Front seat JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 3 of 2490

Rear Toe Adjustment (57.65. 08)

Whee

l

Bearing Circlip Inspection

Wheel Bearing Inspection

204‐01: Front Suspension

Specification

Description and Operation

Front Suspension

Removal and Installation

Ball Joint (60.15.02)

Rear Lower Arm (60.35.54)

Rear Lower Arm Bushing (60.35.56)

Front Shock Absorber (60.30.04)

Spring

Spring Seat (60.20.03)

Front Sta

bilizer Bar (60.10.01)

Front Stabilizer Bar Bushing (60.10.04)

Front Stabilizer Bar Link (60.10.02)

Upper Arm Bushing

Front Wheel Bearing (60.25.40)

Wheel Hub

Wheel Knuckle (60.25.23)

Wheel Knuckle and Wheel Hub Assembly (60.25.38.90)

Wheel Knuckle and Wheel Hub Assembly Conversion (60.25.43)

204‐02: Rear Suspension

Specif

ication

Description and Operation

Rear Suspension

Removal and Installation

Axle Bump Stop (64.30.15)

Rear Suspension and Axle Assembly (64.25.01)

Rear Shock Absorber (64.30.02)

Shock Absorber Lower Bushing (64.30.39)

Spring (64.20.01)

Rear Stabilizer Bar (64.35.08) ‐ 4.0L SC V8 ‐ AJ26

Rear Stabilizer Bar Bushing (64.35.18) ‐ 4.0L SC V8 ‐ AJ26

Page 27 of 2490

419:

Electronic Featu r

e

Group

419

‐10:

Multifunction Electronic Modules

Removal

and Installation

Driver

Seat Module (DSM) (86.75.28)

5: Body and Paint

501: Body and Paint

501‐00: Body System ‐ Gen

eral Information

Specification

Description and Operation

Body

501‐02: Front End Body Panels

Description and Operation

Front End Body Panels

Removal and Installation

Cowl Panel Grille (76.10.01) (76.43.39)

Driver Side Bulkhead Cover (76.11.34)

Passenger Side Bulkhead Cover (76.11.33)

Radiator Grille Opening Panel (76.10.06)

Radiator Grille Ope

ning Panel Reinforcement (76.11.24)

Radiator Splash Shield (76.22.90)

501‐03: Body Closures

Description and Operation

Body Closures

General Procedures

Hood Alignment (76.16.02)

Diagnosi

s

and Testing

(FDM)

Front

Door Module

(86.80.34)

Rear

(RDM)

Door

Module

Page 30 of 2490

501‐10: Seating

Specificatio

n

Description and Operation

Seats

Removal and Installation

Front Seat (76.70.01)

Front Seat Backrest (76.70.06)

Front Seat Backrest Cover (76.70.15)

Front Seat Backrest Heater Mat (86.75.14)

Front Seat Backrest Trim Panel (76.70.03)

Front Seat Cushion (76.70.11)

Front Seat Cushion Cover (76.70.33)

Front Sea

t Cushion Heater Mat (86.75.13)

Front Seat Head Restraint (76.70.14)

Front Seat Head Restraint Motor (86.75.17)

Front Seat Recliner Motor (86.75.04)

Front Seat Track (76.70.20)

Front Seat Track Motor (86.75.33)

Lumbar Motor (86.75.12)

Rear Seat Armrest (76.70.39)

Rear Seat Backrest (76.70.38)

Rear Seat Backrest Cover (76.70.48) (78.90.12)

Rear Seat Backrest Heater Mat (86.75.35)

Rear Seat Cushio

n (76.70.37)

Rear Seat Cushion Cover (76.70.47)

Rear Seat Cushion Heater Mat (86.75.37)

Rear Seat Head Restraint (76.70.56)

Rear Seat Track

Seat Control Switch (86.75.23)

501‐11: Glass, Frames and Mechanisms

Description and Operation

Glass, Fra

mes and Mechanisms

Removal and Installation

Door Window Control Switch Bulb (86.46.12)

Front Door Window Glass (76.31.01)

Front Door Window Glass Weatherstrip (76.40.28)

Page 38 of 2490

Torque Specifications

Torque sp

ecifications are shown in maintenance procedure illustra

tions and also in the torque specifications chart located at

the front of the relevant section.

Disconnecting/Connecting the Battery

Ow ing t

o the electronic components used on the vehicle, it is important that the battery is disconnected when specified in a

maintenance procedure.

When the battery is connected, the specified procedure must be followed, to ensure the correct operation of all vehicle

systems; refer to Section 414-01.

