JAGUAR XF 2009 1.G Owners Manual

Manufacturer: JAGUAR, Model Year: 2009, Model line: XF, Model: JAGUAR XF 2009 1.GPages: 391, PDF Size: 19.32 MB

Page 231 of 391

231

Wheels and tyres

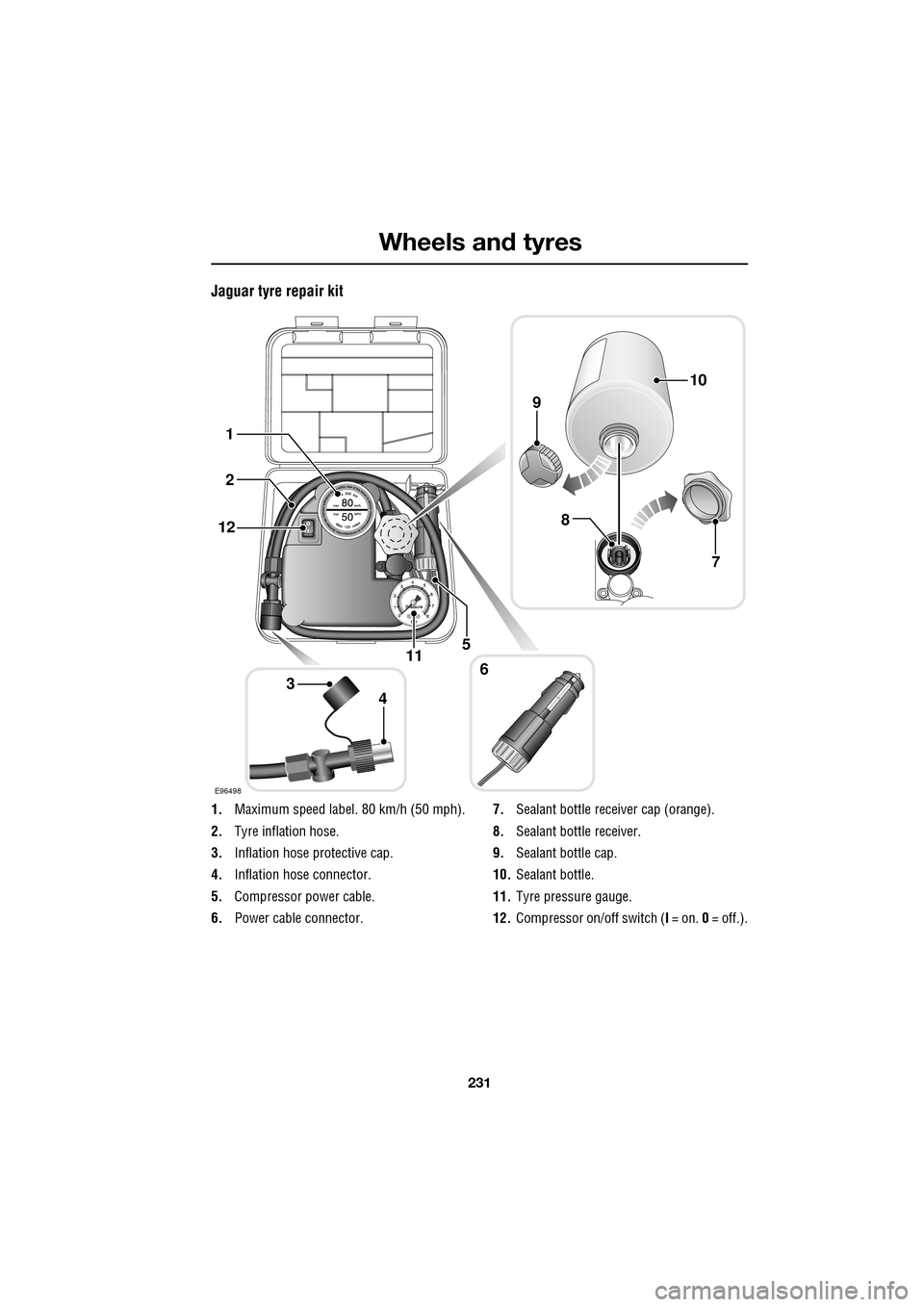

Jaguar tyre repair kit

1.Maximum speed label. 80 km/h (50 mph).

2. Tyre inflation hose.

3. Inflation hose protective cap.

4. Inflation hose connector.

5. Compressor power cable.

6. Power cable connector. 7.

Sealant bottle receiver cap (orange).

