body mounting JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 34 of 2490

501‐20B : Supp l

emental

Restraint System

Specification

Description and Operation

Air Bag Supplemental Restraint System (SRS)

Removal and Installation

Air Bag Control Module (76.73.41)

Driver Air Bag Module (76.73.39)

Passenger Air Bag Module (76.73.37)

Side Air Bag Module (76.73.47)

Side Impact Sensor (76.73.53)

501‐25: Body Repairs ‐ Genera

l Information

Description and Operation

Body Repairs

502: Frame and Mounting

502‐00: Uni ‐Body, Subframe and Mounting System

Removal and Installation

Front Axle Crossmember

Front Axle Crossmember Front Bushing (60.35.24)

Front Axle Crossmember Front Bushing Heat Shield (60.35.37)

Front Axle Crossmember Rear Bushing (

60.35.26)

Rear Axle Crossmember (64.25.16)

Rear Axle Crossmember Bushing (64.25.02)

Page 67 of 2490

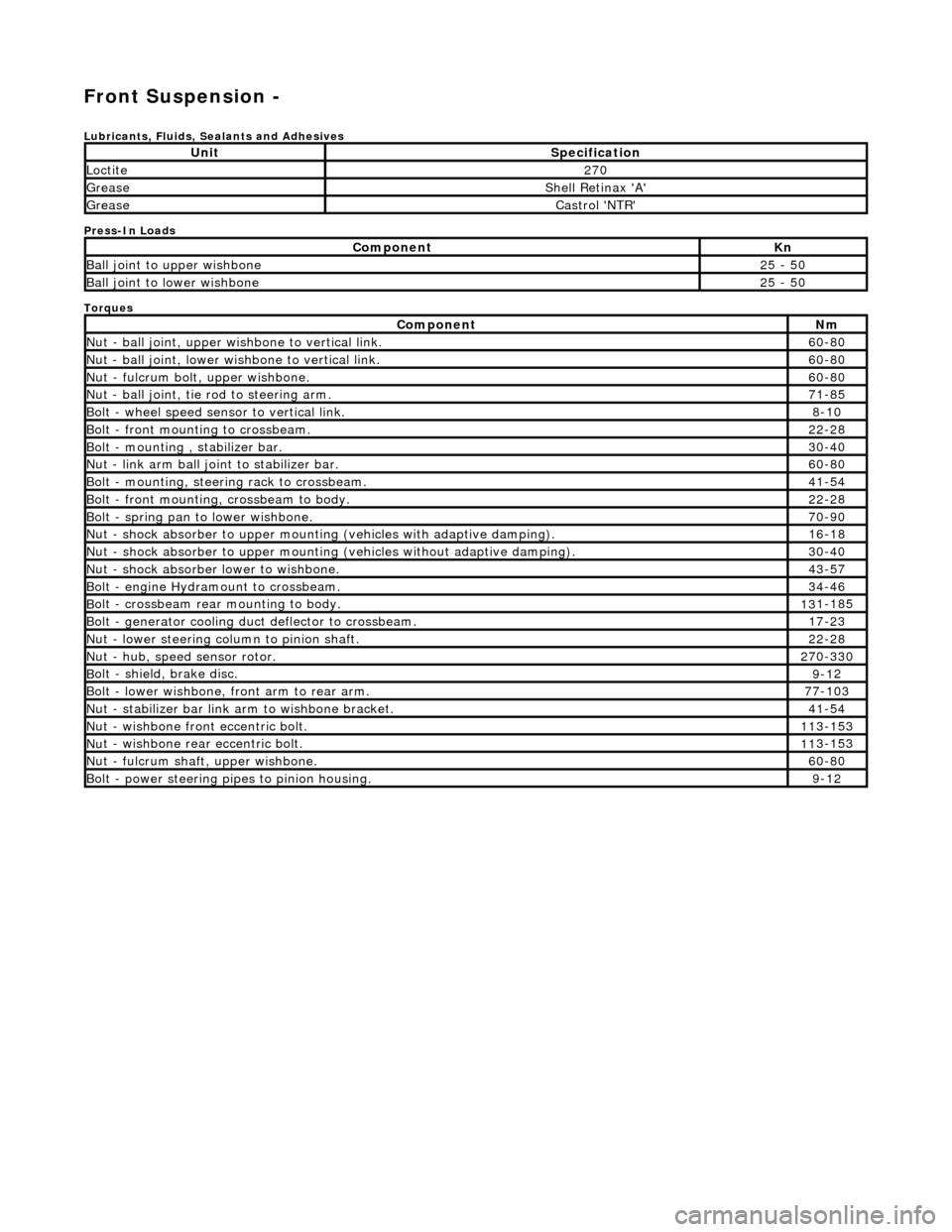

Front Suspension -

Lubri

cants, Fluids, Sealants and Adhesives

Press-In Loads

Torques

UnitS

pecification

Loctite27

0

Greas

e

Shell Retin

ax 'A'

