door panel JAGUAR X308 1998 2.G Service Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 2273 of 2490

Handles, Locks, Latches and Entry Systems - Handles, Locks, Latches and

Entry Systems

Description and Operation

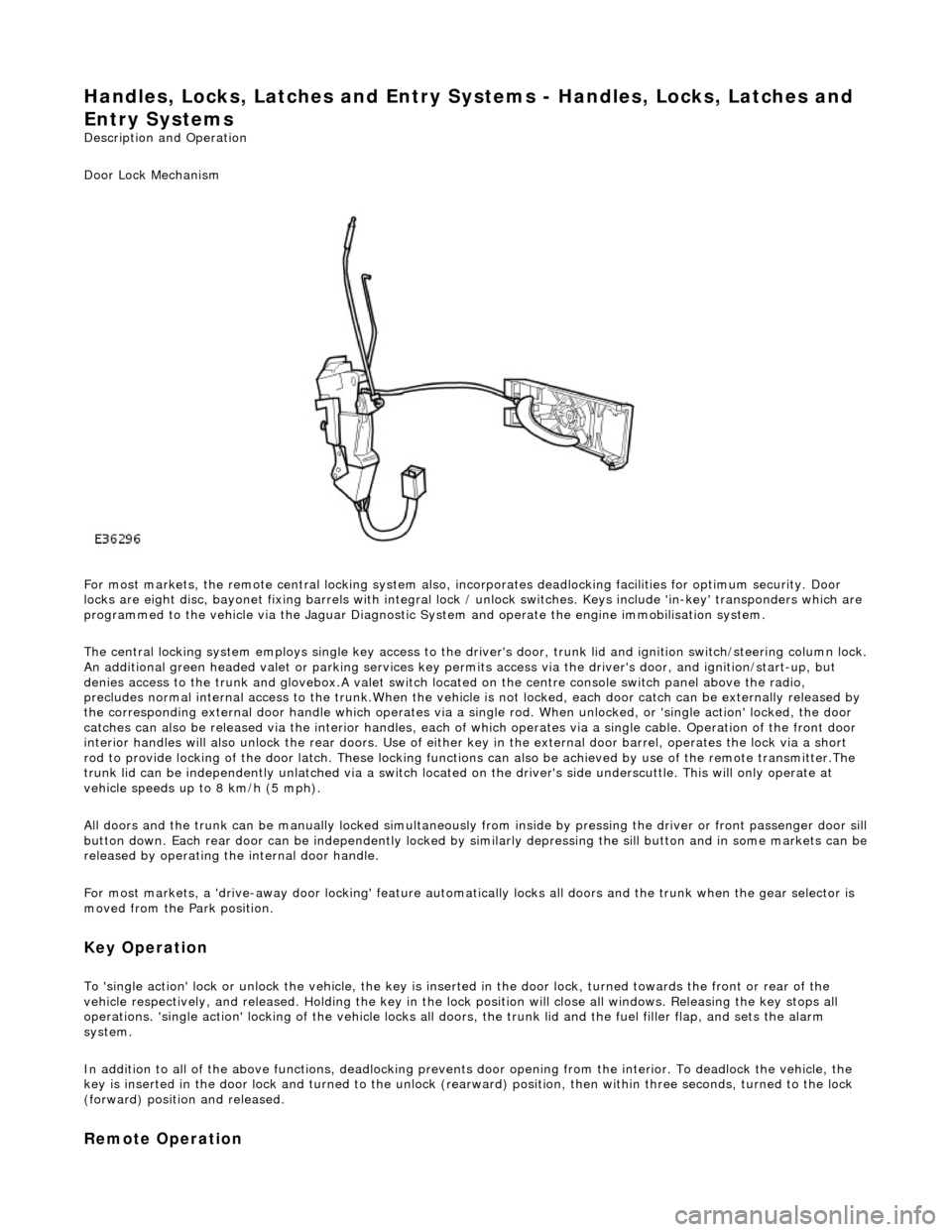

Door Lock Mechanism

For most markets, the remote central locking system also, in corporates deadlocking facilities for optimum security. Door

locks are eight disc, bayonet fixing barrels with integral lock / unlock switches. Keys include 'in-key' transponders which are

programmed to the vehicle via the Jaguar Diagnostic Sy stem and operate the engine immobilisation system.

