evaporative JAGUAR X308 1998 2.G Owner's Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1165 of 2490

Vehicles with AJ26 en

gine:

D

isconnect the ECM electrical connector, EM11

Di

sconnect the FTP sensor electrical connector, FP01

Meas

ure the resistance between EM11,

pin 07 (RG) and FP01, pin 02 (RG)

Vehicles with AJ27 engine:

D

isconnect the ECM electrical connector, EM81

Di

sconnect the FTP sensor electrical connector, FP01

Meas

ure the resistance between EM81,

pin 16 (RG) and FP01, pin 02 (RG)

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. Carry out a full Evaporative system monitor drive cycle. For additional information, see

"diagnostic drive cycles" above.

No GO to D2

.

D2: CHECK

THE FTP SENSOR SENSE CI

RCUIT FOR SHORT CIRCUIT TO GROUND

R

econnect the battery negative terminal.

1

Meas

ure the resistance between

FP01, pin 07 (RG) and GROUND.

2

Is

the resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

Carry out a full Evaporative system monitor drive cycle.

No GO to D4

.

D3: CHECK

THE FTP SENSOR SENSE CIRCUI

T FOR SHORT CIRCUIT TO HIGH VOLTAGE

Turn the ignition swi

tch to the ON

position.

1

Measure the

voltage between FP

01, pin 02 (RG) and GROUND.

2

Is th

e voltage greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

Carry out a full Evaporative system monitor drive cycle.

No GO to D4

.

D

4: CHECK THE FTP SENSOR SIGNAL GROUND CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

Vehicles with AJ26 engine:

D

isconnect the ECM electrical connector, EM10

Meas

ure the resistance between EM11, pin 12 (BG) and FP01, pin 01 (BG)

Meas

ure the resistance between EM10, pin 20 (BG) and FP01, pin 01 (BG)

Vehicles with AJ27 engine:

Re

connect the ECM electrical connector, EM81

D

isconnect the ECM electrical connector, EM82

D

isconnect the ECM electrical connector, EM83

Meas

ure the resistance between EM82, pin 07 (BG) and FP01, pin 01 (BG)

Meas

ure the resistance between EM83, pin 13 (BG) and FP01, pin 01 (BG)

1

Is either resi

stance

greater than 5 ohms?

Yes REPAIR the high resistance circui t. This circuit includes harness splice, EMS02. For additional

information, refer to the wiring diagrams. CLEAR the DTC. Carry out a full Evaporative system

monitor drive cycle. For additional informat ion, see "diagnostic drive cycles" above.

No GO to D5

.

D5:

CHECK THE FTP SENSOR SIGNAL GROUND

CIRCUIT FOR SHORT CIRCUIT TO GROUND

R

econnect the battery negative terminal.

1

Meas

ure the resistance between

FP01, pin 01 (BG) and GROUND.

2

Is

the resistance less than 10,000 ohms?

Page 1166 of 2490

Yes

R

EPAIR the short circuit. For addi

tional information, refer to the wiring diagrams. CLEAR the DTC.

Carry out a full Evaporative system monitor drive cycle.

No GO to D6

.

D6: CHECK

THE FTP SENSOR POWER SU

PPLY CIRCUIT FOR HIGH RESISTANCE

Disc

onnect the battery negative terminal.

Vehicles with AJ26 engine:

Measure t

he resistance between EM11,

pin 08 (UW) and FP01, pin 03 (UW)

Measure t

he resistance between EM10,

pin 21 (UW) and FP01, pin 03 (UW)

Vehicles with AJ27 engine:

Meas ure t

he resistance between EM82,

pin 01 (OY) and FP01, pin 03 (OY)

Measure t

he resistance between EM83,

pin 05 (OY) and FP01, pin 03 (OY)

1

Is either resistance greater

than 5 ohms?

Yes

REPAIR the high resistance circui t. This circuit includes harness splice, EMS01. For additional

information, refer to the wiring diagrams. CLEAR the DTC. Carry out a full Evaporative system

monitor drive cycle. For additional informat ion, see "diagnostic drive cycles" above.

No GO to D7

.

D7: CHECK

THE FTP SENSOR WIRING

FOR SHORT CIRCUIT TO EACH OTHER

Measure

the resistance between FP01, pins 01 (BG) and 02 (RG).

1

M

e

asure the resistance between FP01, pins 02 (RG) and 03 (UW).

2

Is either resi

stance le

ss than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

Carry out a full Evaporative system monitor drive cycle.

