water pump JAGUAR X308 1998 2.G Service Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1783 of 2490

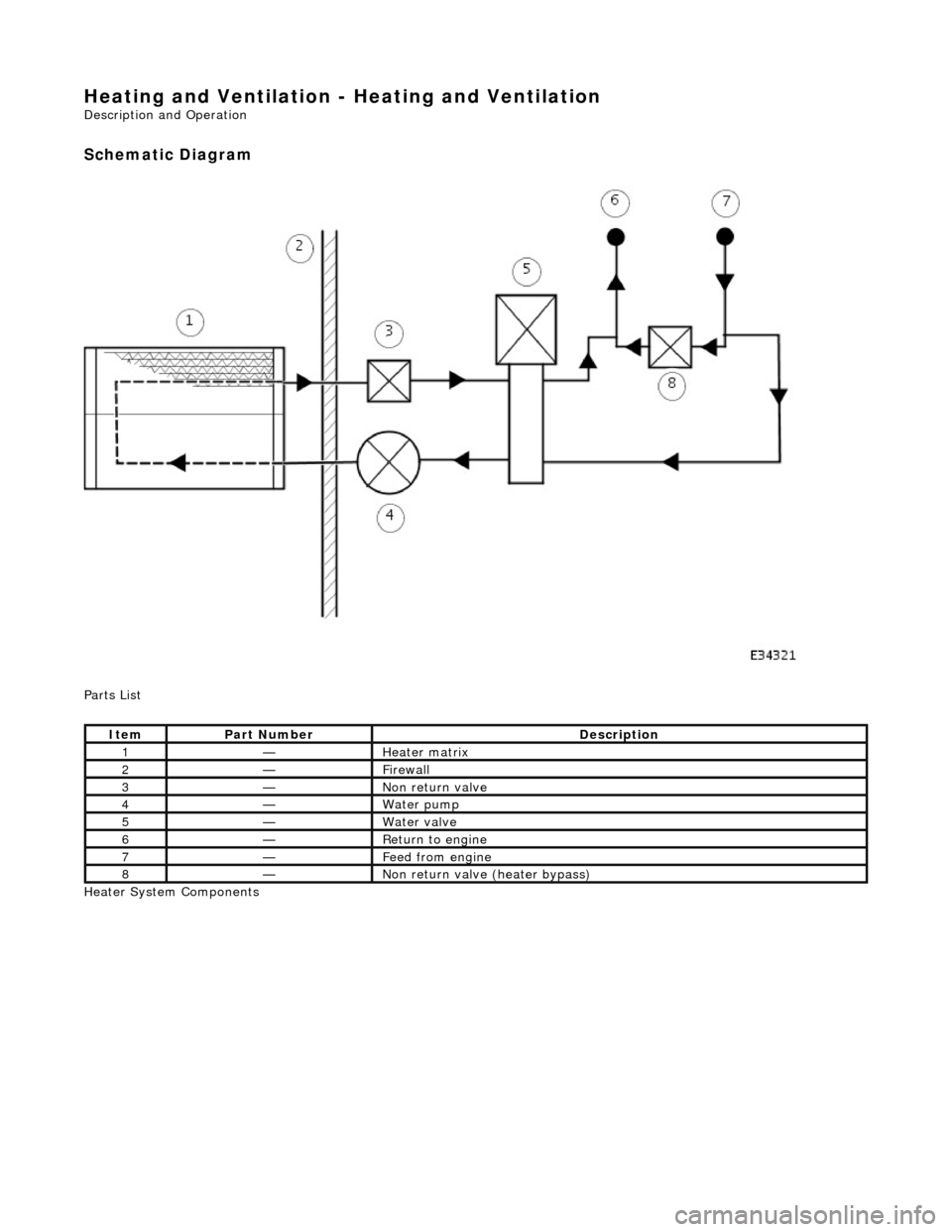

Heating and Ventilation - Heating and Ventilation

Description and Operation

Schematic Diagram

Parts List

Heater System Components

ItemPart NumberDescription

1—Heater matrix

2—Firewall

3—Non return valve

4—Water pump

5—Water valve

6—Return to engine

7—Feed from engine

8—Non return valve (heater bypass)

