body JAGUAR X308 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 464 of 2490

Vibrati

on

Power steeri

ng

pump noisy

Low power steer i

ng fluid.

CHECK

steering system for s

igns of steering fluid

loss.

BLEE D the

power steering system. For additional

information,

REFER to Section 211

-0 0

Steering System

-

Ge n

eral

Informati

o

n

.

Power steeri

ng pump wor

n or

otherwise defective.

CHECK for leaks. R

EPAIR as necessary.

CHECK

the power steering pressure. For additional

information, REFER to th e Power Steering Pressure

Test in this section.

INST ALL a ne

w power steering pump as necessary.

For additional information,

REFER to Section 211

-0 2

Power Steering

.

Wh

in

e type noise

Aerated flui

d.

BLEE

D the

power steering system. For additional

information,

REFER to Power Steering System Bleeding

- in t h

is

section.

Power steering pump.

CHECK for leaks. R

EPAIR as necessary.

INSTALL a ne

w power steering pump as necessary.

For additional information,

REFER to Section 211

-0 2

Power Steering

.

No

i

se during

steering gear movement

Low power steer i

ng fluid.

CHECK

steering system for s

igns of steering fluid

loss.

BLEE D the

power steering system. For additional

information,

REFER to Section 211

-0 0

Steering System

-

Ge n

eral

Informati

o

n

.

Water co

n

tamination to the

power steering fluid.

DR AIN

the power steering system.

BLEE

D the

power steering system. For additional

information,

REFER to Section 211

-00

Steering System

-

Gen

eral

Informati

o

n

.

Cavi

tation due to restricted

po

wer steering feed hose.

CHECK

and reposition power

steering feed hoses and

INSTALL new hoses as necessary.

Continu o

us noise

Low power steer i

ng fluid.

CHECK

steering system for s

igns of steering fluid

loss.

BLEE D the

power steering system. For additional

information,

REFER to Section 211

-0 0

Steering System

-

Ge n

eral

Informati

o

n

.

Power steeri

ng pump dri

ve

loose.

CHECK

power steering coupli

ng and power steering

pump.

IN ST

ALL a new power steering coupling or power

steering pump as nece ssary. For additional

information,

REFER to Section 211

-0 2

Power Steering

.

Incorre

ct

accessory drive belt

tension or accessory drive belt glazed.

CHECK acc

essory drive belt condition and INSTALL a

new accessory drive belt as necessary. For additional

information,

REFER to Section 303

-0 5 Ac

cessory Drive

.

Power steeri

ng pump dri

ve

pulley loose.

CHECK

and TIGHTEN the power steering pump drive

pulley retaining bolts as necessary. For additional

information, REFER to Section 303

-03A En

gine

Coo

ling / 30 3-03

B Supercharger Cooling

.

Power steeri

ng pump

r

etaining bolts loose.

CHECK

the power steering pump retaining bolts and

TIGHTEN as necessary.

Power steering hose/pipe in c

ontact with the vehicles

body.

CHECK

and reposition powe

r steering hoses/pipes,

INSTALL new hoses/pipes as necessary.

Power steeri ng hose

r

estricted/twisted.

CHECK

and reposition powe

r steering hose, replace

hose as necessary.

Conditi

on

Possibl

e Sources

Actio

n

Loose/worn tie-

ro

ds.

INST

ALL a new tie-r

od end. For additional

information,

Page 468 of 2490

Hiss (Swish)

Hiss or Val

ve Hiss is a high-frequency so

und coming from the steering gear when the system is loaded. It is a rushing or

"swish" noise that doesn't change frequency with RPM. Hiss is the general noise generated by the flow of hydraulic fluid

through restrictions in the steer ing system. Restrictions include the rotary stee ring valve, power steering tubes, connectors,

tuning orifices, etc. Hiss can be air- borne and structure-borne, but the structure-borne path through the steering

intermediate shaft is usually dominant.

Moan (Groan)

Moan is the general structu r

e-borne noise of the steering system. Moan is primarily transmitted to the driver via the body

structure through the pump mount, engine mounts, power steering lines and power steering brackets. On some vehicles,

moan is a load humming noise, often present when the wheel is turned and the system is loaded. It may change frequency

with engine RPM and if the sy stem is loaded or unloaded.

