engine JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1600 of 2490

Yes GO to F7

No Renew O2 sensor. Reconnect plug(s)

GO to F8

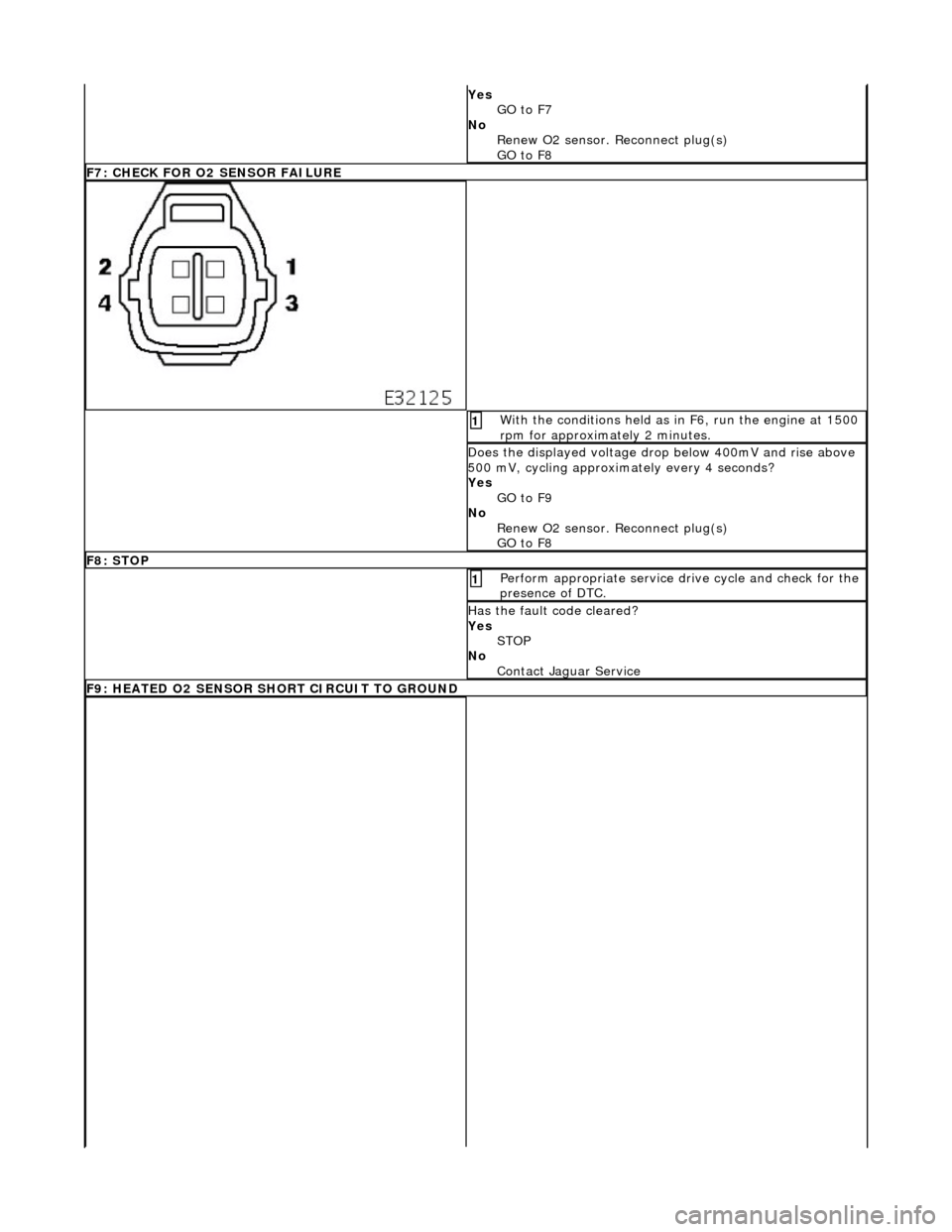

F7: CHECK FOR O2 SENSOR FAILURE

With the conditions held as in F6, run the engine at 1500

rpm for approximately 2 minutes. 1

Does the displayed voltage drop below 400mV and rise above

500 mV, cycling approximately every 4 seconds?

Yes GO to F9

No Renew O2 sensor. Reconnect plug(s)

GO to F8

F8: STOP

Perform appropriate service drive cycle and check for the

presence of DTC. 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

F9: HEATED O2 SENSOR SHORT CIRCUIT TO GROUND

Page 1610 of 2490

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to G2

G2: CHECK FOR O2 SENSOR FAILURE

Run the engine for a period to warm the sensor and then

maintain a steady speed of approximately 2500 rpm. 1

Measure the voltage between EM024/001 and EM024/002. 2

Is the voltage between 600mV and 1.0 Volt?