Page 1784 of 2490

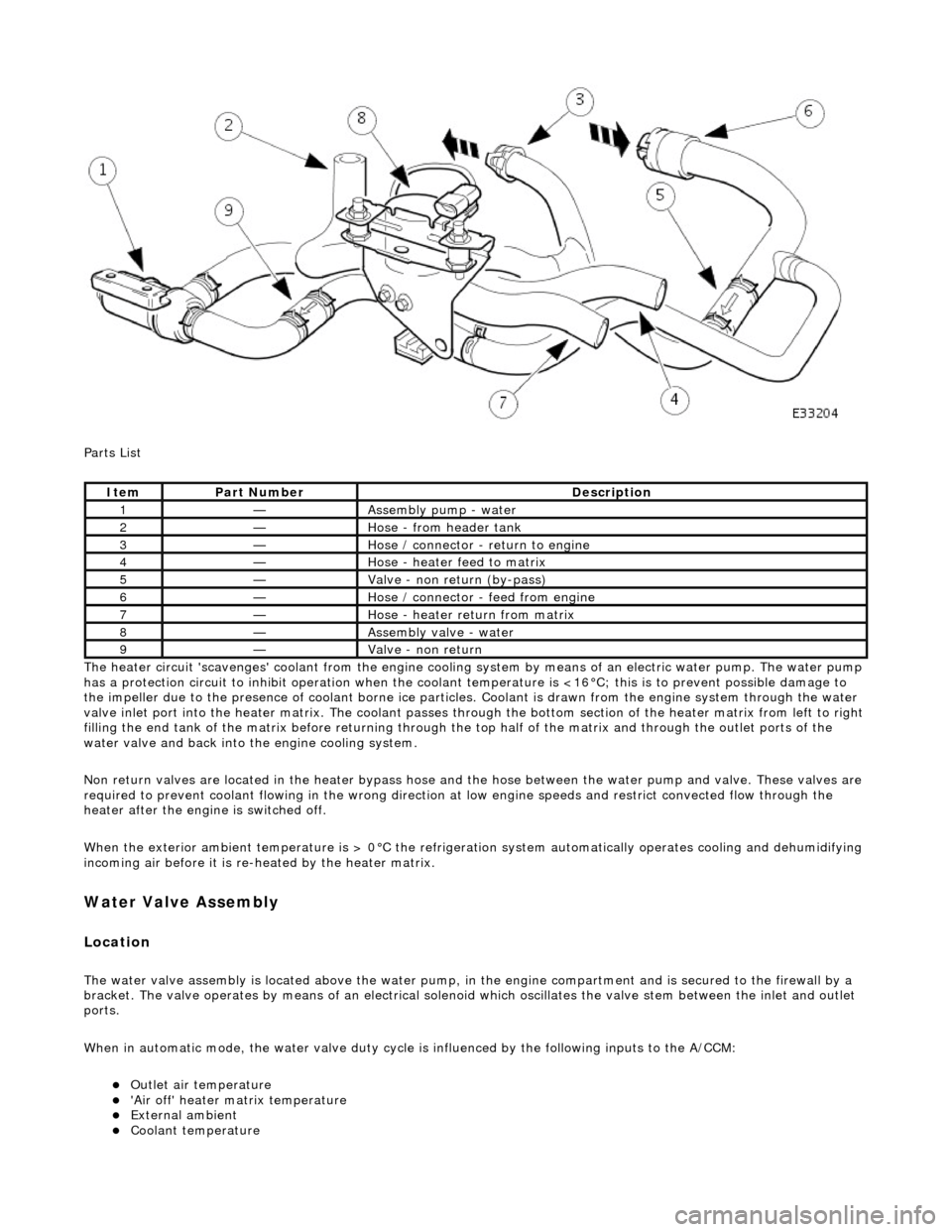

Parts List

The heater circuit 'scavenges' coolant from the engine cooling system by mean s of an electric water pump. The water pump

has a protection circuit to inhibit operation when the coolant temperature is <16°C; this is to prevent possible damage to

the impeller due to the presence of coolant borne ice particles. Coolant is drawn from the en gine system through the water

valve inlet port into the heater matrix. The coolant passes thro ugh the bottom section of the heater matrix from left to right

filling the end tank of the matrix before returning through the top half of the ma trix and through the outlet ports of the

water valve and back into the engine cooling system.

Non return valves are located in the heat er bypass hose and the hose between the water pump and valve. These valves are

required to prevent coolant flowing in th e wrong direction at low engine speeds and restrict convected flow through the

heater after the engine is switched off.

When the exterior ambient temperature is > 0°C the refrigerat ion system automatically operates cooling and dehumidifying

incoming air before it is re -heated by the heater matrix.

Water Valve Assembly

Location

The water valve assembly is located above the water pump, in the engine compartmen t and is secured to the firewall by a

bracket. The valve operates by means of an electrical solenoid which oscillates the valve stem between the inlet and outlet

ports.

When in automatic mode, the water valve duty cycle is influenced by the following inputs to the A/CCM:

Outlet air temperature 'Air off' heater matrix temperature External ambient Coolant temperature

ItemPart NumberDescription

1—Assembly pump - water

2—Hose - from header tank

3—Hose / connector - return to engine

4—Hose - heater feed to matrix

5—Valve - non return (by-pass)

6—Hose / connector - feed from engine

7—Hose - heater return from matrix

8—Assembly valve - water

9—Valve - non return

Page 1785 of 2490

Engine speed (valve closed with the engine not running) Demand (set) temperature In-car temperature sensor Solar sensor

Re-heating of the refrigerated air is contro lled by the time that the water valve is open (i.e. not energised) over a six secon d

interval. The duty cycle of the water valve, the time open / time closed, is controlled by the A/CCM.

Maximum heating demand will cause the water valve to be fu lly open (not energised) to allow maximum coolant flow

through the heater matrix.

At Maximum cooling, the water va lve will be fully closed (energised) to prevent hot (engine temperature) coolant entering

the heater circuit; the pump however will continue to circulate coolant through both the heater matrix and water valve

bypass.

The water valve defaults open when the ignition is OFF.

Under engine stall conditions, when ignition is ON, the water valve will be open.

Water Pump Assembly

Located in the same area as the water valve, the water pump continually circulates coolant through the heater matrix

except when the conditions below apply:

The engine coolant is below 16°C. The ignition is OFF. Under engine stall conditions, when ignition is ON. Control panel OFF

Non return valves

The heater bypass hose has a non-return valve, located between the engine feed and return hoses. The valve prevents the

water pump from recirculating coolant fro m the heater at low engine speeds.

