engine JAGUAR X308 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 389 of 2490

Install brake pads.

1

. Install pads.

2. Position anti-rattle spring.

3. Install pins - make sure pin collets are fully engaged

into caliper.

4. Repeat above procedure to install opposite side brake pads.

5. Fit wheels.

For additional information, refer to: Wheel and Tire

(20

4-04

Wheels and Tires, Remo val and Installation).

6. Remove stands an d lower vehicle.

For additional information, refer to: Using the Workshop Jack

(10

0-02 Jacking and Lifting, General Procedures).

7. CAUTI

ON: Remove brake flui

d spillage immediately from

paint work, with clean water.

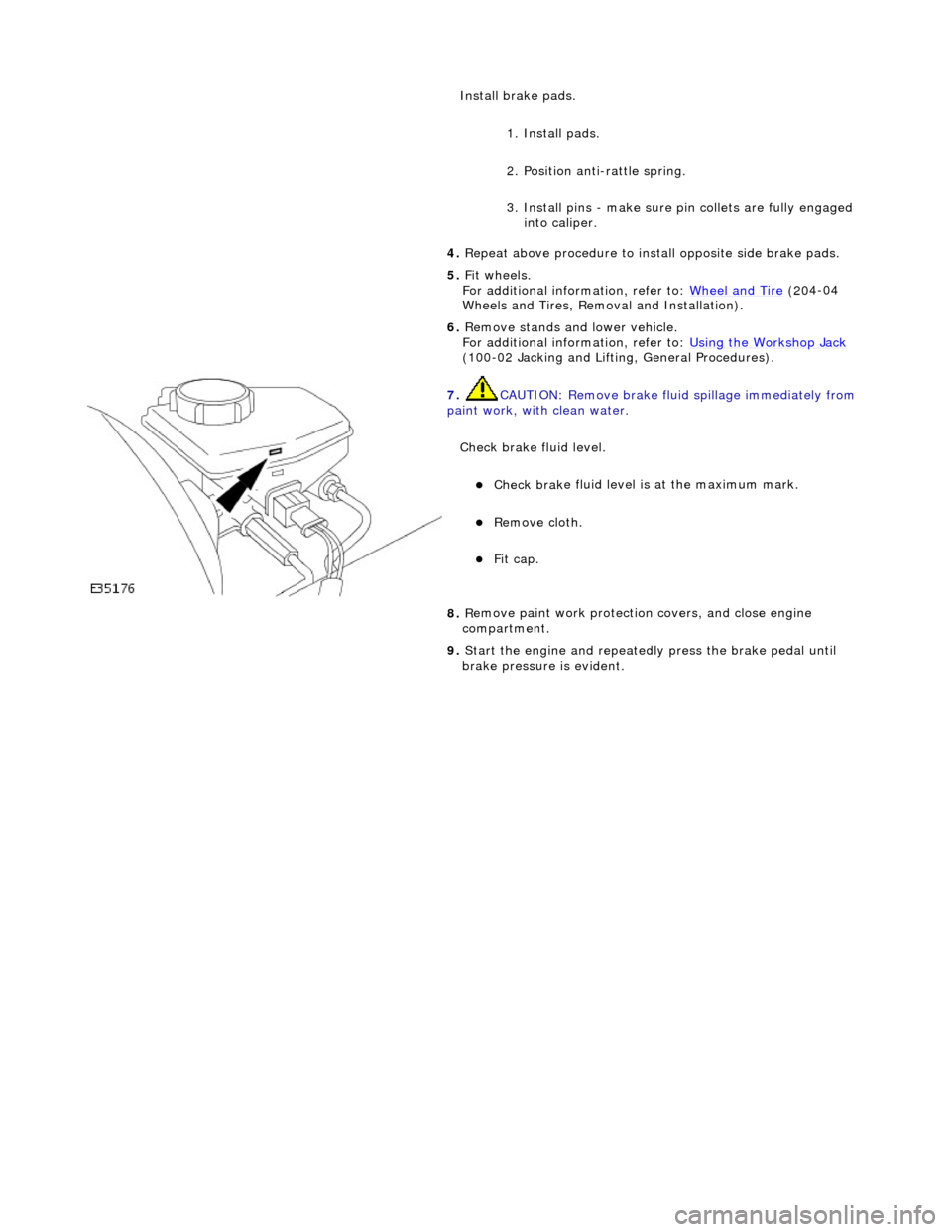

Check brake fluid level.