No INSTALL a new FTP sensor. CLEAR the DTC. Carry out a full Evaporative system monitor drive cycle.

For additional information, see "diagnostic drive cycles" above.

Page 1169 of 2490

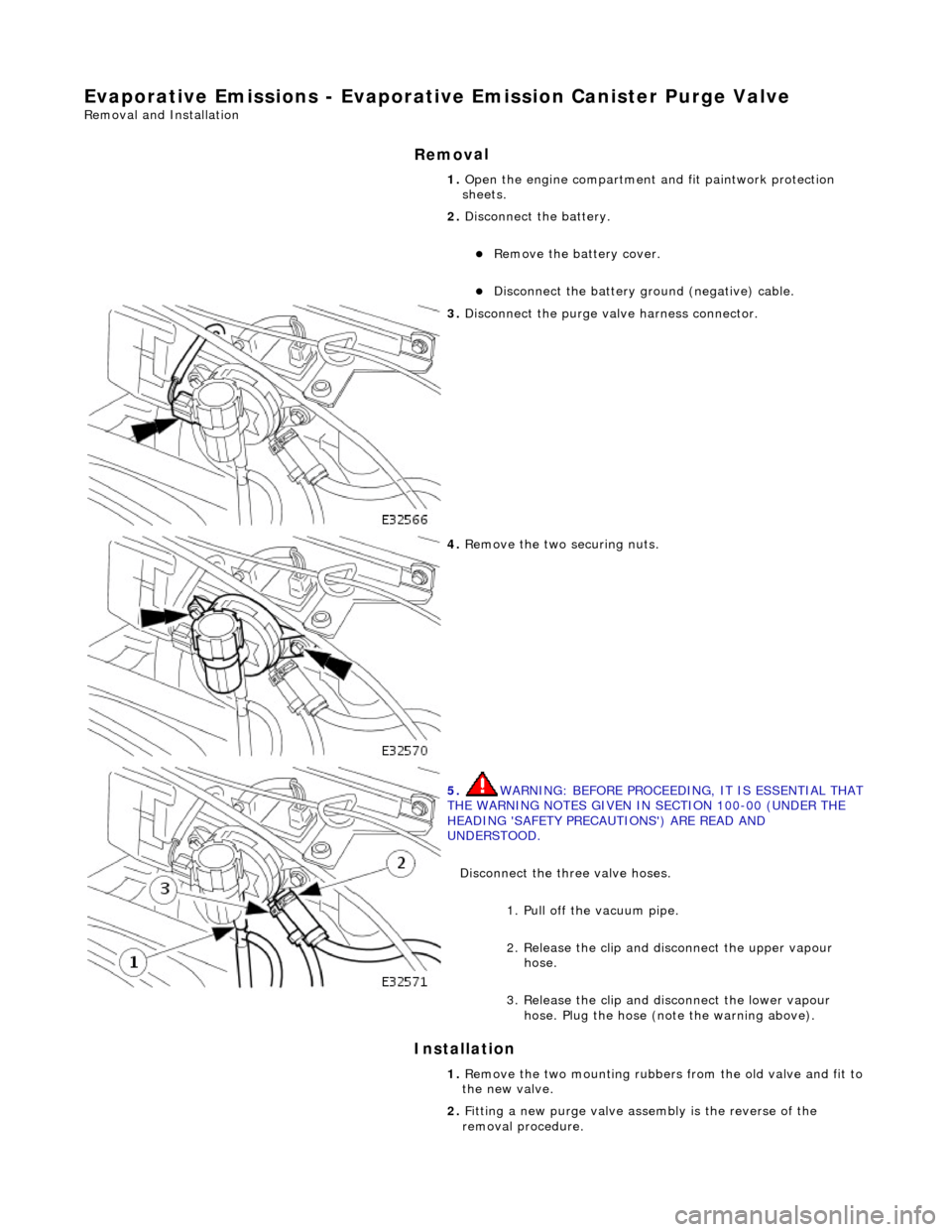

Evaporative Emissions - Evaporative Emission Canister Purg

e Valve

Re

moval and Installation

Remov

al

Installation

1. O

pen the engine compartment and fit paintwork protection

sheets.

2. Disconnect the battery.

R

emove the battery cover.

Di

sconnect the battery ground (negative) cable.

3. Di

sconnect the purge valve harness connector.

4. R

emove the two securing nuts.

