JAGUAR XFR 2010 1.G Workshop Manual

Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1661 of 3039

Published: 11-May-2011

Speed Control - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Speed Control Switch

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Make the SRS system safe.

Refer to: Standard Workshop Practices (100-00 General Information, Description and Operation).

2. Refer to: Driver Air Bag Module (501-20B Supplemental Restraint System, Removal and Installation).

3. Refer to: Upshift Paddle Switch (307-05A Automatic Transmission/Transaxle External Controls - V6 3.0L Petrol, Removal and

Installation).

4. Refer to: Downshift Paddle Switch (307-05A Automatic Transmission/Transaxle External Controls - V6 3.0L Petrol, Removal and

Installation).

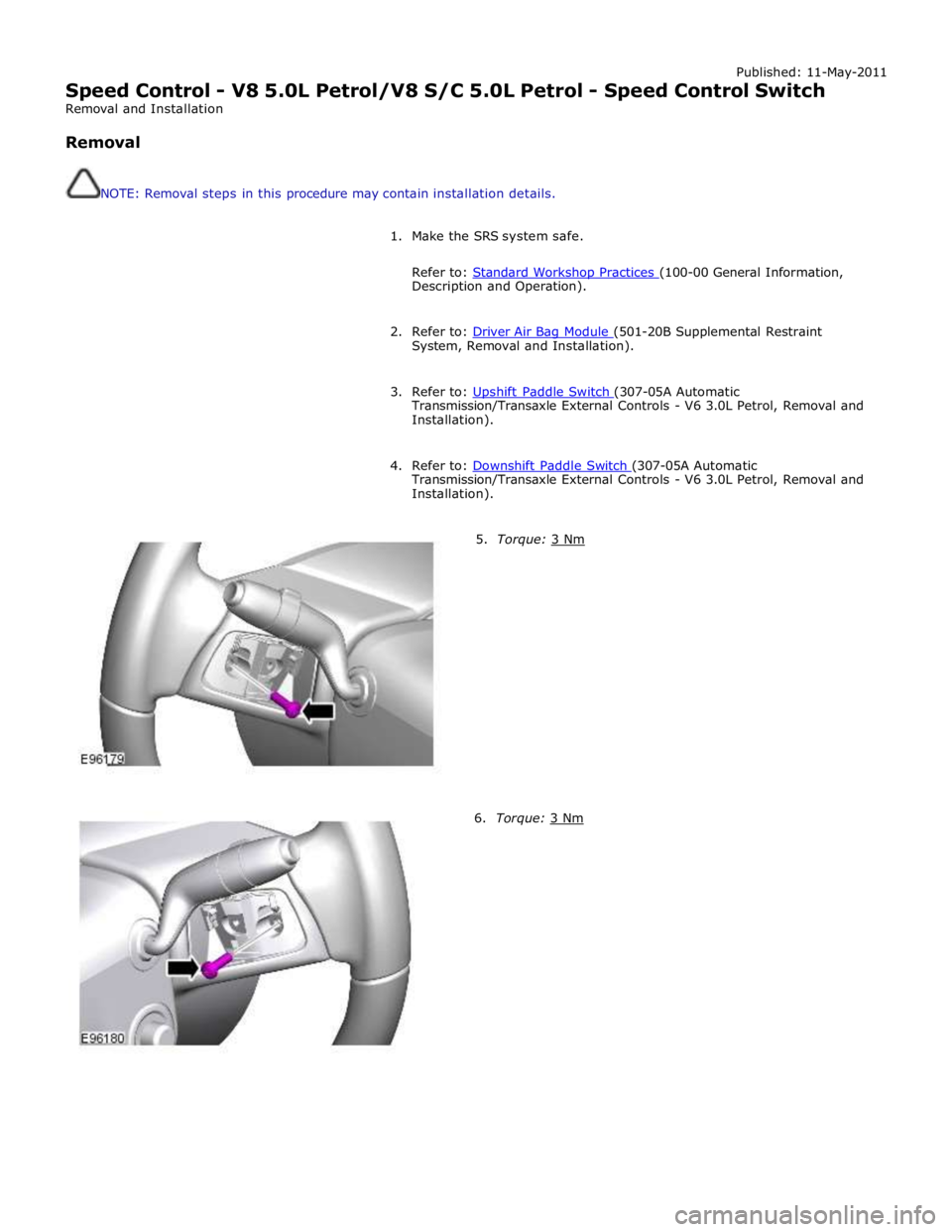

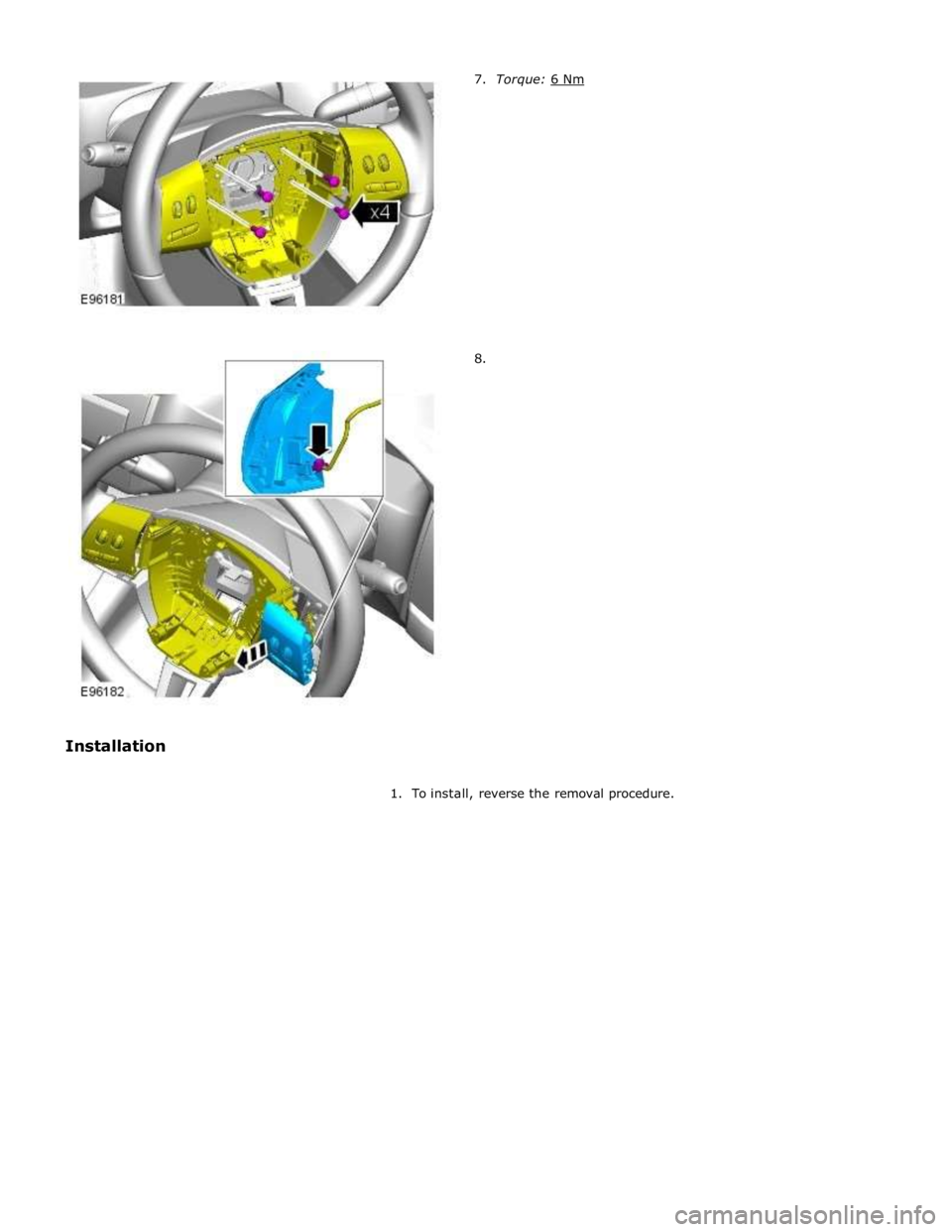