Use of Control Modules

Control modu les may

only be used on the ve

hicle to which they were originally fitted. Do not attempt to use or test a control

module on any other vehicle.

Function

al Test

On

completion of a maintenance procedure, a thorough test should be carried out, to ensu

re that the relevant vehicle

systems are working correctly.

Protecting the Vehicle

Al ways

fit covers to protect

the fenders before commencing work in the engi ne compartment. Cover the seats and carpets,

wear clean overalls and wash hands or wear gloves before working inside the vehicle. Avoid spilling hydraulic fluid,

antifreeze or battery acid on the paintwork. In the event of spillage, wash off with water imme diately. Use polythene sheets

in the trunk to protect carpets. Always use the recommended service tool, or a satisfactory equivalent, where specified.

Protect temporarily exposed screw thread s by replacing nuts or fitting caps.

Preparation

Before disassembly, clean the surrounding ar ea

as thoroughly as possible. When co

mponents have been removed, blank off

any exposed openings using grease-proof paper and masking tape. Immediately seal fuel, oil and hydraulic lines when

separated, using plastic caps or plugs, to prevent loss of fluid and the entry of dirt. Close the open ends of oilways, exposed

by component removal, with tapered hardw ood plugs or readily visible plastic plugs. Immediately a component is removed,

place it in a suitable container; use a se parate container for each component and its associated pa rts. Before dismantling a

component, clean it thoroughly with a recommended cleaning agent; check that the agent will not damage any of the

materials within the component. Clean the bench and obtain ma rking materials, labels, containers and locking wire before

dismantling a component.

Dismantling

O b

serve scrupulous cleanliness when dismantling components,

particularly when parts of the brake, fuel or hydraulic

systems are being worked on. A particle of dirt or a fragment of cloth could caus e a dangerous malfunction if trapped in

these systems. Clean all tapped holes, crev ices, oilways and fluid passages with compressed air. Do not permit compressed

air to enter an open wound. Always use ey e protection when using compressed air.

Ensure that any O-rings used for sealing are correctly refitted or renewed if disturbed. Mark mating parts to ensure that

they are replaced as dismantled. Whenever possible use markin g materials which avoid the possibilities of causing distortion

or the initiation of cracks, which could occur if a center pu nch or scriber were used. Wire together mating parts where

necessary to prevent accidental interchange (e.g roller bearing components). Tie labels on to all parts to be renewed and to

parts requiring further inspection before being passed fo r reassembly. Place labelled parts and other parts for rebuild in

separate containers. Do not disc ard a part which is due for renewal until it ha s been compared with the new part, to ensure

that the correct part has been obtained.