5. WARNING: B

EFORE PROCEEDING, IT IS ESSENTIAL THAT

THE WARNING NOTES GIVEN IN SECTION 100-00 (UNDER THE

HEADING 'SAFETY PRECAUTIONS') ARE READ AND

UNDERSTOOD.

Disconnect the three valve hoses.

1. Pull off the vacuum pipe.

2. Release the clip and di sconnect the upper vapour

hose.

3. Release the clip and disconnect the lower vapour hose. Plug the hose (note the warning above).

1. R

emove the two mounting rubbers from the old valve and fit to

the new valve.

2. Fitting a new purge valve asse mbly is the reverse of the

removal procedure.

Page 1170 of 2490

3.

Connect the battery and fit the battery

cover.

Refe

r to the Battery Reconnection Procedure (86.15.15).

4. Carry out a leak test of the evaporative emissions system.

Page 1171 of 2490

E

vaporative Emissions - Fuel

Tank Pressure Sensor

Re

moval and Installation

Remov

al

Installation

1.

Disc

onnect battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. WARNING: BEFORE PROCEEDING, IT IS ESSENTIAL THAT

THE WARNING NOTES GIVEN IN SECTION 100-00 (UNDER THE

HEADING 'SAFETY PRECAUTIONS') ARE READ AND

UNDERSTOOD.

Drain the fuel tank using a suitab le suction pump/tanker. If the

On-board Refueling Vapor Recove ry (ORVR) system is fitted,

refer to General Procedures Section 310-01.

3. R

emove the fuel tank; refe

r to operation 19.55.01.

4. R

emove pressure sensor fro

m evaporative loss flange.

1. Installation is th e reverse of the re moval procedure.

Page 1172 of 2490

Evaporative E

missions - Fuel

Vapor Vent Valve Housing

Remo

val and Installation

Remov

a

l

Installation

1.

Re

fer to 19.55.25.