5. Torque: 3 Nm 6. Torque: 3 Nm

Page 1662 of 3039

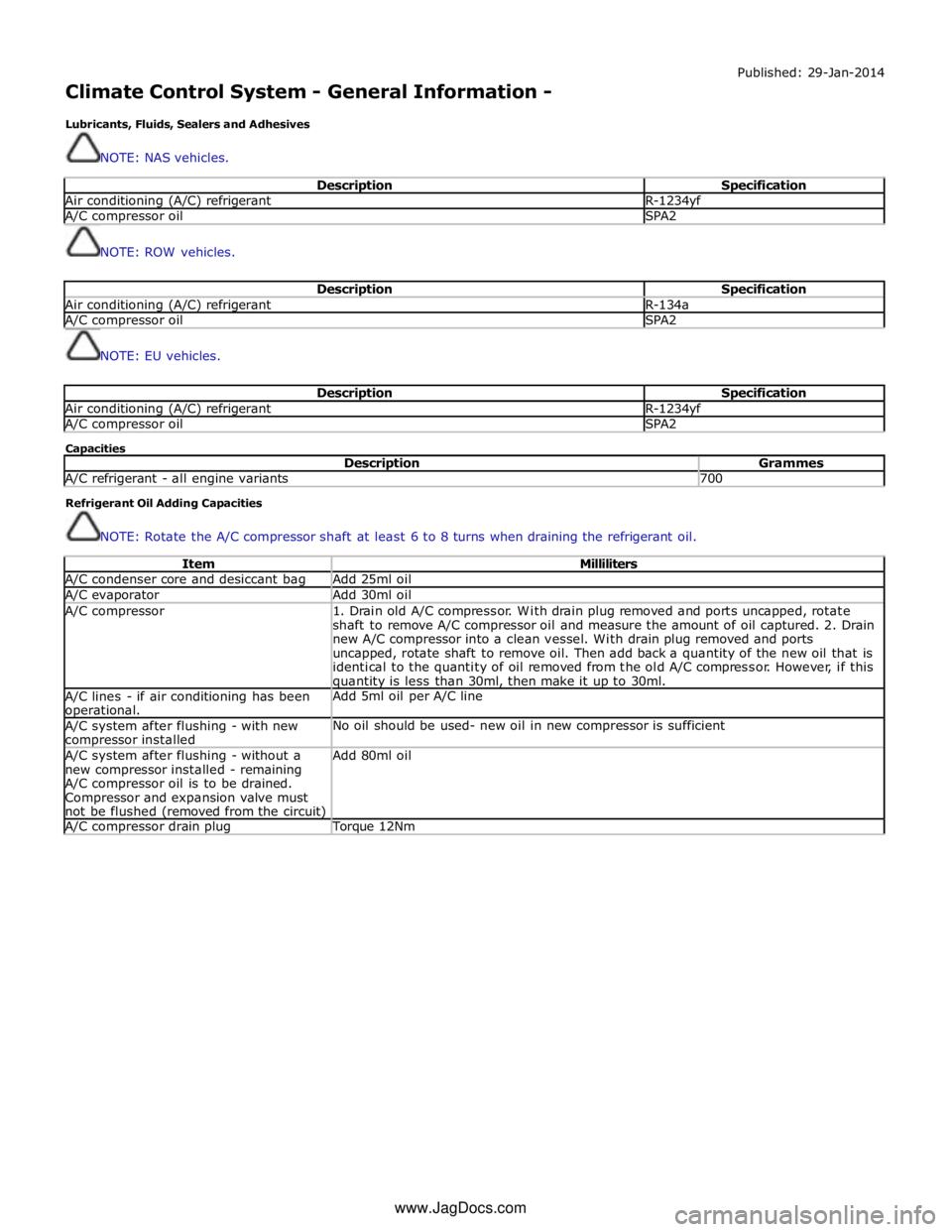

8.

1. To install, reverse the removal procedure.

Page 1663 of 3039

Climate Control System - General Information -

Lubricants, Fluids, Sealers and Adhesives

NOTE: NAS vehicles. Published: 29-Jan-2014

Description Specification Air conditioning (A/C) refrigerant R-1234yf A/C compressor oil SPA2

NOTE: ROW vehicles.