The central locking system employs single key access to the driv er's door, trunk lid and ignition switch/steering column lock.

An additional green headed valet or park ing services key permits access via the driver's door, and ignition/start-up, but

denies access to the trunk and glovebox.A valet switch located on the centre console switch panel above the radio,

precludes normal internal access to the trunk.When the vehicle is not locked, each door catch can be externally released by

the corresponding external door handle which operates via a si ngle rod. When unlocked, or 'single action' locked, the door

catches can also be released via the interior handles, each of which operates via a single cable. Operation of the front door

interior handles will also unlock the rear doors. Use of either key in the external door barrel, operates the lock via a short

rod to provide locking of the door latch. These locking functions can also be achieved by use of the remote transmitter.The

trunk lid can be independently unlatched via a switch located on the driver's side underscuttle. This will only operate at

vehicle speeds up to 8 km/h (5 mph).

All doors and the trunk can be manually lock ed simultaneously from inside by pressing the driver or front passenger door sill

button down. Each rear door can be independently locked by si milarly depressing the sill button and in some markets can be released by operating the internal door handle.

For most markets, a 'drive-away door locking' feature automati cally locks all doors and the trunk when the gear selector is

moved from the Park position.

Key Operation

To 'single action' lock or unlock the vehicle, the key is inserted in the door lock , turned towards the front or rear of the

vehicle respectively, and released. Holding the key in the lock position will close all windows. Releasing the key stops all

operations. 'single action' locking of the vehicle locks all doors, the trunk lid and the fuel filler flap, and sets the alarm

system.

In addition to all of the above functions, deadlocking prevents door opening from th e interior. To deadlock the vehicle, the

key is inserted in the door lock and turned to the unlock (rearw ard) position, then within three seconds, turned to the lock

(forward) position and released.

Remote Operation

Page 2275 of 2490

Handles, Locks, Latches and Entry Systems - Door Lock Control Switch

Removal and Installation

Removal

1. Disconnect battery ground cable; refer to 86.15.19.

2. Remove center console veneer panel; refer to 76.47.26.

3. Displace radio for access; refer to 86.50.03.

4. Disconnect air conditioning control module flying lead

connector (blue) from harness connector located at side of 'J'

gate.

5. Displace air conditioning switch module / center console

switch module assembly.

Remove screw.

Reposition assembly for access to connector.

6. Remove air conditioning switch module / center console switch

module assembly.

Disconnect center console switch module harness

connector.

Remove assembly.