Rack Knock (R

ack Slap)

CAU

T

ION: DO NOT attempt to adjust the stee

ring gear yoke. Failure to follow this instruction will result in the steering

gear warranty to become invalid.

Rack Knock is a rattle sound an d steering wheel vibration caused by separation of the steering gear and pinion while driving

over bumps. It is a structure-borne noise transmitted throug h the intermediate shaft and column. Rack knock can also be

heard as a "thump" or impact noise that occurs with the vehicle stationary when the steering wheel is released from a

loaded position and allowed to return to rest . Noise occurs with the engine on or off.

Rattles

Ra

ttles are noises caused by knocking or hitting with components in the steering system. Steering rattles can occur in the

engine compartment, the suspension, or the passenger compartment . Rattles can be caused by loose parts, movable and

flexible parts, and improper clearances.

Squea k

s/Scrapes

Squeaks/Scrapes are noises due

to fri

ction or component rubbi

ng anywhere in the steering system. Squeaks/Scrapes have

appeared in steering linkages and jo ints, in column components and in co lumn and steering wheel trim parts.

Weep

We

ep is an air-borne noise, occasionally

generated when turning the steering across lock at a constant rate. When present

on a vehicle the noise, once initiated can often be maintained across a large proportion of the available steering movement.

Whistle

Wh

istle is similar to hiss but is louder and of a higher frequency. It is also more

of a pure tone noise than hiss. Whistle is

air-borne and is generated by a high flow rate of hydraulic fluid through a small restriction.

Zip

Zip n

o

ise is the air-borne noise

generated by power steerin g pump cavitation when power steering fluid does not flow freely

through the suction hose from the rese rvoir to the pump. Zip primarily occurs during cold weather at start-up.

Steering System Vibrations and Harshne

ss

Buzz

Buzz is a tactile rotary vi

bration felt in

the steering wheel for slow steering inputs. Buzz can also be called a grinding feel

and it is closely related to grunt and is caused by high system gain with low damping. Buzz is generally excited during

parking manoeuvres with low to medium speed steering input.

Page 478 of 2490

Power Steering -

Lubric

ants, Fluids, Sealants and Adhesives

Capacities

Torques

UnitSp

ecification

PAS flu

i

d

De

xr

on 3

UnitLi

t

ers

PAS syste

m1,0

PAS reservoi

r0,4

Com p

onent

Nm

Rac

k

mountin

g brac

ke

t to suspension crossbeam

40

- 50

PAS pump to front mounti

ng bracket

22

-

26

P

AS pu

mp assembly to cylinder block

38

-

48

Pul

l

ey to PAS pump

18

-

24

Hi

gh pressure hose to PAS pump22 -

28

Rack

pipe latch plate bolt8.5 -

11.5

R

e

servoir mounting bracket to body nuts

4 -

5

R

e

servoir mounting bracket clamp

4 -

5

Fluid cooler to body2.