8. Sealant bottle receiver.

9. Sealant bottle cap.

10. Sealant bottle.

11. Tyre pressure gauge.

12. Compressor on/off switch ( I = on. 0 = off.).

E96498

34

2

6

5

1

12

11

8

9

10

7

Page 232 of 391

Wheels and tyres

232

Using the Jaguar tyre repair kit

Note: All vehicle drivers and occupants should

be made aware that a temporary repair has

been made to a tyre fitted to the vehicle. They

should also be made aware of the special

driving conditions im posed when using a

repaired tyre.

Repair procedure

1. Open the tyre repair kit and peel off the

maximum speed label. Attach the label to

the fascia in the driver's field of vision.

Take care not to obstruct any of the

instruments or warning lights.

2. Uncoil the compressor power cable and

the inflation hose.

3. Unscrew the orange cap from the sealant

bottle receiver and the sealant bottle cap.

4. Screw the sealant bottle into the receiver

(clockwise) until tight.

•Screwing the bottle onto the receiver will

pierce the bottle's se al. Do not unscrew

a full, or partly us ed bottle from the

receiver. Doing so will result in sealant

leaking from the bottle.

5. Remove the valve cap from the damaged

tyre.

6. Remove the protective cap from the

inflation hose and connect the inflation

hose to the tyre valve. Ensure that the hose

is screwed on firmly.

7. Ensure that the compressor switch is in

the off (0) position.

8. Insert the power cable connector into the

auxiliary power socket. See AUXILIARY

POWER SOCKETS (page 125).

WARNINGS

Avoid skin contact with the sealant

which contains natu ral rubber latex.

If the tyre inflati on pressure does not

reach 1.8 bar (26 lbf/in², 180 kPa)

within seven minutes, the tyre may

have suffered excessive damage. A temporary

repair will not be poss ible, and the vehicle

should not be driven until the tyre has been

replaced.

CAUTIONS

Before attempting a ty re repair, ensure

that the vehicle is parked safely, as far

away from passing traffic as possible.

Ensure that the parki ng brake is applied

and P (Park) is selected.

Do not attempt to remove foreign

objects such as nails, screws, etc. from

the tyre.

Always run the engine when using the

compressor, unless the vehicle is in an

enclosed or poorly ventil ated space, as this

may cause asphyxiation.

To prevent overheating, do not operate

the compressor continuously for longer

than ten minutes.

WARNING

Check the tyre sidewall prior to

inflation. If there are any cracks,

bumps or similar damage, do not

attempt to inflate the tyre. Do not stand

directly beside the tyre while the compressor

is pumping. Watch the ty re sidewall. If any

cracks, bumps or simila r damage appear, turn

off the compressor and let the air out by

means of the pressure relief valve. Do not

continue to use the tyre.

Page 233 of 391

233

Wheels and tyres

9.Unless the vehicle is in an enclosed area,

start the engine.

10. Set the compressor switch to the on ( I)

position.

11. Inflate the tyre to a minimum of 1.9 bar

(26 lbf/in²) and a maximum of 3.5 bar

(51 lbf/in²).

•When pumping the sealant through the

tyre valve, the pressure may rise up to 6

bar (87 lbf/in²). The pressure will drop

again after approximately 30 seconds.

12. During the inflation, switch the

compressor off briefly, to check the tyre

pressure using the gauge mounted on the

compressor.

• It should not take longer than seven

minutes to inflate the tyre. If, after seven

minutes, the tyre has not yet reached

minimum pressure, the tyre should not

be used.

13. Once the tyre has been inflated, switch off

the compressor. If desired, the engine may

be turned off after the compressor has

been turned off.

14. Remove the power connector from the

auxiliary power socket.

15. Remove the inflation hose from the tyre

valve, by unscrewing it as quickly as

possible (count er-clockwise).

16. Replace the inflation hose protective cap

and the tyre valve cap.

17. Do not remove the sealant bottle from the

receiver.

18. Ensure that the tyre repair kit (including

the bottle and receiver caps) are placed

securely in the vehicle. You will need to

use the kit to check the tyre pressure after

approximately 3 km (2 miles), so ensure

they are easily accessible. 19.

Immediately drive the vehicle for

approximately 3 km (2 miles), to allow the

sealant to coat the inner surface of the tyre

and form a seal at the puncture.