Page 42 of 2490

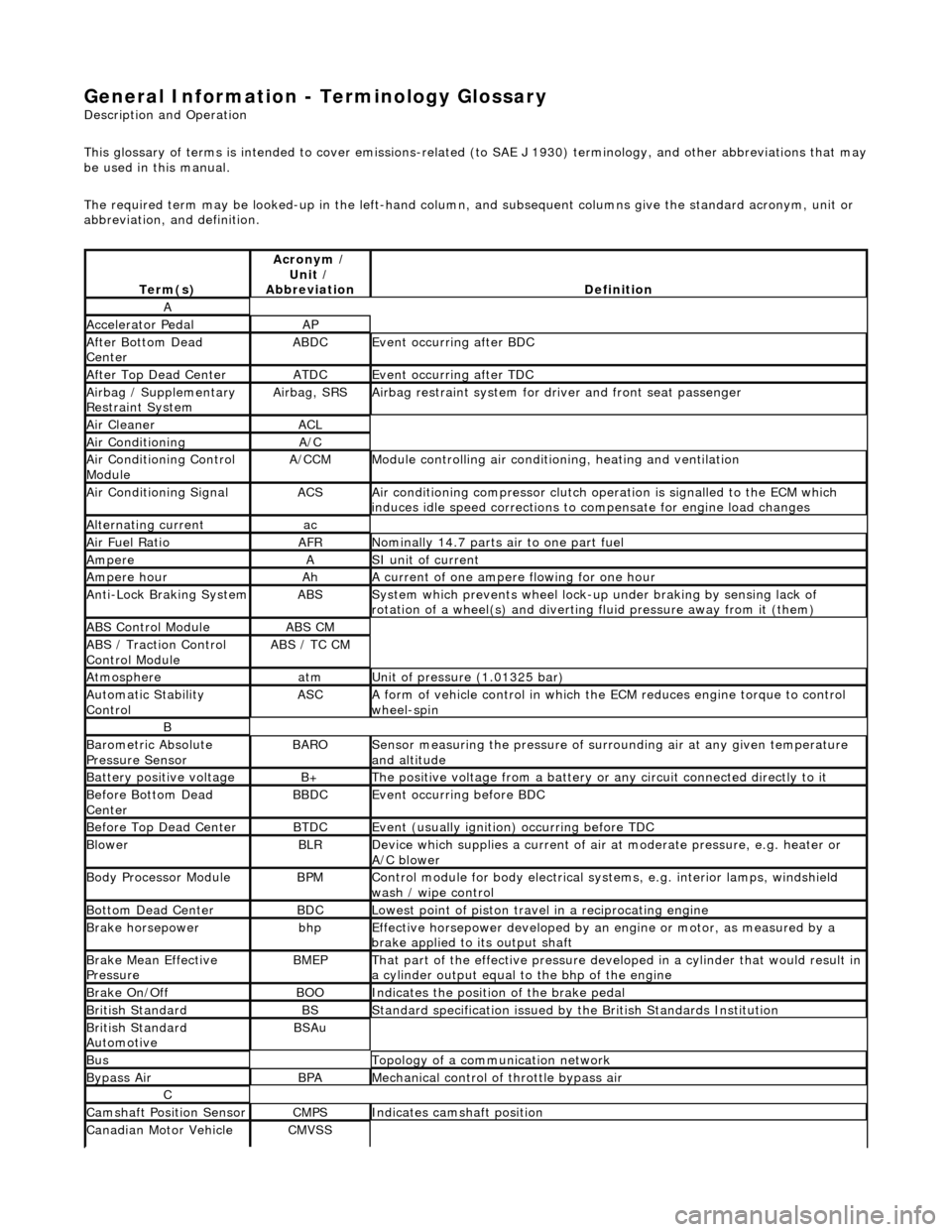

General Information - Terminology Glossary

Description an

d Operation

This glossary of terms is intended to cover emissions-related (to SAE J 1930) term inology, and other abbreviations that may

be used in this manual.

The required term may be looked-up in th e left-hand column, and subsequent columns give the standard acronym, unit or

abbreviation, and definition.

Te rm

(s)

Acr

ony

m /

Unit /

Abbreviation

De fi

nition

A

Accel

e

rator Pedal

AP

Af

ter Botto

m Dead

Center

ABDCEvent occurri ng after

BDC

Af

ter Top Dead CenterATDCEvent occurri ng after

TDC

Ai

rbag /

Supplementary

Restraint System

Airbag, SRSAi rbag restraint system for

dr

iver and front seat passenger

Air Cleane rACL

Air ConditioningA/C

Air Conditioning Con t

rol

Module

A/CCMModule c

ontrolling air conditioning, heating and ventilation

Air Conditioning SignalACSA

i

r conditioning compressor clutch operation is signalled to the ECM which

induces idle speed corrections to co mpensate for engine load changes

Alternating cu

rrent

ac

Ai

r Fuel R

atio

AFRN

omi

nally 14.7 parts air to one part fuel

Ampe

reASI unit of current

Ampere hourAhA current of one ampere

fl

owing for one hour

Anti-Lock Braking SystemABSS

y

stem which prevents wheel lock-up

under braking by sensing lack of

rotation of a wheel(s) and divertin g fluid pressure away from it (them)

ABS Control Mo

dule

ABS CM

ABS /

T

raction Control

Control Module

ABS / T

C CM

Atmosph

e

re

atmU

n

it of pressure (1.01325 bar)