Greas

e

Castro

l 'NTR'

Com

ponent

Kn

Ball join

t to upper wishbone

25

- 50

B

all joint to lower wishbone

25

- 50

Com

ponent

Nm

N

ut - ball joint, upper wishbone to vertical link.

60

-80

N

ut - ball joint, lower wishbone to vertical link.

60

-80

Nu

t - fulcrum bolt, upper wishbone.

60

-80

N

ut - ball joint, tie rod to steering arm.

71

-85

Bol

t - wheel speed sensor to vertical link.

8-1

0

Bol

t - front mounting to crossbeam.

22

-28

Bolt

- mounting , stabilizer bar.

30

-40

N

ut - link arm ball joint to stabilizer bar.

60

-80

Bolt

- mounting, steering rack to crossbeam.

41

-54

B

olt - front mounting, crossbeam to body.

22

-28

Bol

t - spring pan to lower wishbone.

70

-90

N

ut - shock absorber to upper mounting

(vehicles with adaptive damping).

16

-18

Nu

t - shock absorber to upper mounting (vehicles without adaptive damping).

30

-40

N

ut - shock absorber lower to wishbone.

43

-57

B

olt - engine Hydramount to crossbeam.

34

-46

B

olt - crossbeam rear mounting to body.

13

1-185

Bol

t - generator cooling du

ct deflector to crossbeam.

17

-23

N

ut - lower steering column to pinion shaft.

22

-28

N

ut - hub, speed sensor rotor.

27

0-330

B

olt - shield, brake disc.

9-1

2

Bol

t - lower wishbone, front arm to rear arm.

77

-103

Nu

t - stabilizer bar link arm to wishbone bracket.

41

-54

N

ut - wishbone front

eccentric bolt.

11

3-153

Nu

t - wishbone rear

eccentric bolt.

11

3-153

N

ut - fulcrum shaft, upper wishbone.

60

-80

Bolt -

power steering pi

pes to pinion housing.