Description Specification Air conditioning (A/C) refrigerant R-134a A/C compressor oil SPA2

NOTE: EU vehicles.

Description Specification Air conditioning (A/C) refrigerant R-1234yf A/C compressor oil SPA2 Capacities

Description Grammes A/C refrigerant - all engine variants 700 Refrigerant Oil Adding Capacities

NOTE: Rotate the A/C compressor shaft at least 6 to 8 turns when draining the refrigerant oil.

Item Milliliters A/C condenser core and desiccant bag Add 25ml oil A/C evaporator Add 30ml oil A/C compressor

1. Drain old A/C compressor. With drain plug removed and ports uncapped, rotate

shaft to remove A/C compressor oil and measure the amount of oil captured. 2. Drain

new A/C compressor into a clean vessel. With drain plug removed and ports

uncapped, rotate shaft to remove oil. Then add back a quantity of the new oil that is

identical to the quantity of oil removed from the old A/C compressor. However, if this quantity is less than 30ml, then make it up to 30ml. A/C lines - if air conditioning has been operational. Add 5ml oil per A/C line A/C system after flushing - with new compressor installed No oil should be used- new oil in new compressor is sufficient A/C system after flushing - without a

new compressor installed - remaining

A/C compressor oil is to be drained.

Compressor and expansion valve must

not be flushed (removed from the circuit) Add 80ml oil A/C compressor drain plug Torque 12Nm www.JagDocs.com

Page 1664 of 3039

Published: 11-Jul-2014

Climate Control System - General Information - Climate Control System

Diagnosis and Testing

Principles of Operation

For a detailed description of the Climate Control System, refer to the relevant Description and Operation sections in the

Workshop Manual. REFER to:

Air Distribution and Filtering (412-01 Climate Control, Description and Operation), Air Distribution and Filtering (412-01 Climate Control, Description and Operation), Air Distribution and Filtering (412-01 Climate Control, Description and Operation), Heating and Ventilation (412-01 Climate Control, Description and Operation), Heating and Ventilation (412-01 Climate Control, Description and Operation), Heating and Ventilation (412-01 Climate Control, Description and Operation), Air Conditioning (412-01 Climate Control, Description and Operation), Air Conditioning (412-01 Climate Control, Description and Operation), Air Conditioning (412-01 Climate Control, Description and Operation), Control Components (412-01 Climate Control, Description and Operation), Control Components (412-01 Climate Control, Description and Operation), Control Components (412-01 Climate Control, Description and Operation), Electric Booster Heater (412-02 Auxiliary Climate Control, Description and Operation), Electric Booster Heater (412-02 Auxiliary Climate Control, Description and Operation), Electric Booster Heater (412-02 Auxiliary Climate Control, Description and Operation).

Inspection and Verification

WARNING: Servicing must be carried out by personnel familiar with both vehicle system and the charging and testing

equipment. All operations must be carried out in a well ventilated area away from open flame and heat sources.

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTE: Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