Au

to

matic Stability

Control

ASCA form of vehicle

control

in which the ECM reduces en gine torque to control

wheel-spin

B

Baro me

tric Absolute

Pressure Sensor

BAR OSensor measuring the pressure of surr ou

nding air at any given temperature

and altitude

Bat t

ery positive voltage

B+The posi

ti

ve voltage from a battery or

any circuit connected directly to it

Before Bottom Dead

CenterBBDCEvent occurri ng before BD

C

Before Top Dead

Center

BTD

CEvent (usual ly

ignition) occurring before TDC

Blowe

rBLRDe

vice which supplies a current of air at

moderate pressure, e.g. heater or

A/C blower

Body Processor M

odule

BPMControl modu

le

for body electrical systems, e.g. interior lamps, windshield

wash / wipe control

Bott om D

ead Center

BD

CLowest poin t of piston

travel in a reciprocating engine

Brake hors

epowe

r

bhpEffecti

ve horsepower devel

oped by an

engine or motor, as measured by a

brake applied to its output shaft

Brake Mean Effective

Pres sureBME PThat p

art of the effective

pressure developed in a cyli nder that would result in

a cylinder output equal to the bhp of the engine

Brake On/ O

ff

BOOIn

dic

ates the position of the brake pedal

Br

it

ish Standard

BSStan

dar

d specification issued by the British Standards Institution

Br

it

ish Standard

Automotive

BSAu

BusTopology of a commu n

ication network

Bypass

AirBPAMechanica l

control of throttle bypass air

C

Camshaft Posit

i

on Sensor

CMPSIndi

cat

es camshaft position

Canadian Motor

V

ehicle

CMVSS

Page 70 of 2490

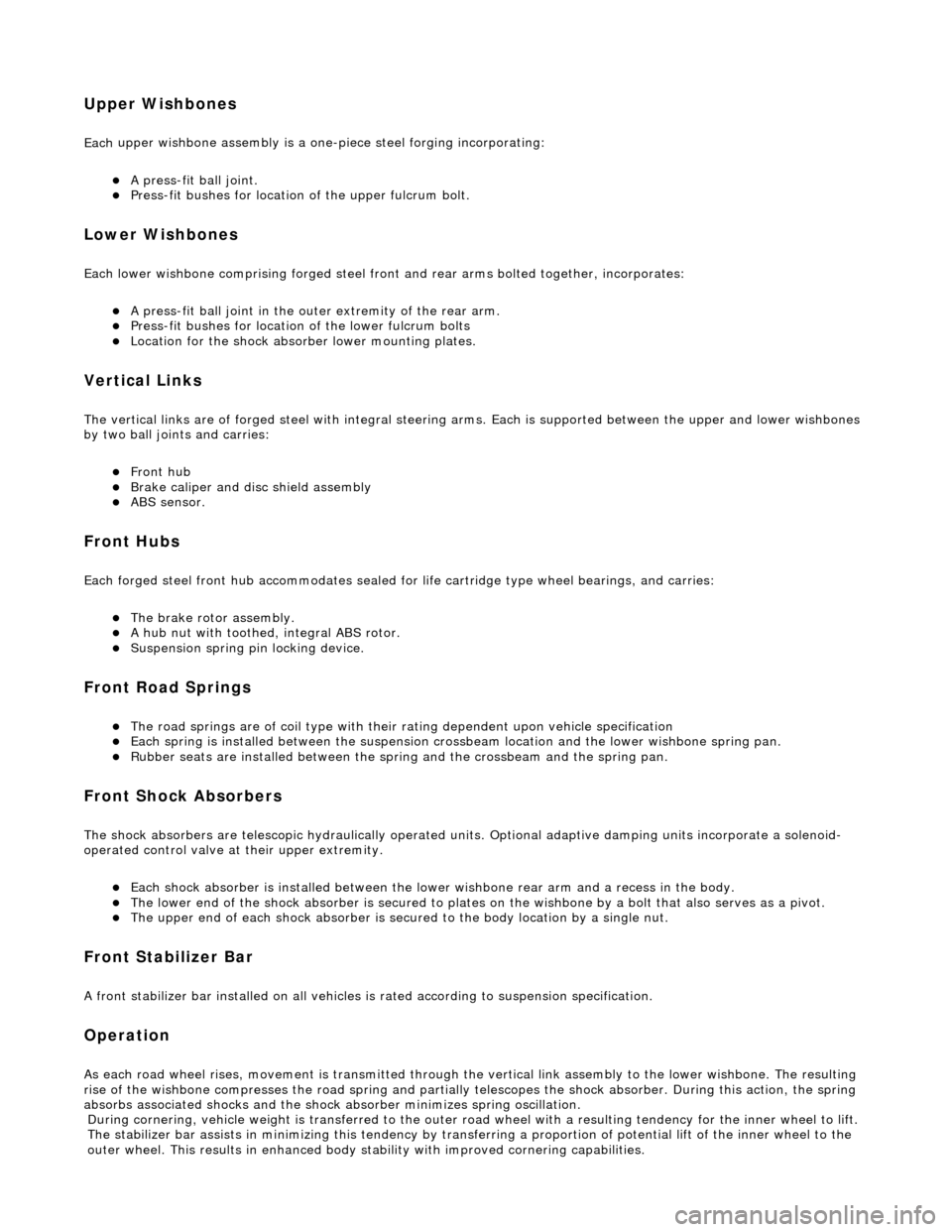

Upper

Wishbones

Each

upper wi

shbone assembly is a on

e-piece steel forging incorporating:

A pres

s-fit ball joint.

Press-fi

t bushes for location of the upper fulcrum bolt.

Lower Wishbones

Each l

o

wer wishbone comprising

forged steel front and rear arms bolted together, incorporates:

A p

ress-fit ball joint in the outer extremity of the rear arm.