9-1

2

Page 69 of 2490

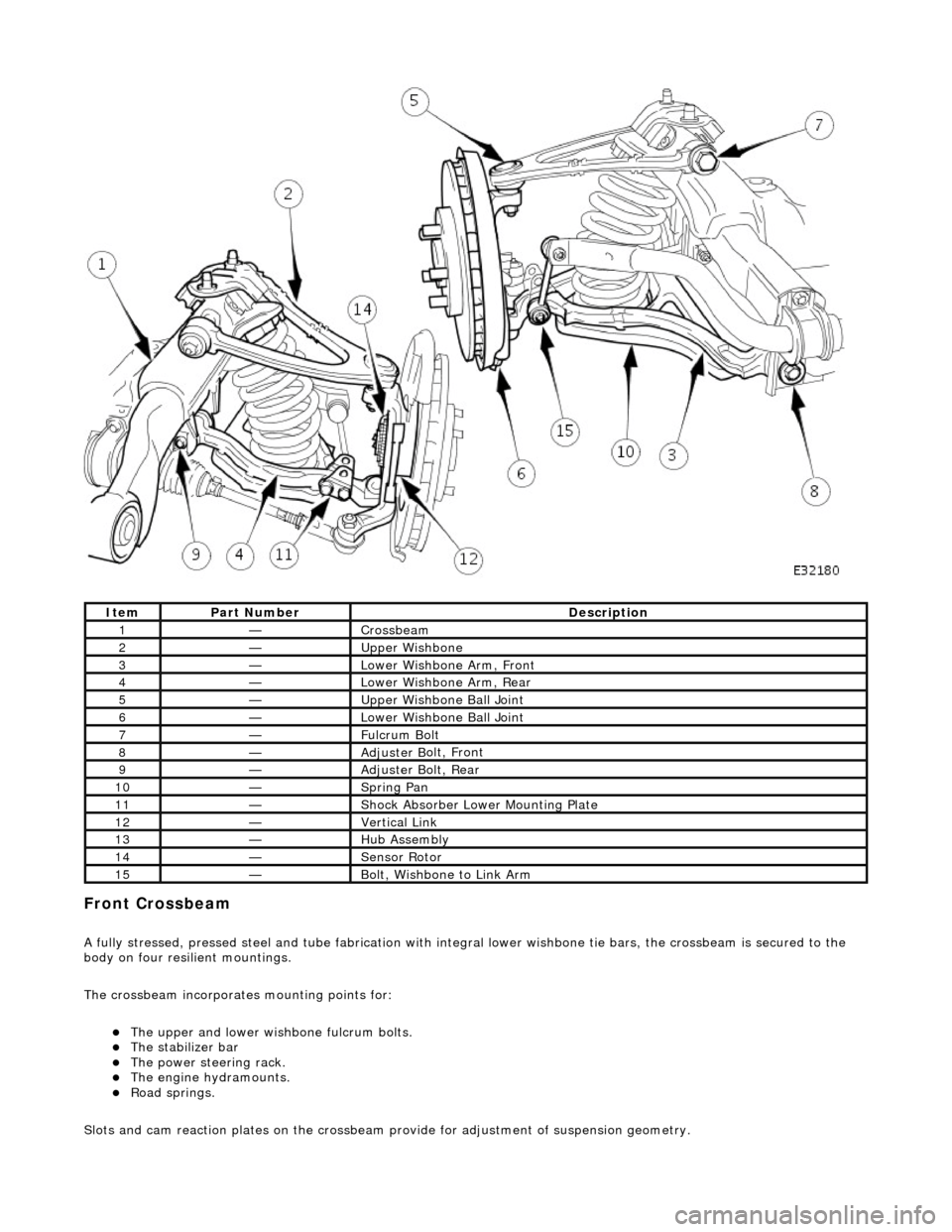

Front C

rossbeam

A

fully stressed, pressed steel and tube fa

brication with integral lower wishbone tie bars, the crossbeam is secured to the

body on four resilient mountings.

The crossbeam incorporates mounting points for:

The u

pper and lower wish

bone fulcrum bolts.

The

stabilizer bar

The power steering rack. The engine h

ydramounts.

R

oad springs.

Slots and cam reaction pl ates on the crossbeam provide for ad justment of suspension geometry.

It

em

Par

t Number

De

scription

1—Cro

ssbeam

2—Upper

Wishbone

3—Lower Wi

shbone Arm, Front

4—Lower Wi

shbone Arm, Rear

5—Upper

Wishbone Ball Joint

6—Lower Wi

shbone Ball Joint

7—Ful

crum Bolt

8—Adjuster B

olt, Front

9—Adjuster B

olt, Rear

10—S

pring Pan

11—Shock Absorber Lower M

ounting Plate

12—Vertical Link

13—Hub Assembly

14—Sensor R

otor

15—B

olt, Wishbone to Link Arm

Page 70 of 2490

Upper

Wishbones

Each

upper wi

shbone assembly is a on

e-piece steel forging incorporating:

A pres

s-fit ball joint.

Press-fi

t bushes for location of the upper fulcrum bolt.

Lower Wishbones

Each l

o

wer wishbone comprising

forged steel front and rear arms bolted together, incorporates:

A p

ress-fit ball joint in the outer extremity of the rear arm.

Press-f

i

t bushes for location of the lower fulcrum bolts

Locati

on for the shock absor

b

er lower mounting plates.

Vertica l Links

The vertical

links are of forged steel

wi

th integral steering arms. Each is suppo rted between the upper and lower wishbones

by two ball joints and carries:

Front hub

Brake ca

liper and disc shield assembly

ABS se

nsor

.

Front Hub

s

Each f

o

rged steel front hub accommodates sealed for life cartridge

type wheel bearings, and carries:

The brake rotor assembl

y.

A

h

ub nut with toothed, integral ABS rotor.

Su

s

pension spring pi

n locking device.

Front Road

Springs

The road spri

ng

s are of coil type with their

rating dependent upon vehicle specification

Ea

ch spring is installed between the suspension crossbeam location and the lower wishbone spring pan.

