steering JAGUAR X308 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 470 of 2490

3.CAUT

ION: DO NOT attempt to adjust the

steering gear yoke. Failure to follow this instruction will result in the

steering gear warranty to become invalid.

3. The backlash of the steering gear cannot be adjusted, in stall a new steering gear. For additional information,

REFER to Section 211

-02

Power Steering

.

4. 4. Grasp the steering wheel firm

ly and move it up an

d down and to the left and right without turning the wheel to

check for column bearing wear, steering wheel or steering column. For additional information,

REFER to Section 211

-04

Steering Column

.

Page 471 of 2490

Stee

ring System - General Informatio

n - Power Steering System Filling

and Bleeding

Gen

eral Procedures

Fluid Level Indica

tor

1.

F

ill the reservoir to the bo

ttom of the filler neck.

W

ait for any air to escape and top up again.

W

ithout the engine running, tu

rn from lock to lock two or

three times, topping up to the maximum level on the dip

reservoir stick.

St

art the engine and

immediately top up as air is vented.

W

ith the engine idling, turn

lock to lock two or three

times, topping up to the ma ximum level on the reservoir

dip stick.

W

hen no further change of

fluid level occurs, run the

engine for twenty minutes to vent any remaining air.

If po

ssible, allow the vehicle

to stand for thirty minutes

before restarting the engine to vent any further air.

2. Note that air in the fluid can temporarily result in PAS pump

noise, but this will not cause damage. The time allowances

mentioned in the above procedures are to reduce the possibility

of a customer collecting a vehicle while still subject to

excessive pump noise.

Page 472 of 2490

Steering System - General Information - Power Steeri

ng System Flushing

Gen

e

ral Procedures

• NOTE: If heavy steering or contamination within the power steering system is found, it is necessary to carry out the

system flush procedure as detailed below. If any components have been replaced in the power steering system the

procedure below must be carried out in full.

• NOTE: Some variation in the illustrations may occur, but the essential information is always correct.

1. Remove the power steering fluid reservoir cap.

2. Using a suitable syringe, remove the power steering fluid from

the power steering fluid reservoir.

3. CAUTIO

N: Be prepared to

collect escaping fluids.

• NOTE: Note the orientation of the clip. Detach the power steeri ng fluid reservoir.

De

tach but do not remove the power steering fluid

reservoir.

Re lea

se the power steering fluid return hose from the

power steering fluid reservoir.

If a qui

ck release coupling is fitted to the power

steering return ho se, release the powe r steering fluid

return hose from the coupling by removing the clip.

4. CAUTIO

N: Be prepared to

collect escaping fluids.

• NOTE: Make sure that all openings are sealed. Use new

blanking caps.

Using a suitable blanking cap, cap the power steering

reservoir return pipe.

5. CAUTIO

N: Be prepared to

collect escaping fluids.

• NOTE: Make sure the extended pipe is not kinked or twisted

and is correctly secure d with hose clips.

Attach a suitable pipe to the power steering return hose to

allow the fluid to drain.

Page 473 of 2490

6. NO

TE: The suitable funnel should have the a capacity of 4

litres and O-ring seal

• NOTE: The suitable funnel must be tightly sealed to the

power steering fluid reservoi r to avoid fluid leakage.

Install a suitable funnel onto the power steering fluid

reservoir.

7. WARNING: Do not work on or under a vehicle supported

only by a jack. Always support the vehicle on safety stands.

Raise and support the vehicle with the wheels just clear of the

ground.

8. CAUTI

ONS:

Steps 8 and 9 must be carried out within 2 - 3 seconds of

each other. Failure to follow this instruction may result in damage

to the power steering system.

Be prepared to collect escaping fluids.

Using the suitable funnel, top up the power steering system

with the specified fluid. Make su re the fluid level is maintained

at two thirds full in the funnel.

9. CAUTI

ONS:

Be prepared to collect escaping fluids.