Page 2277 of 2490

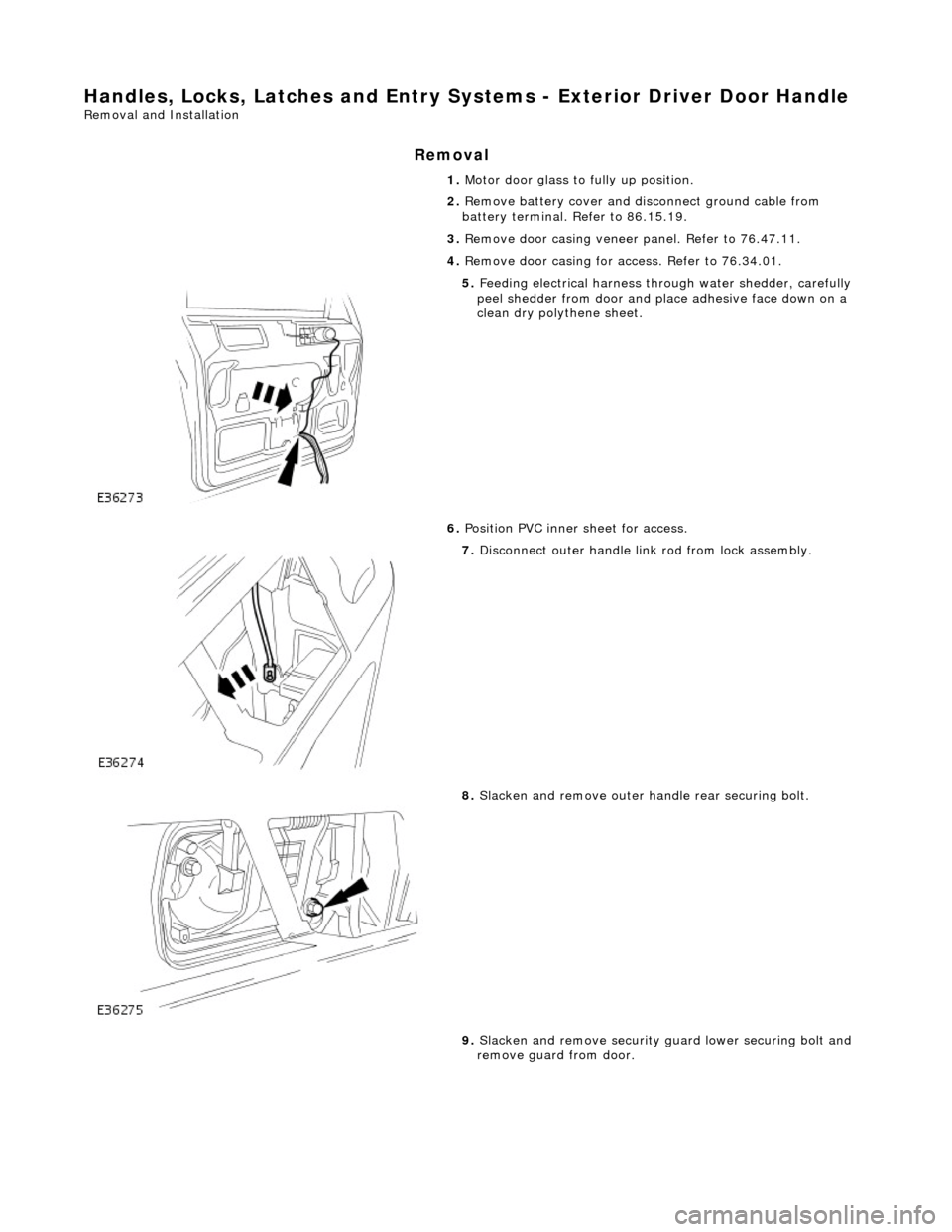

Handles, Locks, Latches and Entry Systems - Exterior Driver Door Handle

Removal and Installation

Removal

1. Motor door glass to fully up position.

2. Remove battery cover and disconnect ground cable from

battery terminal. Refer to 86.15.19.

3. Remove door casing veneer panel. Refer to 76.47.11.

4. Remove door casing for access. Refer to 76.34.01.

5. Feeding electrical harness thro ugh water shedder, carefully

peel shedder from door and pl ace adhesive face down on a

clean dry polythene sheet.

6. Position PVC inner sheet for access.

7. Disconnect outer handle link rod from lock assembly.

8. Slacken and remove outer handle rear securing bolt.

9. Slacken and remove security gu ard lower securing bolt and

remove guard from door.

Page 2280 of 2490

19.

Fit door casing. Refer to 76.34.01.

20. Fit door casing veneer panel. Refer to 76.47.11.

21. Connect ground cable to battery terminal and fit battery

cover. Refer to 86.15.15.

