping:

Conne ct

the shock absorber elec

trical connector, ensuring

the electrical connector key locates in the socket keyway.

15 . Seat

the upper mounting in the body location.

1. If adaptive damping is installed, ensure the harness is

correctly positioned.

16 . Ensuri

ng that the spri

ng is seated on the isolator and spring

pan, position the u pper spring pan on to the body studs.

17. Release the spring tension.

Ensuring that the spri

ng is

correctly located, evenly

slacken the adjuster bolts on the special tools 204-179.

Page 205 of 2490

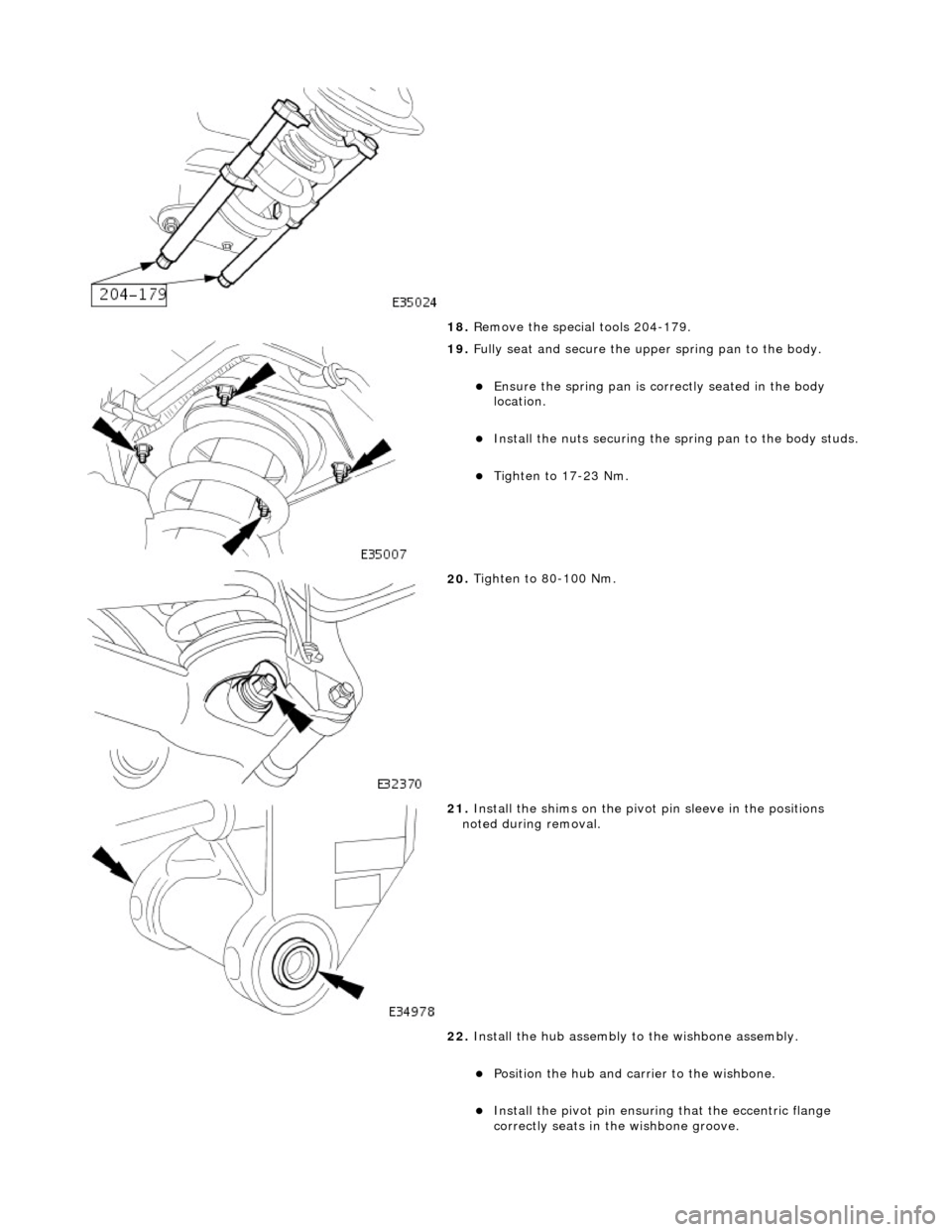

18

.

Remove the special tools 204-179.

19

.

Fully seat and secure the u pper spring pan to the body.

Ensure the spri

ng pan is correctly seated in the body

location.

Inst

all the nuts securing the sp

ring pan to the body studs.

Tigh

ten to 17-23 Nm.

20

.

Tighten to 80-100 Nm.

21

.

Install the shims on the pivot pin sleeve in the positions

noted during removal.

22. Install the hub assembly to the wishbone assembly.

Position the hub and carri

er to the wishbone.

Inst

all the pivot pin ensuring that the ecce

ntric flange

correctly seats in the wishbone groove.