throttle JAGUAR X308 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 898 of 2490

ENSURE THAT ALL FIRE PREVENTION PROCEDURES ARE ACTIVE.

BEFORE PROCEEDING, IT IS ESSENTIAL THAT THE WARNING NOTES GIVEN IN SECTION 100-00 (UNDER THE

HEADING 'SAFETY PRECAUTIONS') ARE READ AND UNDERSTOOD.

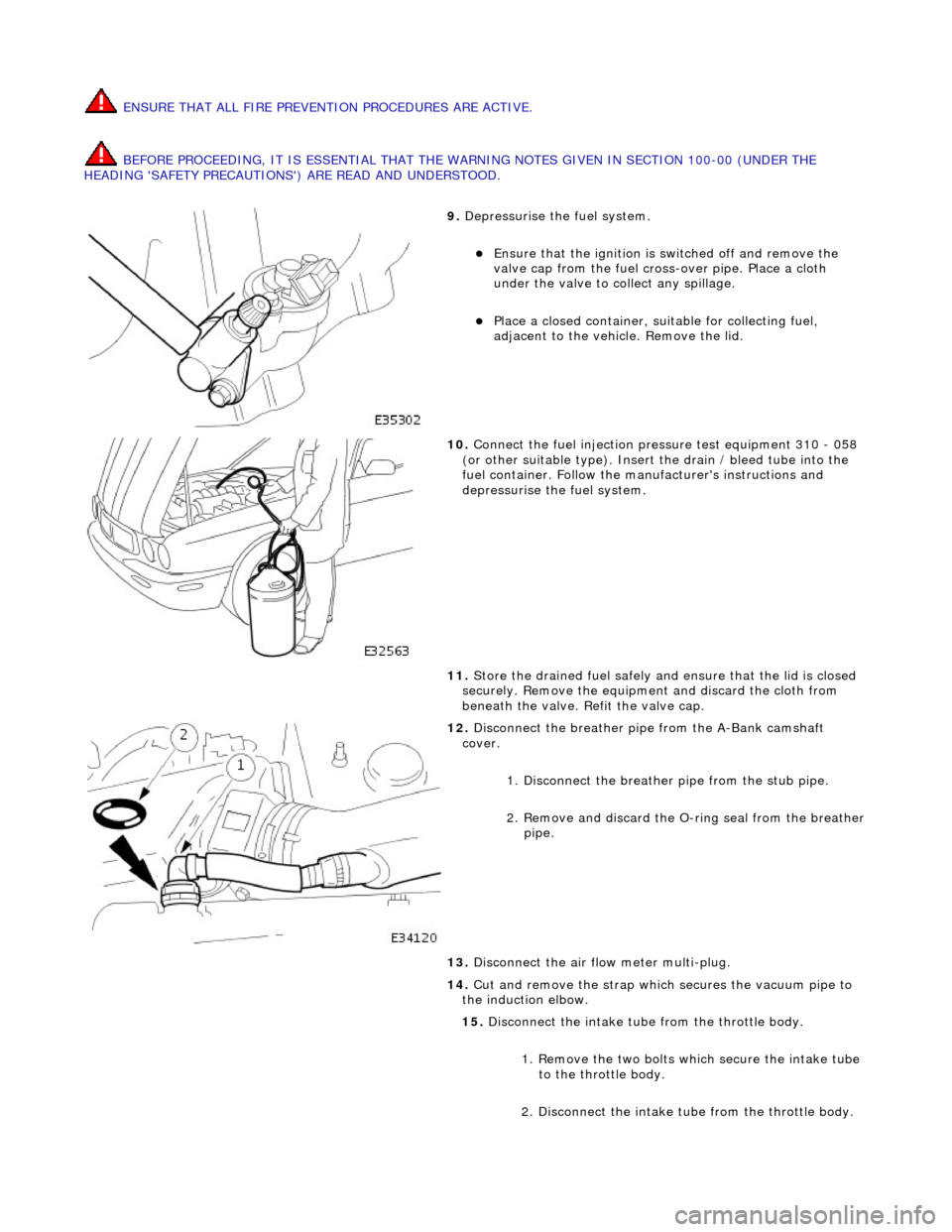

9. Depressurise the fuel system.

Ensure that the ignition is switched off and remove the

valve cap from the fuel cross-over pipe. Place a cloth

under the valve to collect any spillage.

Place a closed container, su itable for collecting fuel,

adjacent to the vehicle. Remove the lid.

10. Connect the fuel injection pressure test equipment 310 - 058

(or other suitable type). Insert the drain / bleed tube into the

fuel container. Follow the ma nufacturer's instructions and

depressurise the fuel system.

11. Store the drained fuel safely and ensure that the lid is closed

securely. Remove the equipmen t and discard the cloth from

beneath the valve. Refit the valve cap.

