speed control JAGUAR X308 1998 2.G Manual PDF

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1746 of 2490

No

GO to A3.

A3: CHECK THE SPEED CONTRO L CANCEL SWITCH

ACTION

Meas

ure t

he resistance between SW02,

pin 06 (BO) and SW02, pin 03 (SG).

1

Operate

the speed control

CANCEL switch.

2

Do

es the resistance

vary by 680 ohms?

Yes Recheck DTCs. No short found. Po ssible intermittent fault. CLEAR the DTC. TEST the system for

normal operation.

No INSTALL a new speed control switchpack. CLEAR the DTC. TEST the system for normal operation.

PINPOINT TEST B : DTC

P0567; SPEED

CONTROL RESUME SWITCH ON FAULT

WARN

ING: Where tests involve the removal of the steering

wheel, and/or disconnection of air bag connectors, the

procedure for disarming air bags must be followed,

REFER to: Air Bag Supplemental Re straint System (SRS)

(50

1-20B Supplemental Restra

int System, Description and

Operation).

TE S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

B1: CHECK

THE SPEED CONTR

OL SWITCHPACK IN

TERNAL CIRCUITS FOR SHORT TO GROUND

Disc

onnect the speed control switch

pack electrical connector, SW02.

1

Measure t

he resistance between SW

02, pin 06 (BO) and GROUND.

2

Measure t

he resistance between SW

02, pin 03 (SG) and GROUND.

3

Is either resistance le

ss than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to B2

.

B2: CHECK THE SPEED CONTR

OL CASSETTE REEL FOR SHORT TO GROUND

M

e

asure the resistance between SW02, pin 06 (at the cassette reel side of the connector) and

GROUND.

1

Me

asure the resistance between SW02, pin 03 (at the cassette reel side of the connector) and

GROUND.

2

Is either resistance le

ss than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to B3

.

B3: CHECK THE SPEED CONTR

OL RESUME SWITCH ACTION

Meas

ure t

he resistance between SW02,

pin 06 (BO) and SW02, pin 03 (SG).

1

Operate

the speed control

RESUME switch.

2

Do

es the resistance

vary by 430 ohms?

Yes Recheck DTCs. No short found. Po ssible intermittent fault. CLEAR the DTC. TEST the system for

normal operation.

No INSTALL a new speed control switchpack. CLEAR the DTC. TEST the system for normal operation.

PINPOINT TES

T C : DTC P0568; SPEED CONTROL SWITCH GROUND MALFUNCTION

WAR

N

ING: Where tests involve the removal of the steering

wheel, and/or disconnection of air bag connectors, the

procedure for disarming air bags must be followed,

REFER to: Air Bag Supplemental Re straint System (SRS)

(50

1-20B Supplemental Restra

int System, Description and

Operation).

TE S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

C1: CHECK FOR CONTINUITY T

H

ROUGH STEERING WHEEL

CANCEL AND RESUME SWITCHES (SWITCHES OPEN)

Disc

onnect the speed control switch

pack electrical connector, SW02.

1

Check for c

ontinuity between SW02

, pins 06 (BO) and 03 (SG) wi th the steering wheel switches

inactive.

2

Page 1747 of 2490

Is th

e circuit continuous?

Yes INSTALL a new speed control switchpack. CLEAR the DTC. TEST the system for normal operation.

No GO to C2

.

C2

: CHECK FOR CONTINUITY THROUGH STEERIN

G WHEEL CANCEL SWITCH (SWITCH CLOSED)

Check f

or continuity between SW02, pins 06

(BO) and 03 (SG) with the steering wheel CANCEL

switch operated.

1

Is th

e circuit continuous?

Yes GO to C3

.

No

INSTALL a new speed control switchpack. CLEAR the DTC. TEST the system for normal operation.

C3

: CHECK FOR CONTINUITY THROUGH STEERIN

G WHEEL RESUME SWITCH (SWITCH CLOSED)

Check f

or continuity between SW02, pins 06

(BO) and 03 (SG) with the steering wheel RESUME

switch operated.

1

Is th

e circuit continuous?

Yes GO to C4

.

No

INSTALL a new speed control switchpack. CLEAR the DTC. TEST the system for normal operation.

C4

: CHECK FOR CONTINUITY THROUGH STEERING

WHEEL + AND - SWITCHES (SWITCHES OPEN)

Chec

k for continuity between SW02

, pins 06 (BO) and 04 (SR) with the steering wheel switches

inactive.