Press-f

i

t bushes for location of the lower fulcrum bolts

Locati

on for the shock absor

b

er lower mounting plates.

Vertica l Links

The vertical

links are of forged steel

wi

th integral steering arms. Each is suppo rted between the upper and lower wishbones

by two ball joints and carries:

Front hub

Brake ca

liper and disc shield assembly

ABS se

nsor

.

Front Hub

s

Each f

o

rged steel front hub accommodates sealed for life cartridge

type wheel bearings, and carries:

The brake rotor assembl

y.

A

h

ub nut with toothed, integral ABS rotor.

Su

s

pension spring pi

n locking device.

Front Road

Springs

The road spri

ng

s are of coil type with their

rating dependent upon vehicle specification

Ea

ch spring is installed between the suspension crossbeam location and the lower wishbone spring pan.

Ru

bber seats ar

e installed betw

een the spring and the crossb eam and the spring pan.

Front Shock A

bsorbers

Th

e

shock absorbers are telescopic hydrau

lically operated units. Optional adaptive damping units incorporate a solenoid-

operated control valve at their upper extremity.

Each shoc

k absorber is installed between the lowe

r wishbone rear arm and a recess in the body.

The l

o

wer end of the shock absorber is se

cured to plates on the wishbone by a bolt that also serves as a pivot.

The u

pper en

d of each shock absorber is secured to the body location by a single nut.

Front Sta

b

ilizer Bar

A

front stabil

izer bar installed on all vehicles

is rated according to suspension specification.

Opera

tion

As each road wheel r

i

ses, move

ment is transmitted through the vertical link assembly to the lower wishbone. The resulting

rise of the wishbone compresses the road spring and partially telescopes the shock absorber. During this action, the spring

absorbs associated shocks and the shock absorber minimizes sprin

g os c

illation.

Du

ring cornering, vehicle weight

is transferred to the outer road wheel with a resulting tendency for the inner wheel to lift.

The stabilizer bar assists in minimizing this tendency by transf erring a proportion of potential lift of the inner wheel to the

outer wheel. This result s in enhanced body stability with improved corner ing capabilities.