12. Disconnect the breather pipe from the A-Bank camshaft

cover.

1. Disconnect the breather pipe from the stub pipe.

2. Remove and discard the O-ring seal from the breather

pipe.

13. Disconnect the air flow meter multi-plug.

14. Cut and remove the strap which secures the vacuum pipe to

the induction elbow.

15. Disconnect the intake tube from the throttle body.

1. Remove the two bolts which secure the intake tube to the throttle body.

2. Disconnect the intake tube from the throttle body.

Page 899 of 2490

16. Disconnect the air cleaner cover.

Remove the five clips which se cure the air cleaner cover.

17. Remove the intake tube / air flow meter / air cleaner cover

assembly.

1. Remove the intake tube / air flow meter / air cleaner

cover assembly.

2. Remove and discard the ru bber seal; air intake tube

to throttle body.

18. Remove the centre trim panel from the engine compartment.

1. Remove the left hand side enclosure panel.

2. Remove the centre trim panel.

19. Release the hoses (Quick Fit connections) from the expansion

tank, using 303 - 623.

1. Release the hose, expansion tank to thermostat housing (coolant outlet pipe on supercharged

engines).

Page 907 of 2490

56. Disconnect the fuel feed and return hoses.

1. Disconnect the fuel hoses at the Quick Fit connectors,

using special tool 310 - 044 for the feed hose and

310 - 54 for the return hose.

Disconnect the return hose from the feed hose clip.

Fit blanking plugs to the pipes.

57. Disconnect the pipes from the purge valve.

1. Remove the clip which secu res the part load breather

hose to the purge valve.

2. Disconnect the part load breather hose.

3. Disconnect the vacuum hose from the purge valve and reposition the hose.

58. Disconnect the throttle cable.

1. Secure the cable abutment to the bracket with tape or a ratchet strap, if nece ssary (to save subsequent

adjustment procedure). Remove the bolts which

secure the abutment bracke t to the throttle body.

2. Rotate the butterfly actuator cam and disconnect the cable. Reposition the cable.

59. Disconnect the heater and brake servo hoses.

1. Disconnect the he ater return hose.

2. Release the heater feed hose locking lever and

disconnect the hose.

Page 916 of 2490

3. Conne

ct the brake servo hose.

26. Conne

ct the P.I. harness to the engine management

harness.

1. Reposition the engi ne management harness

connector to the bracket.

2. Fit the nut which secures the engine management harness connector to the mounting bracket.

3. Connect the connectors.

4. Fit the bolt which secures the P.I. harness connector to the engine management harness.

27 . Conne

ct the transmission rotary

switch harness connector.

Re

position and connect the harness.

28 . Con

nect the throttle cable.

1. Fit the bolts which secure the abutment bracket to the throttle body. Tighten to 4-6 Nm.

2. Rotate the butterfly actuator cam and connect the cable. Reposition the cable into the cam.

Re

move any tape or plastic

strap which was fitted when

disconnecting the cable abutment.

29. Connect the pipes to the purge valve.

1. Connect the part load breather hose.

2. Fit the clip which secures the part load breather hose

to the purge valve.