Page 474 of 2490

Do not al

low the power steering fluid level in the power

steering fluid reservoir to fall below the minimum power

steering fluid level. Fa ilure to follow this instruction may result

in damage to the po wer steering system.

Make sure the engine is swit ched off as soon as the full

4 litres of power steering flui d has entered the power steering

fluid reservoir.

Flush the power steering system.

St art

the engine

W

it

h assistance turn the stee

ring slowly lock to lock 3

times at approximately 1 revo lution every 5 seconds.

Continue

to flush the power steering system until 4

litres of power steering fl uid has been added to the

power steering reservoir. This should take

approximately 30 seconds.

10 . CAUTI

ON: Be prepared to

collect escaping fluids.

Remove the suitable funnel.

11 . CAUTI

ON: Be prepared to

collect escaping fluids.

Remove the suitable pipe to th e power steering return hose.

12. CAUTI

ON: Be prepared to

collect escaping fluids.

Page 475 of 2490

•

NOTE: Note the orientation of the clip.

If a quick release coupling is fitt ed to the power steering return

hose, connect the power steerin g fluid return hose to the

coupling by installing the clip.

13. Install a new power steering fl uid reservoir. For additional

information, refer to: (211-02) Power Steering Fluid Reservoi r - 4.2L/3.0L/2.7L Diesel

(Removal and Installation),

Power Steering Fluid Reservoir - 3.0L Diesel (Removal and

Installation).

Page 476 of 2490

Steering System - Gen

eral Informatio

n - Power Steering System Vacuum

Filling and Bleeding

Gen e

ral Procedures

Fluid Ho

ses

1.

Parts L i

st

It

e

m

De

scr

iption

1R

e

turn hose

2High

pressure h

ose

2. If vacuum filling equipment is available, proceed as follows:

Disconnect both the

high pres

sure hose and return hose

from the PAS pump and the re turn hose from the steering

rack.

D rain as much fl

uid as possible from the system by

turning the steering from lock to lock two or three times.

Re conn

ect all hoses.

Fi

ll

the system using the vacuum equipment according to

the manufacturers instructions.

St art

the engine and top up

the fluid as necessary.

Turn the steering from lock to lock two or three ti mes wi

th

the engine running, topping up with fluid as necessary.

If possibl

e, run the engine for twenty minutes to expel any

remaining air.

Page 477 of 2490

Stee

ring System - General Informat

ion - Steering Gear Centralizing

Gen

eral Procedures

Rack Al

ignment Markers

1.

The steering rack should al

ways

be centralized prior to steering

column or suspension geometry adjustment.

Central

ization of the steering ra

ck is achieved by aligning

the marker on the centralizing cap with a locator on the

pinion housing.