Checking the tyre pressure after a repair

1.Drive the vehicle for 3 km (2 miles) then

stop in a safe place. Carry out a visual

examination of the tyres condition.

2. Make sure that the sealant container

section is in its original position.

3. Screw the inflation hos e connector firmly

onto the tyre valve.

4. Read the tyre pressure from the gauge.

5. If the pressure of the sealant filled tyre is

above 1.3 bar (19 lb/in²) adjust the

pressure to the correct value. See TYRE

CARE (page 217).

6. Ensure that the compressor switch is in

the off (O ) position and insert the power

cable connector into the auxiliary power

socket.

If the vehicle is in a well ventilated area,

start the engine.

WARNINGS

When driving the vehicle, if you

experience vibr ations, abnormal

steering, or noises, reduce speed

immediately. Drive with extreme caution and

reduced speed, to the first safe place to stop

the vehicle. Visually examine the tyre and

check its pressure. If there are any signs of

damage or deformity to the tyre, or the tyre

pressure is below 1.3 bar (19 lb/in²), do not

continue driving.

Consult a tyre repair centre or your

Dealer/Authorised Repairer, for

advice concerning the replacement of

a tyre after using a tyre repair kit.

Page 234 of 391

Wheels and tyres

234

7.Switch the compressor to on ( I) and inflate

the tyre to the correct pressure.

8. To check the tyre pressure, turn off the

compressor then read the pressure from

the gauge.

9. When the compressor is off, if the tyre

pressure is too high, release the required

amount of pressure using the pressure

relief valve.

10. Once the tyre is inflated to the correct

pressure, switch off the compressor and

remove the power plug from the auxiliary

socket.

•The use of the tyre re pair kit sealant may

lead to error prompts and incorrect

readings of the Tyre Pressure

Monitoring System. Therefore, use the

tyre repair kit pressure gauge to check

and adjust the damaged tyre's inflation

pressure.

11. Unscrew the inflation hose connector from

the tyre valve, replace the tyre valve cap

and the inflation hose connector protective

cap.

12. Ensure that the tyre repair kit is placed

securely in the vehicle.

13. Drive to the nearest tyre repair centre or

Dealer/Authorised Repairer, for a

replacement tyre to be fitted. Ensure that

you make the repair centre aware that the

tyre repair kit has been used before the tyre

is removed.

14. Both the tyre inflation hose, and the sealant

container should be replaced once a new

tyre has been fitted. Only sealant containers which are

completely empty should be

disposed of with normal household

waste. Sealant containe rs which contain some

sealant, and the tyre in flation hose, should be

disposed of by a tyre specialist or your

Dealer/Authorised Repairer, in compliance with

local waste dispos al regulations.

TYRE PRESSURE MONITORING

SYSTEM

Note: Non-approved accessories may interfere

with the system. If this occurs, TYRE

PRESSURE SYSTEM FAULT is displayed in the

message centre.

WARNINGS

The Tyre Pressure Monitoring (TPM)

system is NOT a substitute for

manually checking ty re pressures.

The TPM system only provides a low pressure

warning and does not re-i nflate your tyres.

Tyre pressures should be checked regularly

using an accurate pressure gauge when cold.

Failure to properly maintain your pressures

could increase the risk of tyre failure, with

consequential loss of vehicle control and

personal injury.

The TPM system can NOT register

damage to a tyre. Regularly check the

condition of your tyre s, especially if

the vehicle is driven off-road.

CAUTION

When inflating tyre s, care should be

taken to avoid bend ing or damaging the

TPM system valves. Always ensure correct

alignment of the inflation head to the valve

stem.

Page 235 of 391

235

Wheels and tyres

Note: Different types of tyre may affect the

performance of the TPM system. Always

replace tyres in accordance with

recommendations. See TYRE

SPECIFICATIONS - ARDUOUS TERRAIN

(page 239).

Your vehicle may be equipped with a TPM

System which monitors pressure in each tyre

(temporary use spare wheels are not fitted with

sensors and are conseque ntly not monitored).