Page 113 of 2490

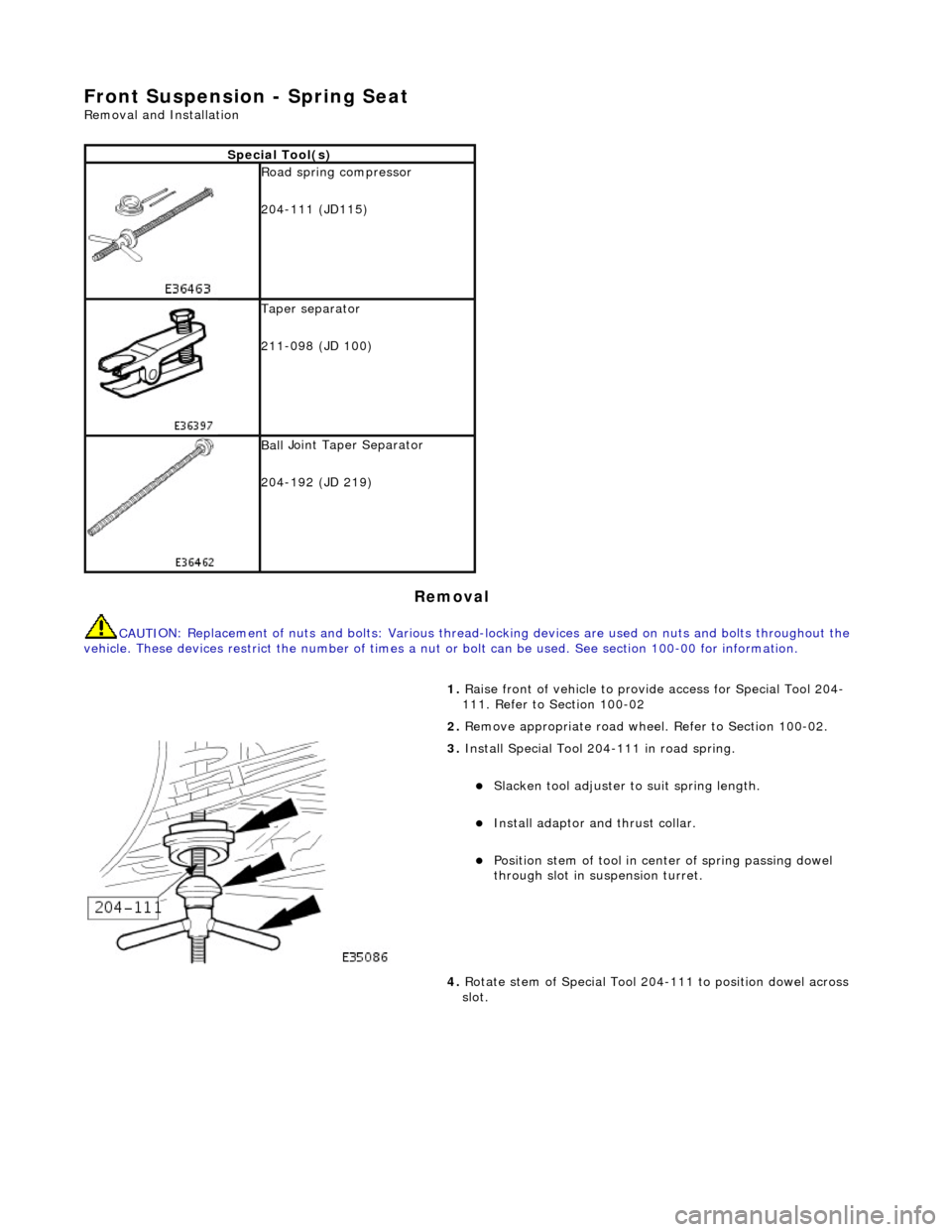

Front Suspension - Spring Seat

Re

moval and Installation

Remov

al

CAUTI

ON: Replacement of

nuts and bolts: Various thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

S

pecial Tool(s)

R

oad spring compressor

204-111 (JD115)

Taper separator

211-098 (JD 100)

Ball

Joint Taper Separator

204-192 (JD 219)

1. R

aise front of vehicle to provid

e access for Special Tool 204-

111. Refer to Section 100-02

2. Remove appropriate road wheel. Refer to Section 100-02.

3. Ins

tall Special Tool 204-111 in road spring.

Sl

acken tool adjuster to suit spring length.

Install adaptor

and thrust collar.

Posit

ion stem of tool in center of spring passing dowel

through slot in su spension turret.

4. Rotate stem of Special Tool 204-111 to position dowel across

slot.