пЃ¬Check brak

e fluid level is

at the maximum mark.

пЃ¬Re

move cloth.

пЃ¬Fi

t cap.

8.

R

emove paint work protection

covers, and close engine

compartment.

9. Start the engine and repeatedly press the brake pedal until

brake pressure is evident.

Page 408 of 2490

Hydraulic Br

ake Actuation

- Brake Fluid Reservoir

Remo

val and Installation

Remov

a

l

• C

A

UTIONS:

Replacement of nuts and bolts: Various thread-locking de vices are used on nuts and bolts throughout the vehicle.

These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

Remove brake fluid spilla ge immediately from paint work, with clean water.

1. Position vehicl

e on a four-post lift.

2. Open engine compartment and fit paint work protection covers

to fenders.

3. Disconnect battery ground cable (IMPORTANT, see operation

86.15.19 for further information).

4. Remove engine compartment rear cover. Refer to operation

76.11.35.

5. Remove pedal housing, brake booster and master cylinder

assembly. Refer to operation 70.35.39.

6. Remove reservoir filler cap and empty residual brake fluid into

a container. Refit cap.

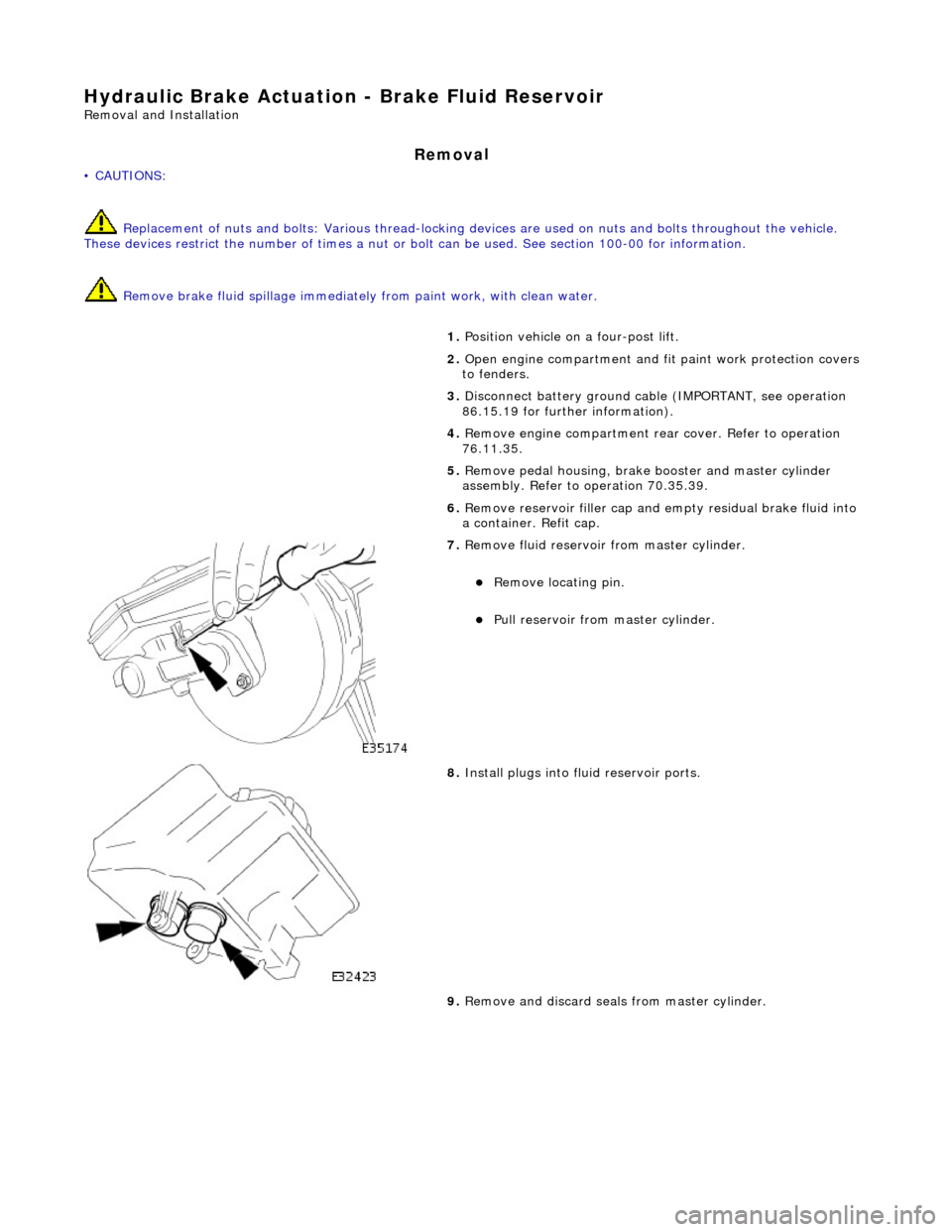

7. Re

move fluid reservoir from master cylinder.

