Interior JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 23 of 3039

Removal and InstallationApproach Lamp

Headlamp Assembly

Headlamp Leveling Front Sensor

Headlamp Leveling Rear Sensor

High Mounted Stoplamp

Rear Fog Lamp

Rear Lamp Assembly

Side Turn Signal Lamp417-02: Interior Lighting

Description and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingInterior Lighting417-04: Daytime Running Lamps (DRL)

Description and OperationOverview

System Operation and Component Description418: Electrical Distribution

418-00: Module Communications Network

Description and OperationOverview

System Operation and Component DescriptionDiagnosis and TestingCommunications NetworkRemoval and InstallationAuxiliary Junction Box (AJB)

Central Junction Box (CJB)418-02: Wiring Harnesses

Description and OperationWiring HarnessGeneral ProceduresWiring Harness RepairRemoval and InstallationLuggage Compartment Lid Wiring Harness419: Electronic Feature Group

419-01A: Anti-Theft - Active

Description and OperationComponent Location

Overview

Page 25 of 3039

SpecificationRemoval and InstallationAir Deflector

Cowl Vent Screen (76.10.01)

Engine Rear Undershield

Fender Splash Shield

Hood

Radiator Splash Shield

Secondary Bulkhead Center Panel

Secondary Bulkhead Panel LH - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol

Secondary Bulkhead Panel RH - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol501-03: Body Closures

Removal and InstallationFront Door

Fuel Filler Door

Fuel Filler Door Assembly

Luggage Compartment Lid (76.19.01)

Rear Door501-05: Interior Trim and OrnamentationSpecificationRemoval and InstallationA-Pillar Trim Panel

B-Pillar Lower Trim Panel

B-Pillar Upper Trim Panel

C-Pillar Lower Trim Panel

C-Pillar Trim Panel

Cowl Side Trim Panel

Engine Cover - V8 5.0L Petrol/V8 S/C 5.0L Petrol

Front Door Trim Panel (76.34.01)

Front Scuff Plate Trim Panel

Instrument Panel Speaker Grille

Headliner

Loadspace Scuff Plate Trim Panel

Loadspace Trim Panel

Loadspace Trim Panel LH

Loadspace Trim Panel RH

Luggage Compartment Lid Trim Panel

Parcel Shelf

Rear Door Trim Panel

Rear Scuff Plate Trim Panel

Sun Visor (76.10.48)

Sun Visor Vanity Mirror

Page 26 of 3039

SpecificationRemoval and InstallationRadiator Grille

Luggage Compartment Lid Moulding

Front Fender Moulding

Rocker Panel Moulding501-09: Rear View MirrorsSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingRear View MirrorsRemoval and InstallationExterior Mirror

Exterior Mirror Cover

Exterior Mirror Glass

Exterior Mirror Motor

Interior Rear View Mirror501-10: SeatingSpecificationDescription and OperationComponent Location

Overview

System Operation and Component Description

Seat Cover InspectionDiagnosis and TestingSeats

Heater Mats

Seats - Vehicles With: Climate Controlled SeatsGeneral ProceduresSeat SmoothingRemoval and InstallationFront Seat (76.70.01)

Front Seat Backrest (76.70.06)

Front Seat Backrest Cover (76.70.15)

Front Seat Bolster

Front Seat Bolster Pump

Front Seat Cushion Cover

Front Seat Track Motor

Lumbar Assembly501-08: Exterior Trim and Ornamentation

Page 28 of 3039

Instrument Panel Console

Instrument Panel Lower Trim Panel

Overhead Console501-14: Handles, Locks, Latches and Entry SystemsSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingLocks, Latches and Entry SystemsRemoval and InstallationDoor Lock Cylinder Cover

Exterior Front Door Handle

Exterior Luggage Compartment Lid Release Switch

Exterior Rear Door Handle

Front Door Latch

Front Door Lock Cylinder

Interior Front Door Handle

Luggage Compartment Lid Latch Actuator

Luggage Compartment Lid Lock Cylinder

Rear Door Latch501-16: Wipers and WashersSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingWipers and WashersRemoval and InstallationHeadlamp Washer Jet