5 -

3.5

Transfer pipe

to steering rack7 -

8

Transfer pipe

to hydraulic con

trol valve

7 -

8

Page 485 of 2490

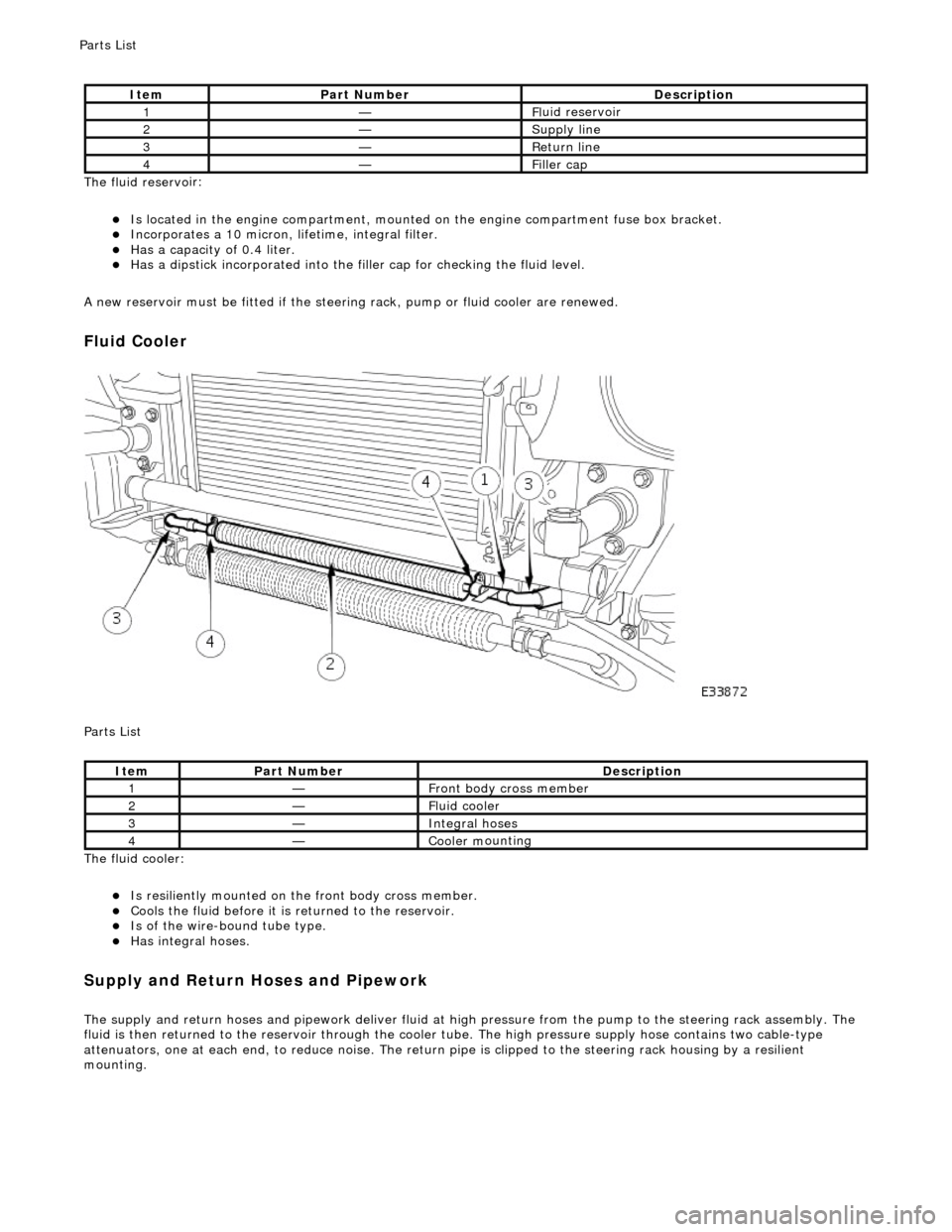

The fluid reservo

ir:

Is lo

cated in the engine compartment, mounted on the engine compartment fuse box bracket.

Incorporates

a 10 micron, li

fetime, integral filter.

Has a cap

acity of 0.4 liter.

Has a dipsti

ck incorporated into the filler cap for checking the fluid level.

A new reservoir must be fitted if the steering rack, pump or fluid cooler are renewed.

Fluid C

ooler

P

arts List

The fluid cooler:

Is

resiliently mounted on th

e front body cross member.

Coo

ls the fluid before it is

returned to the reservoir.

Is

of the wire-bound tube type.

Has i

ntegral hoses.

Supply and Return Hoses a

nd Pipework

The supply and return h

oses and

pipework deliver fluid at high pressure from the pump to th e steering rack assembly. The

fluid is then returned to th e reservoir through the cooler tube. The high pressure supply hose contains two cable-type

attenuators, one at each end, to reduce nois e. The return pipe is clipped to the steering rack housing by a resilient

mounting.