пЃ¬R

e

move locating pin.

пЃ¬Pull reservoir

from master cylinder.

8. Install plugs into f

luid reservoir ports.

9. Remove and discard seal s from master cylinder.

Page 409 of 2490

I

nstallation

10

.

Install plugs into master cylinder ports.

11. Clean components and mating surfaces.

1. Inst

all seals into master cylinder.

пЃ¬Re

move plugs.

пЃ¬Lubricate seals with

cl

ean brake fluid.

пЃ¬Inst

all seals.

2. Install

reservoir to master cylinder.

пЃ¬Re

move plugs.

пЃ¬Install

reservoir, making sure

reservoir is fully seated.

пЃ¬Inst

all locating pin.

3. Install pedal housing, brake booster and master cylinder

assembly. Refer to operation 70.35.39.

4. Install engine compartment rear cover. Refer to operation

76.11.35.

5. Reconnect battery ground cable (IMPORTANT, see operation

Page 410 of 2490

8

6

.15.15 for further information).

6. Bleed brake system. Refer to operation 70.25.03.

7. Remove paint-work protection covers and close engine

compartment.

Page 411 of 2490

Hydraulic B

rake Actuation

- Brake Master Cylinder

Re

moval and Installation

Remov

al

• C

AUTIONS:

Replacement of nuts and bolts: Various thread-locking de vices are used on nuts and bolts throughout the vehicle.

These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

Remove brake fluid spilla ge immediately from paint work, with clean water.

1. Position vehi

cle on a four-post lift.

2. Open engine compartment and fit paint work protection covers

to fenders.

3. Disconnect battery ground cable (IMPORTANT, refer to

operation 86.15.19 for fu rther information).

4. Remove engine compartment rear cover. Refer to operation

76.11.35.

5. Remove pedal housing, brake booster and master cylinder

assembly. Refer to operation 70.35.39.