Headlamp Washer Pump

Rain Sensor

Windshield Washer Reservoir

Windshield Wiper Motor

Windshield Wiper Pivot Arm

Windshield Washer Pump501-17: Roof Opening PanelSpecificationDescription and OperationComponent Location

Page 50 of 3039

disconnected, a Radio Code Saver will allow sufficient current to pass to maintain the radio receiver/cassette player/mini disc

player and compact disc player memory, operate the clock and supply the door operated interior lights while isolating the

battery in the event of a short circuit.

Reconnecting the Battery

WARNING: If the battery has been on bench charge the cells may be giving off explosive hydrogen gas. Avoid creating

sparks, and if in doubt cover the vent plugs or covers with a damp cloth.

Always make sure that all electrical systems are switched OFF before reconnecting the battery to avoid causing sparks or

damage to sensitive electrical equipment.

Always reconnect the battery positive lead first and the negative last, ensuring that there is a good electrical contact and the

battery terminals are secure.

Restart the clock (where installed) and set it to the correct time.

Enter the radio receiver/cassette player/mini disc player and compact disc player keycodes and preset' frequencies, if known.

Following reconnection of the battery, the engine should be allowed to idle until it has reached normal operating temperature

as the stored idle and drive values contained within the ECM have been lost. Allow the vehicle to idle for a further three

minutes. Drive the vehicle at constant speeds of approximately 48 km/h (30 mph), 64 km/h (40 mph), 80 km/h (50 mph), 96

km/h (60 mph) and 112 km/h (70 mph) for three minutes each. This will allow the ECM to relearn idle and drive values, and

may cause driveability concerns if the procedure is not carried out.