Page 922 of 2490

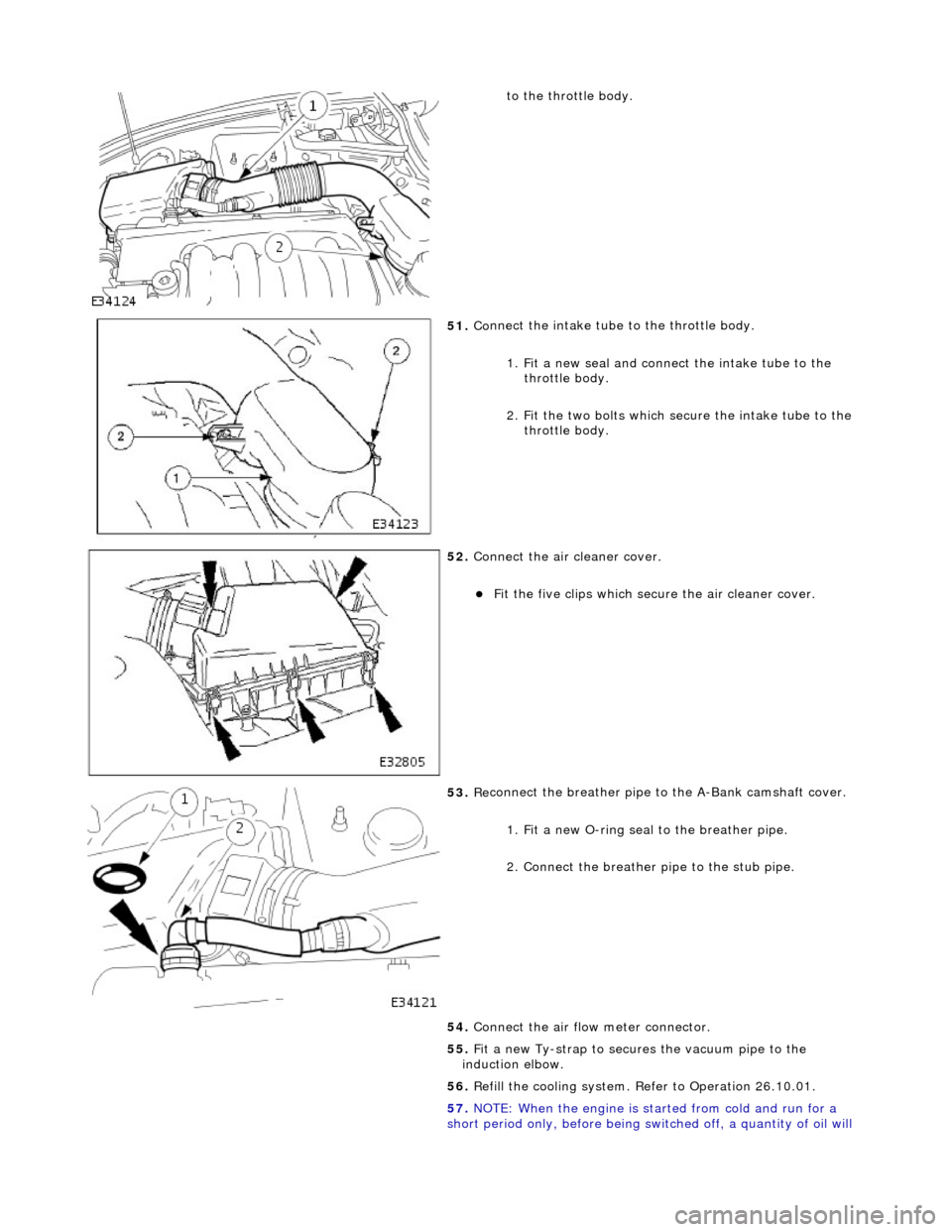

to th

e throttle body.

51 . Co

nnect the intake tube to the throttle body.

1. Fit a new seal and connect the intake tube to the throttle body.

2. Fit the two bolts which secure the intake tube to the throttle body.

52 . Conne

ct the air cleaner cover.

F

it

the five clips which secu

re the air cleaner cover.

53 . Re

connect the breather pipe to the A-Bank camshaft cover.

1. Fit a new O-ring seal to the breather pipe.

2. Connect the breather pipe to the stub pipe.

54. Connect the air flow meter connector.

55. Fit a new Ty-strap to secures the vacuum pipe to the

induction elbow.