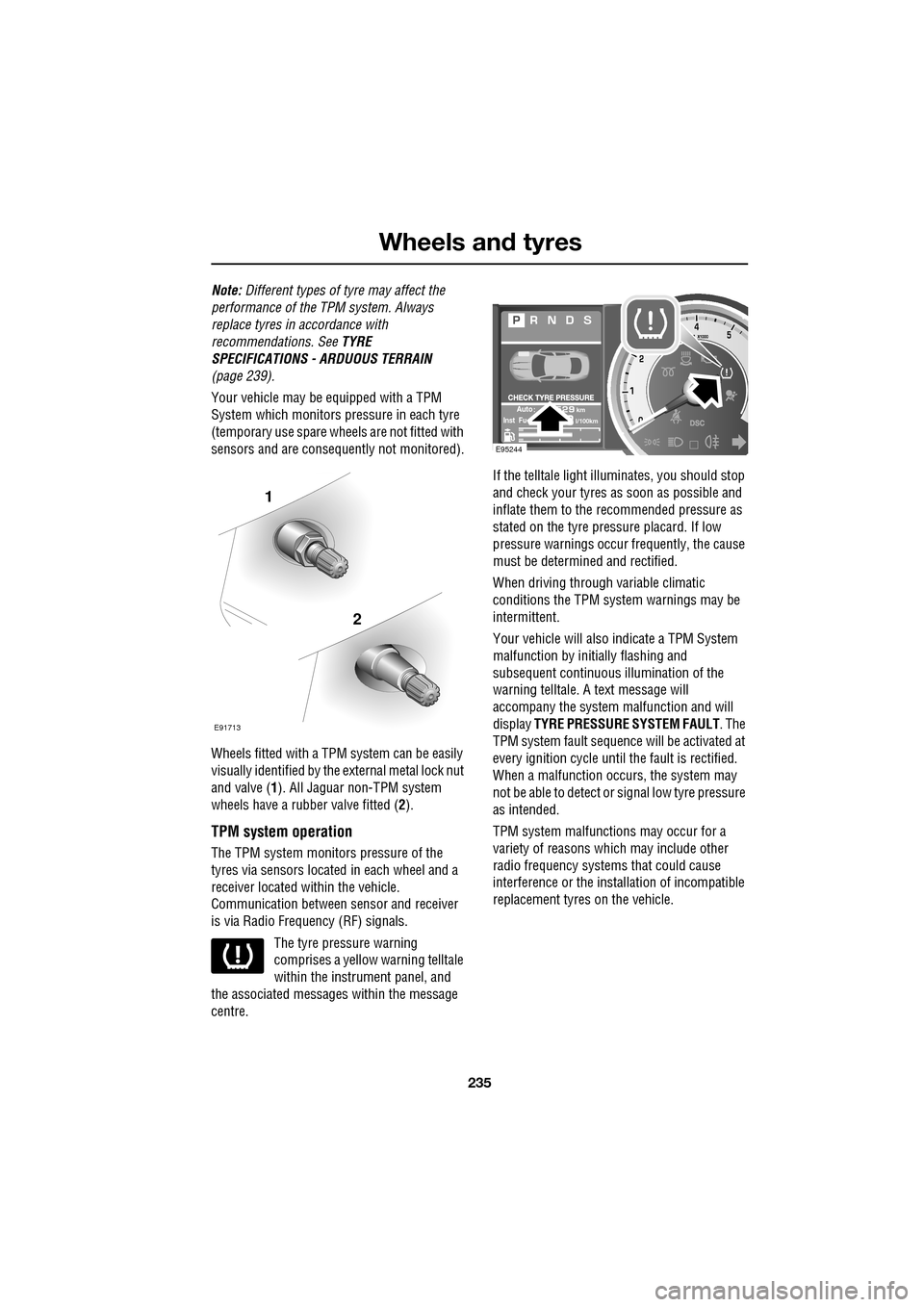

Wheels fitted with a TPM system can be easily

visually identified by the external metal lock nut

and valve ( 1). All Jaguar n on-TPM system

wheels have a rubber valve fitted (2).

TPM system operation

The TPM system monitors pressure of the

tyres via sensors located in each wheel and a

receiver located within the vehicle.

Communication between se nsor and receiver

is via Radio Frequency (RF) signals.

The tyre pressure warning

comprises a yellow warning telltale

within the instrument panel, and

the associated messages within the message

centre. If the telltale light illu

minates, you should stop

and check your tyres as soon as possible and

inflate them to the recommended pressure as

stated on the tyre pressure placard. If low

pressure warnings occur frequently, the cause

must be determined and rectified.

When driving through variable climatic

conditions the TPM syst em warnings may be

intermittent.