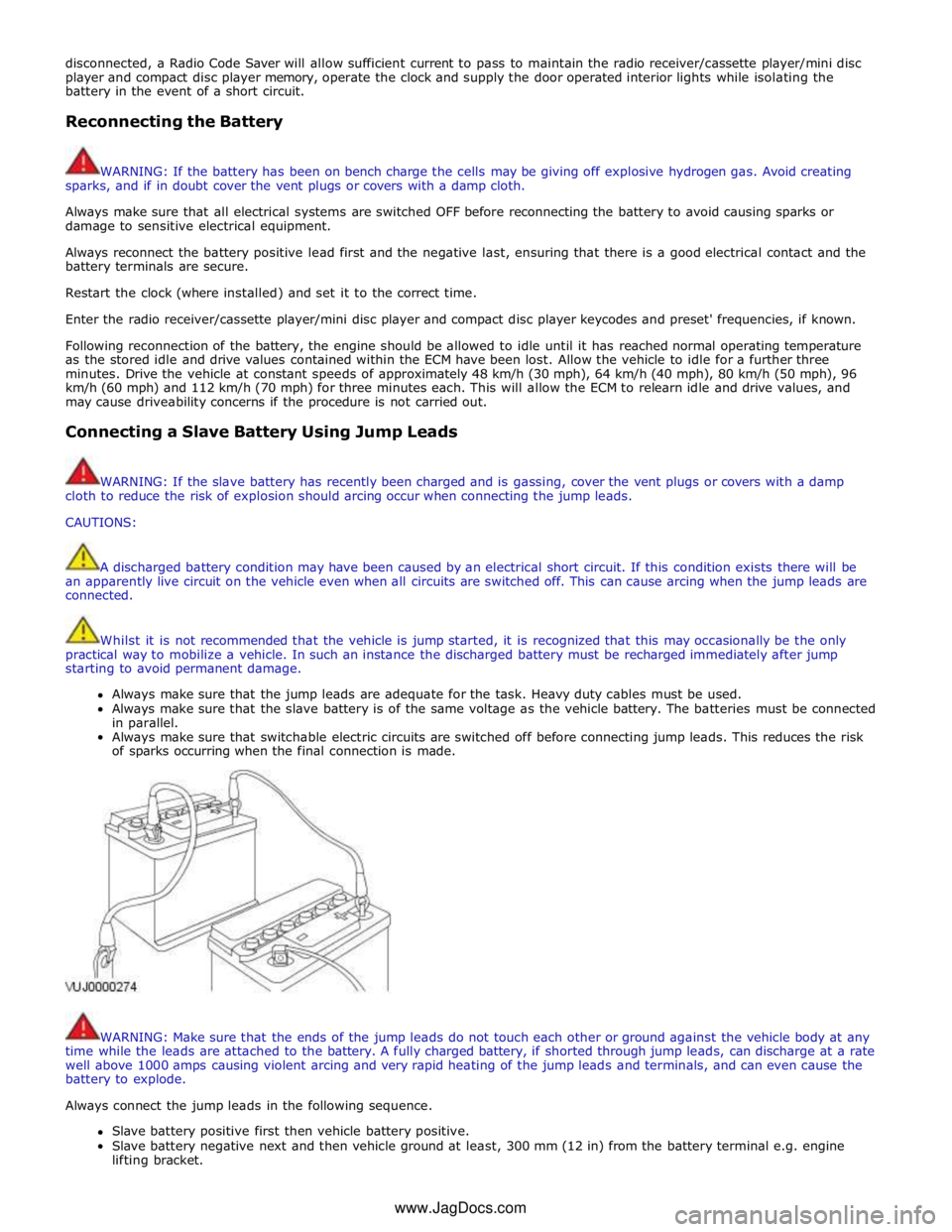

Connecting a Slave Battery Using Jump Leads

WARNING: If the slave battery has recently been charged and is gassing, cover the vent plugs or covers with a damp

cloth to reduce the risk of explosion should arcing occur when connecting the jump leads.

CAUTIONS:

A discharged battery condition may have been caused by an electrical short circuit. If this condition exists there will be

an apparently live circuit on the vehicle even when all circuits are switched off. This can cause arcing when the jump leads are

connected.

Whilst it is not recommended that the vehicle is jump started, it is recognized that this may occasionally be the only

practical way to mobilize a vehicle. In such an instance the discharged battery must be recharged immediately after jump

starting to avoid permanent damage.

Always make sure that the jump leads are adequate for the task. Heavy duty cables must be used.

Always make sure that the slave battery is of the same voltage as the vehicle battery. The batteries must be connected

in parallel.

Always make sure that switchable electric circuits are switched off before connecting jump leads. This reduces the risk

of sparks occurring when the final connection is made.

WARNING: Make sure that the ends of the jump leads do not touch each other or ground against the vehicle body at any

time while the leads are attached to the battery. A fully charged battery, if shorted through jump leads, can discharge at a rate

well above 1000 amps causing violent arcing and very rapid heating of the jump leads and terminals, and can even cause the

battery to explode.

Always connect the jump leads in the following sequence.

Slave battery positive first then vehicle battery positive.

Slave battery negative next and then vehicle ground at least, 300 mm (12 in) from the battery terminal e.g. engine

lifting bracket. www.JagDocs.com

Page 72 of 3039

General Information - Standard Workshop Practices

Description and Operation

Protecting the Vehicle Published: 04-Jul-2014

Always install covers to protect the fenders before commencing work in the engine compartment. Always install the interior

protection kit, wear clean overalls and wash hands or wear gloves before working inside the vehicle. Avoid spilling hydraulic

fluid, antifreeze or battery acid on the paintwork. In the event of spillage, wash off with water immediately. Use polythene

sheets in the luggage compartment to protect carpets. Always use the recommended service tool, or a satisfactory equivalent,

where specified. Protect temporarily exposed screw threads by replacing nuts or installing caps.