56. Refill the cooling system. Refer to Operation 26.10.01.

57. NOTE: When the engine is star ted from cold and run for a

short period only, before being swit ched off, a quantity of oil will

Page 930 of 2490

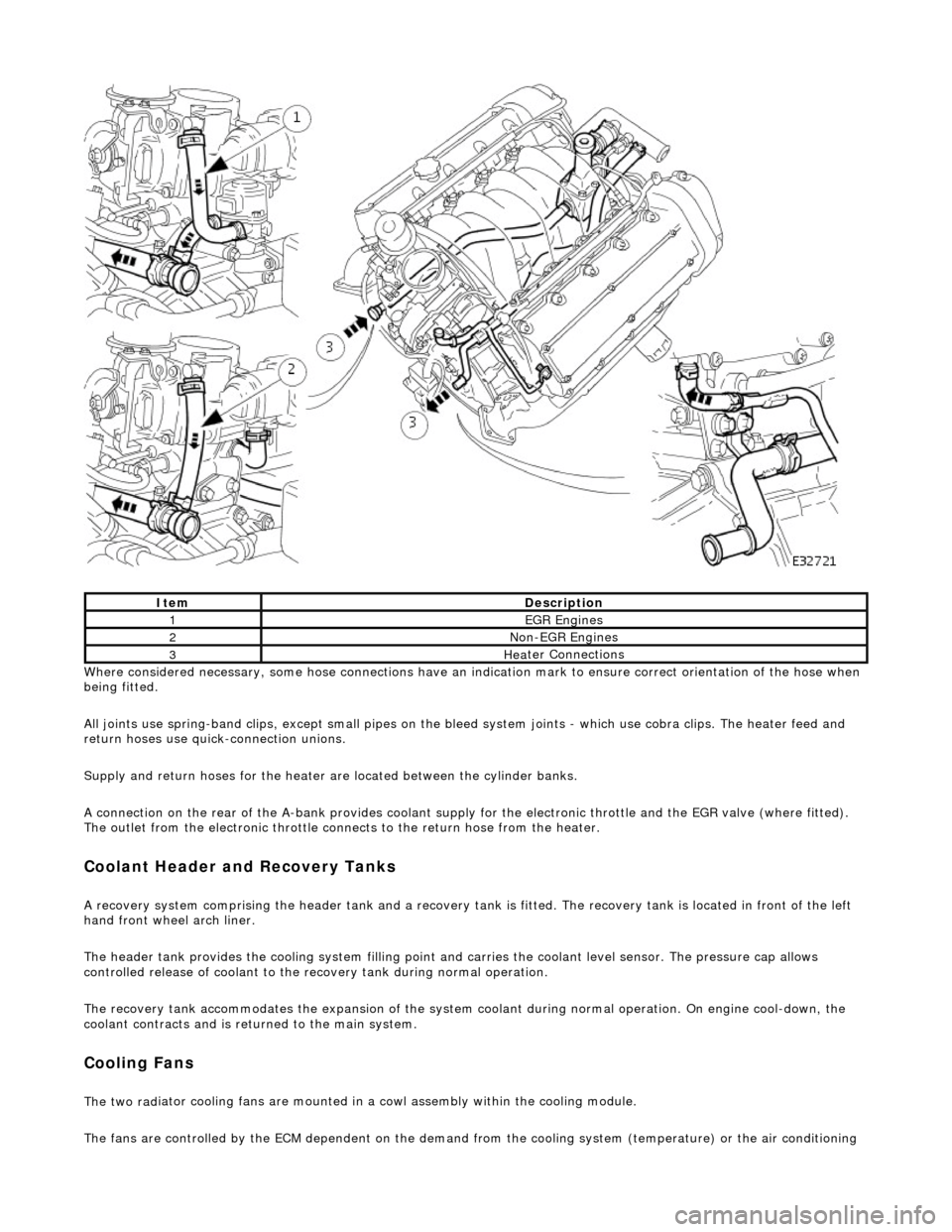

Whe r

e considered necessary, some hose conn

ections have an indication mark to ensure correct orientation of the hose when

being fitted.

All joints use spring-band clips, except small pipes on the bleed system joints - which use cobra clips. The heater feed and

return hoses use quick-connection unions.

Supply and return hoses for the heater are located between the cylinder banks.

A connection on the rear of the A-bank provides coolant supply for the electronic throttle and the EGR valve (where fitted).

The outlet from the electronic throttle connects to the return hose from the heater.

Cool

ant Header and Recovery Tanks

A recovery system comp

rising the header tank

and a recovery tank is fitted. The recove ry tank is located in front of the left

hand front wheel arch liner.

The header tank provides the cooling system filling point and carries the coolant level sensor. The pressure cap allows

controlled release of coolant to the re covery tank during normal operation.

The recovery tank accommodates the expansion of the system coolant during normal operation. On engine cool-down, the

coolant contracts and is returned to the main system.

Coo lin

g Fans

The two

rad

iator cooling fans are mounted in

a cowl assembly within the cooling module.

The fans are controlled by the ECM dependent on the demand fr om the cooling system (temperature) or the air conditioning