It

em

Par

t Number

De

scription

1—Fl

uid reservoir

2—Supply line

3—R

eturn line

4—Fi

ller cap

It

em

Par

t Number

De

scription

1—Front body cross member

2—F

luid cooler

3—Inte

gral hoses

4—Cooler m

ounting

P

arts List

Page 504 of 2490

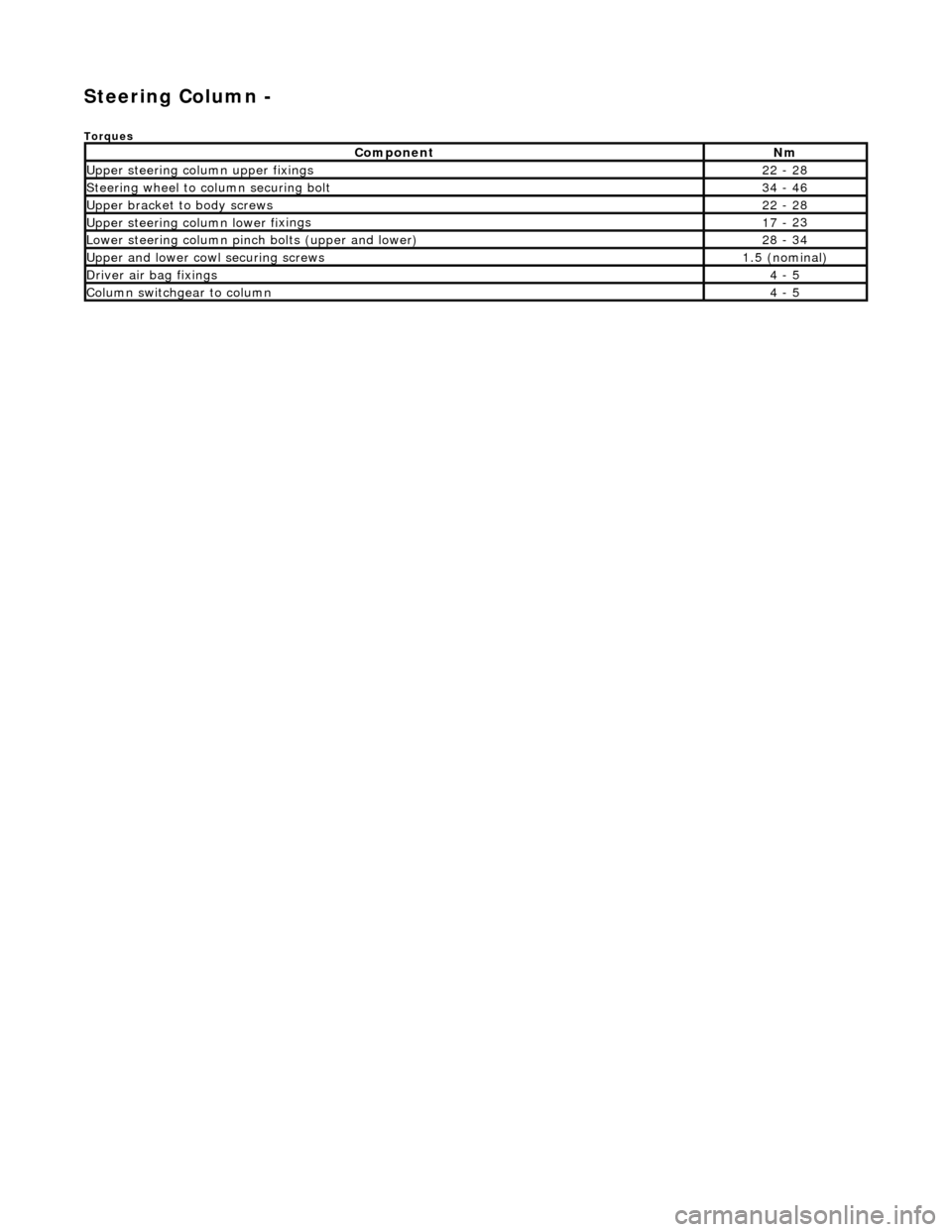

Steering Column -

Torques

Comp

onent

Nm

Upper

steering column upp

er fixings

22

-

28

S

t

eering wheel to column securing bolt

34

-

46

Upper

bracket

to body screws

22

-

28

Upper

steering colu mn lower fi

xings

17

-

23

Lower steeri

ng col

umn pinch bolts (upper and lower)

28

-

34

U

pper

and lower cowl securing screws

1.

5 (

nominal)

D

river ai

r bag fixings

4 -

5

Colum

n switchgear to column

4 -

5

Page 528 of 2490

Speed an

d load

Coo

l

ant temperature

Ti

me el

apsed from start up

Cl

osed l

oop fuelling

Determination of the vapour concentration is made by stepped opening of the EVAP valve and subsequent monitoring of the

fuelling correction. This function is performed prior to purging, so that at the onse t of purging the EVAP valve can be set to

the optimum position. Should the ECM be unable to determine the concentration before purging, a default value is

employed, which is then modified whilst purging is in progress.