1

Is th

e circuit continuous?

Yes INSTALL a new speed control switchpack. CLEAR the DTC. TEST the system for normal operation.

No GO to C5

.

C5

: CHECK FOR CONTINUITY THROUGH STEER

ING WHEEL + SWITCH (SWITCH CLOSED)

Check f

or continuity between SW02, pins 06

(BO) and 04 (SR) with the steering wheel CANCEL

switch operated.

1

Is th

e circuit continuous?

Yes GO to C6

.

No

INSTALL a new speed control switchpack. CLEAR the DTC. TEST the system for normal operation.

C6

: CHECK FOR CONTINUITY THROUGH STEER

ING WHEEL - SWITCH (SWITCH CLOSED)

Check f

or continuity between SW02, pins 06

(BO) and 04 (SR) with the steering wheel CANCEL

switch operated.

1

Is th

e circuit continuous?

Yes GO to C7

.

No

INSTALL a new speed control switchpack. CLEAR the DTC. TEST the system for normal operation.

C7: CHECK THE STEERING

WHEEL CASSETTE

REEL FOR CONTINUITY (CIRCUIT #1)

Di

sconnect the steering wheel cassette electrical connector, SW01.

1

Meas

ure the resistance between SW01, pin 06

and SW02, pin 06 through the cassette reel.

2

Is th

e cassette reel continuous?

Yes GO to C8

.

No

INSTALL a new steering wheel cassette. CLEAR the DTC. TEST the system for normal operation.

C8: CHECK THE STEERING

WHEEL CASSETTE

REEL FOR CONTINUITY (CIRCUIT 2)

Meas

ure the resistance between SW01, pin 03

and SW02, pin 03 through the cassette reel.

1

Is th

e cassette reel continuous?

Yes GO to C9

.

No

INSTALL a new steering wheel cassette. CLEAR the DTC. TEST the system for normal operation.

C9: CHECK THE ECM

TO CASSETTE REEL

CIRCUIT FOR CONTINUITY (CIRCUIT 1)

Di

sconnect the battery negative terminal.

1

D

isconnect the ECM electrical connector, EM11.

2

Meas

ure the resistance between EM11, pin 01 (SR) and SW01, pin 04 (SR).

3

Page 1748 of 2490

Is the res

istance greater than 5 ohms?

Yes REPAIR the circuit. For additional information, refer to the wiring diagrams. CLEAR the DTC. TEST

the system for normal operation.

No GO to C10

.

C10: CHECK T H

E ECM TO CASSETTE REEL

CIRCUIT FOR CONTINUITY (CIRCUIT 2)

Measure t

he resistance between EM11,

pin 05 (SG) and SW01, pin 03 (SG).

1

Is the res

istance greater than 5 ohms?

Yes REPAIR the circuit. For additional information, refer to the wiring diagrams. CLEAR the DTC. TEST

the system for normal operation.

No Contact dealer technical support for advice on possible ECM failure.

PI

NPOINT TEST D : DTC P0

569; SPEED CONTROL DECEL/SET- SWITCH ON FAULT

WARN

ING: Where tests involve the removal of the steering

wheel, and/or disconnection of air bag connectors, the

procedure for disarming air bags must be followed,

REFER to: Air Bag Supplemental Re straint System (SRS)

(50

1-20B Supplemental Restra

int System, Description and

Operation).

TE S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

D1: CHECK

THE SPEED CONTROL SWITCHPACK IN

TERNAL CIRCUITS FOR SHORT TO GROUND

Disc

onnect the speed control switch

pack electrical connector, SW02.

1

Measure t

he resistance between SW

02, pin 06 (BO) and GROUND.

2

Measure t

he resistance between SW

02, pin 04 (SR) and GROUND.

3

Is either resistance le

ss than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to D2

.

D2: CHECK

THE SPEED CONTROL CASSE

TTE REEL FOR SHORT TO GROUND

Me

asure the resistance between SW02, pin 06 (at the cassette reel side of the connector) and

GROUND.

1

M e

asure the resistance between SW02, pin 04 (at the cassette reel side of the connector) and

GROUND.

2

Is either resi stance le

ss than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to D3

.