ItemDescrip

tion

1EGR

E

ngines

2Non

-

EGR Engines

3Hea

ter Connections

Page 937 of 2490

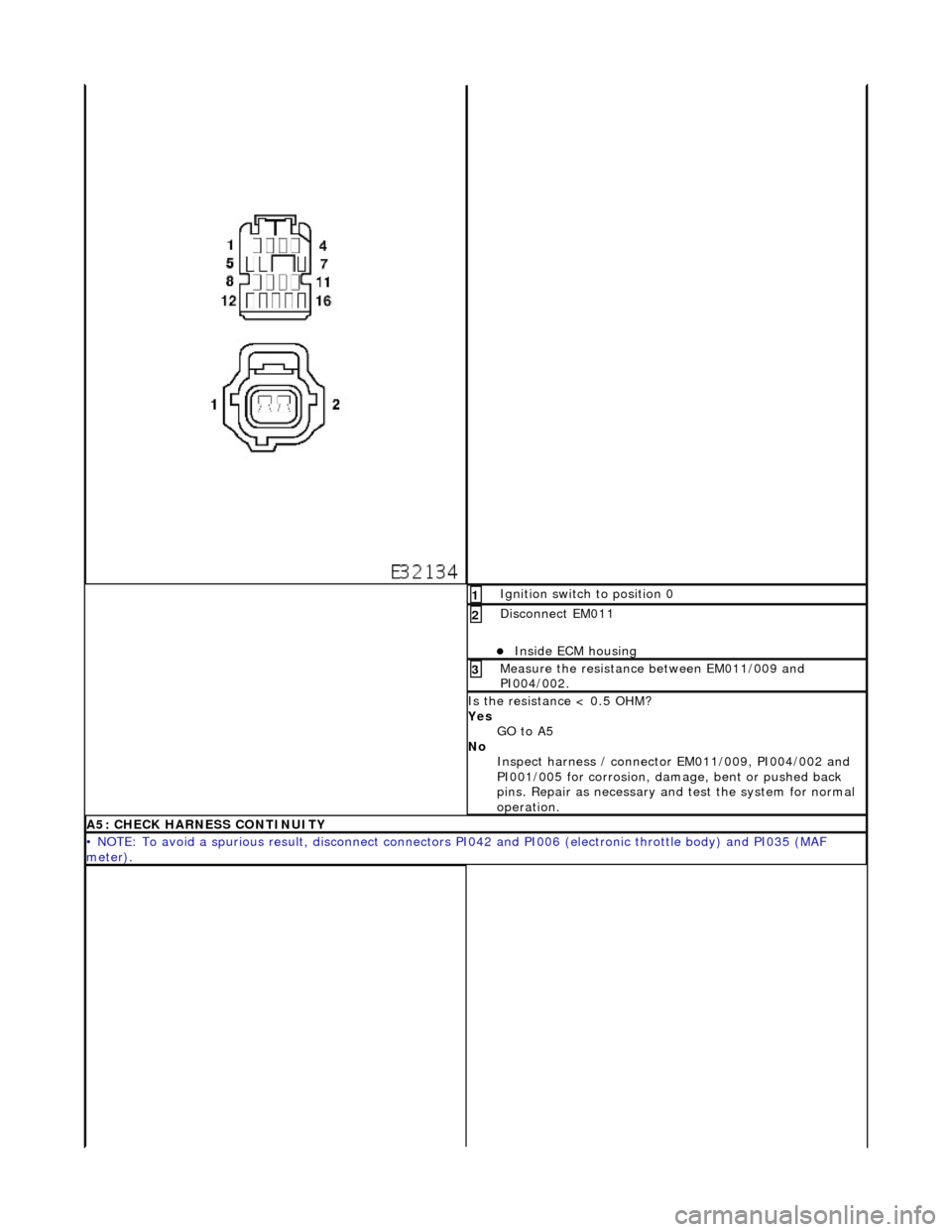

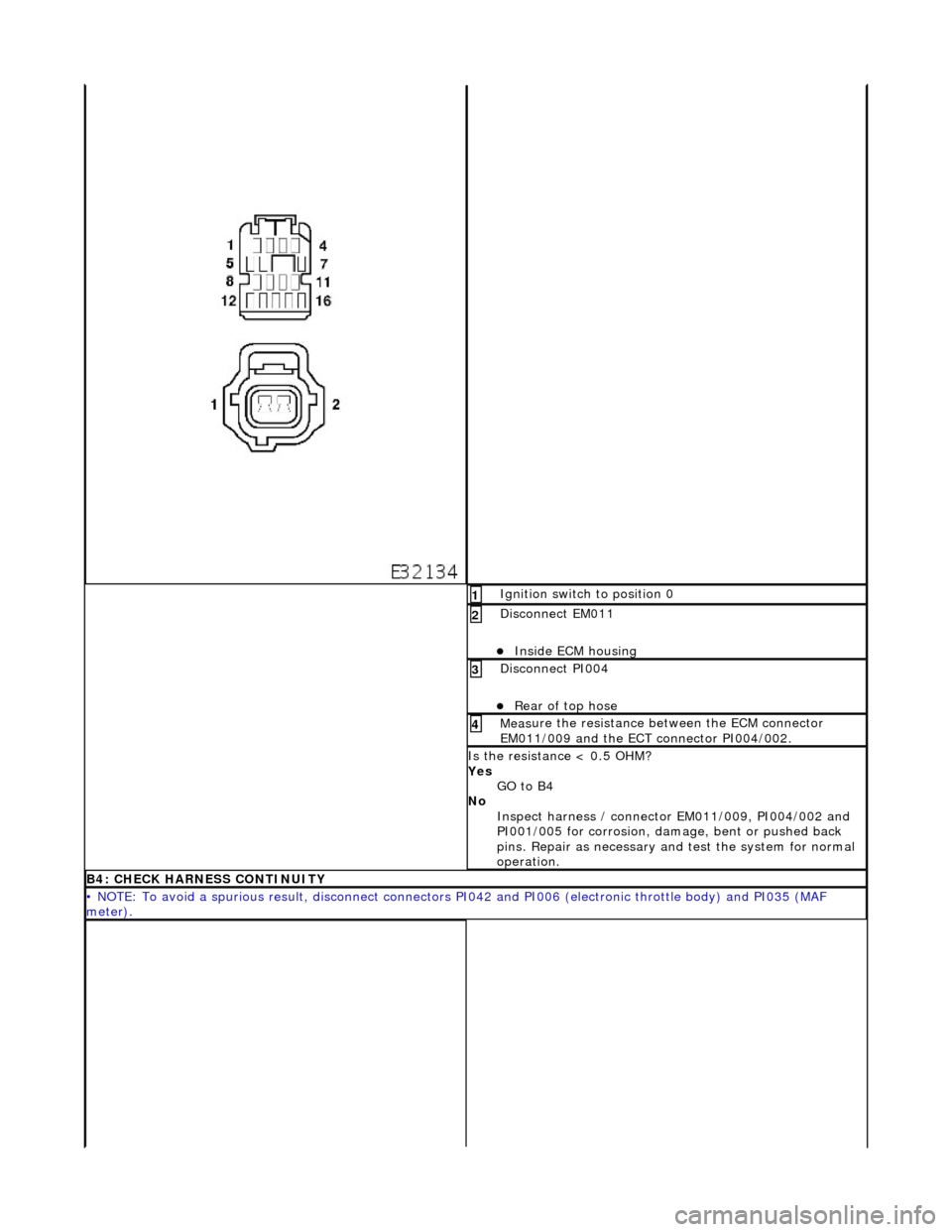

I

gnition switch to position 0

1

Di

sconnect EM011

Inside E

CM housing

2

Me

asure the resistance between EM011/009 and

PI004/002.

3

I

s the resistance < 0.5 OHM?

Yes GO to A5

No Inspect harness / connector EM011/009, PI004/002 and

PI001/005 for corrosion, damage , bent or pushed back

pins. Repair as necessary and test the system for normal

operation.

A5: CHECK

HARNESS CONTINUITY

•

NOTE: To avoid a spurious result, disconnect connectors PI042 and PI006 (electronic throttle body) and PI035 (MAF

meter).

Page 941 of 2490

I

gnition switch to position 0

1

Di

sconnect EM011

Inside E

CM housing

2

D

isconnect PI004

Re

ar of top hose

3

Meas

ure the resistance between the ECM connector

EM011/009 and the ECT connector PI004/002.

4

I

s the resistance < 0.5 OHM?

Yes GO to B4

No Inspect harness / connector EM011/009, PI004/002 and

PI001/005 for corrosion, damage , bent or pushed back

pins. Repair as necessary and test the system for normal

operation.

B4: CHECK

HARNESS CONTINUITY

•

NOTE: To avoid a spurious result, disconnect connectors PI042 and PI006 (electronic throttle body) and PI035 (MAF

meter).