When the purging process is operational th e ECM modifies the basic fuelling calculation to maintain the correct air / fuel

ratio.

Purging is inhibited during fuel cut-off and stability / traction control intervention.

Coolant Temperature Sen

sor

Th

e

sensor outputs a voltage to the ECM which decreases as temperature increases.

Cooling Fans

In response to engi

ne coolant temperat

u

re and climate control system demand, the ECM will energize the cooling fans.

Climate Control Compressor

The E

C

M will allow the compressor clutch to be engaged if th

e engine temperature and load demand are normal. Should the

driver require maximum engine powe r or the coolant temperature be high, the request will be denied.

Cranking Signal

The ECM reacts to a signal fr

om th

e Body Processor Module (BPM) when the starter motor relay is energi

zed. This signal is

used to trigger starting, fu el and ignition strategies.

Engine Speed and Cranksh

aft Position

Engine

speed and cran

k position are moni

tored by a sensor which is mounted on the cylinder block (flywheel housing)

behind the crankshaft drive plat e. It indicates rotational speed to the ECM in the form of 12 pulses per crank revolution.

Engine speed is used for synchronization of fuel an d ignition systems, as well as other functions.

Camshaft Position

The ca

mshaft position sensor is mounted at

the rear of Bank 2 cylinder head on the inlet side and provides one signal every

720 degrees of crankshaft rotation. The signal, in conjunction with the signal from the crankshaft position sensor, indicates

to the ECM that the piston of cylinder 1A is approaching TDC on the compression stroke.

Variable Valve

Timing (Where Fitted)

By energi

si

ng a solenoid to allow the pass

age of pressurized oil on each of the inle t camshaft drives, the ECM can vary by a

single stepped amount, the relati ve timing of the inlet valves.

Ign

ition

Ignit

i

on spark is produced by

individual on-plug coil units.

There are two ignition amplifiers; module #1 drives coils 1A, 2B, 3B and 4A, whilst module #2 drives coils 1B, 2A, 3A and

4B. The ECM controls the amplifiers.