Vehicle in Workshop

When working on a vehicle in the workshop always make sure that:

The parking brake is applied or the wheels are securely chocked to prevent the vehicle moving forwards or backwards

If the engine is to be run, there is adequate ventilation, or an extraction hose to remove exhaust fumes is installed

There is adequate room to jack up the vehicle and remove the wheels, if necessary

Fender covers are always installed if any work is to be carried out in the engine compartment

The battery is disconnected if working on the engine, underneath the vehicle, or if the vehicle is jacked up

CAUTION: When electric arc welding on a vehicle, always disconnect the generator wiring to prevent the possibility of a

surge of current causing damage to the internal components of the generator.

If using welding equipment on the vehicle, ensure a suitable fire extinguisher is readily available.

Screw Threads

Damaged nuts, bolts and screws must always be discarded. Attempting to recut or repair damaged threads with a tap

or die impairs the strength and fit of the threads and is not recommended.

NOTES:

During certain repair operations, it may be necessary to remove traces of thread locking agents using a tap. Where this

is necessary, the instruction to do so will appear in the relevant operation and it is essential that a tap of the correct size and

thread is used.

New Taptite bolts when used cut their own threads on the first application.

Some bolts are coated with a thread locking agent and unless stated otherwise, they must not be reused. New bolts

having the same part number as the original must always be installed. When nuts or bolts are to be discarded, the

repair operation and relevant torque chart will include an instruction to that effect. Do not use proprietary thread

locking agents as they may not meet the specification required. See also Encapsulated ('Patched') Bolts and Screws.

Always make sure that replacement nuts and bolts are at least equal in strength to those that they are replacing.

Castellated nuts must not be loosened to accept a split pin except in recommended cases when this forms part of an

adjustment.

Do not allow oil or grease to enter blind holes, the hydraulic action resulting from tightening the bolt or stud can split

the housing and also give a false torque reading.

Always tighten a nut, bolt or screw to the specified torque figure, damaged or corroded threads can give a false torque

reading.

Nut and bolt loosening and tightening sequences, where given, must ALWAYS be followed. Distortion of components or

faulty sealing of joints will result if the sequences are not followed. Where an instruction is given to tighten in stages,

these stages must be adhered to; do not attempt to combine stages particularly where certain stages involve

tightening by degrees.

To check or re-tighten a fixing to a specified torque, first loosen a quarter of a turn, then retighten to the specified

torque figure.

Unless instructed otherwise, do not lubricate bolt or nut threads prior to installing.

Where it is stated that bolts and screws may be reused, the following procedures must be carried out:

Check that threads are undamaged.

Remove all traces of locking agent from the threads.

CAUTION: DO NOT use a wire brush; take care that threads are not damaged.

Make sure that threads are clean and free from oil or grease.

Apply the specified locking agent to the bolt threads.

Page 73 of 3039

Supplementary Restraint System (SRS) Precautions

WARNING: Do not install rear facing child seats in the front passenger seat.

The SRS contains components which are potentially hazardous to service personnel if not handled correctly. The following

guidelines and precautions are intended to alert personnel to potential sources of danger and emphasise the importance of

ensuring the integrity of the SRS components installed to the vehicle.

WARNING: The following precautions MUST be adhered to when working on the SRS system:

The correct procedures must always be used when working on SRS components.

Persons working on the SRS system must be fully trained and have been issued with the safety guidelines.

The airbag modules contain extremely flammable and hazardous compounds. Contact with water, acids or heavy

metals may produce harmful or explosive results. Do not dismantle, incinerate or bring into contact with electricity

before the unit has been deployed.

Always replace a seat belt assembly that has withstood the strain of a severe vehicle impact or if the webbing

shows signs of fraying.

Always disconnect the vehicle battery before carrying out any electric welding on a vehicle installed with an SRS

system.

CAUTION: Do not expose airbag modules or seat belt pre-tensioners to temperatures exceeding 85° C (185° F).