Ru

bber seats ar

e installed betw

een the spring and the crossb eam and the spring pan.

Front Shock A

bsorbers

Th

e

shock absorbers are telescopic hydrau

lically operated units. Optional adaptive damping units incorporate a solenoid-

operated control valve at their upper extremity.

Each shoc

k absorber is installed between the lowe

r wishbone rear arm and a recess in the body.

The l

o

wer end of the shock absorber is se

cured to plates on the wishbone by a bolt that also serves as a pivot.

The u

pper en

d of each shock absorber is secured to the body location by a single nut.

Front Sta

b

ilizer Bar

A

front stabil

izer bar installed on all vehicles

is rated according to suspension specification.

Opera

tion

As each road wheel r

i

ses, move

ment is transmitted through the vertical link assembly to the lower wishbone. The resulting

rise of the wishbone compresses the road spring and partially telescopes the shock absorber. During this action, the spring

absorbs associated shocks and the shock absorber minimizes sprin

g os c

illation.

Du

ring cornering, vehicle weight

is transferred to the outer road wheel with a resulting tendency for the inner wheel to lift.

The stabilizer bar assists in minimizing this tendency by transf erring a proportion of potential lift of the inner wheel to the

outer wheel. This result s in enhanced body stability with improved corner ing capabilities.

Page 166 of 2490

Rear Su

spension -

Lubric

ants, Fluids, Sealants and Adhesives

Torques

UnitSp

ecification

Loctite27

0

Greas eShell Retin a

x 'A'

Greas

eCastro l 'NT

R'

Com

p

onent

Nm

N

u

t - hub to axle shaft

3

04 -

336

Nu

t -

hub carrier pivot pin

88

-

118

Bol

t

- ABS sensor to hub carrier

8-1

0

Nu

t - stabilizer bar link to lower wishbone.

30

-40

Nu

t - stabilizer bar to link assembly.