The flow indicator arrow embossed on the valve bo dy MUST point towards the coolant header tank.

CAUTION: Coolant flow will be compromi sed if either valve is fitted incorrectly. Observe the correct direction.

A second non-return valve is located betw een the water pump and water valve. This valve prevents hot coolant from flowing

into the heater with the engine switched off. The flow indicator arrow MUST point towards the water pump.

Heater feed and return hoses

The heater feed and return hoses are connected to the engine feed and return hoses by 'Quick-Fit' connection unions. The

feed hose has a Norma R20 connector and the return hose a Norma push and seal connector. The coolant system bleed

joints have Cobra clamps. All remaining hose connections have spring band hose clamps.

The engine feed hose is connected to the engine bypass hous ing and the engine return hose is connected to the engine

water pump.

Clamp Identification

Page 1798 of 2490

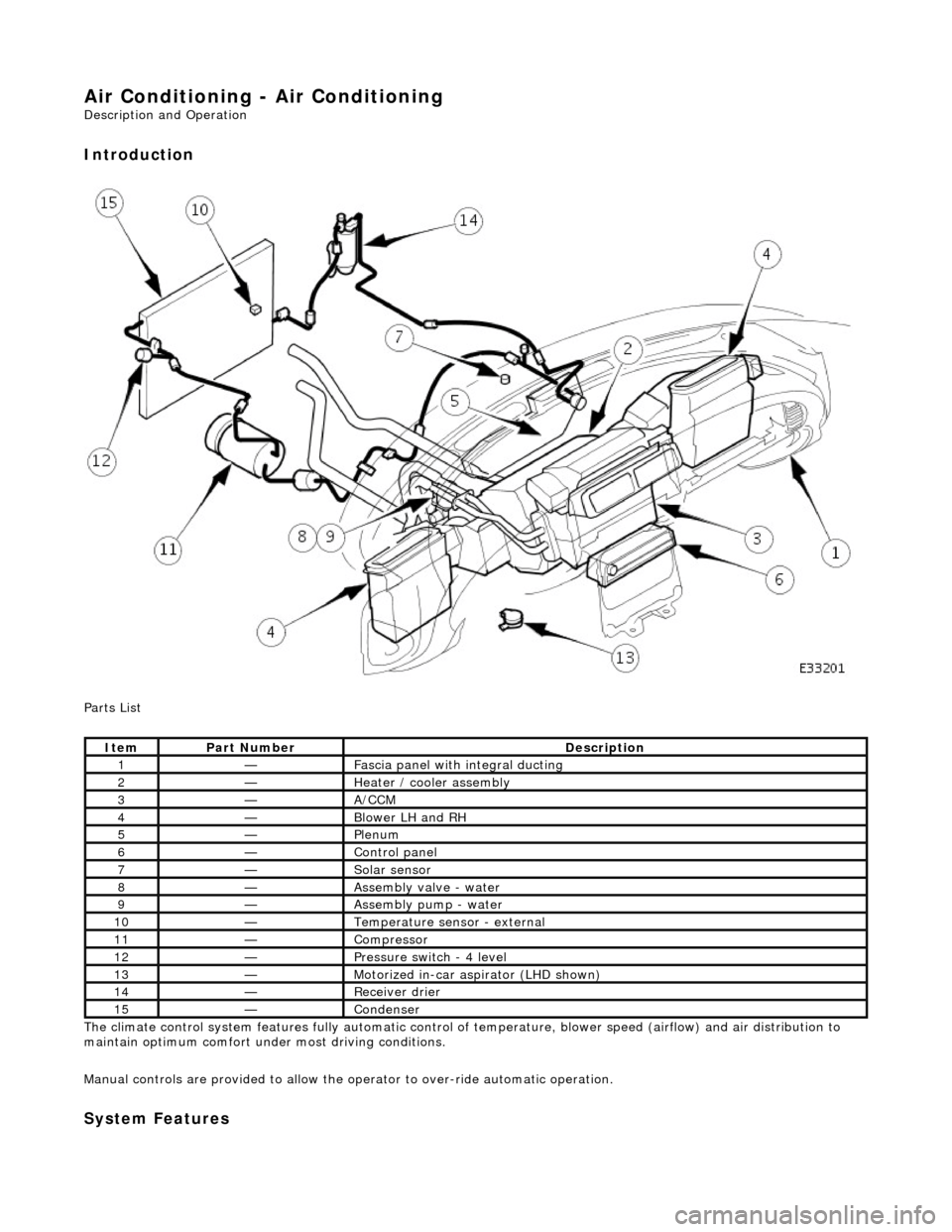

Air Conditioning - Air Conditioning

Description and Operation

Introduction

Parts List

The climate control system features fully automatic control of temperature, blower speed (airflow) and air distribution to

maintain optimum comfort under most driving conditions.

Manual controls are provided to allow the operator to over-ride automatic operation.