Yes

GO to G3

No Renew O2 sensor and reconnect plug(s)

GO to G6

G3: CHECK FOR O2 SENSOR FAILURE

Page 1613 of 2490

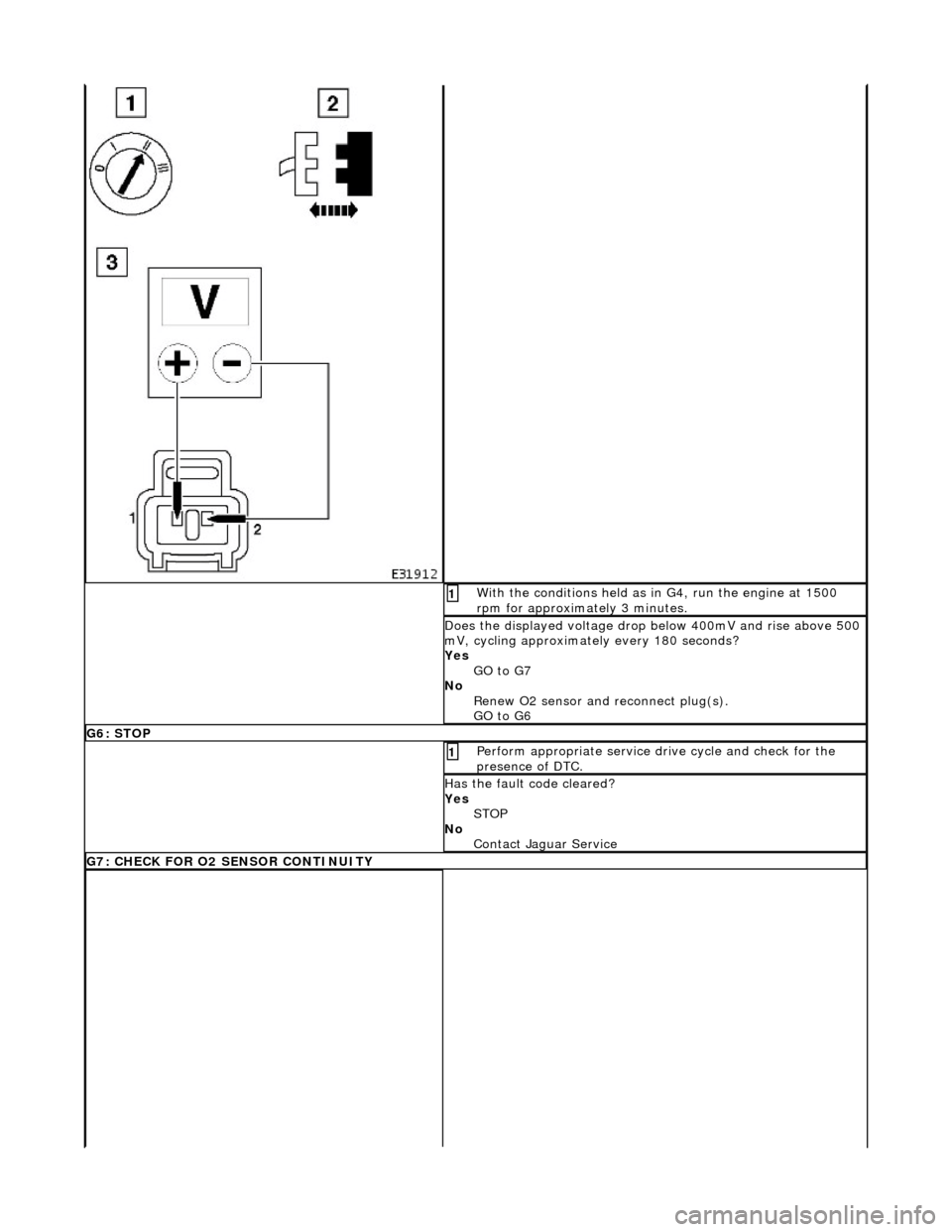

With the conditions held as in G4, run the engine at 1500

rpm for approximately 3 minutes. 1

Does the displayed voltage drop below 400mV and rise above 500

mV, cycling approximately every 180 seconds?

Yes GO to G7

No Renew O2 sensor and reconnect plug(s).

