rear axle JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 3 of 2490

Rear Toe Adjustment (57.65. 08)

Whee

l

Bearing Circlip Inspection

Wheel Bearing Inspection

204‐01: Front Suspension

Specification

Description and Operation

Front Suspension

Removal and Installation

Ball Joint (60.15.02)

Rear Lower Arm (60.35.54)

Rear Lower Arm Bushing (60.35.56)

Front Shock Absorber (60.30.04)

Spring

Spring Seat (60.20.03)

Front Sta

bilizer Bar (60.10.01)

Front Stabilizer Bar Bushing (60.10.04)

Front Stabilizer Bar Link (60.10.02)

Upper Arm Bushing

Front Wheel Bearing (60.25.40)

Wheel Hub

Wheel Knuckle (60.25.23)

Wheel Knuckle and Wheel Hub Assembly (60.25.38.90)

Wheel Knuckle and Wheel Hub Assembly Conversion (60.25.43)

204‐02: Rear Suspension

Specif

ication

Description and Operation

Rear Suspension

Removal and Installation

Axle Bump Stop (64.30.15)

Rear Suspension and Axle Assembly (64.25.01)

Rear Shock Absorber (64.30.02)

Shock Absorber Lower Bushing (64.30.39)

Spring (64.20.01)

Rear Stabilizer Bar (64.35.08) ‐ 4.0L SC V8 ‐ AJ26

Rear Stabilizer Bar Bushing (64.35.18) ‐ 4.0L SC V8 ‐ AJ26

Page 4 of 2490

Stabilizer Bar Mount i

ng

Frame (64.25.12)

Stabilizer Bar Mounting Frame Bushing (64.25.13)

Rear Wheel Bearing (64.15.14)

Wheel Hub Seal (64.15.15)

Wheel Knuckle Bushing (64.15.24)

204‐04: Wheels and Tires

Specification

Description and Operation

Wheels and Tires

Diagnosis and Testing

Wheels and Tires

Removal and Installation

Whee

l and Tire (74.20.05)

204‐05: Vehicle Dynamic Suspension

Description and Operation

Vehicle Dynamic Suspension

Diagnosis and Testing

Vehicle Dynamic Suspension

205: Driveline

205‐00: Driveline System ‐ General Information

Description and Operation

Driveline System

205‐01: Driveshaft

Specification

Description and Operation

Drives

haft

Removal and Installation

Driveshaft (47.15.01)

205‐02: Rear Drive Axle/Differential

Specification

Description and Operation

Page 5 of 2490

Rear Drive Axle and Diffe rential

General Procedures

Differential Output Shaft End Float Check (51.10.24)

In‐Vehicle Repair

Axle Shaft (47.10.01)

Differential Output Shaft Bearing (51.10.22)

Drive Pinion Flange and Drive Pinion Seal (51.20.01)

Removal and Installation

Axle Assembly (51.25.13)

206: Brake System

206‐00: Brake System ‐ Gen

eral Information

Specification

Description and Operation

Brake System

Diagnosis and Testing

Brake System

General Procedures

Brake System Bleeding (70.25.03) ‐ Vehicles With: Standard Brakes

Brake System Bleeding (70.25.03) ‐ Vehicles With: High Performance Brakes

Front Brake Disc Runout Check ‐ Vehicles With: Standard Brakes

Front Brake Disc Runout Chec

k ‐ Vehicles With: High Performance Brakes

Rear Brake Disc Runout Check (70.12.36) ‐ Vehicles With: Standard Brakes

Rear Brake Disc Runout Check (70.12.36) ‐ Vehicles With: High Performance

Brakes

206‐03: Front Disc Brake

Specification

Description and Operation

Front Disc Brake

Removal and Installation

Brake Caliper (70.55.02) ‐ Vehicles With: Standard Brakes

Brake Caliper (70.55.02) ‐ Vehicles With: High Perfo

rmance Brakes

Brake Disc (70.10.10) ‐ Vehicles With: Standard Brakes

Brake Disc (70.10.10) ‐ Vehicles With: High Performance Brakes

Brake Pads (70.40.02) ‐ Vehicles With: Standard Brakes

Page 34 of 2490

501‐20B : Supp l

emental

Restraint System

Specification

Description and Operation

Air Bag Supplemental Restraint System (SRS)

Removal and Installation

Air Bag Control Module (76.73.41)

Driver Air Bag Module (76.73.39)

Passenger Air Bag Module (76.73.37)

Side Air Bag Module (76.73.47)