6. Place assembly on a work bench.

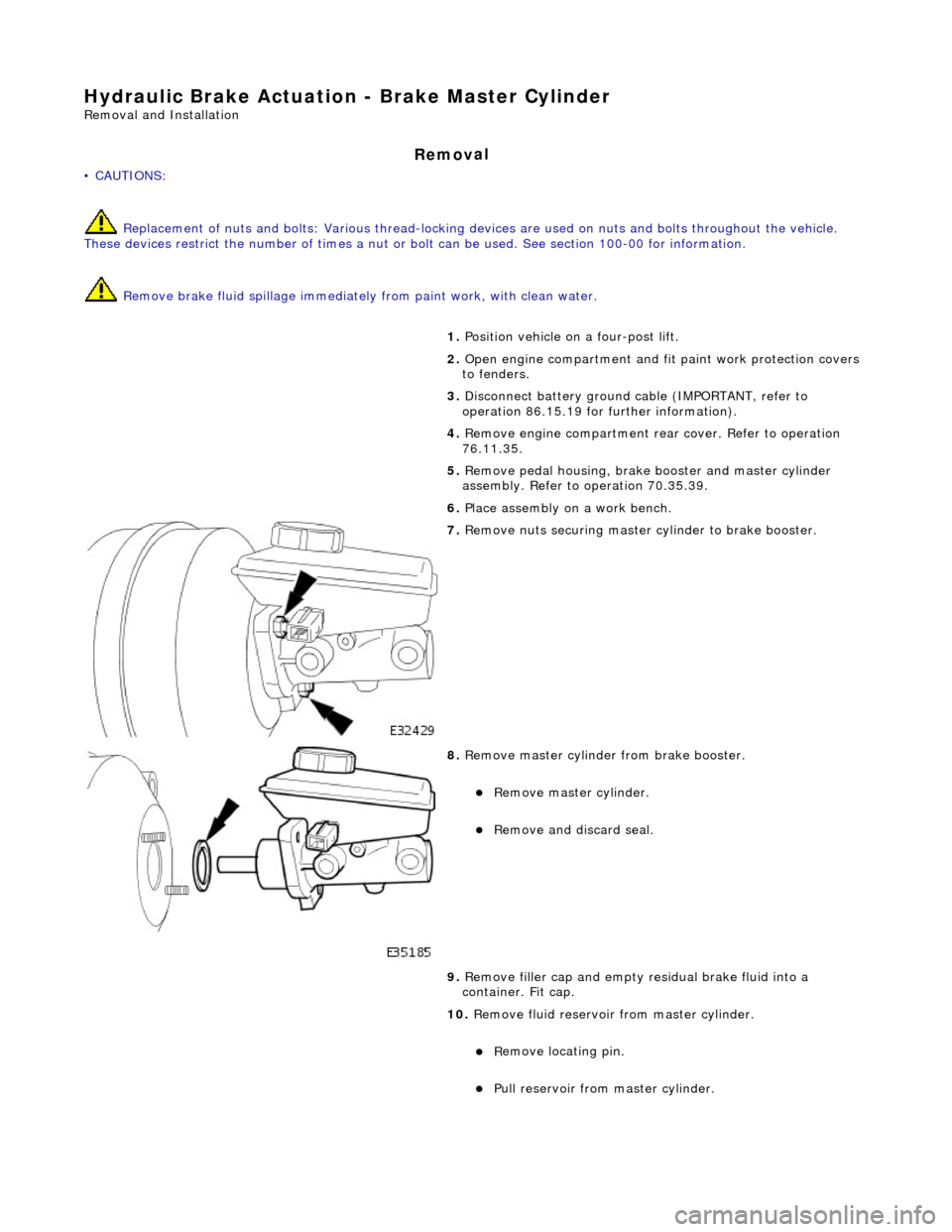

7. R

emove nuts securing master cylinder to brake booster.

8. R

emove master cylinder from brake booster.

пЃ¬Re

move master cylinder.

пЃ¬Remove an

d discard seal.

9. Remove filler cap and empty residual brake fluid into a

container. Fit cap.

10. Remove fluid reservoir from master cylinder.

пЃ¬R

emove locating pin.

пЃ¬Pull

reservoir from master cylinder.

Page 413 of 2490

пЃ¬Lubricate seals with cl

ean brake fluid.

пЃ¬Inst

all seals.

2. Install

fluid reservoir to master cylinder.

пЃ¬R

emove plugs from reservoir

пЃ¬Install

reservoir, making sure

reservoir is fully seated.

пЃ¬Inst

all locating pin.

3. Inst

all master cylinder to brake booster.

пЃ¬Inst

all seal.

пЃ¬Inst

all master cylinder, make sure master cylinder rod

locates brake booster rod.

4. Inst

all and tighten nuts to 21-29 Nm.

5. Install pedal housing, brake booster and master cylinder

assembly. Refer to operation 70.35.39.

6. Install engine compartment rear cover. Refer to operation

76.11.35.

7. Connect battery ground cable (IMPORTANT, see operation

86.15.15 for further information).

8. Bleed brake system. Refer to operation 70.25.03.

9. Remove paint-work protection covers and close engine

com

partment.

Page 414 of 2490

Hydrau

lic Brake Actuation - Brake Pedal and Bracket

Re

mo

val and Installation

Remov

a

l

• C

A

UTIONS:

Replacement of nuts and bolts: Various thread-locking de vices are used on nuts and bolts throughout the vehicle.

These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

Remove brake fluid spilla ge immediately from paint work, with clean water.

In

stallation

1.

Position vehicl

e on a four-post lift.

2. Open hood and fit suitable pa intwork protection equipment.

3. Disconnect battery ground cabl e. (IMPORTANT, see 86.15.19

for further information).

4. Remove engine compartment rear cover. Refer to operation

76.11.35.

5. Remove pedal housing, brake booster and master cylinder

assembly. Refer to operation 70.35.39.

6. Remove brake booster and master cylinder assembly. Refer to

operation 70.50.18.