D3: CHECK

THE SPEED CONTROL DECEL/SET- SWITCH ACTION

Meas

ure t

he resistance between SW02,

pin 06 (BO) and SW02, pin 04 (SR).

1

Operate

the speed control

DECEL/SET- switch.

2

Do

es the resistance

vary by 680 ohms?

Yes Recheck DTCs. No short found. Po ssible intermittent fault. CLEAR the DTC. TEST the system for

normal operation.

No INSTALL a new speed control switchpack. CLEAR the DTC. TEST the system for normal operation.

PINPOI

NT TEST E : DTC P0570; SPEED CONTROL "ACCEL/SET+" SWITCH "ON" FAULT

WAR

N

ING: Where tests involve the removal of the steering

wheel, and/or disconnection of air bag connectors, the

procedure for disarming air bags must be followed,

REFER to: Air Bag Supplemental Re straint System (SRS)

(50

1-20B Supplemental Restra

int System, Description and

Operation).

TE S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

E1

: CHECK THE SPEED CONTROL

SWITCHPACK IN

TERNAL CIRCUITS FOR SHORT TO GROUND

Page 1749 of 2490

Di

sconnect the speed control switch

pack electrical connector, SW02.

1

Meas

ure the resistance between SW

02, pin 06 (BO) and GROUND.

2

Meas

ure the resistance between SW

02, pin 04 (SR) and GROUND.

3

Is either resi

stance

less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to E2

.

E2

: CHECK THE SPEED CONTROL CASSE

TTE REEL FOR SHORT TO GROUND

M

easure the resistance between SW02, pin 06 (at the cassette reel side of the connector) and

GROUND.

1

M

easure the resistance between SW02, pin 04 (at the cassette reel side of the connector) and

GROUND.

2

Is either resi

stance

less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to E3

.

E3

: CHECK THE SPEED CONTROL

ACCEL/SET+ SWITCH ACTION

Meas

ure the resistance between SW02,

pin 06 (BO) and SW02, pin 04 (SR).

1

Op

erate the cruise control

ACCEL/SET+ switch.

2

D

oes the resistance

vary by 430 ohms?

Yes Recheck DTCs. No short found. Po ssible intermittent fault. CLEAR the DTC. TEST the system for

normal operation.

No INSTALL a new speed control switchpack. CLEAR the DTC. TEST the system for normal operation.

P

INPOINT TEST F : DTC P1571;

BRAKE SWITCH MALFUNCTION

WAR

NING: Where tests involve the removal of the steering

wheel, and/or disconnection of air bag connectors, the

procedure for disarming air bags must be followed,

REFER to: Air Bag Supplemental Re straint System (SRS)

(501-20B Supplemental Restra

int System, Description and

Operation).

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

F1: CHECK THE BRAKE

SWITCH TO

ECM CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

Di

sconnect the brake switch electrical connector, AC24.

2

D

isconnect the ECM electrical connector, EM10.

3

Meas

ure the resistance between AC24,

pin 01 (US) and EM10, pin 10 (US).

4

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to F2

.

F2: CHECK THE BRAKE

SWITCH TO ECM

CIRCUIT FOR SHORT TO HIGH VOLTAGE

R

econnect the battery negative terminal.

1

Turn the ignition swi

tch to the ON

position.

2

M

easure the voltage between AC24, pin 01 (US) and GROUND.

3

Is th

e voltage greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to F3

.

F3: CHECK THE BRAKE

SWITCH TO

ECM CIRCUIT FOR SHORT TO GROUND

Turn the ignition swi

tch to the OFF

position.

1

Meas

ure the resistance between AC24, pin 01 (US) and GROUND.

2

Page 1750 of 2490

Is t

he resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to F4

.

F4: CHECK THE BRAKE SWITCH IGNITION SWIT

C

HED GROUND CIRCUIT FOR HIGH RESISTANCE

Di

sc

onnect the battery negative terminal.

1

Di

sc

onnect the brake switch electrical connector, AC24.

2

Di

sc

onnect the ignition switch electrical connector, FC04.

3

Measure t

he resistance between AC24,

pin 04 (WO) and FC04, pin 03 (WO).

4

Is the res

istance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to F5

.

F5: CHECK THE BRAKE SWITCH O

PERATION

Me

asure

the resistance between AC24, pins 01 and 04.

1

O

p

erate the brake pedal up and down.