Page 478 of 2490

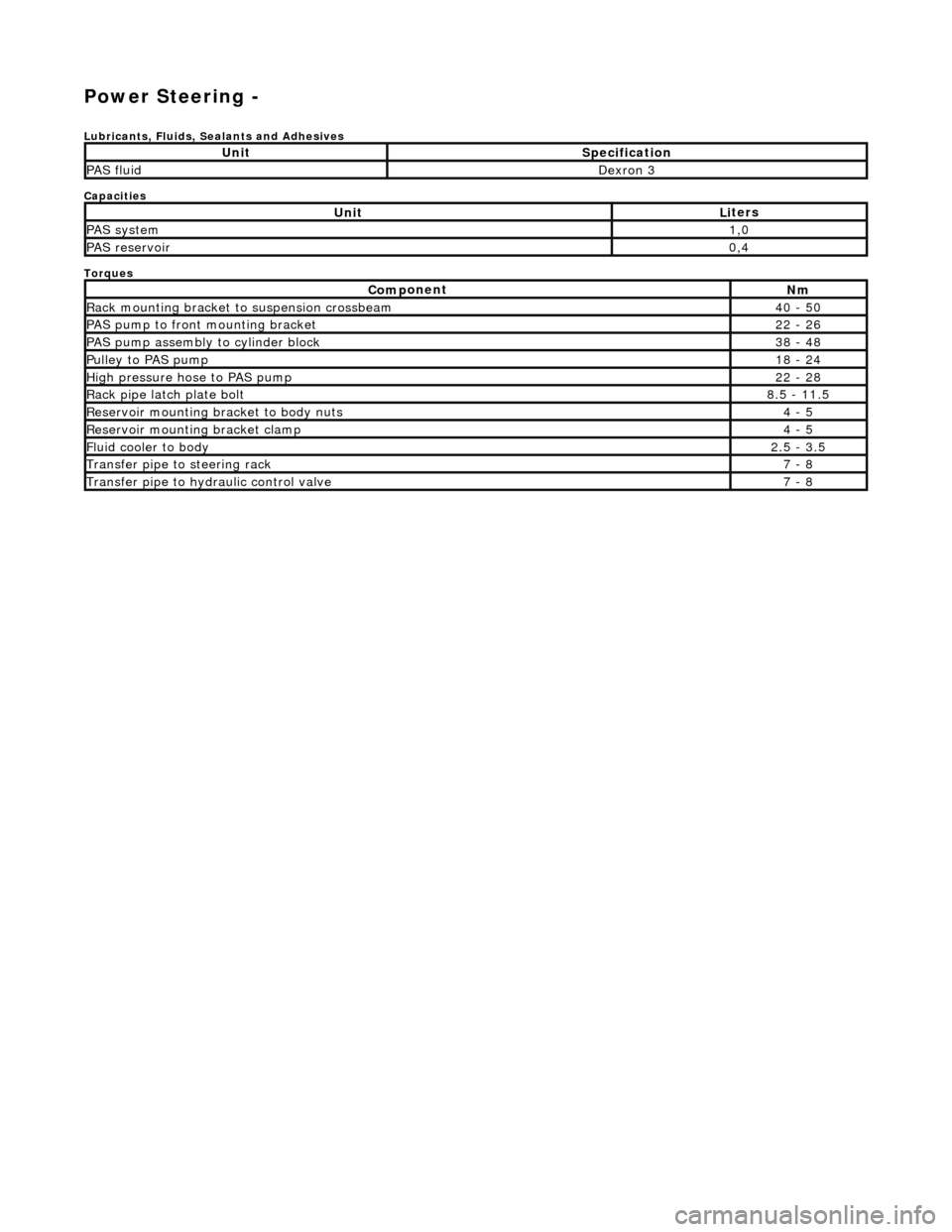

Power Steering -

Lubric

ants, Fluids, Sealants and Adhesives

Capacities

Torques

UnitSp

ecification

PAS flu

i

d

De

xr

on 3

UnitLi

t

ers

PAS syste

m1,0

PAS reservoi

r0,4

Com p

onent

Nm

Rac

k

mountin

g brac

ke

t to suspension crossbeam

40

- 50

PAS pump to front mounti

ng bracket

22

-

26

P

AS pu

mp assembly to cylinder block

38

-

48

Pul

l

ey to PAS pump

18

-

24

Hi

gh pressure hose to PAS pump22 -

28

Rack

pipe latch plate bolt8.5 -

11.5

R

e

servoir mounting bracket to body nuts

4 -

5

R

e

servoir mounting bracket clamp

4 -

5

Fluid cooler to body2.