Page 2297 of 2490

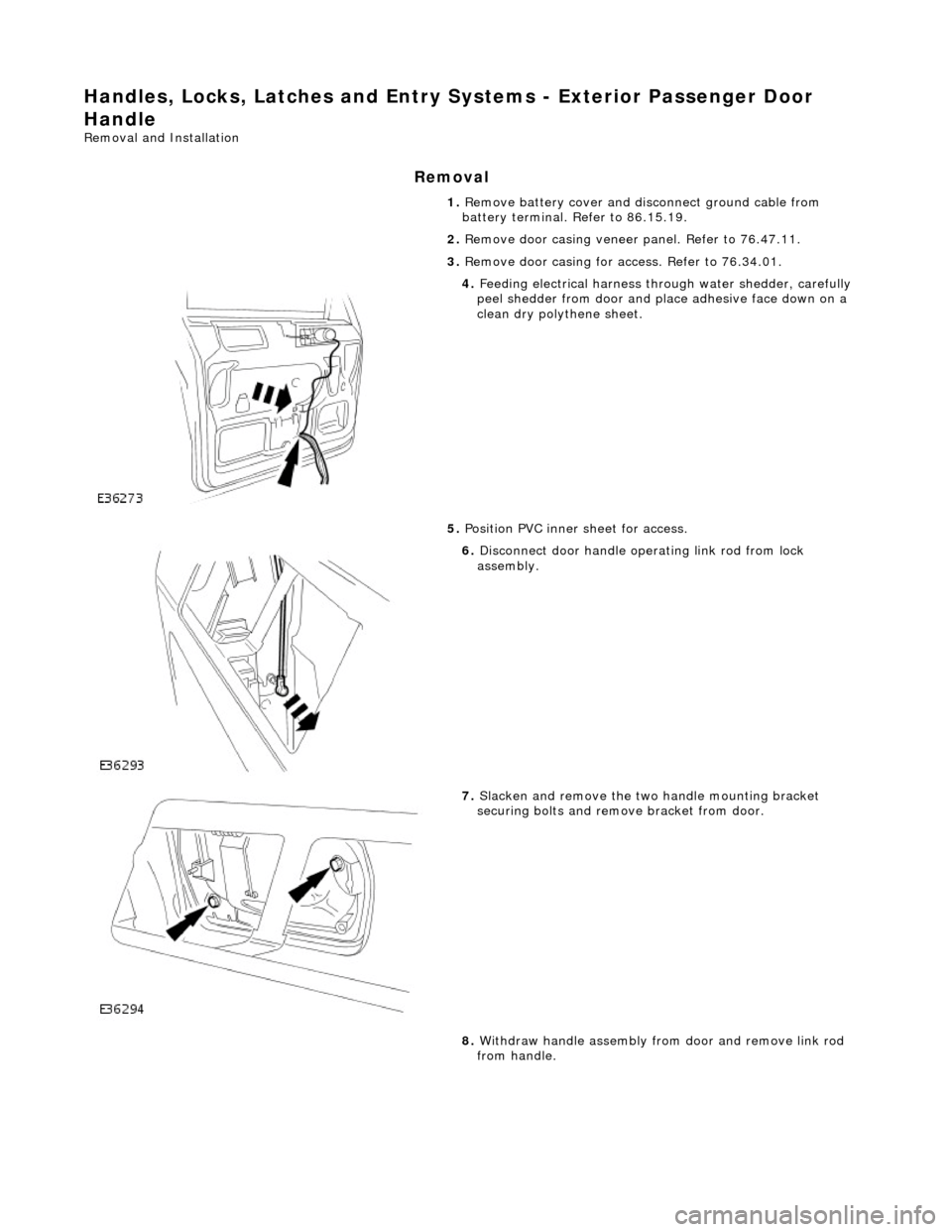

Handles, Locks, Latches and Entry Systems - Exterior Passenger Door

Handle

Removal and Installation

Removal

1. Remove battery cover and disconnect ground cable from

battery terminal. Refer to 86.15.19.

2. Remove door casing veneer panel. Refer to 76.47.11.

3. Remove door casing for access. Refer to 76.34.01.

4. Feeding electrical harness thro ugh water shedder, carefully

peel shedder from door and pl ace adhesive face down on a

clean dry polythene sheet.

5. Position PVC inner sheet for access.

6. Disconnect door handle operating link rod from lock

assembly.

7. Slacken and remove the two handle mounting bracket

securing bolts and remove bracket from door.