GO to G6

G6: STOP

Perform appropriate service drive cycle and check for the

presence of DTC. 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

G7: CHECK FOR O2 SENSOR CONTINUITY

Page 1625 of 2490

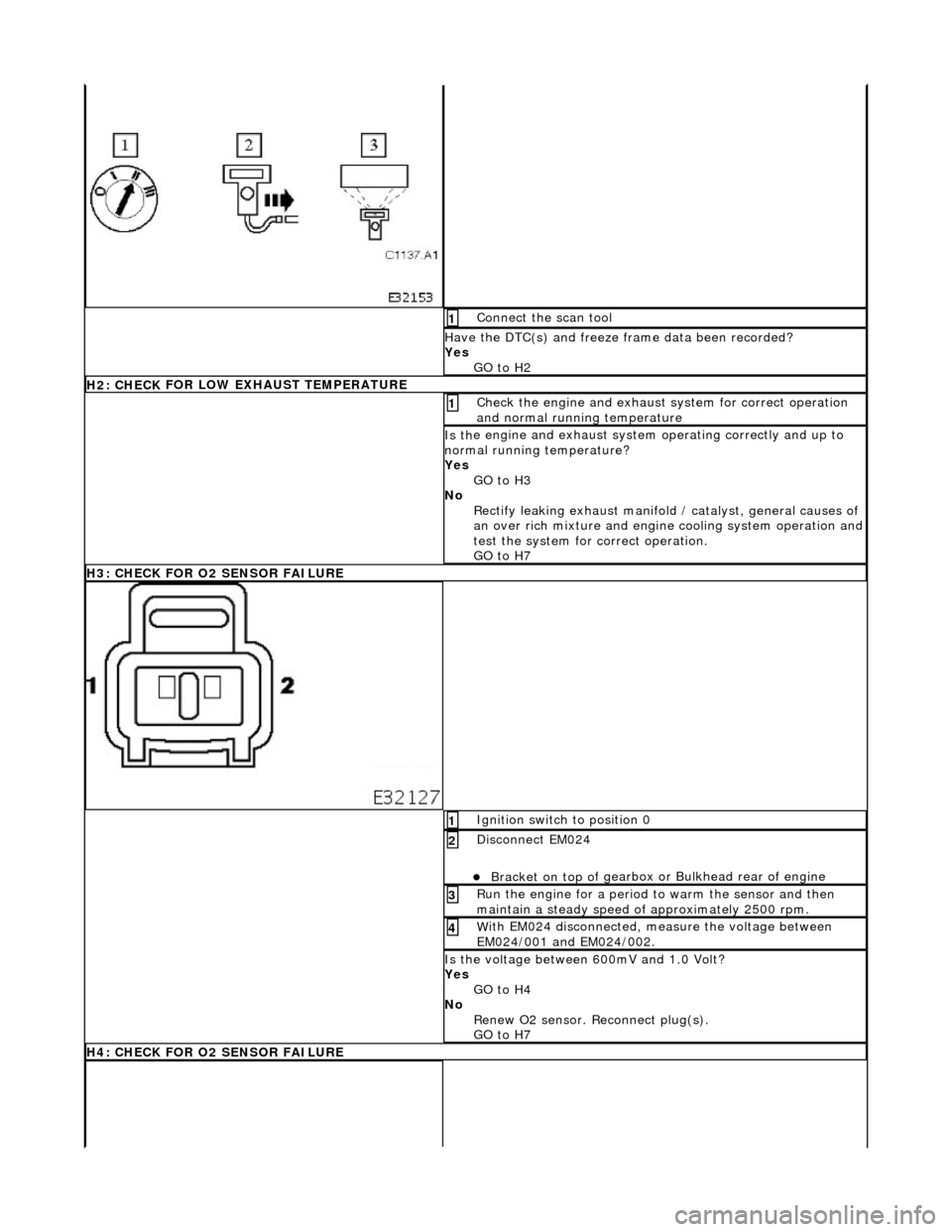

Conne

ct the scan tool

1

Have the DTC(s) and fr

eeze

frame data been recorded?

Yes GO to H2

H2: CHECK

FOR LOW EXHAUST TEMPERATURE

Chec

k the engine and exhaust

system for correct operation

and normal running temperature

1

Is th

e engine and exhaust system operating correctly and up to

normal running temperature?

Yes GO to H3

No Rectify leaking exhaust manifold / catalyst, general causes of

an over rich mixture and engine cooling system operation and

test the system for correct operation.