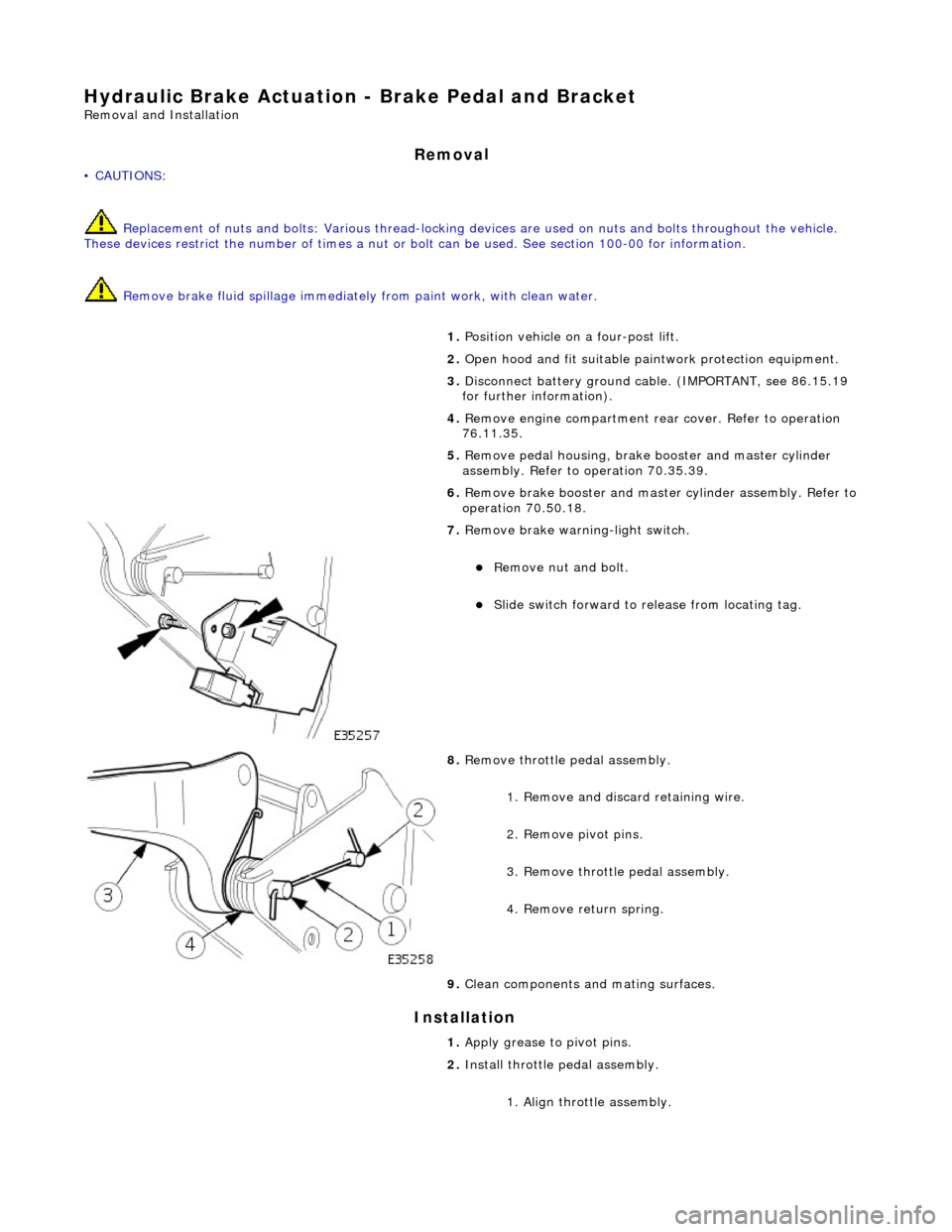

7. Remove brake wa

rning-light switch.

пЃ¬Remove n

u

t and bolt.

пЃ¬Slide sw

itch forward to release from locating tag.

8. Re

move throttle pedal assembly.