30

-40

Bolts -

monostrut to body mounting brackets

88

-

118

Bolt

s

- monostrut to wishbone tie assembly

77

-

103

Bolts

- bu

mp stop to body

26

-34

Bol t

- damper lower mounting

80

-

100

N

u

t - damper top

31

-39

Bolts -

damper mounting plate to body

17

-23

Page 174 of 2490

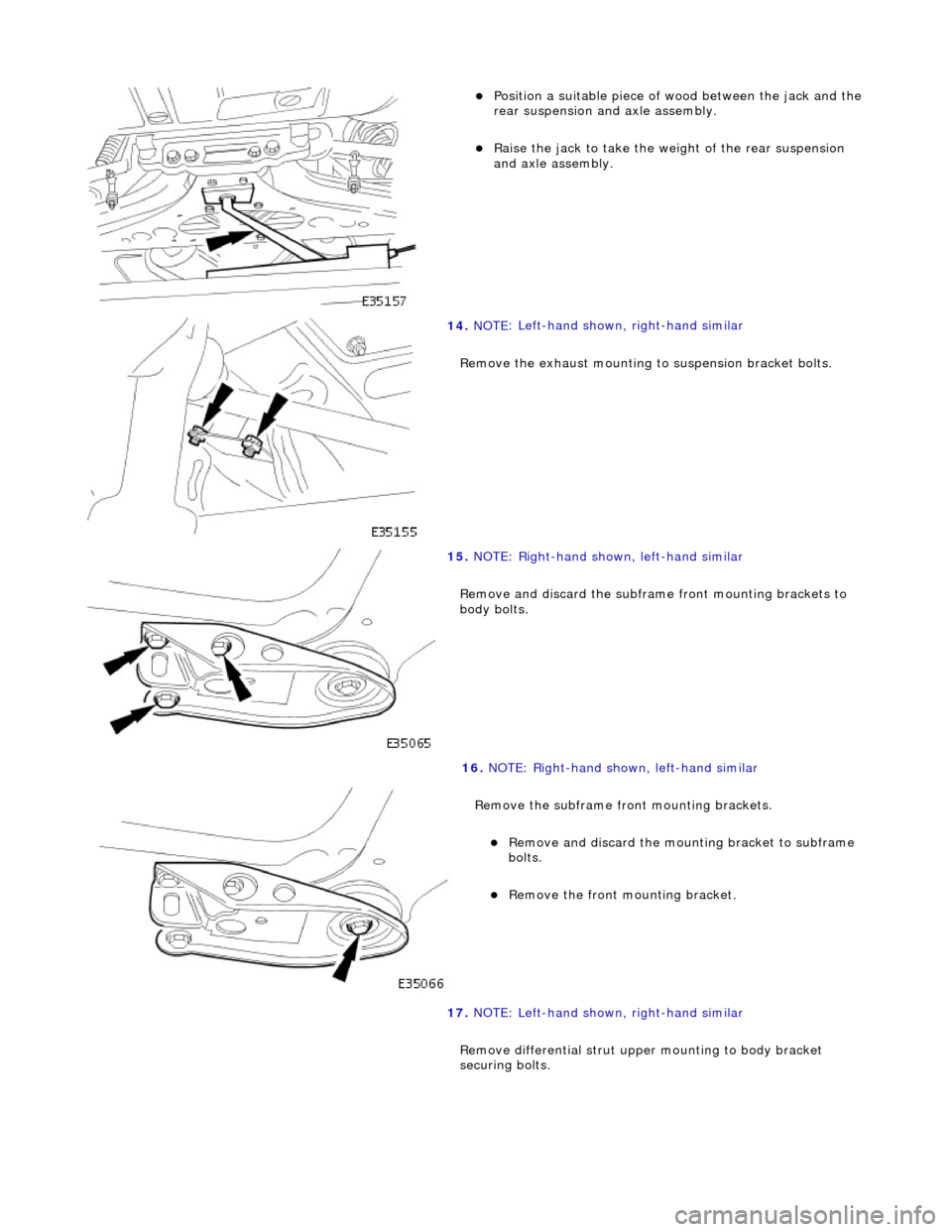

Position a suitable piece o

f wood between the jack and the

rear suspension and axle assembly.

Rai s

e the jack to take the weight of the rear suspension

and axle assembly.

14 . NOTE

: Left-hand shown, right-hand similar

Remove the exhaust mounting to suspension bracket bolts.

15 . NOTE

: Right-hand shown, left-hand similar

Remove and discard the subframe front mounting brackets to

body bolts.

16 . NOTE

: Right-hand shown, left-hand similar

Remove the subframe front mounting brackets.

Remove an d discard the mount

ing bracket to subframe

bolts.

R e

move the front mounting bracket.

17. NOTE: Left-hand shown, right-hand similar

Remove differential strut upper mounting to body bracket

securing bolts.