1. Installation is a reversal of the removal procedure.

Page 1173 of 2490

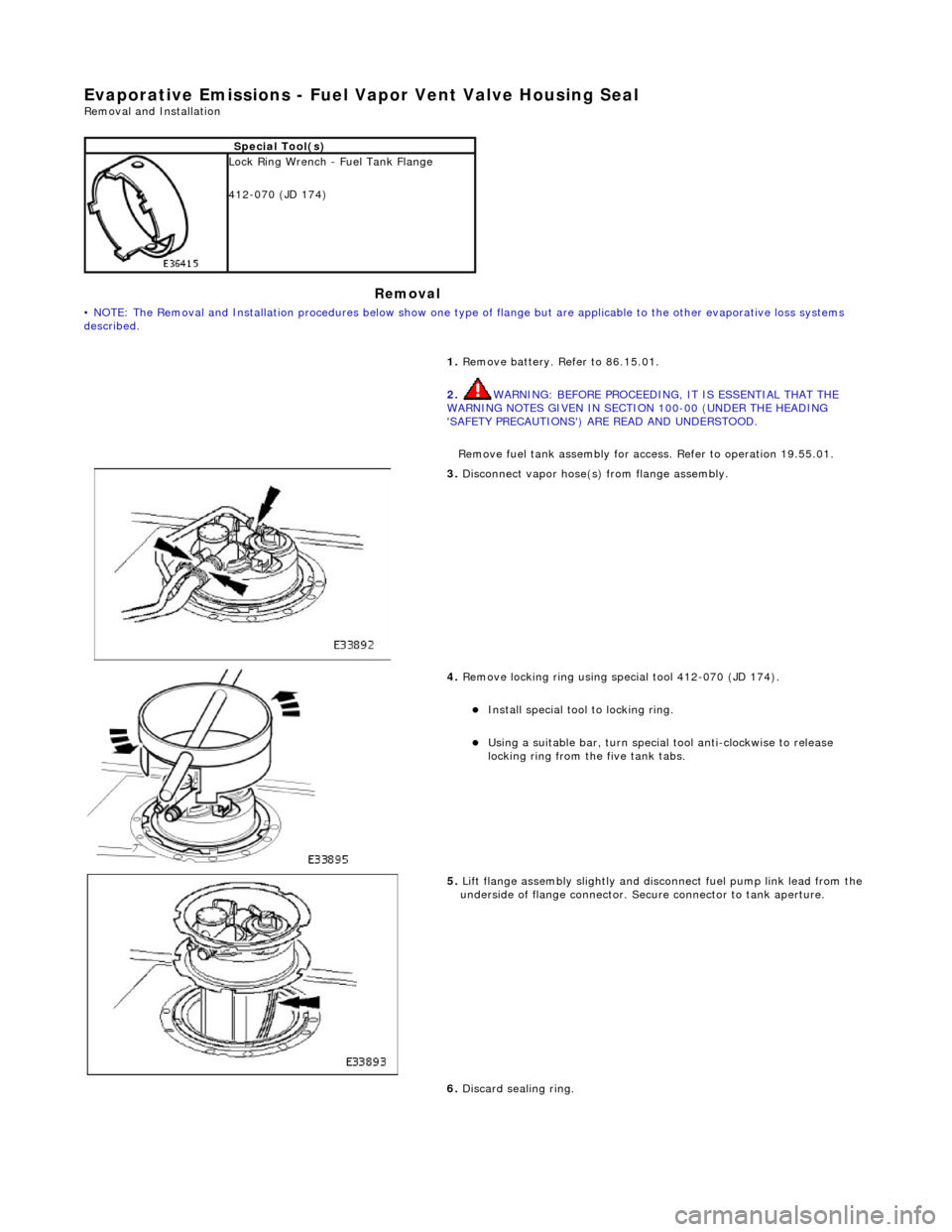

Evapor

ative Emissions - Fuel Va

por Vent Valve Housing Seal

Remov

al and Installation

Re

moval

• NO

TE: The Removal and Installation procedur

es below show one type of flange but are applicable to the other evaporative loss systems

described.

Special To

ol(s)

Lock

Ring Wrench - Fuel Tank Flange

412-070 (JD 174)

1. Remove battery. Refer to 86.15.01.

2. WARNING: BEFORE PROCEEDING, IT IS ESSENTIAL THAT THE

WARNING NOTES GIVEN IN SECTIO N 100-00 (UNDER THE HEADING

'SAFETY PRECAUTIONS') ARE READ AND UNDERSTOOD.

Remove fuel tank assembly for access. Refer to operation 19.55.01.

3. Discon

nect vapor hose(s) from flange assembly.

4. Remov

e locking ring using special tool 412-070 (JD 174).

Insta

ll special tool to locking ring.

Usi

ng a suitable bar, turn special tool anti-clockwise to release

locking ring from the five tank tabs.

5. Lift

flange assembly slightly and disconnect fuel pump link lead from the

underside of flange connector. Secure connector to tank aperture.