1. Remove and discard retaining wire.

2. Remove pivot pins.

3. Remove throttle pedal assembly.

4. Remove return spring.

9. Clean components and mating surfaces.

1. Apply grease to pivot pins.

2. Install throttle pedal assembly.

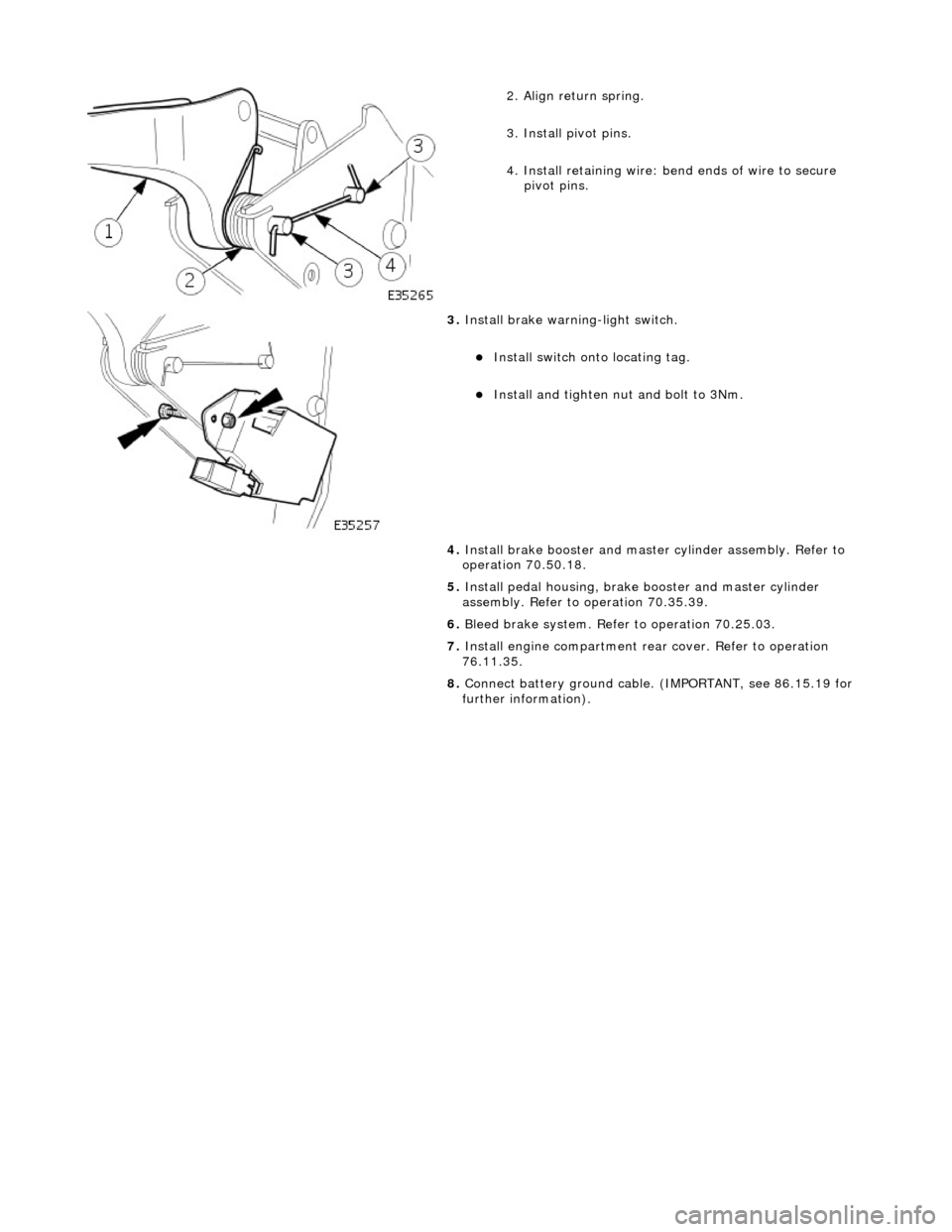

1. Align throttle assembly.

Page 415 of 2490

2

. Align return spring.

3. Install pivot pins.

4. Install retaining wire: bend ends of wire to secure

pivot pins.

3. Inst

all brake warning-light switch.

пЃ¬Inst

all switch onto locating tag.

пЃ¬Install and tigh

ten nut and bolt to 3Nm.

4. Install brake booster and master cylinder assembly. Refer to

operation 70.50.18.

5. Install pedal housing, brake booster and master cylinder

assembly. Refer to operation 70.35.39.

6. Bleed brake system. Refer to operation 70.25.03.

7. Install engine compartment rear cover. Refer to operation

76.11.35.

8. Connect battery ground cable. (IMPORTANT, see 86.15.19 for

further information).