1. Verify the customer concern

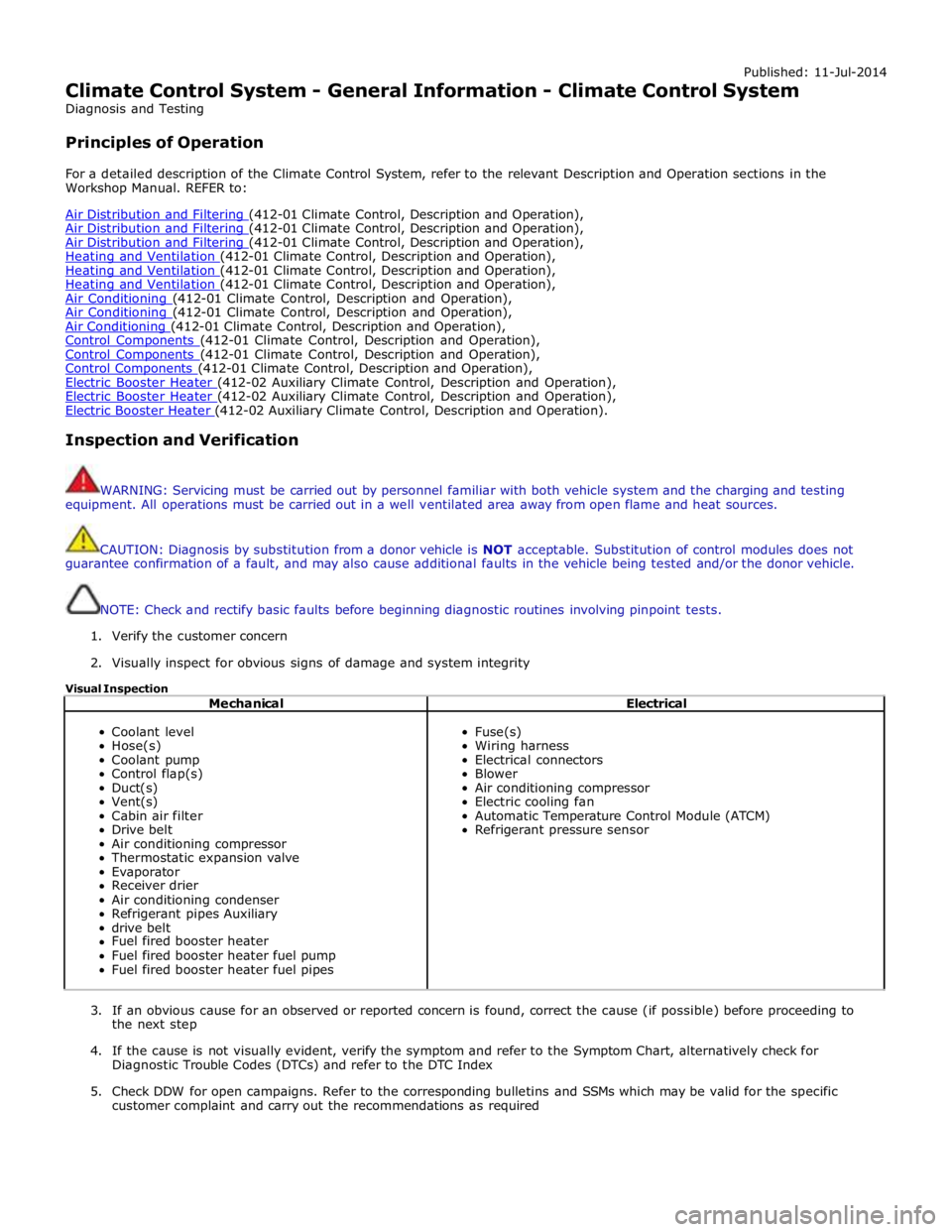

2. Visually inspect for obvious signs of damage and system integrity

Visual Inspection

Mechanical Electrical

Coolant level

Hose(s)

Coolant pump

Control flap(s)

Duct(s)

Vent(s)

Cabin air filter

Drive belt

Air conditioning compressor

Thermostatic expansion valve

Evaporator

Receiver drier

Air conditioning condenser

Refrigerant pipes Auxiliary

drive belt

Fuel fired booster heater

Fuel fired booster heater fuel pump

Fuel fired booster heater fuel pipes

Fuse(s)

Wiring harness

Electrical connectors

Blower

Air conditioning compressor

Electric cooling fan

Automatic Temperature Control Module (ATCM)

Refrigerant pressure sensor

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for

Diagnostic Trouble Codes (DTCs) and refer to the DTC Index

5. Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required

Page 1665 of 3039

Symptom Chart

Symptom Possible Causes Action Air conditioning performance poor or

inoperative

Refrigerant undercharged

Refrigerant overcharged

Thermostatic expansion valve

faulty

Receiver drier restricted

Water in refrigerant

GO to Pinpoint Test A. Air conditioning operates briefly and

then switches off

Electric cooling fan inoperative

Air conditioning condenser

airflow obstructed

Test the operation of the electric cooling

fan

Check the air conditioning condenser for

external obstructions Pinpoint Tests

PINPOINT TEST A : PRELIMINARY TESTS TEST CONDITIONS DETAILS/RESULTS/ACTIONS A1: PRELIMINARY TEST 1 NOTES:

This test is performed with the engine not running.