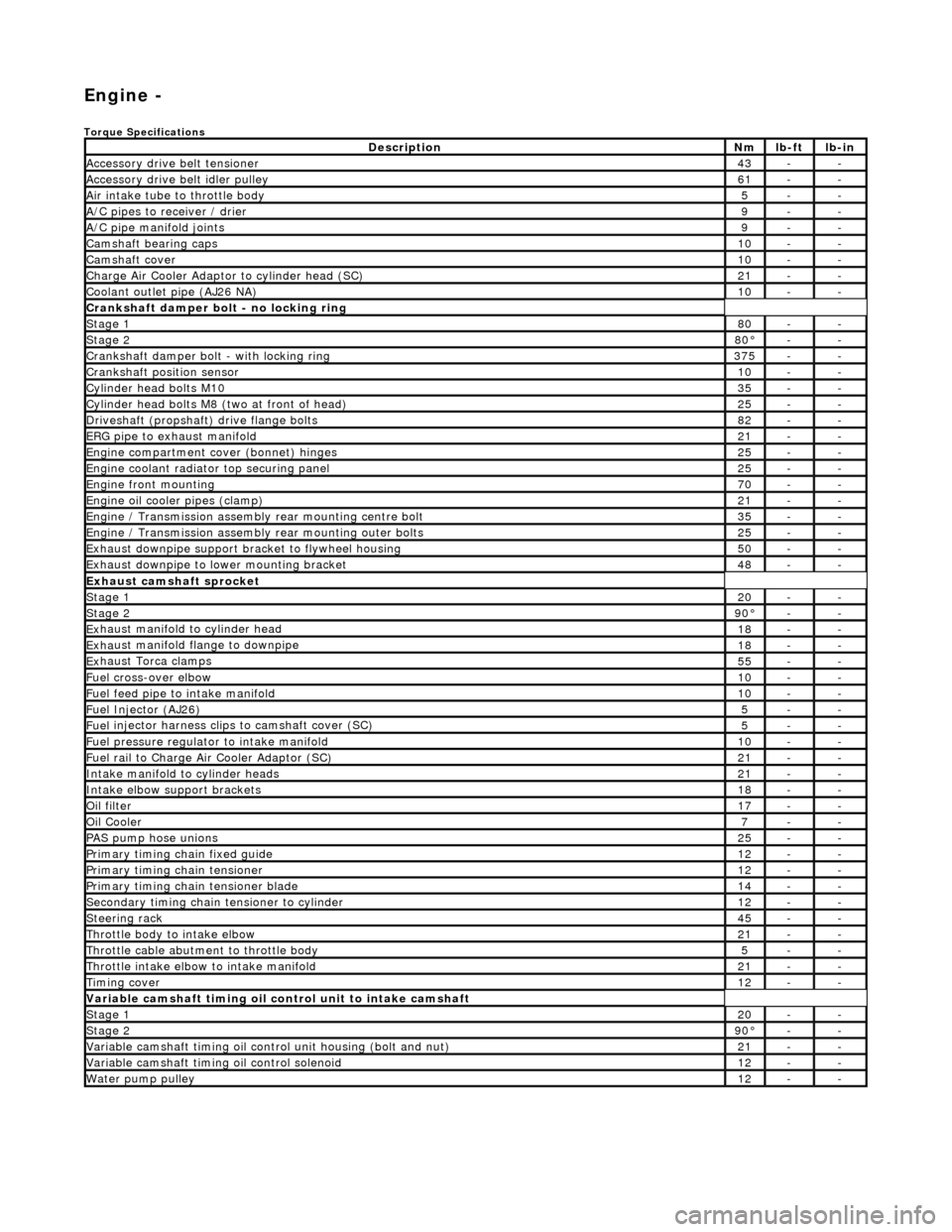

Page 530 of 2490

Engi

ne -

Torqu

e Specifications

De

s

cription

Nmlb

-

ft

lb

-

in

A

ccessory

drive belt tensioner

43--

A

ccessory

drive belt idler pulley

61--

Air in

ta

ke tube to throttle body

5--

A/C

pipes t

o receiver / drier

9--

A/C pipe m

anifold joints

9--

Camsh

aft bearin

g caps10--

Ca

msh

aft cove

r10--

Ch

arge Air Co

oler Adaptor to cylinder head (SC)

21--

Co

olan

t outlet pipe (AJ26 NA)

10--

Cran

kshaft damper bolt - no lockin

g ring

St

ag

e 1

80--

Stag

e 2

80°--

C

r

ankshaft damper bolt - with locking ring

37

5--

Cra

nkshaft position sensor

10--

Cy

li

nder head bolts M10

35--

Cy

lin

der head bolts M8 (two at front of head)

25--

Driv

es

haft (propshaft) drive flan

ge bo

l

ts

82--

ERG p

i

pe to exhaust manifold

21--

Engi

ne compartment cover (bonnet) hinges

25--

En

gine

coolant radiator top securing panel

25--

E

ng

ine front mounting

70--

En

gine

oil cooler pipes (clamp)

21--

En

gi

ne / Transmission assembly rear mounting centre bolt

35--

En

gi

ne / Transmission assembly rear mounting outer bolts

25--

Ex

ha

ust downpipe support bracket to flywheel housing

50--

Ex

ha

ust downpipe to lower mounting bracket

48--

E

x

haust camshaft sprocket

St

age 120--

Stage 290 °--

Ex

haust manifold to cylinder head

18--

Ex

ha

ust manifold flange to downpipe

18--

E

x

haust Torca clamps

55--

Fuel cross-over elbo

w

10--

Fu

el f

eed pipe to intake manifold

10--

Fuel

Injector (AJ

26)

5--

Fuel

injector ha

rness clips to camshaft cover (SC)

5--

Fu

el p

ressure re

gu

l

ator to intake manifold

10--

F

u

el rail to Char

ge

A

ir Cooler Adaptor (SC)