Your vehicle will also indicate a TPM System

malfunction by initially flashing and

subsequent continuous illumination of the

warning telltale. A text message will

accompany the system malfunction and will

display TYRE PRESSURE SYSTEM FAULT . The

TPM system fault sequence will be activated at

every ignition cycle until the fault is rectified.

When a malfunction occurs, the system may

not be able to de tect or signal low tyre pressure

as intended.

TPM system malfuncti ons may occur for a

variety of reasons which may include other

radio frequency systems that could cause

interference or the installation of incompatible

replacement tyres on the vehicle.

1

2

E91713

AutokmInst Ful/100km

E95244

Page 236 of 391

Wheels and tyres

236

Tyre pressure warning with speed

If the vehicle is to be driven at speeds in excess

of 160 km/h (100 mph), the tyre pressures

should be increased as stated in this handbook

or on the placard label. Failure to increase the

tyre pressures and driving in excess of

160 km/h (100 mph), will illuminate the yellow

warning telltale and display a text message

TYRE PRESSURES LOW FOR SPEED . In the

event of this warning be ing displayed, vehicle

speed should be reduced

Temporary use spare wheel and tyre

change

If the temporary use spare wheel is fitted the

system will automatically recognise the change

in wheel positions. The n after approximately

ten minutes of driv ing above 25 km/h

(18 mph), a message TYRE NOT MONITORED

will be displayed accompanied by illumination

of the warning telltale and the corresponding

block in the vehicle graphic.

The warning telltale will initially flash and will

subsequently revert to continuous illumination.

Extended use of the temporary use spare wheel

will produce an additional text message TYRE

PRESSURE SYSTEM FAULT .

This TPM system display sequence will be

activated at every ignition cycle until the

temporary use spare wheel is replaced by a

fully operational full size wheel and tyre

assembly.

Always replace the temporary use wheel before

having TPM system faults investigated. The

fault may well be rectified with the fitment of a

fully operational full size running tyre in lieu of

the temporary use spare wheel assembly.

Tyre changing

Always have your tyres serviced or changed by

a qualified engineer.

Care must be taken to avoid contact between

the bead of the tyre and the sensor during

removal and refitting of the tyre, otherwise the

sensor may become damaged and or

inoperable.

Sensors can be removed from the wheel by the

unscrewing of the va lve retention nut.

Replacement sensor

Should the sensor require replacing, it should

be carried out by a Dealer/Authorised Repairer.

A replacement sensor must be fitted to a

running wheel in order to be recognised by the

system. The vehicle needs to be stationary for

15 minutes during the se nsor fitment before

the system is ready to detect the new sensor.

The vehicle must be driven for a minimum of

fifteen minutes after the sensor change, and

then remain stationary for fifteen minutes to

activate full TPM system operation.

If the TPM system warning for any wheel does

not clear, even after ensuring correct inflation

and driving for more than ten minutes above

25 km/h (18 mph), you should seek qualified

assistance as soon as possible.

CAUTION

Valve stem seal, washer, nut, valve core

and cap should be replaced at every tyre

change. Valve stem seal, washer and nut must

be replaced if valve re tention nut is loosened.

Sensor units and nuts must be refitted using

correct torque figures and associated profile.

Damage to the vehicle may result if these

precautions are not taken.

Page 237 of 391

237

Wheels and tyres

TPM System information messages

Message Warning IndicatorPriority

Indicator Meaning

CHECK TYRE PRESSURE

(Graphic indication displays

which tyre is under-inflated.) TPM

System Amber You should as soon as

possible stop, check

your tyre and inflate them to the

recommended pressure.

CHECK ALL TYRE PRESSURES TPM

System Amber May be displayed when

the vehicle is learning

that a new sensor is fitted to the vehicle and

one or more tyres has low pressure. You

should as soon as possi ble stop, check your

tyres and inflate them to the recommended

pressure.

TYRE PRESSURE SYSTEM FAULT TPM

System Amber 1. The wheels do

not have TPM System

sensors fitted.

2. The TPM System se nsors have become

defective, an unapproved accessory is

interfering with the syst em or a general fault

has been detected. Seek qualified assistance

as soon as possible.

TYRE NOT MONITORED

(Graphic indication displays

which tyre is not monitored.) TPM

System Red 1. A temporary use spare wheel is fitted.

Vehicle speed should be limited to 80 km/h

(50 mph). 2. A TPM System sensor has

become defective, an unapproved accessory

is interfering with the system or a wheel has

been fitted that does not have a sensor. Seek

qualified assistance as soon as possible.