8. Withdraw handle assembly from door and remove link rod

from handle.

Page 2298 of 2490

Installation

1. Fit link rod to door handle.

2. Position handle assembly on door.

3. Position mounting bracket on insi de of door and connect lock

link rod.

4. Fit and tighten mounting bracket securing bolts.

5. Reposition PVC inner sheet in door.

6. Check for satisfactory door handle operation.

7. Connect ground cable to battery terminal. Refer to 86.15.15.

8. Check for satisfactory operation of locking system.

9. Disconnect ground cable from battery terminal. Refer to

86.15.15.

10. Ensure that water shedder contact area of door is clean and

dry.

11. Position water shedder at door and carefully pass harness

through.

12. Fit and firmly seat water shedder on door ensuring

satisfactory adhesion.

13. Fit door casing. Refer to 76.34.01.

14. Fit door casing veneer panel. Refer to 76.47.11.

15. Fit ground cable to battery term inal and fit cover to battery.

Refer to 86.15.15.

Page 2302 of 2490

Installation

8. Remove lock link rod from door handle assembly.

1. Fit link rod to handle assembly.

2. Position handle assembly on door.

3. Position mounting bracket on insi de of door and connect lock

link rod.

4. Fit and tighten mounting bracket securing bolts.

5. Reposition PVC inner sheet in door.

6. Check for satisfactory door handle operation.

7. Connect ground cable to battery terminal. Refer to 86.15.15.

8. From driver door check for satisfactory operation of locking

system.

9. Disconnect ground cable from battery terminal. Refer to

86.15.15.

10. Ensure that water shedder contact area of door is clean and

dry.

11. Position water shedder at door and carefully pass harness

through.

12. Fit and firmly seat water shedder on door ensuring

satisfactory adhesion.

13. Fit door casing. Refer to 76.34.01.

14. Fit door casing veneer panel. Refer to 76.47.11.

15. Fit ground cable to battery term inal and fit cover to battery.

Refer to 86.15.15.

Page 2303 of 2490

Handles, Locks, Latches and Entry Systems - Rear Door Latch

Removal and Installation

Removal

1. Remove battery cover and disco nnect earth cable from battery

terminal. Refer to 86.15.19.

2. Remove rear door casing veneer panel. Refer to 76.47.12.

3. Remove rear door casing. Refer to 76.34.04.

4. Carefully withdraw water shedder passing harness through it

and remove water shedder from door.

5. Place water shedder adhesive face down on clean dry plastic

sheet.

6. Release door lock actuator ha rness multiplug from mounting

bracket and disconnect multiplug.

7. Position PVC inner sheet for access and disconnect door

outer handle operating ro d from lock mechanism.

8. Disconnect inner door lock operating rod from lock

mechanism and remove rod assembly.

Page 2305 of 2490

1.

Position lock mechanism at door and connect operating cable.

2. Fit and fully seat cable rear abutment securing clip.

3. Fit and fully seat lock mechanism in door and fit and tighten

securing bolts.

4. Align glass guide and fit and tighten securing bolts.

5. Fit and fully seat inner cheater finisher.

6. Align and connect inner operating rod to lock mechanism.

7. Fit outer door handle operating rod to lock

8. Check for satisfactory door handle operation.

9. Reposition inner plastic sheet.

10. Connect lock actuator harness multiplug and fit to mounting

bracket.

11. Connect ground cable to battery terminal. Refer to 86.15.15.

12. From driver door, check for satisfactory operation of locking

system.

13. Disconnect ground cable from battery terminal. Refer to

86.15.19.

14. Ensure that water shedder contact area of door is clean and

dry.

15. Position water shedder at d oor and carefully pass door

harness through.

16. Fit and firmly seat water shedde r on door ensuring satifactory

adhesion.

17. Fit door casing. Refer to 76.34.04.

18. Fit door casing veneer panel. Refer to 76.47.12.

19. Connect ground cable to battery terminal and fit battery

cover. Refer to 86.15.15.