21--

In

ta

ke manifold to cylinder heads

21--

Inta

ke elbow support brackets

18--

Oil f

i

lter

17--

Oil C

o

oler

7--

P

AS pu

mp hose unions

25--

P

r

imary timing chain fixed guide

12--

P

r

imary timing chain tensioner

12--

Pr

imary timing chain tensioner blade

14--

S

e

condary timing chain tensioner to cylinder

12--

S

t

eerin

g ra

ck45--

Thro

ttle body to intake elbow

21--

Th

ro

ttle cable abutment to throttle body

5--

Th

ro

ttle intake elbow to intake manifold

21--

Ti

mi

ng cover

12--

Variable camshaft t

i

ming oil control unit to intake camshaft

St

ag

e 1

20--

St

ag

e 2

90

°--

Var

iable camshaft timing oil control unit housing (bolt and nut)

21--

Va

ria

ble camshaft timi

ng oil control solenoid

12--

Wa

ter pump pulley

12--

Page 552 of 2490

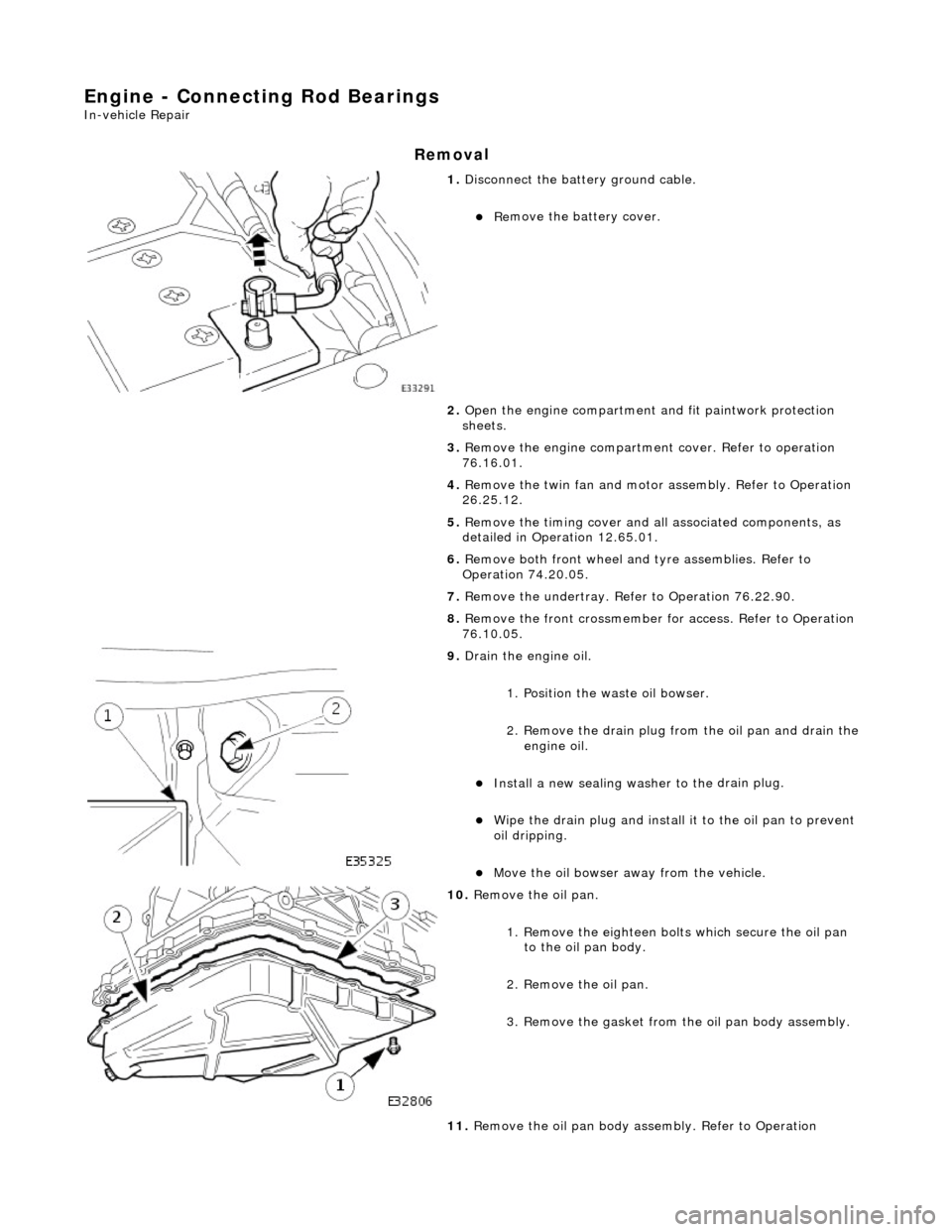

Engine - Connecting Rod Bearings

In-vehic

le Repair

Remov

a

l

1.