Page 343 of 2490

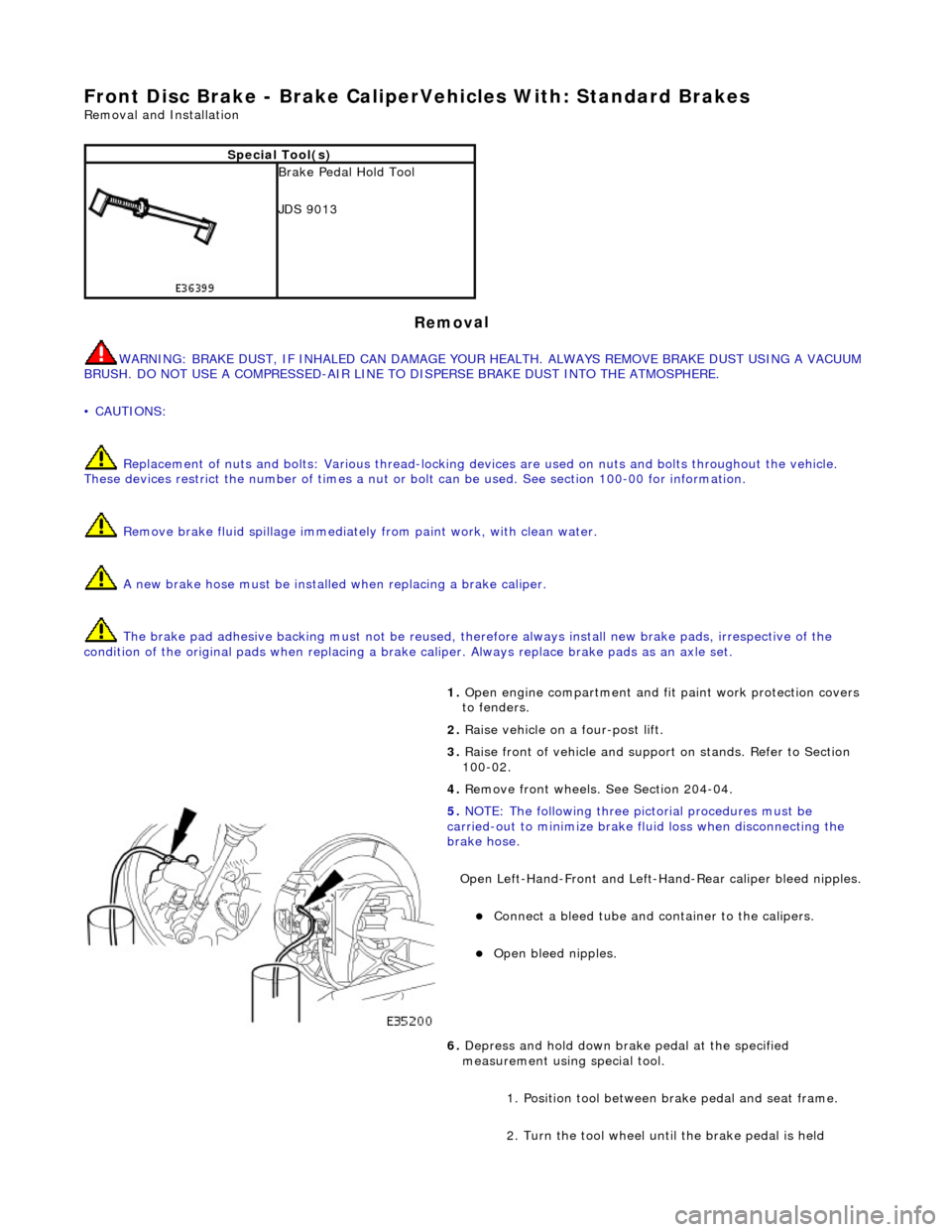

Front Disc Brake - Brake CaliperVehicles

With: Standard Brakes

Re

moval and Installation

Remov

al

W

ARNING: BRAKE DUST, IF INHALED CAN DAMAGE YOUR

HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM

BRUSH. DO NOT USE A COMPRESSED-AIR LINE TO DISPERSE BRAKE DUST INTO THE ATMOSPHERE.

• CAUTIONS:

Replacement of nuts and bolts: Various thread-locking de vices are used on nuts and bolts throughout the vehicle.

These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

Remove brake fluid spilla ge immediately from paint work, with clean water.

A new brake hose must be installe d when replacing a brake caliper.

The brake pad adhesive backing must not be reused, therefore always install new brake pads, irrespective of the

condition of the original pads when replacing a brake caliper. Always replace brake pads as an axle set.

S

pecial Tool(s)

Brake Pedal

Hold Tool

JDS 9013

1. O

pen engine compartment and fit

paint work protection covers

to fenders.

2. Raise vehicle on a four-post lift.

3. Raise front of vehicle and support on stands. Refer to Section

100-02.

4. Remove front wheels. See Section 204-04.

5. NOTE

: The following three pictorial procedures must be

carried-out to minimize brake fl uid loss when disconnecting the

brake hose.

Open Left-Hand-Front and Left-H and-Rear caliper bleed nipples.

Connect

a bleed tube and co

ntainer to the calipers.

O

pen bleed nipples.

6. Depress and hold down brak e pedal at the specified

measurement using special tool.