System Features

ItemPart NumberDescription

1—Fascia panel with integral ducting

2—Heater / cooler assembly

3—A/CCM

4—Blower LH and RH

5—Plenum

6—Control panel

7—Solar sensor

8—Assembly valve - water

9—Assembly pump - water

10—Temperature sensor - external

11—Compressor

12—Pressure switch - 4 level

13—Motorized in-car aspirator (LHD shown)

14—Receiver drier

15—Condenser

Page 1799 of 2490

Twin blower assemblies Center mounted evaporator, heater and air distribution unit Electric solenoid water valve controlled heating Electric water pump assembly Servo motor driven air distribution flaps Dedicated side glass defrost / demist vents External temperature sensor Motorised in-car aspirator Solar sensor

Electronic Control Panel

Liquid Crystal Display (LCD) Digital temperature display Manual fan speed level External temperature display Celsius / Fahrenheit selection Heated windshield switch (where fitted) Heated backlight switch Defrost switch Manual airflow distribution overrides (4) Access to self diagnostic system and error codes

Sensors

External ambient temperature sensor Motorized in-car aspirator Heater matrix temperature sensor Evaporator temperature sensor Solar sensor

These sensors feedback information to the Air Conditioning Control Module (A/CCM) which automatically adjusts air

temperature, airflow volume and distributi on from the air conditioning unit to maintain a stable passenger compartment

average temperature under changing weather conditions.

Major Components

Page 1828 of 2490

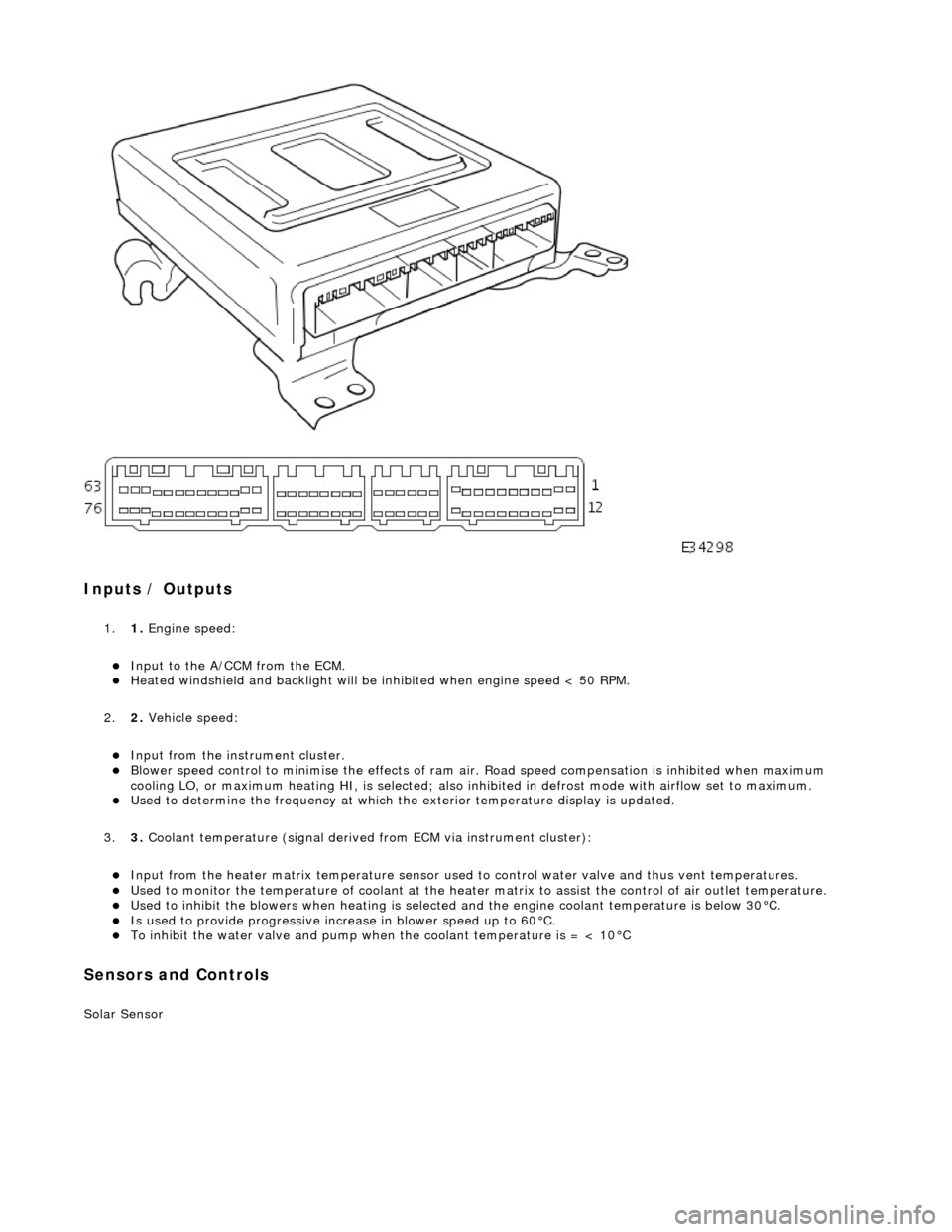

Inputs / Outputs

1.1. Engine speed:

Input to the A/CCM from the ECM. Heated windshield and backli ght will be inhibited when engine speed < 50 RPM.

2. 2. Vehicle speed:

Input from the instru ment cluster. Blower speed control to minimise the effects of ram ai r. Road speed compensation is inhibited when maximum

cooling LO, or maximum heating HI, is selected; also inhi bited in defrost mode with airflow set to maximum.

Used to determine the frequency at which the exterior temperature display is updated.