Page 175 of 2490

I

nstallation

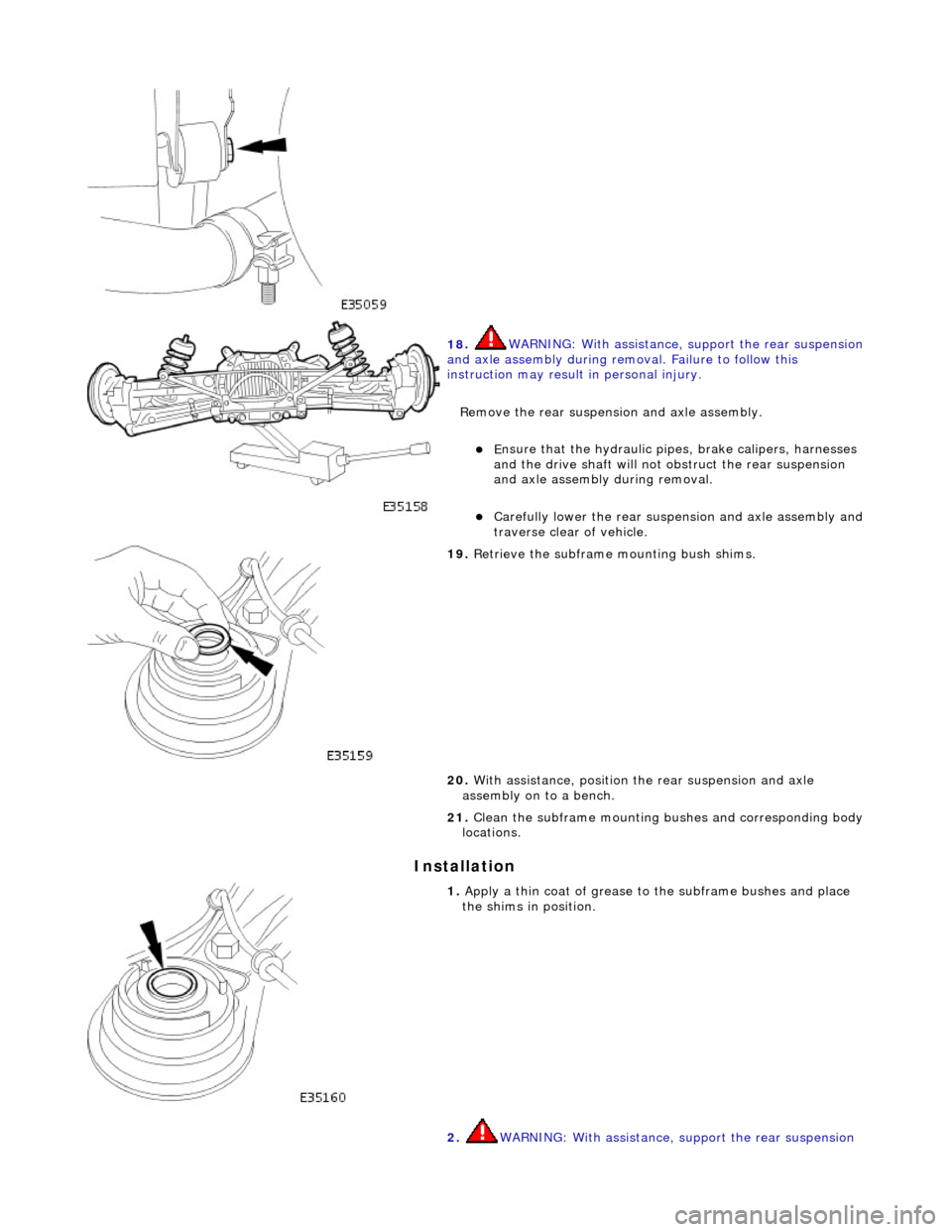

18

.

WARNING: With assistance, support the rear suspension

and axle assembly during remo val. Failure to follow this

instruction may result in personal injury.

Remove the rear suspensi on and axle assembly.

E

nsure that the hydr

aulic pipes, brake calipers, harnesses

and the drive shaft will not obstruct the rear suspension

and axle assembly during removal.

Carefull

y lower the rear suspen

sion and axle assembly and

traverse clear of vehicle.

19

.

Retrieve the subframe mounting bush shims.

20. With assistance, position th e rear suspension and axle

assembly on to a bench.

21. Clean the subframe mounting bushes and corresponding body

locations.

1. Apply a th

in coat of grease to the subframe bushes and place

the shims in position.

2. WARNING: With assistance, support the rear suspension

Page 177 of 2490

Inst

all new inner mounting bracket bolts.

Ti

ghten to 88-118 Nm.

8. NOTE

: Right-hand shown, left-hand similar

Tighten to 88-118 Nm.

9. NOTE

: Right-hand shown, left-hand similar

Install new different ial strut to body bracket bolts.

Tigh

ten to 68-92 Nm.

10. Lower and remove trolley jack.

11

.

Attach the drive shaft to the flexible coupling.

Align the marks previously pain

ted on drive shaft and

flexible coupling.

Inst

all new drive shaft coupling bolts and nuts.

12. Tighten to 76-88 Nm.

Page 182 of 2490

Withdraw th

e hub carrier and support on a block of wood.

9. CAUTIO

N: Note the position of

the shims during removal.

They must be returned to th eir original position during

installation.

Noting their positions, remove the shim from each end of the

pivot pin sleeve.

10 . WAR

NINGS:

ENSURE THE SPECIAL TOOLS ARE POSITIONED

DIAMETRICALLY OPPOSITE ON THE SPRING AND THE ARMS ARE

CORRECTLY SEATED .

WHEN COMPRESSING THE SPRING, TIGHTEN THE

SPECIAL-TOOL ADJUSTMENT BOLTS EVENLY.

Compress the spring.

Install and alig n th

e special

tools 204-179 diametrically

opposite on the spring.

Eve n

ly tighten the special tool tensioning bolts to

compress the spring.

11 . R

emove the shock absorber to

wishbone mounting nut and

bolt.

12. Remove the nuts securing th e shock absorber and spring

upper mounting to the body.