It should be noted that these precautions are not restricted to operations performed when servicing the SRS system. The same

care should be exercised when working on ancillary systems and components located in the vicinity of SRS components; these

include but are not limited to:

Steering wheel airbag, rotary coupler.

Passenger front airbag.

Head airbag modules - front and rear.

Seat belt pre-tensioners.

SRS harnesses, link leads and connectors.

Side (thorax) air bags.

Making the system safe

Before working on or in the vicinity of SRS components, make sure the system is rendered safe by performing the following

operations:

Remove the ignition key.

Disconnect battery, earth lead first.

Wait 2 minutes for the SRS power circuit to discharge before commencing work.

NOTE: The SRS uses energy reserve capacitors to keep the system active in the event of electrical supply failure under

crash conditions. It is necessary to allow the capacitors sufficient time to discharge (2 minutes) in order to avoid the risk of

accidental deployment.

Installation

In order to make sure system integrity, it is essential that the SRS system is regularly checked and maintained so that it is

ready for effective operation in the event of a collision. Carefully inspect SRS components before installation. Do not install a

part that shows signs of being dropped or improperly handled, such as dents, cracks or deformation.

WARNING: The integrity of the SRS systems is critical for safety reasons. Make sure the following precautions are always

adhered to:

Do not install accessories or other objects to trim panels which cover ITS airbags.

Never install used SRS components from another vehicle or attempt to repair an SRS component.

When repairing an SRS system, only use genuine new parts.

Never apply electrical power to an SRS component unless instructed to do so as part of an approved test

procedure.

Special fixings are necessary for installing an airbag module – do not use other fixings and make sure that all

fixings are tightened to the correct torque.

Always use new fixings when replacing an SRS component.

CAUTIONS:

Take care not to trap airbag modules when installing interior trim components.

Make sure SRS components are not contaminated by oil or grease.

NOTES:

Following seat belt pre-tensioner deployment, the seat belts can still be used as conventional seat belts but will need to

Page 95 of 3039

7

Center punch 8

Marker 9

Metal inert gas (MIG) welding equipment 10

Hose clamp 11

Interior trim remover 12

Vacuum cleaner 13

Strap wrench 14

Wedge 15

Pin Punch Material symbols

The material symbols are used to show where to use which type of material to carry out a procedure step.