Side Impact Sensor (76.73.53)

501‐25: Body Repairs ‐ Genera

l Information

Description and Operation

Body Repairs

502: Frame and Mounting

502‐00: Uni ‐Body, Subframe and Mounting System

Removal and Installation

Front Axle Crossmember

Front Axle Crossmember Front Bushing (60.35.24)

Front Axle Crossmember Front Bushing Heat Shield (60.35.37)

Front Axle Crossmember Rear Bushing (

60.35.26)

Rear Axle Crossmember (64.25.16)

Rear Axle Crossmember Bushing (64.25.02)

Page 49 of 2490

Identification

Codes -

Identification Codes

Descr

iption and Operation

En

gine Number

The en

gine number (10 digits) is stamped on a raised pad on th

e front of the engine block near the thermostat housing. The

piston grade reference (8 digits) is also shown.

Automatic Transmission

Number

The

serial number of the transmission unit is displayed on

a metal or bar code label attached to the LH side of the

transmission casing.

Veh

icle Identification

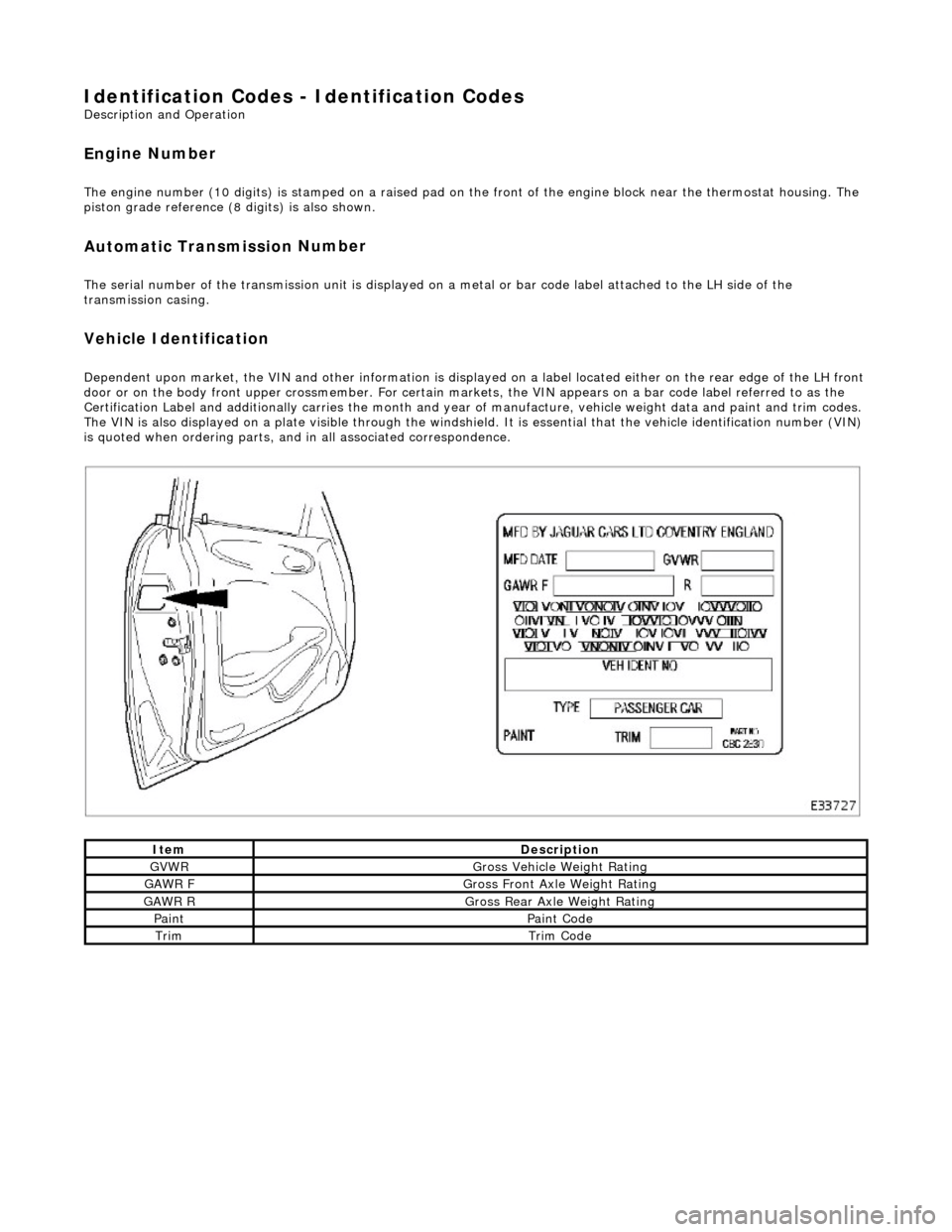

Dependent

upon market, the VIN and other info

rmation is displayed on a label located ei ther on the rear edge of the LH front

door or on the body front upper crossmember. For certain mark ets, the VIN appears on a bar code label referred to as the

Certification Label and additionally carries the month and year of manufacture, vehicle weight data and paint and trim codes.