1. Position tool between brake pedal and seat frame.

2. Turn the tool wheel unti l the brake pedal is held

Page 368 of 2490

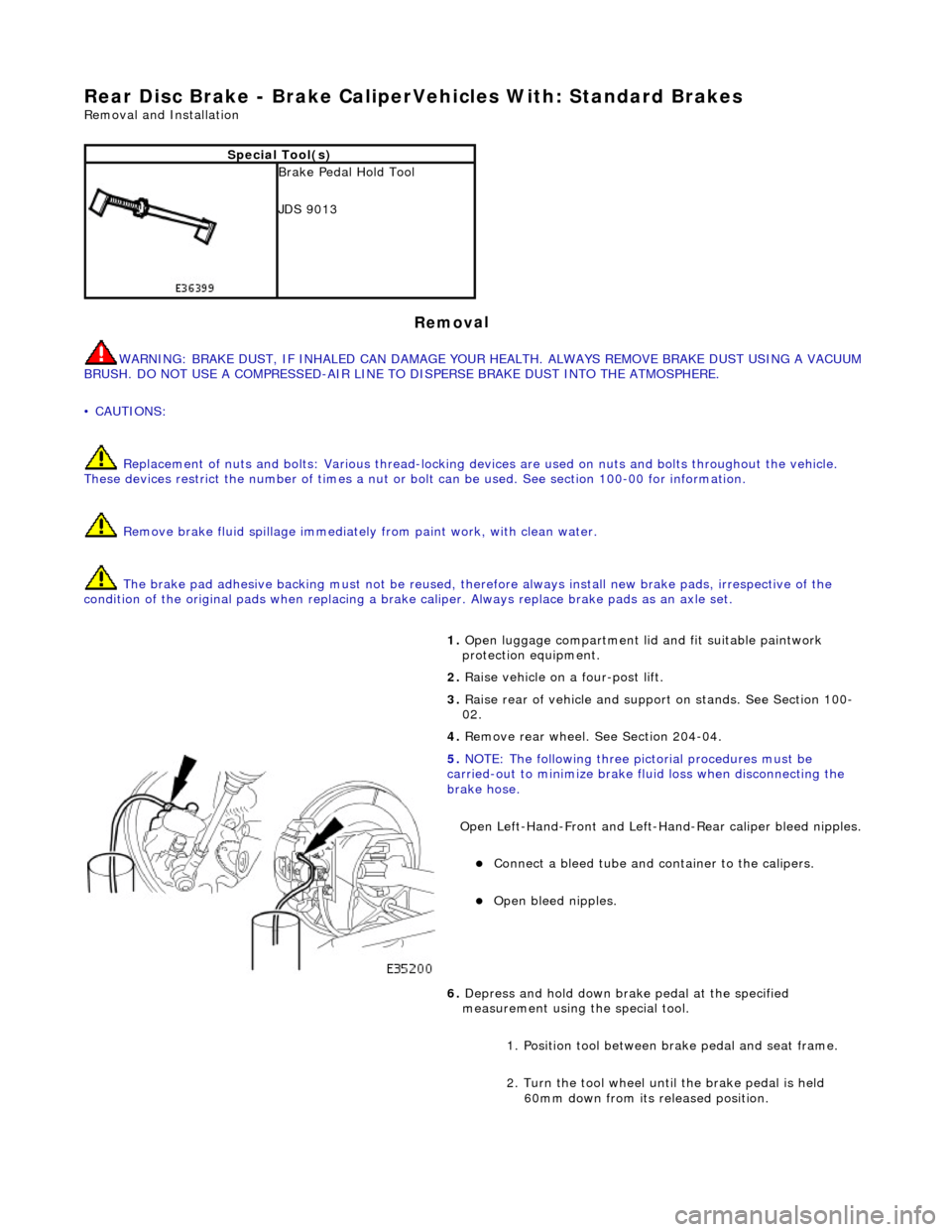

Rear Disc Brake - Brake CaliperVehicles W

ith: Standard Brakes

Re

mo

val and Installation

Remov

a

l

WA

RNING: BRAKE DUST, IF INHALED CAN DAMAGE YOUR

HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM

BRUSH. DO NOT USE A COMPRESSED-AIR LINE TO DISPERSE BRAKE DUST INTO THE ATMOSPHERE.

• CAUTIONS:

Replacement of nuts and bolts: Various thread-locking de vices are used on nuts and bolts throughout the vehicle.

These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

Remove brake fluid spilla ge immediately from paint work, with clean water.

The brake pad adhesive backing must not be reused, therefore always install new brake pads, irrespective of the

condition of the original pads when replacing a brake caliper. Always replace brake pads as an axle set.

Sp

ecial Tool(s)

Brake Pedal

H

old Tool

JDS 9013

1. Op

en luggage compartment lid and fit suitable paintwork

protection equipment.

2. Raise vehicle on a four-post lift.

3. Raise rear of vehicl e and support on stan ds. See Section 100-

02.

4. Remove rear wheel. See Section 204-04.

5. NOTE

: Th

e following three pictorial procedures must be

carried-out to minimize brake fl uid loss when disconnecting the

brake hose.

Open Left-Hand-Front and Left-H and-Rear caliper bleed nipples.

Connect a

bleed tube and co

ntainer to the calipers.

Op

en bleed nipples.

6. Depress and hold down brak e pedal at the specified

measurement using the special tool.

1. Position tool between brake pedal and seat frame.

2. Turn the tool wheel unti l the brake pedal is held

60mm down from its released position.

Page 401 of 2490

I

nstallation

1

. Remove upper return spring.

2. Remove lower return spring.

9. Remove brake dust and clean components, see WARNING

above.

10. Repeat procedure to remove pa rking brake shoes on opposite

side of vehicle.

1. I

nstall brake shoes to vehicle.

Install brake shoes to parkin

g brake lever-me

chanism in

the arrangement shown.

2. N

OTE: Make sure retaining pin is seated correctly in backing

plate.

Install rear shoe retaining pin.

Align hu

b access hole.

Inst

all retaining pin.

3. Inst

all adjuster assembly.

Lubricate adjuster

mechanism

with appropriate grease.

Move

front shoe forwards.

Inst

all adjuster assembly.

4. NOTE: Make sure retaining pin is seated correctly in backing