6. Discard sealing ring.

Page 1174 of 2490

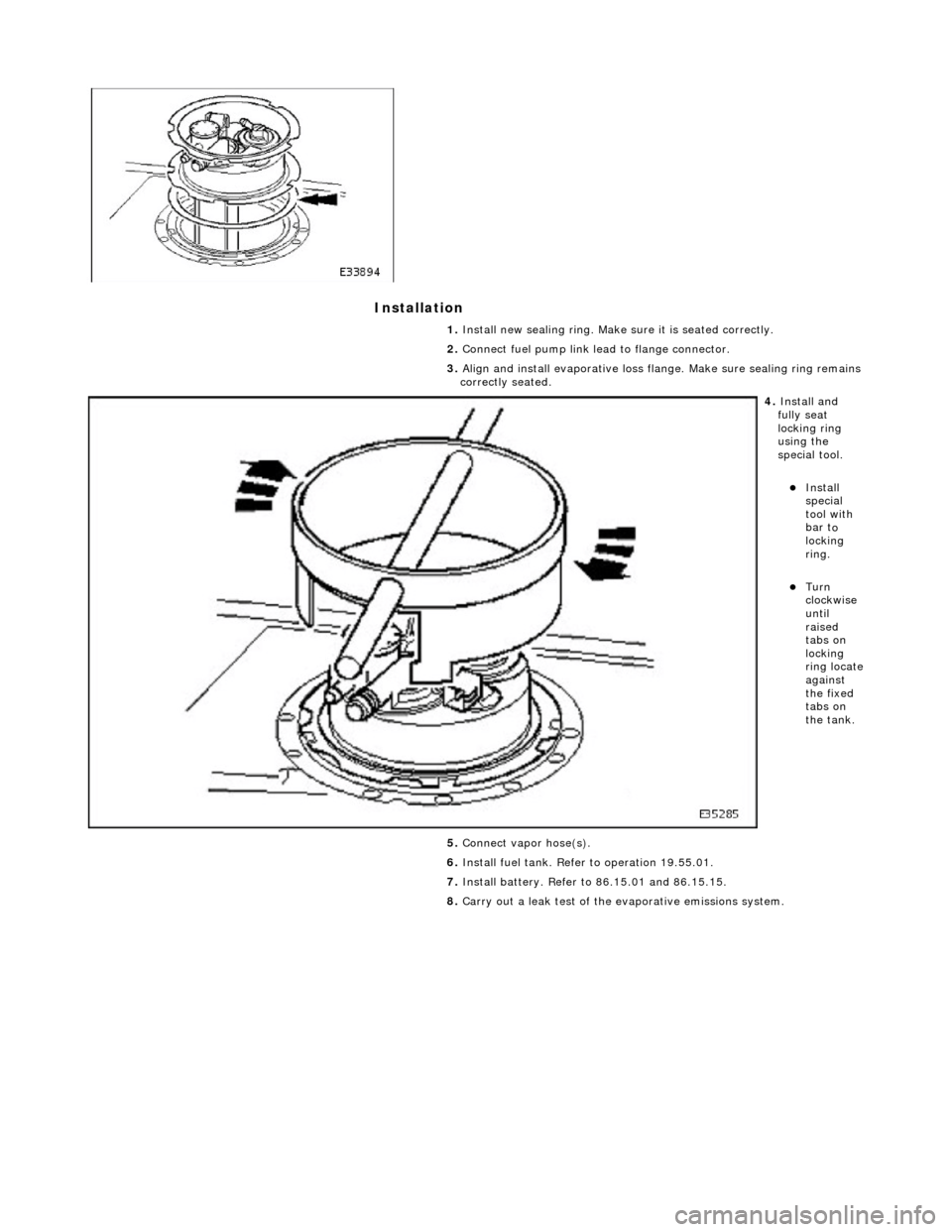

Installation

1.

Insta ll n

ew sealing ring. Make sure it is seated correctly.

2. Connect fuel pump link lead to flange connector.

3. Align and install evaporative loss flange. Make sure sealing ring remains

correctly seated.

4. Insta ll a

nd

fully seat

locking ring

using the

special tool.

Insta ll

special

tool with

bar t

o

locking

ring.

Turn

clock w

ise

until

raised

tabs on

locking

ring locate

against

the fixed

tabs on

the tank.