Item

Description 1

Remove/Install the specified blind rivet 2

Apply tape to the specified component/area 3

Remove/Install the specified cable tie www.JagDocs.com

Page 223 of 3039

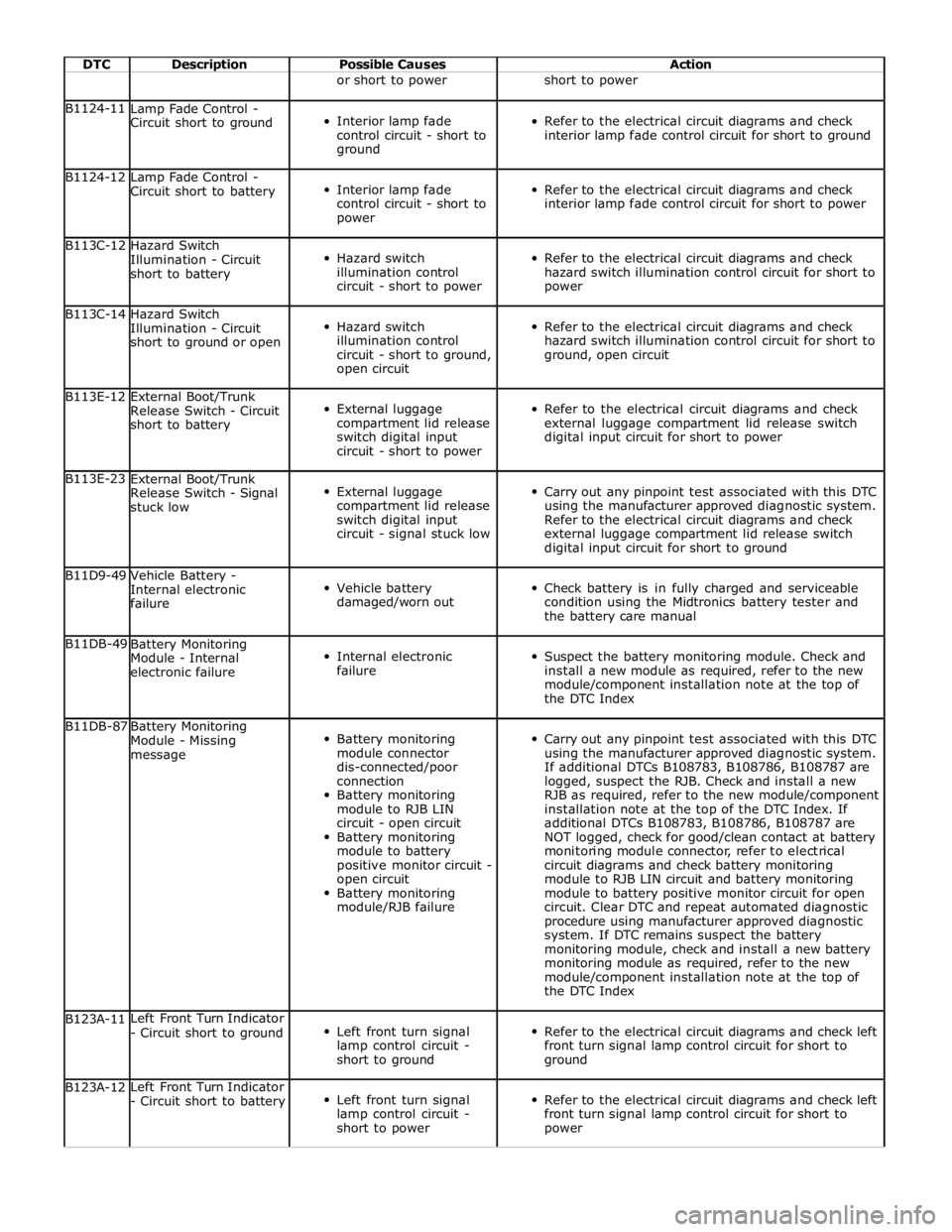

DTC Description Possible Causes Action or short to power short to power B1124-11

Lamp Fade Control -

Circuit short to ground

Interior lamp fade

control circuit - short to

ground

Refer to the electrical circuit diagrams and check

interior lamp fade control circuit for short to ground B1124-12

Lamp Fade Control -

Circuit short to battery

Interior lamp fade

control circuit - short to

power

Refer to the electrical circuit diagrams and check

interior lamp fade control circuit for short to power B113C-12

Hazard Switch

Illumination - Circuit

short to battery

Hazard switch

illumination control

circuit - short to power

Refer to the electrical circuit diagrams and check

hazard switch illumination control circuit for short to

power B113C-14

Hazard Switch

Illumination - Circuit

short to ground or open

Hazard switch

illumination control

circuit - short to ground,

open circuit

Refer to the electrical circuit diagrams and check

hazard switch illumination control circuit for short to

ground, open circuit B113E-12

External Boot/Trunk

Release Switch - Circuit

short to battery

External luggage

compartment lid release

switch digital input

circuit - short to power

Refer to the electrical circuit diagrams and check

external luggage compartment lid release switch

digital input circuit for short to power B113E-23

External Boot/Trunk

Release Switch - Signal

stuck low

External luggage

compartment lid release

switch digital input

circuit - signal stuck low

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

external luggage compartment lid release switch

digital input circuit for short to ground B11D9-49

Vehicle Battery -

Internal electronic

failure

Vehicle battery

damaged/worn out

Check battery is in fully charged and serviceable

condition using the Midtronics battery tester and

the battery care manual B11DB-49

Battery Monitoring

Module - Internal

electronic failure

Internal electronic

failure

Suspect the battery monitoring module. Check and

install a new module as required, refer to the new

module/component installation note at the top of

the DTC Index B11DB-87

Battery Monitoring

Module - Missing

message

Battery monitoring

module connector

dis-connected/poor

connection