3. 3. Coolant temperature (signal derived from ECM via instrument cluster):

Input from the heater matrix temperature sensor used to control water valve and thus vent temperatures. Used to monitor the temperature of coolant at the heater matrix to assist the control of air outlet temperature. Used to inhibit the blowers when heating is selected and the engine coolant temperature is below 30°C. Is used to provide progressive increase in blower speed up to 60°C. To inhibit the water valve and pump when the coolant temperature is = < 10°C

Sensors and Controls

Solar Sensor

Page 1831 of 2490

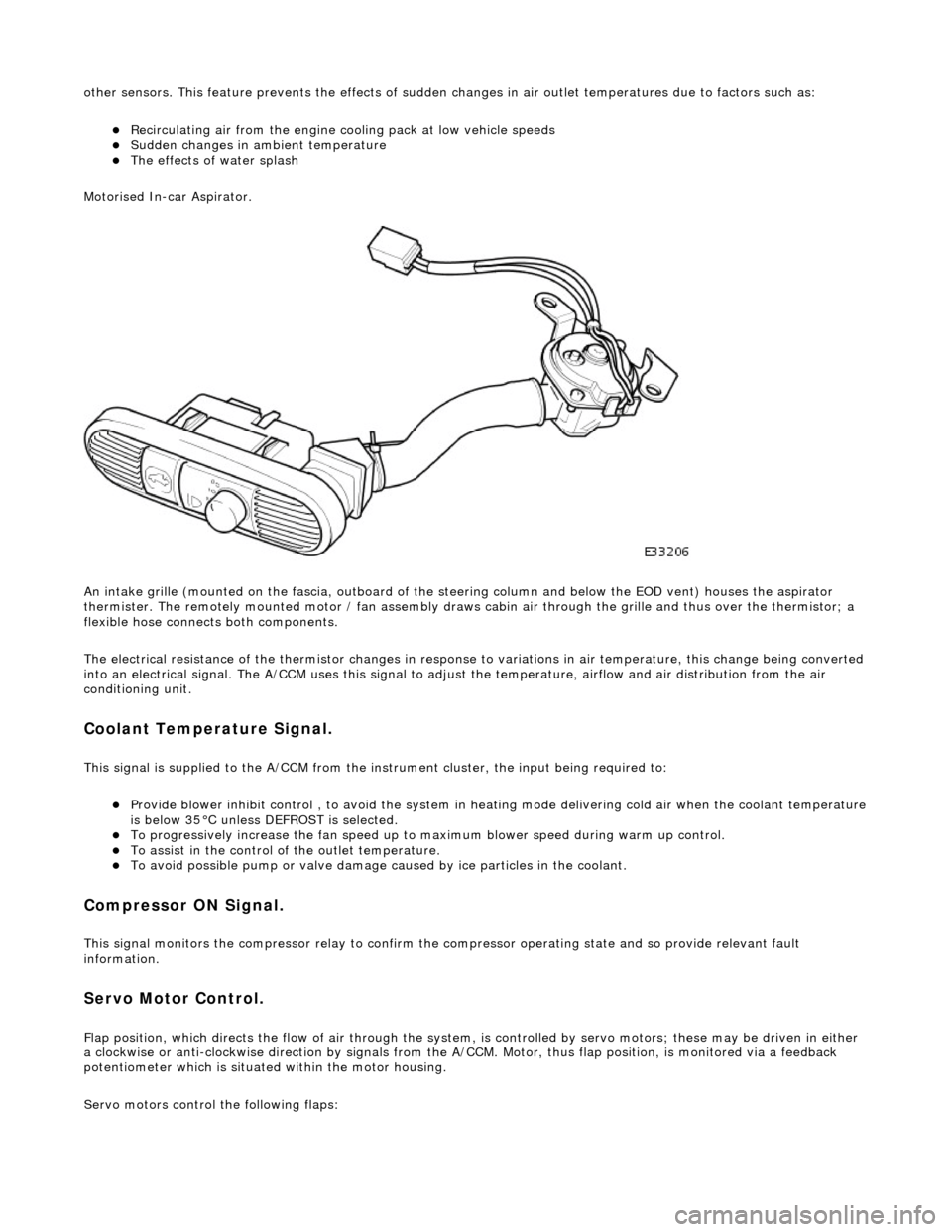

other sensors. This feature prevents the effects of sudden changes in air outlet temperatures due to factors such as:

Recirculating air from the engine cooling pack at low vehicle speeds Sudden changes in ambient temperature The effects of water splash

Motorised In-car Aspirator.

An intake grille (mounted on the fascia , outboard of the steering column and below the EOD vent) houses the aspirator

thermister. The remotely mounted motor / fan assembly draws ca bin air through the grille and thus over the thermistor; a

flexible hose connects both components.

The electrical resistance of the thermistor changes in response to variations in air temperatur e, this change being converted

into an electrical signal. The A/CCM uses this signal to adjust the temperature, airflow and air distribution from the air

conditioning unit.

Coolant Temperature Signal.

This signal is supplied to the A/CCM from the instrument cluster, the input being required to:

Provide blower inhibit control , to avoid the system in heat ing mode delivering cold air when the coolant temperature is below 35°C unless DEFROST is selected. To progressively increase the fan speed up to maximum blower speed during warm up control. To assist in the control of the outlet temperature. To avoid possible pump or valve damage ca used by ice particles in the coolant.