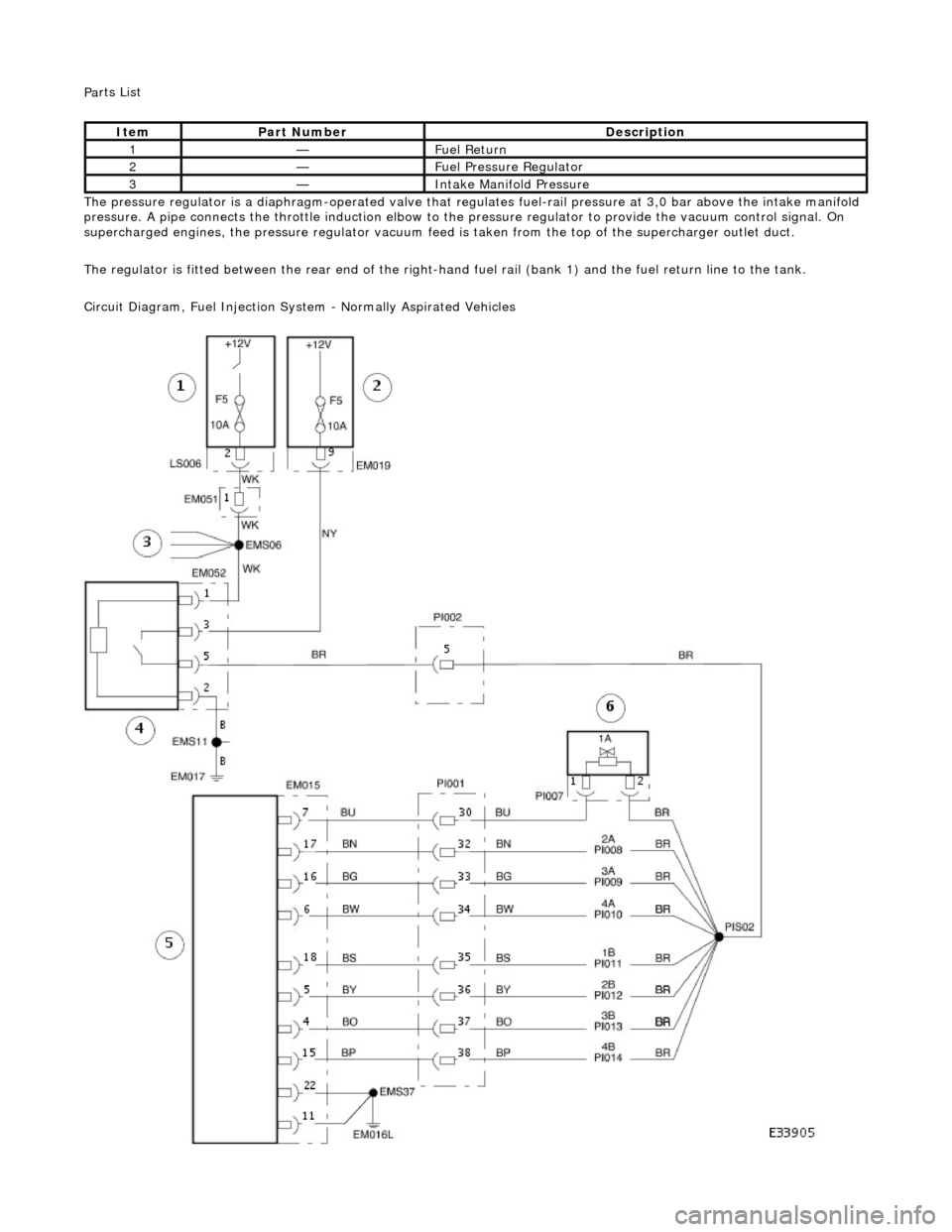

Page 1016 of 2490

Pa

rts List

The pressure regulator is a diap hragm-operated valve that regula tes fuel-rail pressure at 3,0 bar above the intake manifold

pressure. A pipe connects the throttle induction elbow to the pressure regulator to provide the vacuum control signal. On

supercharged engines, the pressure regulator vacuum feed is taken from the top of the supercharger outlet duct.

The regulator is fitted between the rear end of the right-hand fuel rail (bank 1) and the fuel return line to the tank.