Battery monitoring

module to RJB LIN

circuit - open circuit

Battery monitoring

module to battery

positive monitor circuit -

open circuit

Battery monitoring

module/RJB failure

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

If additional DTCs B108783, B108786, B108787 are

logged, suspect the RJB. Check and install a new

RJB as required, refer to the new module/component

installation note at the top of the DTC Index. If

additional DTCs B108783, B108786, B108787 are

NOT logged, check for good/clean contact at battery

monitoring module connector, refer to electrical

circuit diagrams and check battery monitoring

module to RJB LIN circuit and battery monitoring

module to battery positive monitor circuit for open

circuit. Clear DTC and repeat automated diagnostic

procedure using manufacturer approved diagnostic

system. If DTC remains suspect the battery

monitoring module, check and install a new battery

monitoring module as required, refer to the new

module/component installation note at the top of

the DTC Index B123A-11 Left Front Turn Indicator

- Circuit short to ground

Left front turn signal

lamp control circuit -

short to ground

Refer to the electrical circuit diagrams and check left

front turn signal lamp control circuit for short to

ground B123A-12 Left Front Turn Indicator

- Circuit short to battery

Left front turn signal

lamp control circuit -

short to power

Refer to the electrical circuit diagrams and check left

front turn signal lamp control circuit for short to

power

Page 228 of 3039

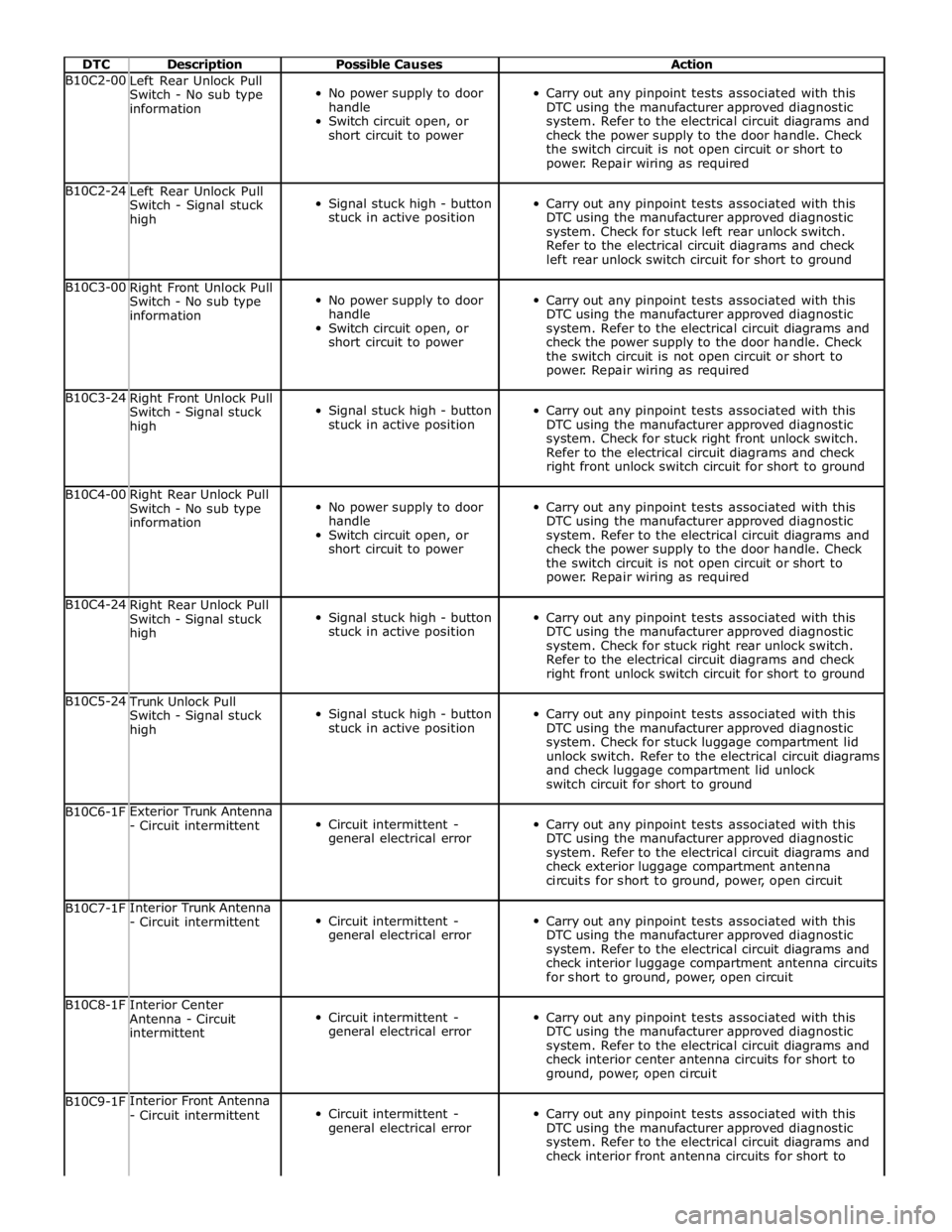

DTC Description Possible Causes Action B10C2-00

Left Rear Unlock Pull

Switch - No sub type

information

No power supply to door

handle

Switch circuit open, or

short circuit to power

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams and

check the power supply to the door handle. Check

the switch circuit is not open circuit or short to

power. Repair wiring as required B10C2-24

Left Rear Unlock Pull

Switch - Signal stuck

high

Signal stuck high - button

stuck in active position

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check for stuck left rear unlock switch.

Refer to the electrical circuit diagrams and check

left rear unlock switch circuit for short to ground B10C3-00

Right Front Unlock Pull

Switch - No sub type

information

No power supply to door

handle

Switch circuit open, or

short circuit to power

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams and