Page 416 of 2490

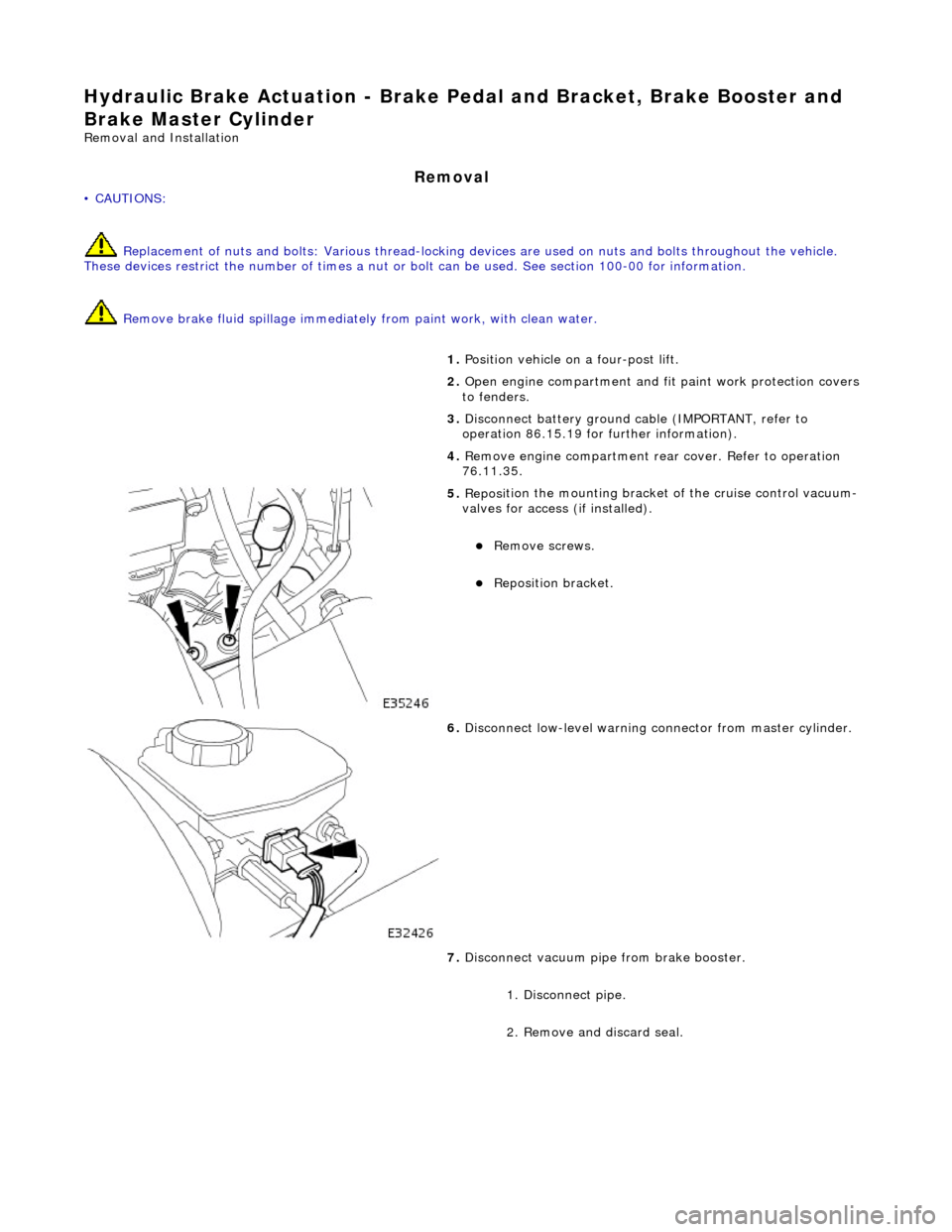

Hydrau

lic Brake Actuation - Brake Pedal and Bracket, Brake Booster and

Brake Master Cylinder

Re mo

val and Installation

Remova

l

• C

A

UTIONS:

Replacement of nuts and bolts: Various thread-locking de vices are used on nuts and bolts throughout the vehicle.

These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

Remove brake fluid spilla ge immediately from paint work, with clean water.

1. Position vehi cl

e on a four-post lift.

2. Open engine compartment and fit paint work protection covers

to fenders.

3. Disconnect battery ground cable (IMPORTANT, refer to

operation 86.15.19 for fu rther information).

4. Remove engine compartment rear cover. Refer to operation

76.11.35.

5. Reposi

tion the mounting bracket of the cruise control vacuum-

valves for access (if installed).

пЃ¬R e

move screws.

пЃ¬Reposition bracket.

6. Disc

onnect low-level warning connector from master cylinder.