5. Connect vapor hose(s).

6. Install fuel tank. Refer to operation 19.55.01.

7. Install battery. Refer to 86.15.01 and 86.15.15.

8. Carry out a leak test of the evaporative emissions system.

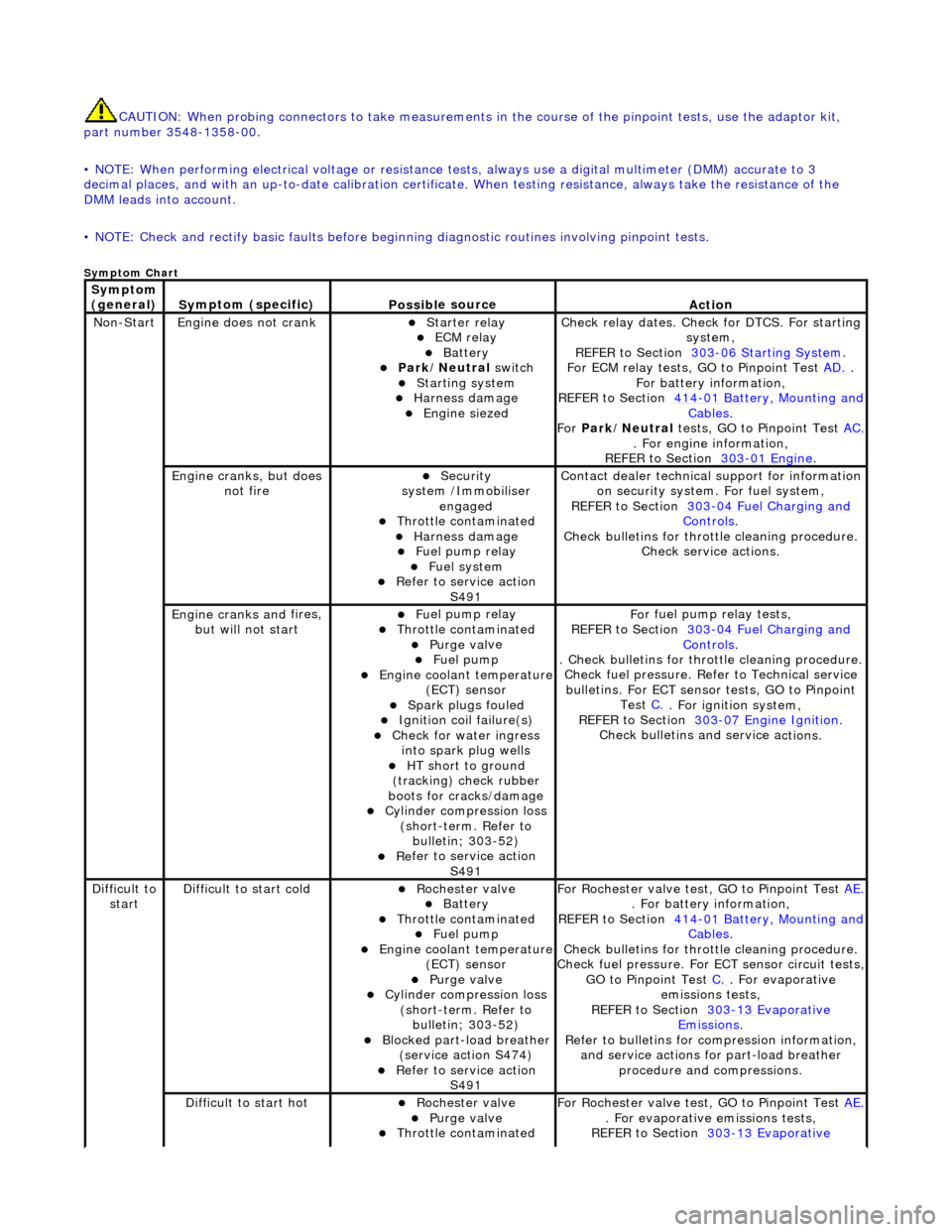

Page 1190 of 2490

CAUTIO

N: When probing connectors to take

measurements in the course of the pinpoint tests, use the adaptor kit,

part number 3548-1358-00.

• NOTE: When performing electrical voltag e or resistance tests, always use a digital multimeter (DMM) accurate to 3

decimal places, and with an up-t o-date calibration certificate. When testing resistance, always take the resistance of the

DMM leads into account.

• NOTE: Check and rectify basic faults before beginning diagnostic ro utines involving pinpoint tests.

Sym

ptom Chart

Sym

ptom

(general)

S y

mptom (specific)

Possib

l

e source

Acti

o

n

No

n

-Start

Engine

does not cran

k

Starter relay ECM relay Batt

ery Park

/Neutral

switch

Starting system

Harness damage

Engine s

iezed

Check r

e

lay dates. Check

for DTCS. For starting

system,

REFER to Section 303

-06 Sta r

ting System

.

F or ECM

relay tests, GO to Pinpoint Test

AD.

.

F o

r battery information,

REFER to Section 414

-0 1

Battery, Mounting and

Cables.

Fo r

Park/Neutral tests, GO to Pinpoint Test AC.

. Fo

r engine information,

REFER to Section 303

-01 En

gine

.

Engine cranks, but does

not fireSecurity

syst

em /Immobiliser

engaged

Thr o

ttle contaminated

Harness damage

Fu

el pump relay

Fue

l

system

R

e

fer to service action

S491

Contact dealer techni

cal

support for information

on security system. For fuel system,

REFER to Section 303

-0 4

Fuel Charging and

Controls.

Check bull etins for throttl

e cleaning procedure.

Check service actions.

Engine cranks an d

fires,

but will not start

F u

el pump relay

Thr

o

ttle contaminated

Purge

val

ve

Fue

l

pump

Engine coolan

t

temperature

(ECT) sensor

Spark plugs

fouled

Ignition coil

fail

ure(s)

Check f

o

r water ingress

into spark plug wells

HT sh o

rt to ground

(tracking) check rubber

boots for cracks/damage

Cyli

nder compression loss

(short-term. Refer to bulletin; 303-52)

Re

fer to service action

S491

Fo

r fuel pump relay tests,

REFER to Section 303

-0 4

Fuel Charging and

Controls.

. Check bulletins for throttl

e cleaning procedure.

Check fuel pressure. Refe r to Technical service

bulletins. For ECT sensor tests, GO to Pinpoint Test C.

. Fo

r ignition system,

REFER to Section 303

-07 En

gine Ignition

.

Check bulletins an d service a

ctions.