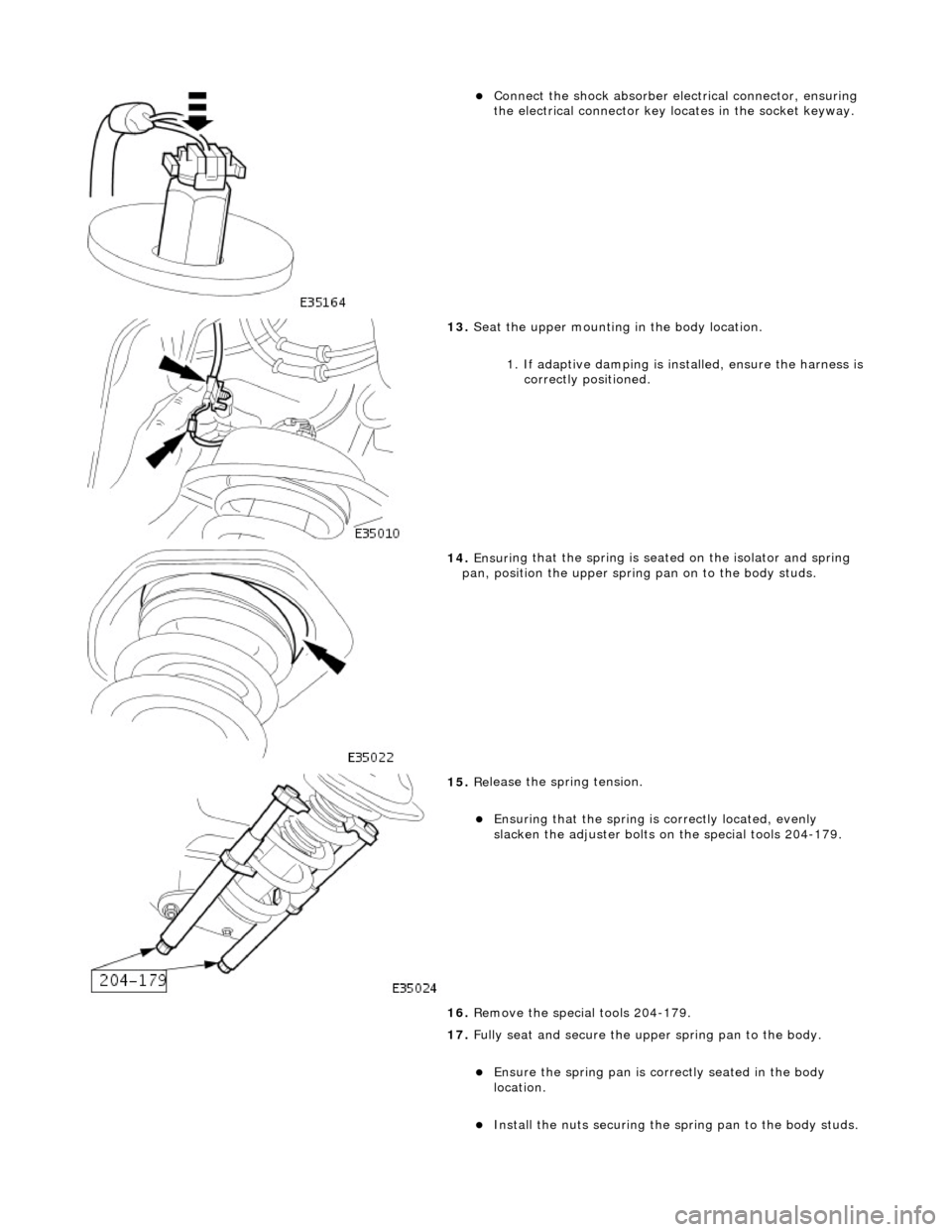

Page 188 of 2490

Connect

the shock absorber elec

trical connector, ensuring

the electrical connector key locates in the socket keyway.

13. Seat

the upper mounting in the body location.

1. If adaptive damping is installed, ensure the harness is

correctly positioned.

14 . Ensuri

ng that the spri

ng is seated on the isolator and spring

pan, position the u pper spring pan on to the body studs.

15 . Re

lease the spring tension.

Ensuri

ng that the spri

ng is

correctly located, evenly

slacken the adjuster bolts on the special tools 204-179.

16. Remove the special tools 204-179.

17. Fully seat and secure the u pper spring pan to the body.

Ensure the spring pan i

s correctly seated in the body

location.

Inst al

l the nuts securing the sp

ring pan to the body studs.