Normal pressure for a correctly charged and switched off system is approximately 4.5 bar on both gauges (system

equalised). 1 Close the valves on the air conditioning station 2 Connect the air conditioning station to the vehicle charging ports 3 Check the pressure values Is a pressure registered on both gauges? Yes

GO to Pinpoint Test B. No

GO to Pinpoint Test D.

PINPOINT TEST B : FUNCTIONALITY TESTS TEST CONDITIONS DETAILS/RESULTS/ACTIONS B1: FUNCTIONALITY TEST 1 NOTES:

Normal pressures for a correctly charged and working system are 1.0 bar to 2.0 bar (low) and 11.0 bar to 15.0 bar (high).

Normal temperature (measured at the center air vent) for a correctly charged and working system is -7°C to -2°C when

ambient temperature is 20°C. 1 Close the valves on the air conditioning station 2 Connect the air conditioning station to the vehicle charging ports 3 Open all doors and the tailgate 4 Start the engine 5 Set the temperature to the lowest setting (all zones) 6 Set the fan speed to maximum 7 Set the recirculate switch to off 8 Insert a temperature probe into the centre air vent 9 Raise engine speed to 1500rpm and maintain this speed for 5 minutes 10 Check the temperature value 11 Check the pressure values Are the pressure readings stable and in the green 'normal' region of the gauge? Yes

Air conditioning system operating normally No

Air conditioning system fault present. GO to Pinpoint Test C.

PINPOINT TEST C : GAUGE TESTS

Page 1666 of 3039

TEST

CONDITIONS DETAILS/RESULTS/ACTIONS C1: GAUGE TEST 1

NOTE: This test is performed with the engine running and the air conditioning set to on. 1 Check the pressure values Did the gauges register a change in pressure when the air conditioning was switched on? Yes

GO to C2. No

Using the manufacturer approved diagnostic system, check the Automatic Temperature Control Module (ATCM) for related DTCs and refer to the relevant DTC index C2: GAUGE TEST 2

NOTE: This test is performed with the engine running and the air conditioning set to on. 1 Check the pressure values Are the pressure gauge readings fluctuating? Yes

Moisture present in the air conditioning system. Recover the refrigerant. Install a new receiver drier.

Refer to the relevant section of the workshop manual and evacuate and recharge the air conditioning

system. GO to Pinpoint Test B. No

GO to C3. C3: GAUGE TEST 3 NOTES:

This test is performed with the engine running and the air conditioning set to on.

Normal pressures for a correctly charged and working system are 1.0 bar to 2.0 bar (low) and 11.0 bar to 15.0 bar (high). 1 Check the pressure values Are the pressure gauge readings too low? Yes

GO to C4. No

GO to C6. C4: GAUGE TEST 4

NOTE: This test is performed with the engine not running. 1 Stop the engine 2 Using the manufacturer approved refrigerant leak detector, check for a refrigerant leak Was a refrigerant leak detected? Yes

Refer to the relevant section of the workshop manual and recover the refrigerant. Repair as necessary.

Evacuate and recharge the air conditioning system. GO to Pinpoint Test B. No

GO to C5. C5: GAUGE TEST 5

NOTE: This test is performed with the engine not running. 1 Refer to the relevant section of the workshop manual and recover the refrigerant Was the weight of the recovered refrigerant less than specified for the air conditioning system? Yes

Refer to the relevant section of the workshop manual and evacuate and recharge the air conditioning

system. GO to Pinpoint Test B. No

Install a new receiver drier. Refer to the relevant section of the workshop manual and evacuate and recharge the air conditioning system. GO to Pinpoint Test B. C6: GAUGE TEST 6 NOTES:

This test is performed with the engine running and the air conditioning set to on.

Normal pressures for a correctly charged and working system are 1.0 bar to 2.0 bar (low) and 11.0 bar to 15.0 bar (high).