5 -

3.5

Transfer pipe

to steering rack7 -

8

Transfer pipe

to hydraulic con

trol valve

7 -

8

Page 479 of 2490

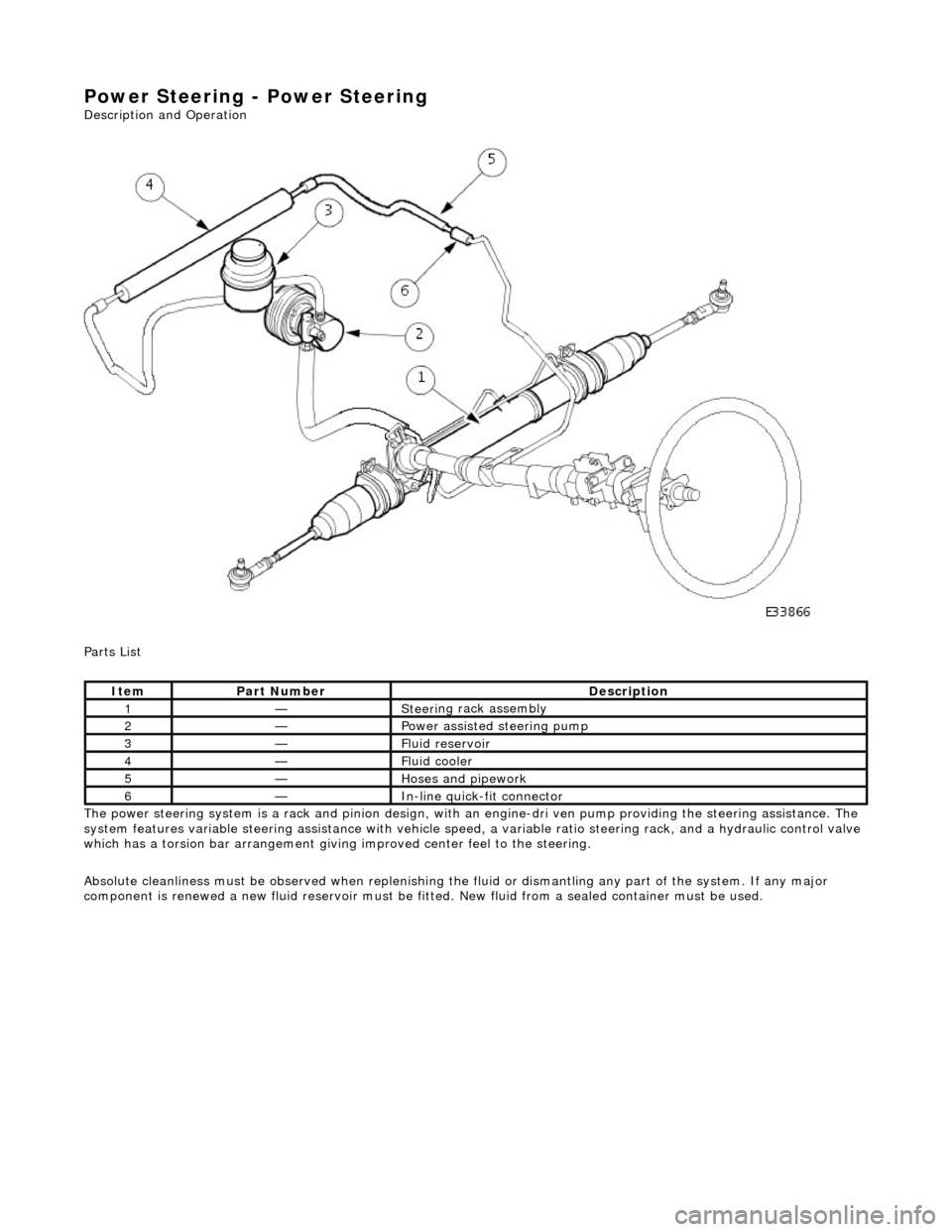

Power Steering - Power Steering

Description an

d Operation

Parts List

The power steering system is a rack and pinion design, with an engine-dri ve n pump providing the steering assistance. The

system features variable steering assistance with vehicle spee d, a variable ratio steering rack, and a hydraulic control valve

which has a torsion bar arrangement giving improved center feel to the steering.

Absolute cleanliness must be observed wh en replenishing the fluid or dismantling any part of the system. If any major

component is renewed a new fluid rese rvoir must be fitted. New fluid from a sealed container must be used.

It

em

Par

t Number

De

scription

1—Steeri

ng rack assembly

2—Power as

sisted steering pump

3—F

luid reservoir

4—F

luid cooler

5—Hoses and pipework

6—In-

line quick-fit connector