The VIN is also displayed on a plate visible through the windshie ld. It is essential that the vehicle identification number (VIN)

is quoted when ordering parts, and in all associated correspondence.

ItemDe

scription

GVW

R

G

ross Vehicle Weight Rating

GAW

R F

Gros

s Front Axle Weight Rating

GAW

R R

Gros

s Rear Axle Weight Rating

Pai

nt

Pai

nt Code

TrimTrim

Code

Page 50 of 2490

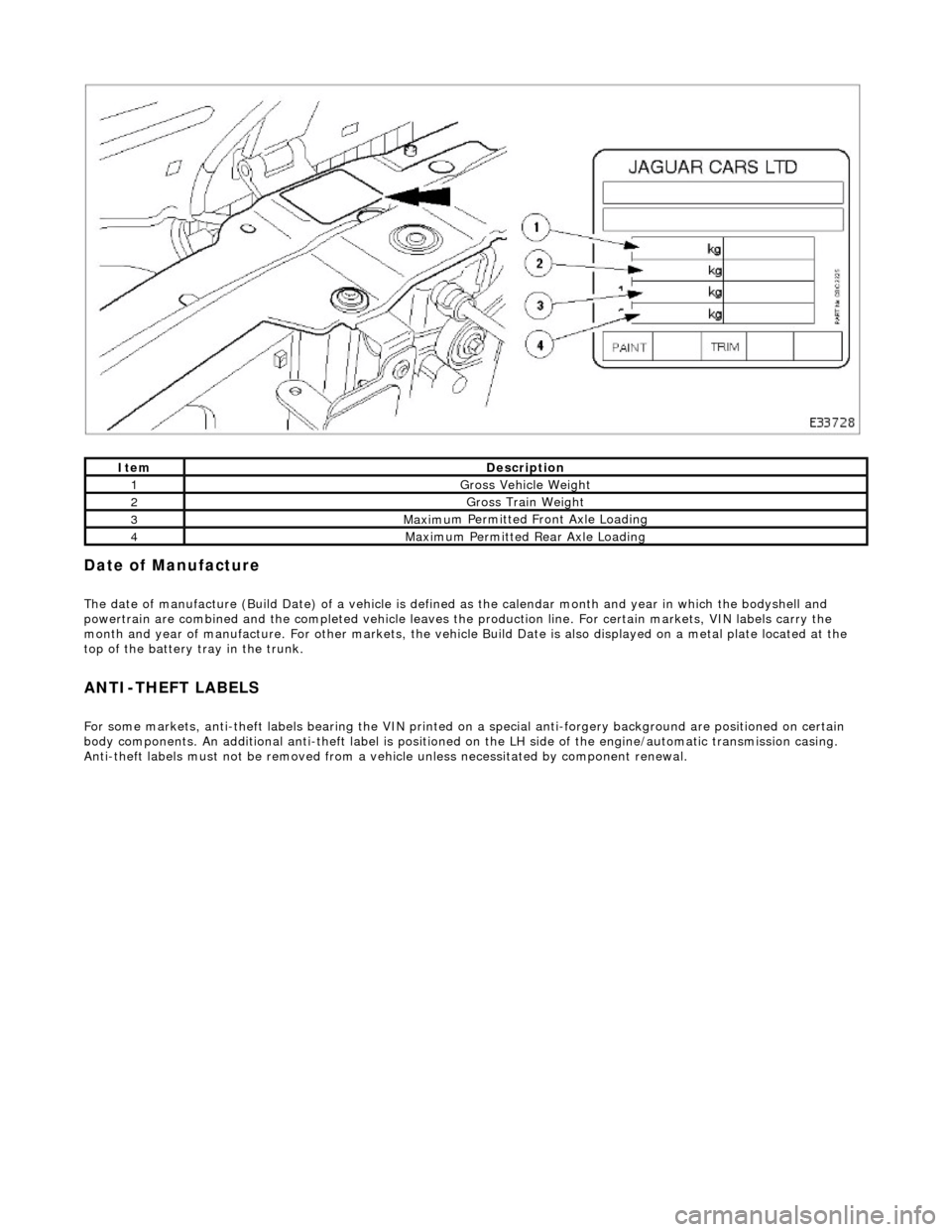

Date of

Manufacture

T

h

e date of manufacture (Build Date) of a vehicle is define

d as the calendar month and year in which the bodyshell and

powertrain are combined and the completed vehicle leaves the production line. For certain markets, VIN labels carry the