2

Doe

s

the resistance switch between open circuit and continuity as the pedal is operated?

Yes GO to F6

.

No

INST

ALL a new brake switch. CLEAR the DTC.

TEST the system for normal operation.

F6: CHECK THE BRAKE CANCEL

SWITCH

TO ECM CIRCUIT FOR HIGH RESISTANCE

Disc

onnect the brake switch electrical connector, AC24.

1

D

i

sconnect the ECM electrical connector, EM10.

2

Me

asure

the resistance between AC24, pin 02 (PG) and EM10, pin 11 (PG).

3

Is th

e res

istance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to F7

.

F7: CHECK THE BRAKE CANCEL

SWITCH TO

ECM CIRCUIT FOR SHORT TO HIGH VOLTAGE

Re

connect the battery negative terminal.

1

Turn the ignition swi

t

ch to the ON

position.

2

Me

asure the voltage between AC24, pin 02 (PG) and GROUND.

3

Is th

e volt

age greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to F8

.

F8: CHECK THE BRAKE CANCEL

SWITCH

TO ECM CIRCUIT FO R SHORT TO GROUND

Turn the ignition swit

ch to the OFF

position.

1

Measure t

he resistance between AC24, pin 02 (PG) and GROUND.

2

Is

t

he resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to F9

.

F9: CHECK THE BRAKE CANCEL

SWITCH

TO CRUISE CONTROL SWITCH TO ECM CIRCUIT FOR HIGH RESISTANCE

Disc

onnect the battery negative terminal.

1

Di

sc

onnect the brake switch electrical connector, AC24.

2

D

i

sconnect the ECM electrical connector, EM11.

3

Di

sc

onnect the speed control switch electrical connector, FC63.

4

Me

asure

the resistance between AC24, pin 03 (WU) and EM11, pin 04 (WU).

5

Is th

e res

istance greater than 5 ohms?

Yes

Page 1758 of 2490

Climate Control System - General Informatio

n - Climate Control System

D

iagn

osis and Testing

I

n

troduction

It is very i

m

portant to positive

ly identify the area of concern before starting a rectification procedure. A little time spent with

your customer to identify the conditions under which a pr oblem occurs will be beneficial. See below for example:

Sym

ptom Chart

Re

lev

ant criteria are: Weather conditions,

ambient temperature, intermittent or cont inuous fault, airflow fault, temperature

control fault, distribution fault and air inlet problem.

Functio n

al Check

This

s

imple 'first line check' will allo

w you to ascertain whether the system is operating within its design parameters, withou t

recourse to PDU.

1. 1. With the engine at normal running temperature.

2. 2. Presss AUTO to display selected temperature and illuminate AUTO and A/C state lamps.

3. 3. Rotate FAN to increase or decrease lowe r speed, verify bar graph representation.

4. 4. Select A/C to toggle on or off. (T he compressor may be inhibited by the ECM should either the engine

temperature NOT be normal or the ambient be < 2° C).

5. 5. Select RECIRC , state lamp should be lit and the recirculation flaps open.

6. 6. Select distribution butt ons in turn, verify correct air distribution and relevant state lamp.

7. 7. Select DEFROST , check max fans and air to the windshield.

8. 8. Cycle TEMPERATURE to ' HI ' and ' LO ' to verify demanded variations and display operation. Note that extremes

will provide max heat or cold independent of in-car temperature.

9. 9. Select EXT to toggle between am bient and control temperatures.

10. 10. Select F (where fitted) and R - noting exterior mirror; verify timer and operation (glass may be warm to the

touch)

11. 11. Initiate system 'Self Test' to display stored faul ts should any of the above not perform as stated.

Sy

stem Symptoms

There

are five

basic symptoms associated

with air conditioning fault diagnosis.

The following conditions are not in order of priority.

Sy m

ptom

Possib

l

e Sources

Acti

o

n

N

o defrostN o

airflow to windshield

*

Check blower s and flaps

*

N o functi

on in defrost mode

*

Check A/CCM

*

Mo de s

election not available

*

Chec k

control panel communication

*

Ai rfl

ow OK but no heat

*

Check water pu

mp and valve

*

Page 1785 of 2490

Engine speed (valve closed with the engine not running) Demand (set) temperature In-car temperature sensor Solar sensor

Re-heating of the refrigerated air is contro lled by the time that the water valve is open (i.e. not energised) over a six secon d

interval. The duty cycle of the water valve, the time open / time closed, is controlled by the A/CCM.