Di

f

ficult to

start

D iff

icult to start cold

Roc

h

ester valve

Batt

ery Thro

ttle contaminated

Fue

l

pump

Engine coolan

t

temperature

(ECT) sensor

Purge val

ve

Cyl

i

nder compression loss

(short-term. Refer to bulletin; 303-52)

Blocked part-load breather (s

ervice action S474)

R

e

fer to service action

S491

For R

ochester valv

e test, GO to Pinpoint Test AE.

. Fo

r battery information,

REFER to Section 414

-0 1

Battery, Mounting and

Cables.

Check bull etins for throttl

e cleaning procedure.

Check fuel pressure. For ECT sensor circuit tests,

GO to Pinpoint Test C.

. F

or evaporative

emissions tests,

REFER to Section 303

-1 3

Evaporative

Emiss

i

ons

.

R e

fer to bulletins for co

mpression information,

and service actions for part-load breather procedure and compressions.

Diff

icult to start hot

Roc

h

ester valve

Purge

val

ve

Thr

o

ttle contaminated

F

or R

ochester valv

e test, GO to Pinpoint Test AE.

. F

or evaporative emissions tests,

REFER to Section 303

-1 3

Evaporative

Page 1200 of 2490

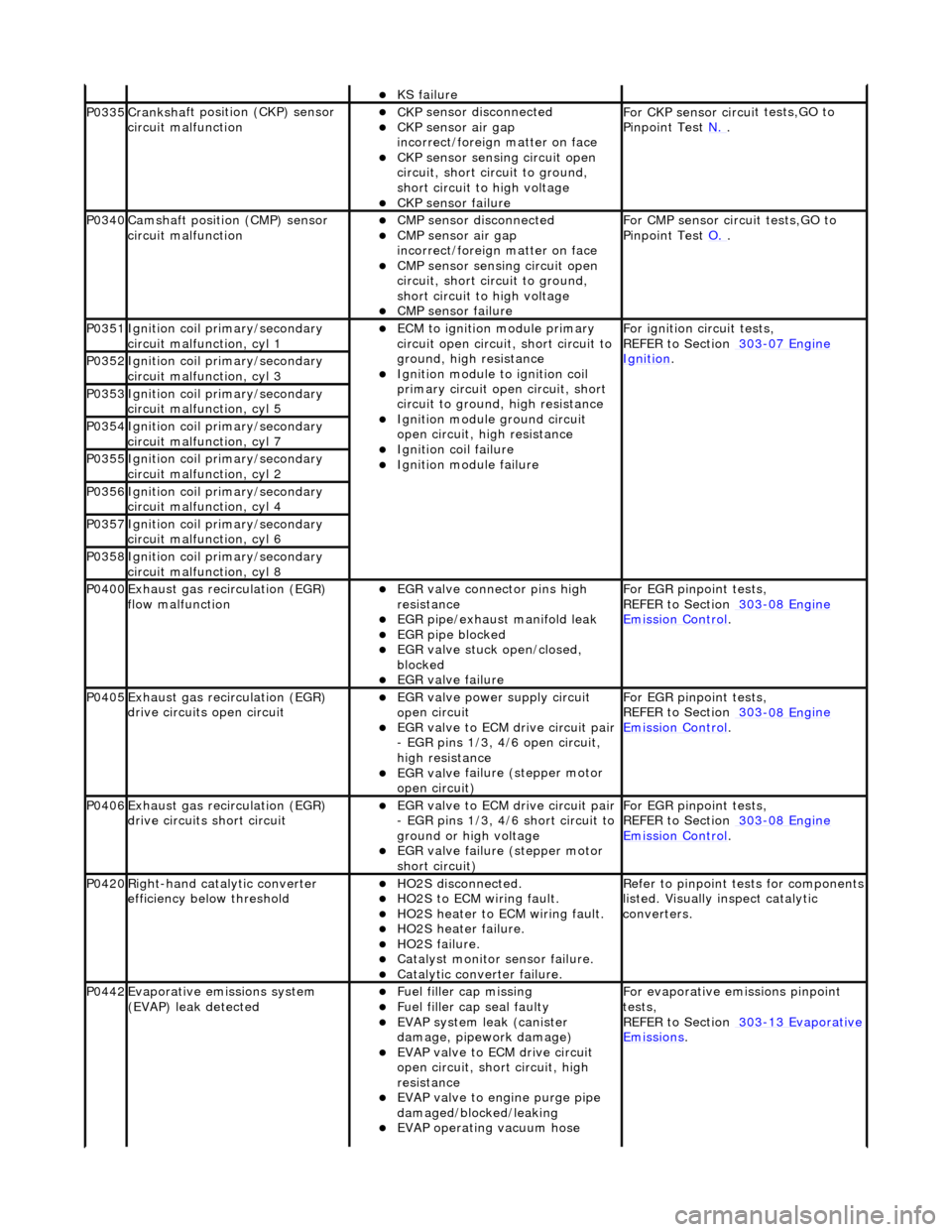

KS fail

ure

P0335Cranksh

a

ft positi

on (CKP) sensor

circuit malfunction

CK P

sensor disconnected

CKP sensor air gap

i

n

correct/foreign matter on face

CKP sensor sen

s

ing circuit open

circuit, short circuit to ground,

short circuit to high voltage

CKP s e

nsor failure

F

or CKP sensor circ ui

t tests,GO to

Pinpoint Test N.

.

P0340Camshaft position

(CMP) sensor

circuit malfunction

CM P

sensor disconnected

CMP sensor air gap

i

n

correct/foreign matter on face

CMP sensor sen

s

ing circuit open

circuit, short circuit to ground,

short circuit to high voltage

CMP s e

nsor failure

F

or CMP sensor circ ui

t tests,GO to

Pinpoint Test O.

.

P0351Igniti

on coil primary/secondary

circuit malfunction, cyl 1

ECM to ignit

ion module primary

circuit open circuit, short circuit to

ground, high resistance

Igniti

on module to ignition coil

primary circuit open circuit, short

circuit to ground, high resistance

Ignition modu le

ground circuit

open circuit, hi gh resistance

Ignition coil fail

ure

Ignition modul

e

failure

F

o

r ignition circuit tests,

REFER to Section 303

-07 En