Page 1667 of 3039

1 Check the pressure values Are the pressure gauge readings too high? Yes

GO to C7. No

Test inconclusive. GO to Pinpoint Test B. C7: GAUGE TEST 7

NOTE: This test is performed with the engine not running. 1 Stop the engine 2 Refer to the relevant section of the workshop manual and recover the refrigerant Was the weight of the recovered refrigerant more than specified for the air conditioning system? Yes

Refer to the relevant section of the workshop manual and evacuate and recharge the air conditioning

system. GO to Pinpoint Test B. No

Install a new thermal expansion valve. Refer to the relevant section of the workshop manual and

evacuate and recharge the air conditioning system. GO to Pinpoint Test B.

PINPOINT TEST D : NITROGEN LEAK TESTS TEST

CONDITIONS DETAILS/RESULTS/ACTIONS D1: NITROGEN LEAK TEST

CAUTION: When charging the system with nitrogen, the pressure should be regulated to 7.0 bar.

NOTE: This test is performed with the engine not running. 1 Charge the air conditioning system with nitrogen 2 Isolate the nitrogen supply 3 Monitor the pressure gauge and check for leaks Has the source of the leak been identified?

Yes

Rectify the leak as necessary. Install a new receiver drier. Refer to the relevant section of the workshop

manual and evacuate and recharge the air conditioning system. GO to Pinpoint Test B. No

Refer to the relevant section of the workshop manual and evacuate and recharge the air conditioning system. GO to Pinpoint Test B.

DTC Index

For a list of Diagnostic Trouble Codes (DTCs) that could be logged on this vehicle, please refer to Section 100-00.

REFER to: Diagnostic Trouble Code (DTC) Index - DTC: Climate Control Module (HVAC) (100-00 General Information, Description and Operation).