Page 2381 of 2490

The body is pre-treated to ensure high resistance to corrosion and stone chip dama ge. Prior to the first major pre-treatment process, the body shell is high-pressure washed to remove any metal dust and residual oil.

The first major pre-treatment process consists of phosphate and electro-paint deposition, which together with zinc coating,

forms the basis of the corrosion protection. This process includes high pressure knock-off, alkali de-greasing, zinc phosphate

conversion of body steel (dissolving iron and coating with zinc phosphate crystals), trivalent chrome rinsing and

demineralized water rinsing, seal ing all chemicals and impurities.

Both dip and spray techniques are employed and the bodies are submerged to the waistline during the first and third rinses

of the main phosphate clean. Chemical strengths and soluti on temperatures are continuously monitored and accurately

controlled throughout the process.

An 80% water primer is then cathodic elec tro-deposition applied to the thoroughly cleansed bodies in a uniform 'sag-free'

film 18 to 32 micron thick. Optimum durabi lity of the electroprimer is achieved by finally curing in a stoving oven at 165 °C

for a period of 20 minutes.

All underbody seams of the fully primed bo dies are then manually sealed, to prevent water and dust ingress into the vehicle

and to enhance corrosion protection.

An 800 to 1000 g/m2 PVC coating is semi-automatic airless sp ray applied to the underside of the main floor panels, trunk

floor and rear wheel arches (ref. illustration above).

The upper panels of primed and external ly sealed bodyshells are next lightly scuffed to remove imperfections and a PVC

coating is applied to all internal seams by an airless spray technique. A PVC bead seal is also applied to the doors, hood and

trunk clinch joints.

Following anti-corrosion, sealing and primin g treatment, the bodies enter the first stage of 'cosmetic' painting. This consists

of the application of two coats of a highly chip resistant po lyester surfacer, employing high voltage electrostatic 'spinning

bells', to achieve a final film thickness of 35 to 50 micron. Between surfacer coats, a polyurethane coat is automatically

applied to the sills to impart even greater resistance to stone chipping.

All interior panels are then painted us ing a color keyed sealer, wet-on-wet wi th a surfacer material, after which the

bodyshells are stoved at 160 °C for a period of 20 minutes. Further protection agai nst corrosion is provided by a medium

solids black pigmented wax which is airless spray applied to vehicle undersides.

Wax Injected Box Sections

Critical body box-sections are si milarly protected by spray injecting a high solids wax. This is then re-flowed at 70 to 90 °C

to achieve optimum seam/joint penetratio n and form a resilient and durable internal coating (ref. illustration above).

After full wet sanding, rinsing and drying to provide a good su bstrate, a color-keyed semi-matt sealer co at is applied using

electrostatic bells to achieve a film build of 25 to 35 micron . The bodies are then stoved for a further 20 minutes at a

temperature of 145 °C and subjected to a local 'seek-and-find' de -nib operation prior to the final two coat process. The final

top coat finish is achieved by using poly ester base coat colors and an acrylic sag resistant clear coat. This clear over base

(COB) process produces a high gloss, durabl e paint finish with a film thickness of 50 to 65 micron, which is finally cured at a

temperature of 135°C for 20 minutes.

The Munsell three dimensional system of color management is em ployed to achieve highly accurate control of vehicle colors.

This system ensures that paint pigmentations are accurately maintained and facilitates vigorous final checking of finished

vehicles for color match. The hu e of individual panels such as trunk lids, doors and hoods is in some instances adjusted to

offset the effects of differing light angles. Where applicable, coachlines are manually applied and radiant heat cured on the

completed and valeted vehicle prior to hand spray applic ation of a protective wax coat.

Introduction

All repairs, whether structural or cosmetic must return the vehicle to the original manufactured condition with regard to

occupant safety, dimensional accuracy, fi nish and corrosion protection, and ensure continuation of the Paint Surface and

Corrosion warranty where applicable.

Similarly, repaired vehicles must be fu lly checked, and where appropriate reset, with regard to steering, suspension,

braking, and occupant restraint systems.