check the power supply to the door handle. Check

the switch circuit is not open circuit or short to

power. Repair wiring as required B10C3-24

Right Front Unlock Pull

Switch - Signal stuck

high

Signal stuck high - button

stuck in active position

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check for stuck right front unlock switch.

Refer to the electrical circuit diagrams and check

right front unlock switch circuit for short to ground B10C4-00

Right Rear Unlock Pull

Switch - No sub type

information

No power supply to door

handle

Switch circuit open, or

short circuit to power

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams and

check the power supply to the door handle. Check

the switch circuit is not open circuit or short to

power. Repair wiring as required B10C4-24

Right Rear Unlock Pull

Switch - Signal stuck

high

Signal stuck high - button

stuck in active position

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check for stuck right rear unlock switch.

Refer to the electrical circuit diagrams and check

right front unlock switch circuit for short to ground B10C5-24 Trunk Unlock Pull

Switch - Signal stuck

high

Signal stuck high - button

stuck in active position

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check for stuck luggage compartment lid

unlock switch. Refer to the electrical circuit diagrams

and check luggage compartment lid unlock

switch circuit for short to ground B10C6-1F Exterior Trunk Antenna

- Circuit intermittent

Circuit intermittent -

general electrical error

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams and

check exterior luggage compartment antenna

circuits for short to ground, power, open circuit B10C7-1F Interior Trunk Antenna

- Circuit intermittent

Circuit intermittent -

general electrical error

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams and

check interior luggage compartment antenna circuits

for short to ground, power, open circuit B10C8-1F

Interior Center

Antenna - Circuit

intermittent

Circuit intermittent -

general electrical error

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams and

check interior center antenna circuits for short to

ground, power, open circuit B10C9-1F Interior Front Antenna

- Circuit intermittent

Circuit intermittent -

general electrical error

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams and

check interior front antenna circuits for short to