Maximum heating demand will cause the water valve to be fu lly open (not energised) to allow maximum coolant flow

through the heater matrix.

At Maximum cooling, the water va lve will be fully closed (energised) to prevent hot (engine temperature) coolant entering

the heater circuit; the pump however will continue to circulate coolant through both the heater matrix and water valve

bypass.

The water valve defaults open when the ignition is OFF.

Under engine stall conditions, when ignition is ON, the water valve will be open.

Water Pump Assembly

Located in the same area as the water valve, the water pump continually circulates coolant through the heater matrix

except when the conditions below apply:

The engine coolant is below 16°C. The ignition is OFF. Under engine stall conditions, when ignition is ON. Control panel OFF

Non return valves

The heater bypass hose has a non-return valve, located between the engine feed and return hoses. The valve prevents the

water pump from recirculating coolant fro m the heater at low engine speeds.

The flow indicator arrow embossed on the valve bo dy MUST point towards the coolant header tank.

CAUTION: Coolant flow will be compromi sed if either valve is fitted incorrectly. Observe the correct direction.

A second non-return valve is located betw een the water pump and water valve. This valve prevents hot coolant from flowing

into the heater with the engine switched off. The flow indicator arrow MUST point towards the water pump.

Heater feed and return hoses

The heater feed and return hoses are connected to the engine feed and return hoses by 'Quick-Fit' connection unions. The

feed hose has a Norma R20 connector and the return hose a Norma push and seal connector. The coolant system bleed

joints have Cobra clamps. All remaining hose connections have spring band hose clamps.

The engine feed hose is connected to the engine bypass hous ing and the engine return hose is connected to the engine

water pump.