TYRE PRESSURES LOW FOR SPEED TPM

System Amber The tyre pressures ar

e not suitable for high

speed driving. You should reduce vehicle

speed and inflate the tyres to recommended

pressures for high speed driving.

Page 238 of 391

Wheels and tyres

238

TYRE GLOSSARY

lbf/in² or psi

Pounds per square inch, an imperial unit of

measure for pressure.

kPa

Kilo Pascal, a metric unit of measure for

pressure.

Cold tyre pressure

The air pressure in a tyre which has been

standing in excess of th ree hours, or driven for

less than 1.6 km (1 mile).

Maximum inflation pressure

The maximum pressure to which the tyre

should be inflated. This pressure is given on

the tyre side wall in lbf/in² (psi) and kPa.

Note: This pressure is the maximum allowed

by the tyre manufacturer. It is not the pressure

recommended for use.

Kerb weight

The weight of a standa rd vehicle, including a

full tank of fuel, any optional equipment fitted,

and with the correct coolant and oil levels.

Gross vehicle weight

The maximum permissible weight of a vehicle

with driver, passen gers, load, luggage,

equipment, and towbar load.

Accessory weight

The combined weight (in excess of those items

replaced) of items available as factory installed

equipment.

Production options weight

The combined weight of options installed

which weigh in excess of 1.4 kg (3 lb) more

than the standard items that they replaced, and

are not already considered in kerb or accessory

weights. Items such as heavy duty brakes, high

capacity battery, special trim etc.

Vehicle capacity weight

The number of seats multiplied by 68 kg

(150 lb) plus the rated amount of load/luggage.

Maximum loaded vehicle weight

The sum of kerb wei ght, accessory weight,

vehicle capacity weig ht, plus any production

option weights.

Rim

The metal support for a ty re, or tyre and tube,

upon which the tyre beads are seated.

Bead

The inner edge of a tyre th at is shaped to fit to

the rim and form an air tight seal. The bead is

constructed of steel wires which are wrapped,

or reinforced, by the ply cords.

Page 239 of 391

239

Wheels and tyres

TYRE SPECIFICATIONS - ARDUOUS TERRAIN

In certain markets, due to the possibility of very uneven or unmetalled roads, it is necessary to fit

tyres suitable for the conditions. These markets and the relevant tyre specification are detailed

below.

The following chart details the tyres recomm ended for use in the countries listed below:

A . Australia, Bahrain, Egypt, Is rael, Jordan, Kuwait, Lebanon, Malaysia, Mexico, Morocco,

Oman, Qatar, Saudi Arabia, South Africa, Syria, Thailand, United Arab Emirates.

B . Argentina, Belarus, Brazil, Bulgaria, Chile, Dominican Republic, Estonia, Guatemala,

Indonesia, Kaxakhstan, Panama, Philippines, Russia, Sri Lanka, Ukraine, Uzbekistan.

Wheel position Tyre size PatternA B

Front and rear 235/55R17 99W Pirelli P7No No

Front and rear 245/45R18 100Y X/L Pir elli PZero Asymmetric Yes Yes

Front and rear 245/45R18 100W X/ L Dunlop Sport 01 Asymmetric Yes Yes

Front and rear 245/40R19 98Y X/L D unlop Sport 01 Asymmetric Yes Yes

Front 255/35R20 97Y X/L Pirelli PZero Asymmetric Yes Yes Rear 285/30R20 99Y X/L Pirelli PZero Asymmetric Yes Yes

Temporary use spare wheel (front and rear):

Alloy 4J x 18 T135/80R18 Pirelli

For all other countries you should refer to your local Dealer/Aut horised Repairer for specific tyre

fitment.

Page 240 of 391

Wheels and tyres

240

Accessory wheels and tyres

1.Front tyre pressure.

2. Rear tyre pressure.

3. Wheel and tyre information (size, speed

rating, etc.).

Note: Use the table above to record accessory

wheel and tyre information.

WARNING

Contact your Dealer/Authorised

Repairer before fitting any accessory

wheels and tyres. Your Dealer/

Authorised Repairer will be able to

offer guidance rega rding the correct

accessories. Fitting incorrect wheel/tyre

combinations can seriously affect the ride and

handling of your vehicl e. In extreme cases,

this may lead to loss of control of the vehicle.

12

3

E95187