Compressor ON Signal.

This signal monitors the compressor relay to confirm the compressor operating state and so provide relevant fault

information.

Servo Motor Control.

Flap position, which directs the flow of air through the system, is controlled by servo motors; these may be driven in either

a clockwise or anti-clockwise direction by signals from the A/ CCM. Motor, thus flap position, is monitored via a feedback

potentiometer which is situated within the motor housing.

Servo motors control the following flaps:

Page 1838 of 2490

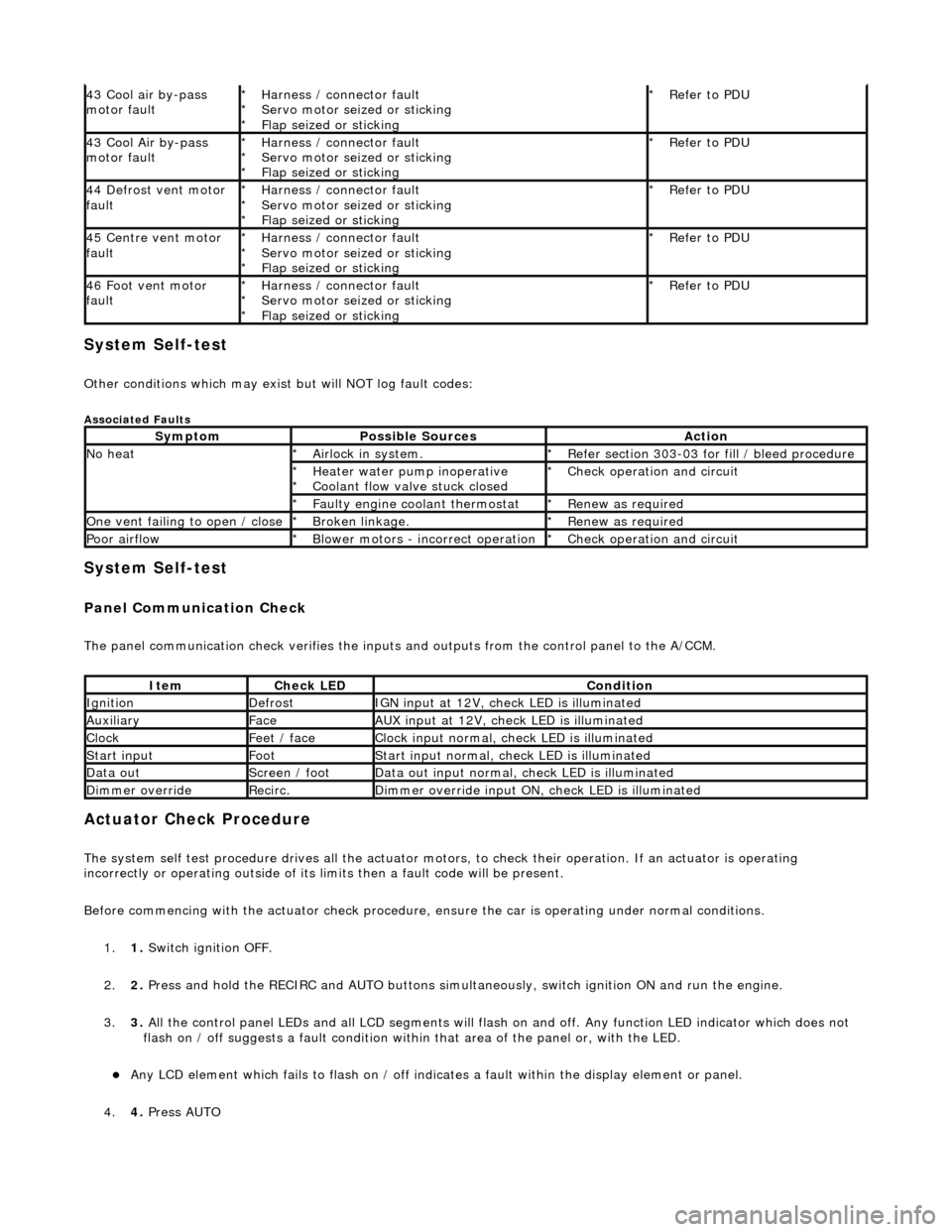

System Self-test

Other conditions which may exist but will NOT log fault codes:

Associated Faults

System Self-test

Panel Communication Check

The panel communication check veri fies the inputs and outputs from the control panel to the A/CCM.

Actuator Check Procedure

The system self test procedure drives all the actuator moto rs, to check their operation. If an actuator is operating

incorrectly or operating outside of its limi ts then a fault code will be present.

Before commencing with the actuator check procedure, ensure the ca r is operating under normal conditions.

1. 1. Switch ignition OFF.

2. 2. Press and hold the RECIRC and AUTO buttons simult aneously, switch ignition ON and run the engine.

3. 3. All the control panel LEDs and all LCD segments will flas h on and off. Any function LED indicator which does not

flash on / off suggests a fault condition within that area of the panel or, with the LED.

Any LCD element which fails to flash on / off indicates a fault within the display element or panel.