Disc

onnect the batt

ery ground cable.

Re

move the battery cover.

2. Open the engine compartment and fit paintwork protection

sheets.

3. Remove the engine compartmen t cover. Refer to operation

76.16.01.

4. Remove the twin fan and motor assembly. Refer to Operation

26.25.12.

5. Remove the timing cover and al l associated components, as

detailed in Operation 12.65.01.

6. Remove both front wheel and tyre assemblies. Refer to

Operation 74.20.05.

7. Remove the undertray. Re fer to Operation 76.22.90.

8. Remove the front crossmember fo r access. Refer to Operation

76.10.05.

9. Drai

n the engine oil.

1. Position the waste oil bowser.

2. Remove the drain plug from the oil pan and drain the engine oil.

Install a new sealing wash er to the

drain plug.

Wipe the drain plug an

d

install

it to the oil pan to prevent

oil dripping.

Move the oil bowser away f

rom the vehicle.

10 . Re

move the oil pan.

1. Remove the eighteen bolt s which secure the oil pan

to the oil pan body.

2. Remove the oil pan.

3. Remove the gasket from the oil pan body assembly.

11. Remove the oil pan body a ssembly. Refer to Operation

Page 555 of 2490

I

nstallation

Tigh

ten each bolt to 8 to 12 Nm initial torque value.

Ti

ghten to a final torque of 57 to 63 Nm.

27. Check that the cranks haft turns freely.

28. Repeat the previous operations for each connecting rod

bearing as necessary.

1. Install the oil pan bo dy assembly. Refer to Operation 12.60.48.

2. Po

sition and align the oil pan gasket to the oil pan body

assembly.

Inse

rt the seal into the locating positions in the groove,

working around from a corner.

Press in the remai

nder of th

e seal, following the same

procedure.

3. Install th

e oil pan to the oil pan body.

1. Position and align the oil pan.

2. Install, but do not tighte n, all eighteen bolts which

secure the oil pan.

4. Tigh

ten the bolts to the correct

torque figure 11-13 Nm, in the

sequence indicated.

Tigh

ten the drain plug to 30-40 Nm.

Install a new oil

filter.

Page 622 of 2490

2. In

stall the camshaft caps to their respective locations (inlet 0 to 4

and exhaust 5 to 9 from the front) and in the correct orientation

(arrow to front of engine).

3. Install and tighten the cap securing bolts. Tighten evenly, in stages, to 10 Nm.

19. Install the camshaft locking tool 303 - 530, align the camshafts as

necessary.

20 . Install the chain guide

.

The

c

hain guide must be installed so that the slotted hole is towards

the top, and the rais ed shoulder to the cylinder block.

1. Install the chain guide to the block and locate it onto the upper retaining pin.

2. Install the retaining bolt and tighten it to 12 Nm.

21. P

ush the secondary chain tensioner piston into the body to provide

clearance for installing the chain.

1. Insert a thin rigid wire through the hole in the end of the tensioner

piston to displace the ball from the non-return valve seat.

2. With the wire in position, press the piston fully into the tensioner body.

Rem

ove the wire.

22 . Ins

tall the secondary chain tensioner to the engine.

1. Fully seat the tensioner to the cylinder head.

2. Install the two bolts which secure the tensioner and tighten to 12 Nm.

23 . N

OTE: Assemble the VVT unit, the exhaust camshaft sprocket and the

secondary chain, in preparation for installing to the engine.

Install the VVT unit to the engine.

1. Install the above assembly to the camshafts with the chain correctly positioned over the tensioner; VVT unit to the inlet and

the sprocket to the exhaust.

2. Install, but do not tighten, each bolt which secures the VVT unit and the exhaust sprocket to the camshafts.

24. Install the chain tensioning tool 303 - 532 to the exhaust camshaft

sprocket.