Circuit Diagram, Fuel Injection Syst em - Normally Aspirated Vehicles

Ite

m

Par

t

Number

De

scr

iption

1—F

u

el Return

2—F

u

el Pressure Regulator

3—Inta

k

e Manifold Pressure

Page 1020 of 2490

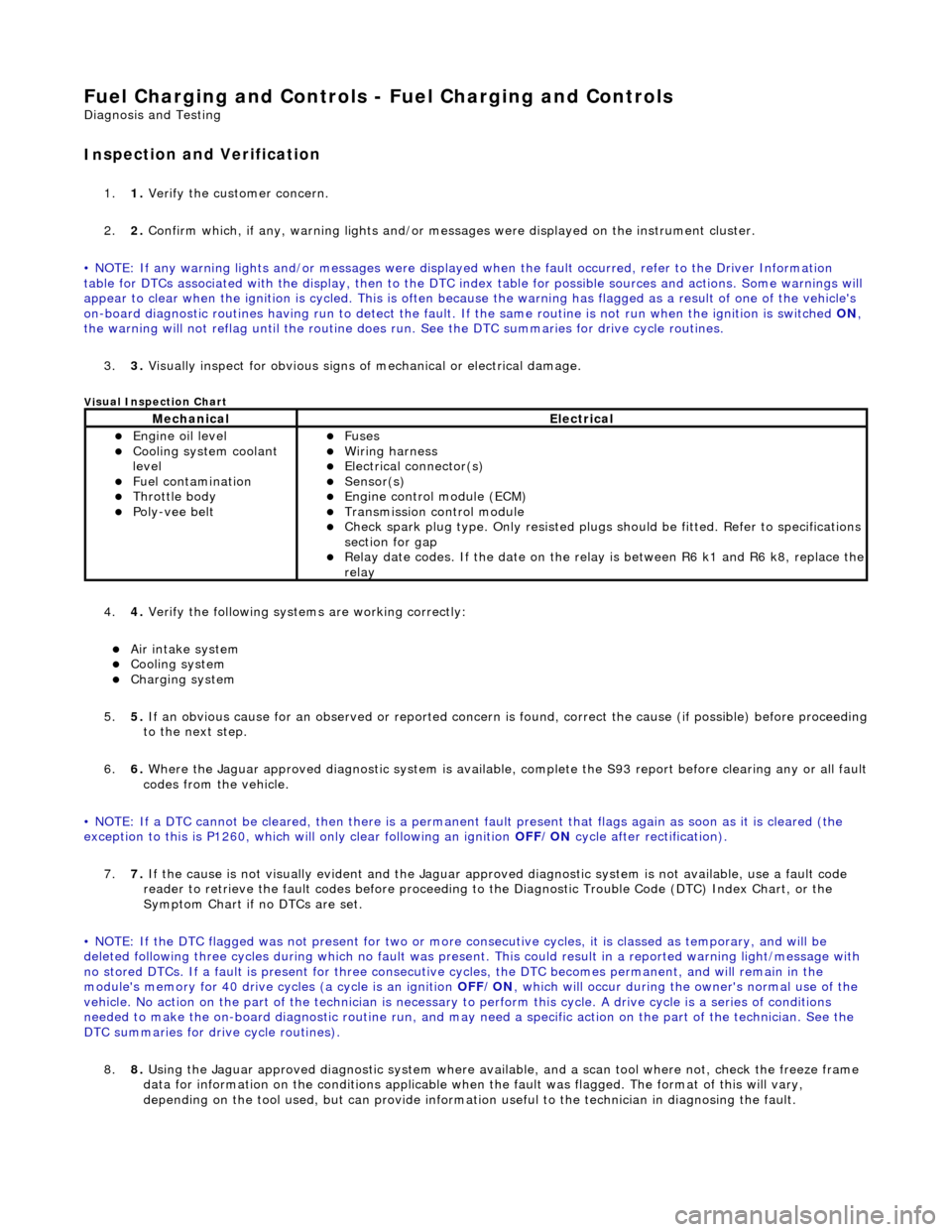

Fuel Char

ging and Controls - Fuel Charging and Controls

D

iagn

osis and Testing

I

n

spection and Verification

1.

1. Veri fy the customer concern.

2. 2. Confi

rm which, if any, warning li

ghts and/or messages were displayed on the instrument cluster.

• NOTE: If any warning lights and/or me ssages were displayed when the fault occurred, refer to the Driver Information

table for DTCs associated with the display, then to the DTC index table for possible sources and actions. Some warnings will

appear to clear when the ignition is cycl ed. This is often because the warning has flagged as a resu lt of one of the vehicle's

on-board diagnostic routines having run to detect the fault. If the same routine is not run when the ignition is switched ON,

the warning will not reflag until the routine does run. See the DTC summaries for drive cycle routines.

3. 3. Visually inspect for obvious signs of mechanical or electrical damage.

Vi

sual Inspection Chart

4.

4. Veri fy the foll

owing syst

ems are working correctly:

Air intake

system

Cooling system

Charging system

5. 5. If

an obvious cause for an observed or

reported concern is found, correct th e cause (if possible) before proceeding

to the next step.

6. 6. Where the Jaguar approved diagnostic sy stem is available, complete the S93 report before clearing any or all fault

codes from the vehicle.

• NOTE: If a DTC cannot be cleared, then there is a permanent fault present that flag s again as soon as it is cleared (the

exception to this is P1260, which will only clear following an ignition OFF/ON cycle after rectification).

7. 7. If the cause is not visually evident and the Jaguar approv ed diagnostic system is not available, use a fault code

reader to retrieve the fault codes be fore proceeding to the Diagnostic Trou ble Code (DTC) Index Chart, or the

Symptom Chart if no DTCs are set.

• NOTE: If the DTC flagged was not present for two or more co nsecutive cycles, it is classed as temporary, and will be

deleted following three cycl es during which no fault was present. This could result in a reported wa rning light/message with

no stored DTCs. If a fault is present for three consecutive cycles, the DTC becomes permanent, and will remain in the

module's memory for 40 drive cycl es (a cycle is an ignition OFF/ON, which will occur during the owner's normal use of the

vehicle. No action on the part of the technician is necessary to perform this cycle. A drive cycle is a series of conditions

needed to make the on-board diagnostic ro utine run, and may need a specific action on the part of the technician. See the

DTC summaries for drive cycle routines).

8. 8. Using the Jaguar approved diagnostic system where available, and a scan tool where not, check the freeze frame

data for information on the conditions applicable when the fault was flagged. The format of this will vary,

depending on the tool used, but can pr ovide information useful to the technician in diagnosing the fault.

MechanicalElectrical

Engine

oil level

Coo

ling system coolant

lev

el

Fuel contamination

Throttle body Poly-ve

e belt

Fu

ses

W

i

ring harness

E

l

ectrical connector(s)

Sens

o

r(s)

Engine

control module (E

CM)

Tran

s

mission control module

Check spark plu

g type. Only r

e

sisted plugs should be fitted. Refer to specifications

section for gap

Relay date codes. I

f the date on the rela

y is between R6 k1 and R6 k8, replace the

relay