4. 4. Press AUTO

43 Cool air by-pass

motor faultHarness / connector fault

Servo motor seized or sticking

Flap seized or sticking

*

*

*Refer to PDU

*

43 Cool Air by-pass

motor faultHarness / connector fault

Servo motor seized or sticking

Flap seized or sticking

*

*

*Refer to PDU

*

44 Defrost vent motor

faultHarness / connector fault

Servo motor seized or sticking

Flap seized or sticking

*

*

*Refer to PDU

*

45 Centre vent motor

faultHarness / connector fault

Servo motor seized or sticking

Flap seized or sticking

*

*

*Refer to PDU

*

46 Foot vent motor

faultHarness / connector fault

Servo motor seized or sticking

Flap seized or sticking

*

*

*Refer to PDU

*

SymptomPossible SourcesAction

No heatAirlock in system.

*Refer section 303-03 for fill / bleed procedure

*

Heater water pump inoperative

Coolant flow valve stuck closed

*

*Check operation and circuit

*

Faulty engine coolant thermostat

*Renew as required

*

One vent failing to open / closeBroken linkage.

*Renew as required

*

Poor airflowBlower motors - incorrect operation

*Check operation and circuit

*

ItemCheck LEDCondition

IgnitionDefrostIGN input at 12V, check LED is illuminated

AuxiliaryFaceAUX input at 12V, check LED is illuminated

ClockFeet / faceClock input normal, check LED is illuminated

Start inputFootStart input normal, check LED is illuminated

Data outScreen / footData out input normal, check LED is illuminated

Dimmer overrideRecirc.Dimmer override input ON, check LED is illuminated

Page 1839 of 2490

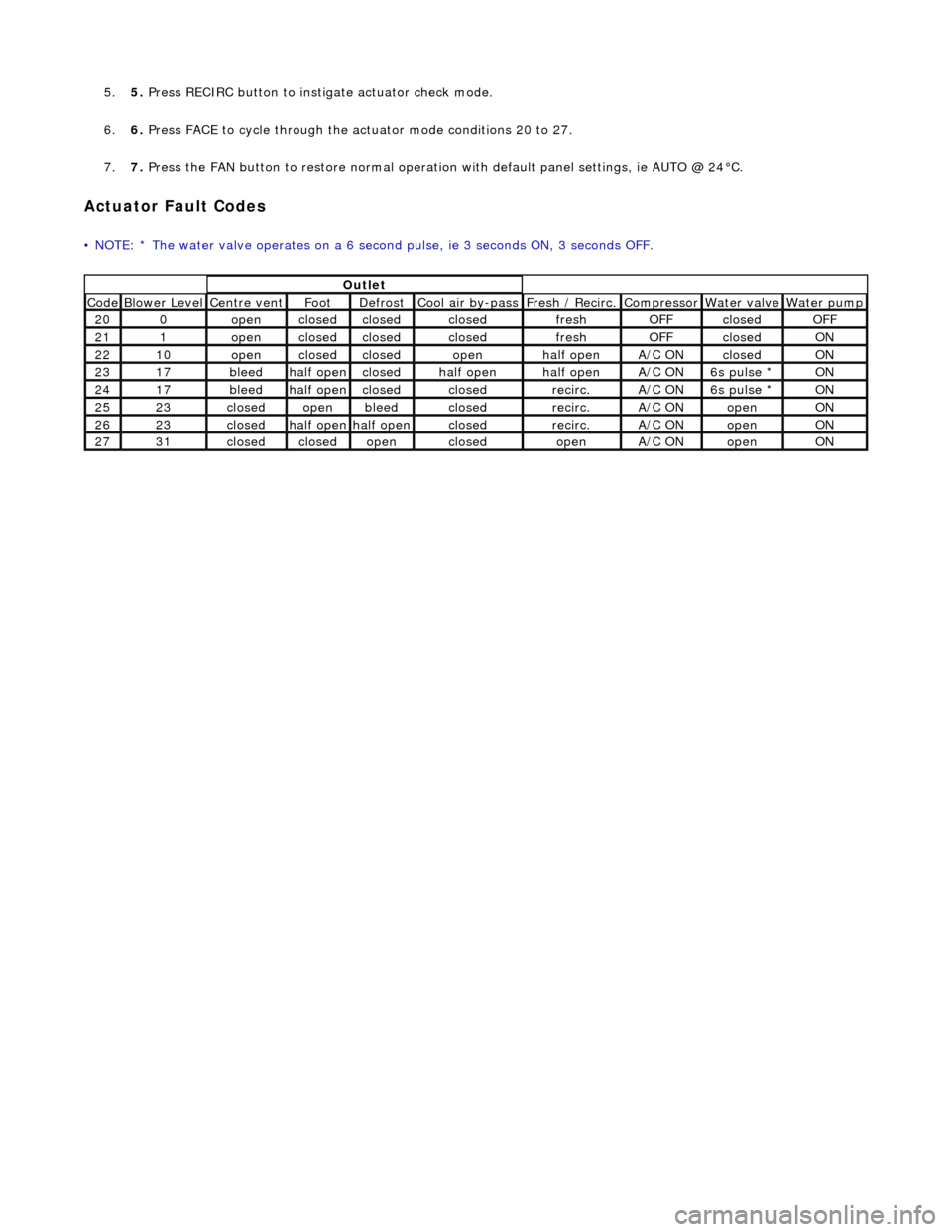

5.5. Press RECIRC button to instigate actuator check mode.

6. 6. Press FACE to cycle through the actu ator mode conditions 20 to 27.