month and year of manufacture. For other markets, the vehicle Build Date is also displayed on a metal plate located at the

top of the battery tray in the trunk.

ANTI-T

HEFT LABELS

F

or

some markets, anti-theft labels bearing the VIN printed on

a special anti-forgery background are positioned on certain

body components. An additional anti-theft label is positioned on the LH side of the engine/automatic transmission casing.

Anti-theft labels must not be removed from a vehicle unless necessitated by component renewal.

ItemDe scrip

tion

1Gross Vehic

l

e Weight

2Gross Trai

n W

eight

3Maxim

u

m Permitted Front Axle Loading

4Maxim

u

m Permitted Rear Axle Loading

Page 166 of 2490

Rear Su

spension -

Lubric

ants, Fluids, Sealants and Adhesives

Torques

UnitSp

ecification

Loctite27

0

Greas eShell Retin a

x 'A'

Greas

eCastro l 'NT

R'

Com

p

onent

Nm

N

u

t - hub to axle shaft

3

04 -

336

Nu

t -

hub carrier pivot pin

88

-

118

Bol

t

- ABS sensor to hub carrier

8-1

0

Nu

t - stabilizer bar link to lower wishbone.

30

-40

Nu

t - stabilizer bar to link assembly.

30

-40

Bolts -

monostrut to body mounting brackets

88

-

118

Bolt

s

- monostrut to wishbone tie assembly

77

-

103

Bolts

- bu

mp stop to body

26

-34

Bol t

- damper lower mounting

80

-

100

N

u

t - damper top

31

-39

Bolts -

damper mounting plate to body

17

-23

Page 168 of 2490

Each r

oad spring and is located between the wishbone in

tegral spring seat and the body suspension turret.

Each shoc

k absorber unit is installed

co-axially within the road spring.

The lo

wer end of each shock absorber is secured to the

wishbone by a bolt which also functions as a pivot.

Adaptive damping is av

ailable as an option.

A

rear stabi

lizer bar is installed on

Supercharged and Sport Suspension models . Mounted at the rear of the wishbone

tie assembly, the stabilizer bar is connected to the wishbone by short links.

Op era

tion

As each road wheel r

i

ses, move

ment is transmitted through th e hub carrier assembly to the wishbone and axle shaft. The

corresponding rise of the wishbone compre sses the road spring and partially telescopes the shock absorber. During this

action, the spring absorbs result ing shocks and the shock absorber minimizes spring oscillation.

During cornering, vehicle weight is transferred to the outer road wheel with a resulting tendency for the inner wheel to lift.

On Supercharged and Sport Suspension vehicl es, a rear stabilizer bar assists in minimizing this tendency by transferring a

proportion of potential lift of the inner wheel to the outer wheel. This results in enhanced body stability with improved

cornering capabilities.