GO to H7

H

3: CHECK FOR O2 SENSOR FAILURE

I

gnition switch to position 0

1

Di

sconnect EM024

пЃ¬Bracket on top o

f gearbox or

Bulkhead rear of engine

2

R

un the engine for a period to

warm the sensor and then

maintain a steady speed of approximately 2500 rpm.

3

W

ith EM024 disconnected, measure the voltage between

EM024/001 and EM024/002.

4

Is

the voltage between 600mV and 1.0 Volt?

Yes GO to H4

No Renew O2 sensor. Reconnect plug(s).

GO to H7

H

4: CHECK FOR O2 SENSOR FAILURE

Page 1626 of 2490

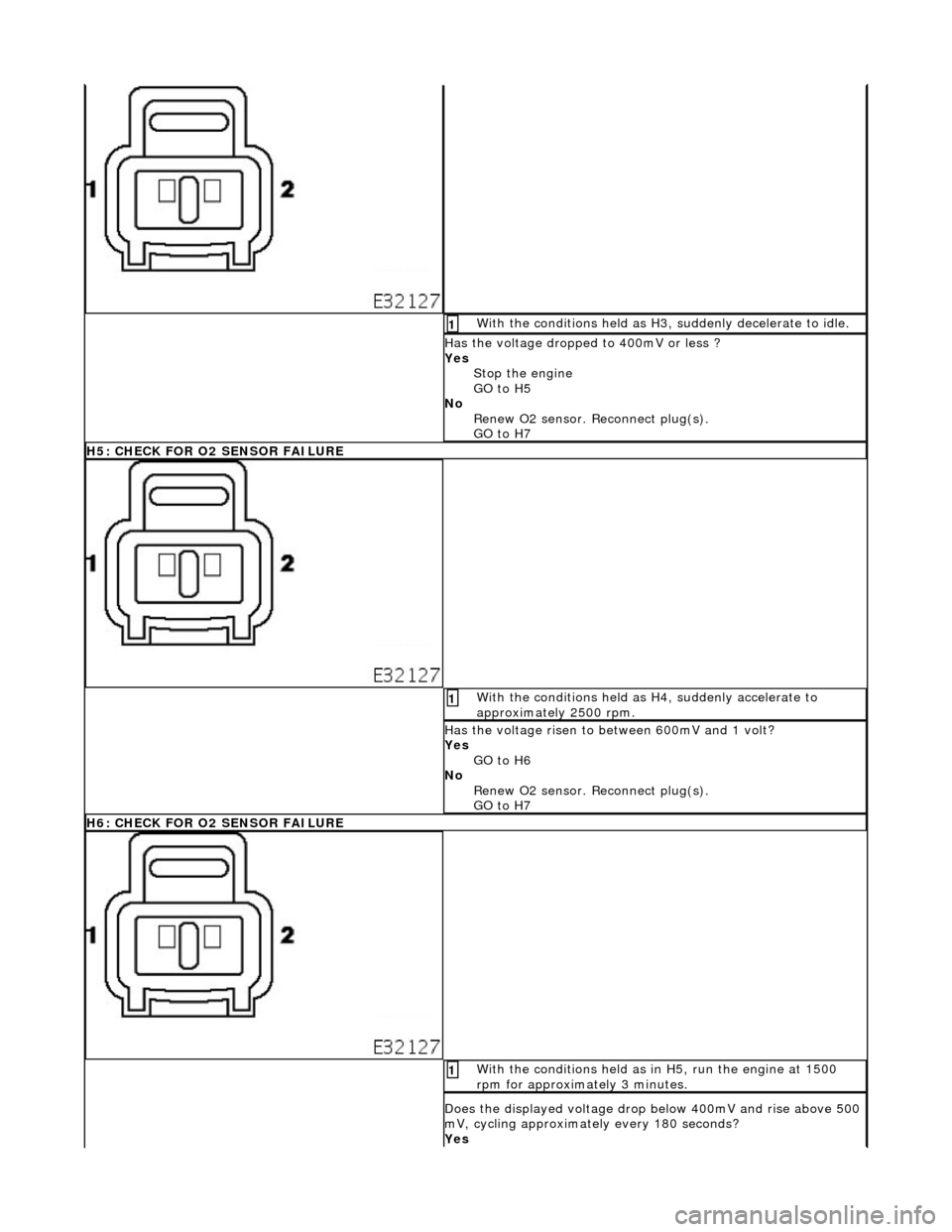

With

the conditions held as H3, suddenly decelerate to idle.