7. 7. Press the FAN button to restore normal operation with default panel settings, ie AUTO @ 24°C.

Actuator Fault Codes

• NOTE: * The water valve operates on a 6 second pulse, ie 3 seconds ON, 3 seconds OFF.

Outlet

Code Blower Level Centre vent Foot Defrost Cool air by-pass Fresh / Recirc. Compressor Water valve Water pump

200openclosedclosedclosedfreshOFFclosedOFF

211openclosedclosedclosedfreshOFFclosedON

2210openclosedclosedopenhalf openA/C ONclosedON

2317bleedhalf openclosedhalf openhalf openA/C ON6s pulse * ON

2417bleedhalf openclosedclosedrecirc.A/C ON6s pulse * ON

2523closedopenbleedclosedrecirc.A/C ONopenON

2623closedhalf openhalf openclosedrecirc.A/C ONopenON

2731closedclosedopenclosedopenA/C ONopenON

Page 1895 of 2490

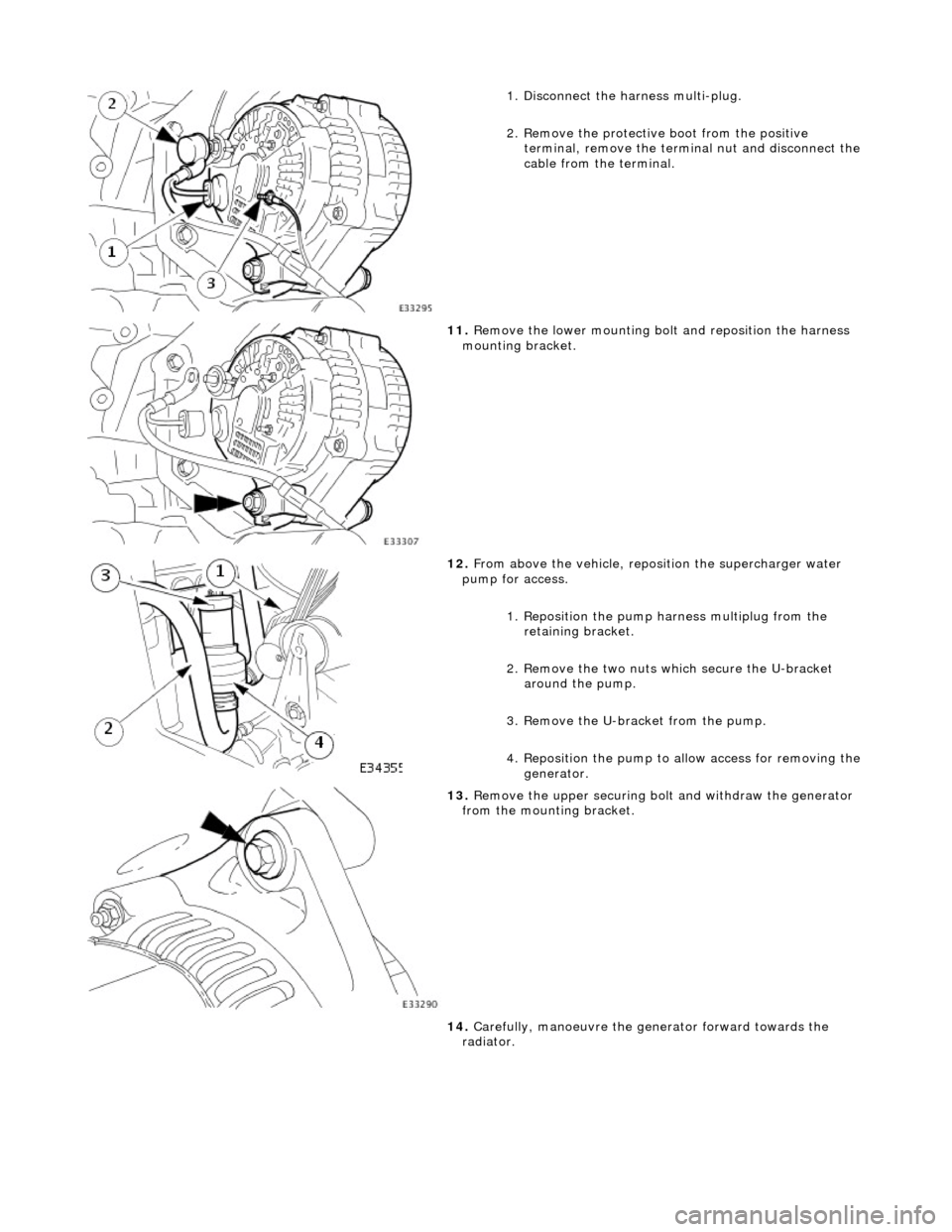

1. Disconnect the harness multi-plug.

2. Remove the protective boot from the positive

terminal, remove the termin al nut and disconnect the

cable from the terminal.

11. Remove the lower mounting bolt and reposition the harness

mounting bracket.

12. From above the vehicle, reposi tion the supercharger water

pump for access.

1. Reposition the pump harness multiplug from the

retaining bracket.

2. Remove the two nuts which secure the U-bracket around the pump.

3. Remove the U-bracket from the pump.

4. Reposition the pump to al low access for removing the

generator.

13. Remove the upper securing bolt and withdraw the generator

from the mounting bracket.

14. Carefully, manoeuvre the ge nerator forward towards the

radiator.