7. Disconnect vacuum pipe from brake booster.

1. Disconnect pipe.

2. Remove and discard seal.

Page 417 of 2490

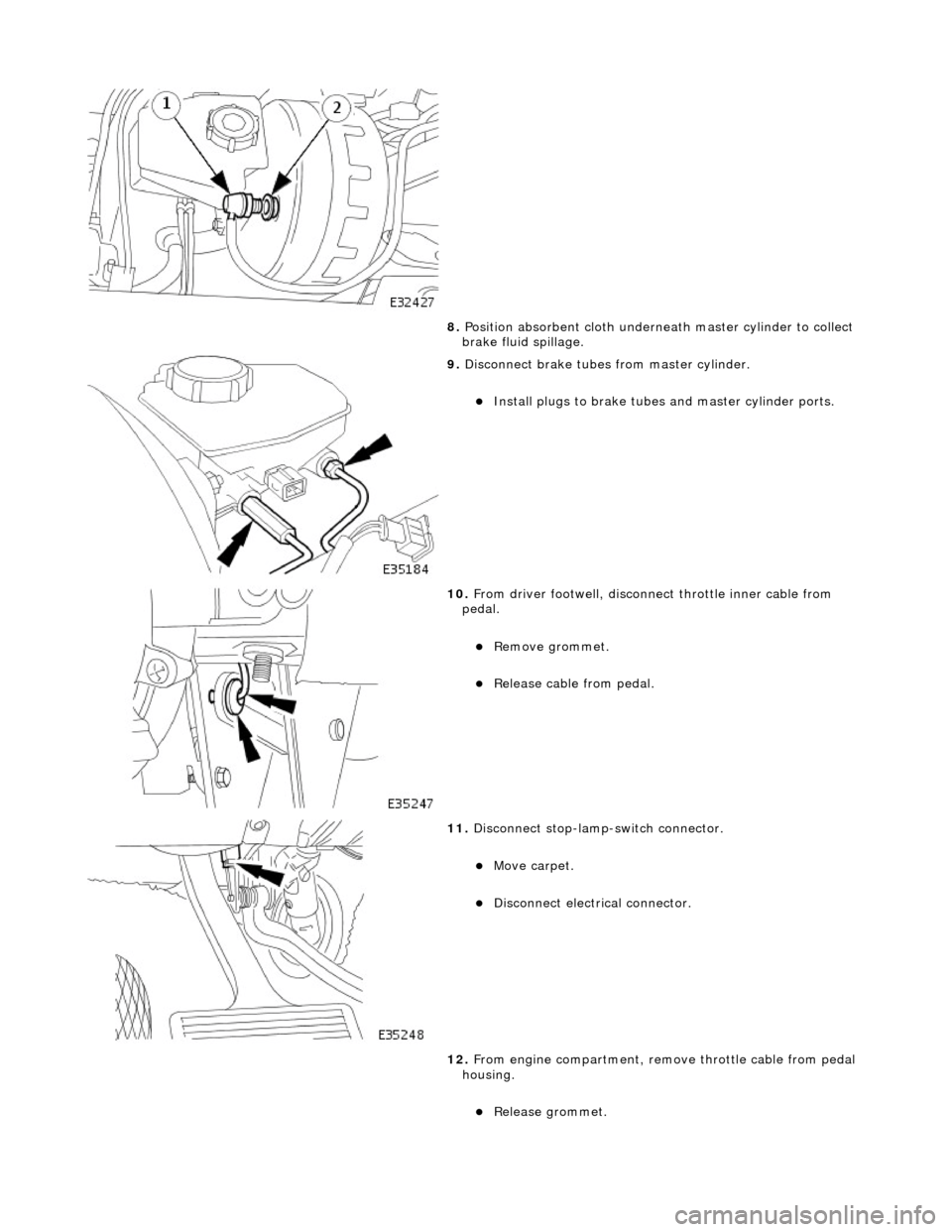

8. Posi

tion absorbent cloth underneath master cylinder to collect

brake fluid spillage.

9. Di

sconnect brake tubes from master cylinder.

пЃ¬Install plugs to brake tu

bes an

d master cylinder ports.

10

.

From driver footwell, disconne ct throttle inner cable from

pedal.

пЃ¬Re

move grommet.

пЃ¬Relea

se cable from pedal.

11

.

Disconnect stop-lamp-switch connector.

пЃ¬Move carpet.

пЃ¬Disc

onnect electrical connector.

12. From engine compartment, remo ve throttle cable from pedal

housing.

пЃ¬Re

lease grommet.