1

Has the voltage

d

ropped to 400mV or less ?

Yes Stop the engine

GO to H5

No Renew O2 sensor. Reconnect plug(s).

GO to H7

H5

: CHECK FOR O2 SENSOR FAILURE

Wi

th

the conditions held as H4, suddenly accelerate to

approximately 2500 rpm.

1

Has the

voltage risen to between 600mV and 1 volt?

Yes GO to H6

No Renew O2 sensor. Reconnect plug(s).

GO to H7

H6

: CHECK FOR O2 SENSOR FAILURE

W

i

th the conditions held as in H5, run the engine at 1500

rpm for approximately 3 minutes.

1

Does th e displayed voltage drop below 40

0mV and rise above 500

mV, cycling approximately every 180 seconds?

Yes

Page 1638 of 2490

Exha

ust System - Catalyti

c Converter LH4.0L NA V8 - AJ27/3.2L NA V8 -

AJ26

Re mo

val and Installation

Remova

l

1.

Op

en the engine compartment and fit paintwork protection

sheets.

2. Remove the front muffler; refer to Operation 30.10.18 in this

section.

3. Re

move the centre trim panel

from the engine compartment.

1. Remove the left hand side enclosure panel.

2. Remove the centre trim panel.

4. Repo

sition the expansion tank from the mounting.

1. Disconnect the coolant level sensor connector.

2. Remove the nuts which secures the tank.

5. CAUT

ION: Note the position of the upstream and

downstream (where fitted) o xygen sensor multiplugs for

reassembly.

Disconnect the oxygen sensor multiplugs.

пЃ¬Di spl

ace the multiplugs from the engine mounting bracket.

пЃ¬Dis

connect the plug(s) from the oxygen sensor(s)

6.

Re

move the four nuts which se

cure the downpipe catalytic

converter to the exhaust manifold.

Page 1641 of 2490

2.

Connect the harness connector

8. R

efit the centre trim panel and th

e left hand enclosure panel to

the engine compartment.

1. Refit the centre trim panel.

2. Refit the left hand enclosure panel.

9. Raise the ramp.

10

.

Tighten the mounting brac ket securing bolts.

11. Fit the front muffler; refer to Operation 30.10.18.

12. Lower the ramp.

13. Remove the paintwork protection sheets and close the engine

cover.

Page 1642 of 2490

Exha

ust System - Catalytic Conv

erter LH4.0L SC V8 - AJ26

Remo

val and Installation

Remov

a

l

1.

Op

en the engine compartment and fit paintwork protection

sheets.

2. Re

move the centre trim panel

from the engine compartment.

1. Remove the left hand side enclosure panel.

2. Remove the centre trim panel.

3. Repo

sition the expansion tank from the mounting.

1. Disconnect the coolant level sensor connector.

2. Remove the nuts which secures the tank.

4. CAUT

ION: Note the position of the upstream and

downstream (where fitted) o xygen sensor multiplugs for

reassembly.

Disconnect the oxygen sensor multiplugs.

пЃ¬Di spl

ace the multiplugs from the engine mounting bracket.

пЃ¬Dis

connect the plug(s) from the oxygen sensor(s)

5.

Re

move the four nuts which se

cure the downpipe catalytic

converter to the exhaust manifold.

Page 1645 of 2490

6. Connec

t the oxygen sensor multiplugs.

пЃ¬Con

nect the plug(s) to the respective (previously noted)

sensor(s).

пЃ¬Cor

rectly position the multiplu

gs on the mounting bracket.

7. F

it the coolant header tank.

1. Reposition the tank and fit the securing nuts.

2. Connect the harness connector

8. R

efit the centre trim panel and th

e left hand enclosure panel to

the engine compartment.

1. Refit the centre trim panel.

2. Refit the left hand enclosure panel.

9. Raise the vehicle on the ramp.

10. Tighten the mounting brac ket securing bolts.

Page 1646 of 2490

11

. Connect

the downpipe cataly

tic converter to the front

muffler.

1. Position a new gasket to the flange studs at each side.

2. Connect the the front mu ffler assembly to each

downpipe.

3. Fit and tighten the nuts to secure the muffler to the downpipes.

12 . F

it the front muffler rear mounting.

1. Reposition the front mu ffler and align the rear

mounting.

2. Fit and tighten the bolts; muffler to mounting bracket.

13. Lower the ramp.

14. Remove the paintwork protection sheets and close the engine

cover.