gine

Ignition. P0352Ignit

i

on coil primary/secondary

circuit malfunction, cyl 3

P0353Ignit i

on coil primary/secondary

circuit malfunction, cyl 5

P0354Ignit i

on coil primary/secondary

circuit malfunction, cyl 7

P0355Ignit i

on coil primary/secondary

circuit malfunction, cyl 2

P0356Ignit i

on coil primary/secondary

circuit malfunction, cyl 4

P0357Ignit i

on coil primary/secondary

circuit malfunction, cyl 6

P0358Ignit i

on coil primary/secondary

circuit malfunction, cyl 8

P0400Exhaus t gas

recirculation (EGR)

flow malfunction

EGR valve c

onnector pins high

resistance

EGR pipe/exhaust manifol

d leak

EGR pipe blocke

d

EGR valve st

uck open/closed,

blocked

EGR valve fai

lure

For EGR

pinpoint t

ests,

REFER to Section 303

-08 En

gine

Emission Control.

P0405Exhaus

t gas

recirculation (EGR)

drive circuits open circuit

EGR valve power supply circuit

o p

en circuit

EGR valve t

o

ECM drive circuit pair

- EGR pins 1/3, 4/6 open circuit,

high resistance

EGR val v

e failure (stepper motor

open circuit)

For EGR pinpoint t

ests,

REFER to Section 303

-08 En

gine

Emissi

on Control.

P0406Exhaus t gas

recirculation (EGR)

drive circuits short circuit

EGR valve t o

ECM drive circuit pair

- EGR pins 1/3, 4/6 short circuit to

ground or high voltage

EGR val v

e failure (stepper motor

short circuit)

For EGR pinpoint t

ests,

REFER to Section 303

-08 En

gine

Emissi

on Control.

P0420Right-

hand catalytic converter

efficiency below threshold

HO2S di

sconnected.

HO2

S

to ECM wiring fault.

HO2

S

heater to ECM wiring fault.

HO2

S

heater failure.

HO2

S

failure.

Cat

a

lyst monitor sensor failure.

Catal

y

tic converter failure.

R

e

fer to pinpoint tests for components

listed. Visually inspect catalytic

converters.

P0442Evaporati v

e emissions system

(EVAP) leak detected

Fue l

filler cap missing

Fu

el filler cap seal faulty

EVAP system

leak (can

ister

damage, pipework damage)

EVAP v a

lve to ECM drive circuit

open circuit, short circuit, high

resistance

EVAP valve to engine pu rge pipe

damaged/blocked/leaking

EVAP ope r

ating vacuum hose

F

or evaporati

ve emissions pinpoint

tests,

REFER to Section 303

-1 3

Evaporative

Emissi

ons

.