Clamp Identification

Page 1798 of 2490

Air Conditioning - Air Conditioning

Description and Operation

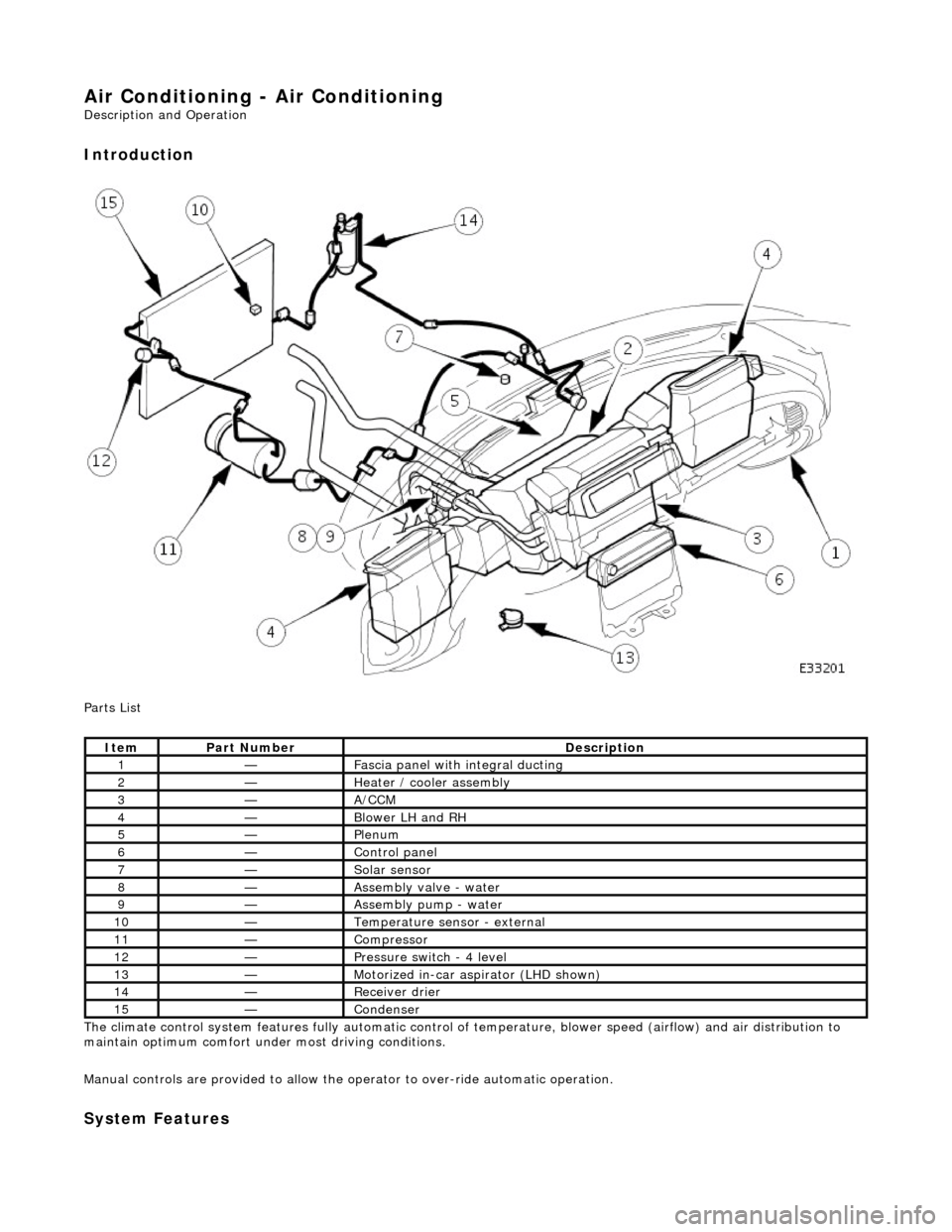

Introduction

Parts List

The climate control system features fully automatic control of temperature, blower speed (airflow) and air distribution to

maintain optimum comfort under most driving conditions.

Manual controls are provided to allow the operator to over-ride automatic operation.

System Features

ItemPart NumberDescription

1—Fascia panel with integral ducting

2—Heater / cooler assembly

3—A/CCM

4—Blower LH and RH

5—Plenum

6—Control panel

7—Solar sensor

8—Assembly valve - water

9—Assembly pump - water

10—Temperature sensor - external

11—Compressor

12—Pressure switch - 4 level

13—Motorized in-car aspirator (LHD shown)

14—Receiver drier

15—Condenser

Page 1799 of 2490

Twin blower assemblies Center mounted evaporator, heater and air distribution unit Electric solenoid water valve controlled heating Electric water pump assembly Servo motor driven air distribution flaps Dedicated side glass defrost / demist vents External temperature sensor Motorised in-car aspirator Solar sensor

Electronic Control Panel

Liquid Crystal Display (LCD) Digital temperature display Manual fan speed level External temperature display Celsius / Fahrenheit selection Heated windshield switch (where fitted) Heated backlight switch Defrost switch Manual airflow distribution overrides (4) Access to self diagnostic system and error codes

Sensors

External ambient temperature sensor Motorized in-car aspirator Heater matrix temperature sensor Evaporator temperature sensor Solar sensor

These sensors feedback information to the Air Conditioning Control Module (A/CCM) which automatically adjusts air

temperature, airflow volume and distributi on from the air conditioning unit to maintain a stable passenger compartment

average temperature under changing weather conditions.

Major Components

Page 1821 of 2490

Control Components - Control Components

Description and Operation

System Controls

The climate control system is controlled by : 1. 1. Manual input from the operator, via the center console located control panel.

2. 2. Automatically by means of the A/CCM.

Output is based upon input from the following devices:

Motorized In-car aspirator External air temperature sensor Coolant temperature sensor Heater 'air-off' (the temperature of the air leaving the matrix fins) temperature sensor Evaporator 'air-off' (the temperature of the air leaving the evaporator fins) temperature sensor Solar sensor Left hand blower recirculation / fresh air flap potentiometer Right hand blower recirculation / fresh air flap potentiometer Upper air distribution box (ADB) center and side face flap servomotor potentiometer ADB defrost flap servomotor potentiometer Air conditioning unit Foot flap servomotor potentiometer Air conditioning unit Cool Air Bypass flap servomotor potentiometer Thumbwheel controls on the facia vent assemblies which provide manu al adjustment of the airflow volume. Road and engine speed signals input to the A/CCM

Climate Control Panel

Communication between the control panel and the A/CCM is via a serial data communications link.

Switching the Climate Control system ON

The climate control system can be switched ON by pressing one of the following :

Ref #1 On / Off (resumes the system on in the previous settings).

Ref #10 A / C (resumes the system on in the previous settings).

Ref #11 AUTO (resumes the system on at the previous temperature setting).