Page 169 of 2490

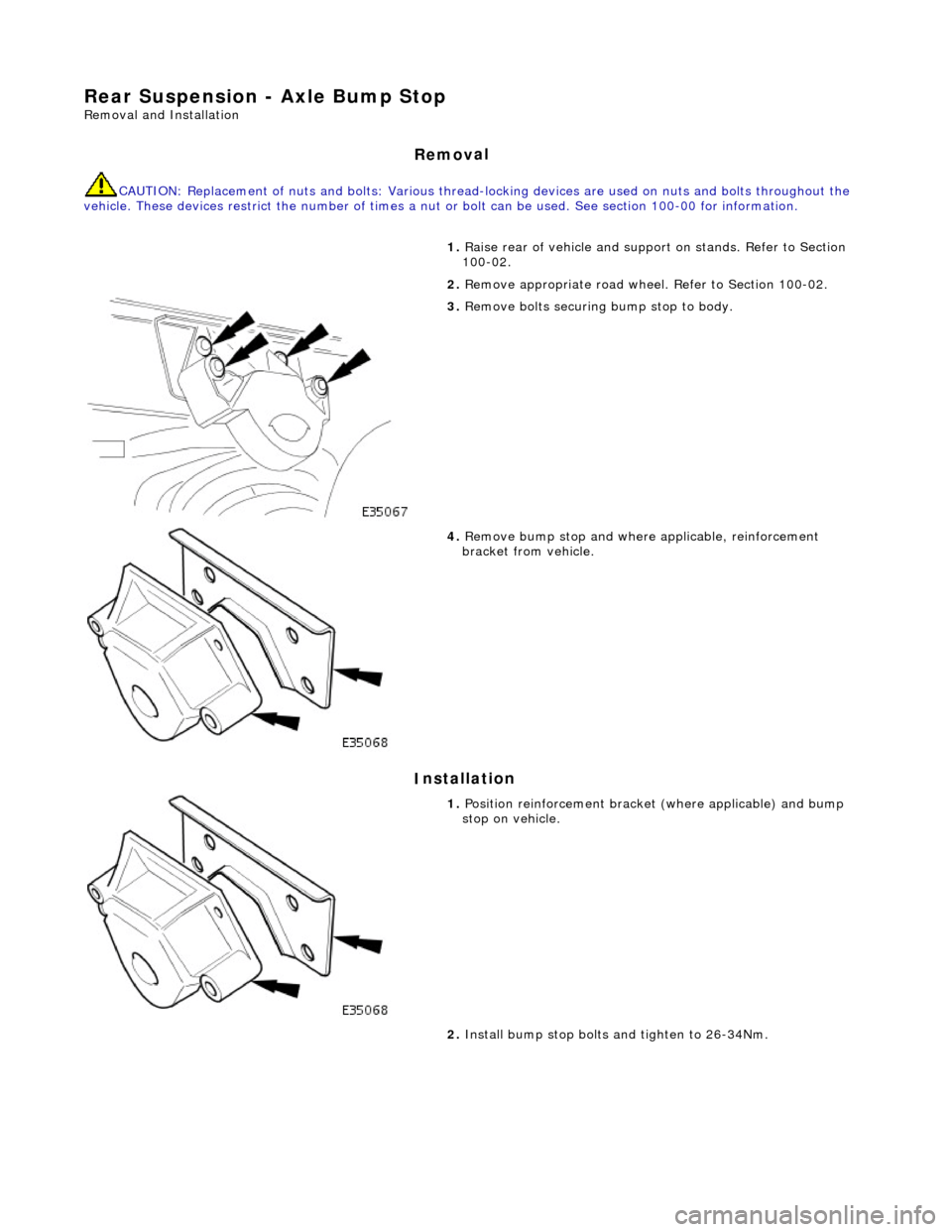

Rear Suspension - Axle B

ump Stop

Re

moval and Installation

Remov

al

CAUTI

ON: Replacement of

nuts and bolts: Various thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

I

nstallation

1.

R

aise rear of vehicle and support

on stands. Refer to Section

100-02.

2. Remove appropriate road wheel. Refer to Section 100-02.

3. Remove bolts securing bump stop to body.

4. Remove bu

mp stop and where applicable, reinforcement

bracket from vehicle.

1. Position reinforcemen t brac

ket (where a

pplicable) and bump

stop on vehicle.

2. Install bump stop bolts and tighten to 26-34Nm.

Page 171 of 2490

Rear

Suspension - Rear Susp

ension and Axle Assembly

Re

moval and Installation

Remov

al

1.

CAUTI

ON: Replacement of nuts and bolts: Various

thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt

can be used.

For additional informat ion, refer to Section 100

-0

0 General

Informati

on

.

R

aise the rear of the vehicle

and support on axle stands.

For additional informat ion, refer to Section 100

-0

2 Jacking and

Liftin

g

.

2.

R

emove the rear wheels.

For additional informat ion, refer to Section 204

-04

Wheels and

Tire

s

.

3. CAUTI

ON: Do not suspend the caliper from the brake

hose as this will damage the hose.

• NOTE: Right-hand shown, left-hand similar

Remove the brake calipers from the carriers.

1. Remove the caliper spring clip.

2. Remove the guide pin dust caps.

3. Slacken and withdr aw the guide pins.

4. Remove the caliper from the carrier and secure to the suspension mounting bracket using a tie strap.

4. NOTE

: Right-hand shown, left-hand similar

Disconnect the wheel speed sensor electrical connectors.

5. NOTE: Right-hand shown, left-hand similar

Remove and discard th e tie straps securing the wheel speed

sensor harnesses to the brake hose clips.