Page 1668 of 3039

Published: 11-May-2011

Climate Control System - General Information - Air Conditioning (A/C) System

Recovery, Evacuation and Charging

General Procedures

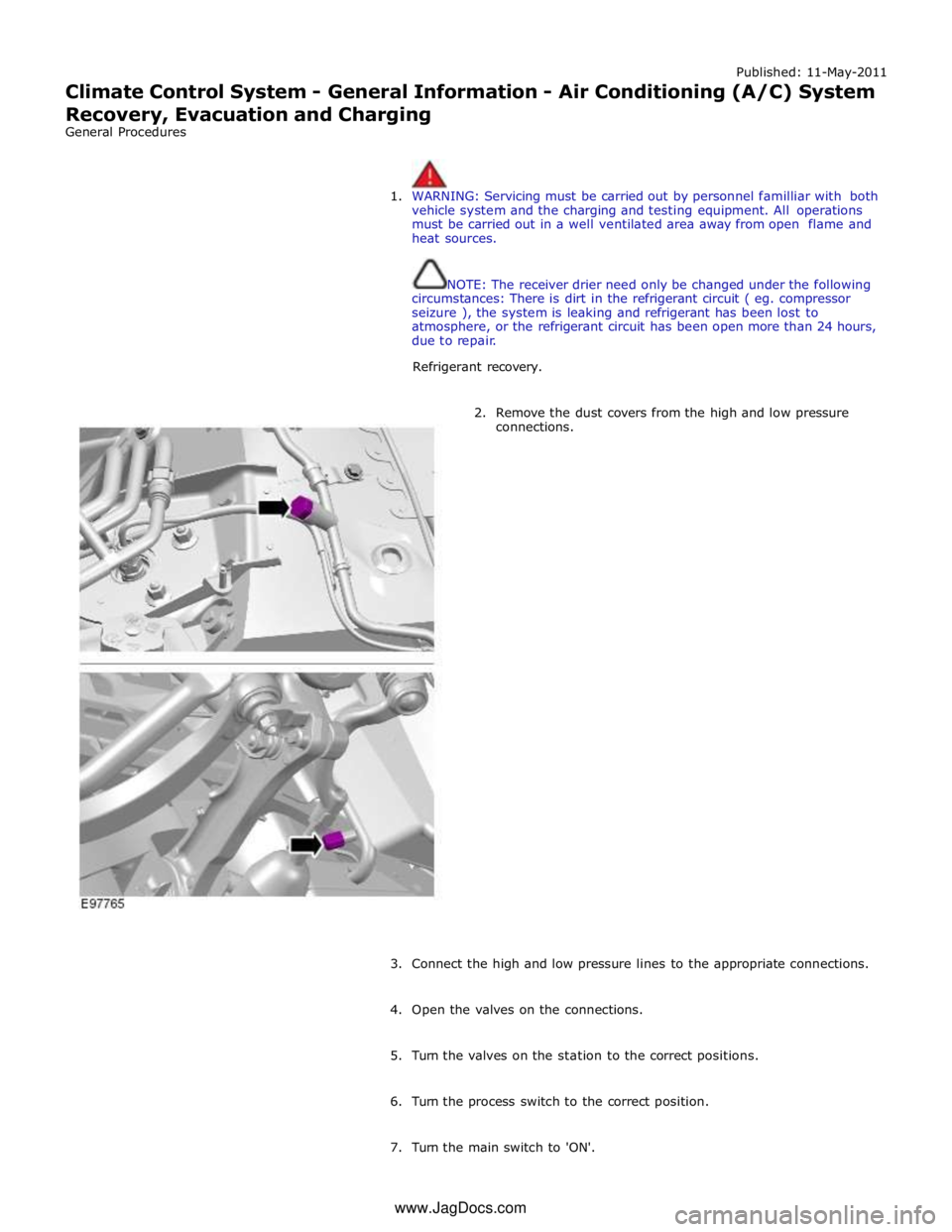

1. WARNING: Servicing must be carried out by personnel familliar with both

vehicle system and the charging and testing equipment. All operations

must be carried out in a well ventilated area away from open flame and

heat sources.

NOTE: The receiver drier need only be changed under the following

circumstances: There is dirt in the refrigerant circuit ( eg. compressor

seizure ), the system is leaking and refrigerant has been lost to

atmosphere, or the refrigerant circuit has been open more than 24 hours,

due to repair.

Refrigerant recovery.

2. Remove the dust covers from the high and low pressure

connections.

3. Connect the high and low pressure lines to the appropriate connections.

4. Open the valves on the connections.

5. Turn the valves on the station to the correct positions.

6. Turn the process switch to the correct position.

7. Turn the main switch to 'ON'. www.JagDocs.com

Page 1669 of 3039

8. WARNING: Refrigerant must always be recycled before re-use to ensure

that the purity of the refrigerantis high enough for safe use in the air

conditioning system. Recycling should always be carried out with

equipment which is design certified by Underwriter Laboratory Inc. for

compliance with SEA J1991. Other equipment may not recycle refrigerant

to the required level of purity. R143a Refrigerant Recover Recycling

Recharging station must not be used with any other type of

refrigerant.Refrigerant R134a from domestic and comercial sources must

not be used in motor vehicles air conditioning systems.

Allow the system to recover the refrigerant from the system.

9. Close the valves on the refrigerant station.

10. Turn the main switch 'OFF'.

11. Close the valves on the connections.

12. Disconnect the high and low pressure connections.

13. Install the dust covers to the connectors.

14. Open the tap at the rear of the station to drain the refrigerant oil.

15. Measure and record the quantity of refrigerant oil recovered from the

system.

16. Close the tap at the rear of the station.

17. Evacuation.

18. Remove the dust covers from the high and low pressure connections.

19. Connect the high and low pressure lines to the appropriate connections.

20. Open the valves on the connections.

21. Turn the valves on the station to the correct positions.

22. Turn the process switch to the correct position.

23. Turn the main switch to 'ON'.

24. Allow the station to evacuate the A/C system.

25. CAUTION: The system must be evacuated immediatley before

recharging commences. Delay between evacuation and recharging is not

permitted

Recharging

26. Close the valves on the refrigerant station.

Page 1670 of 3039

27. Close the valve on the oil charger.

28. Disconnect the yellow line from the refrigerant station.

29. Remove the cover from the oil charger.

30. Pour the correct quantity of refrigerant oil into the oil charger.

31. Install the cover to the oil charger.

32. Connect the yellow line to the refrigerant station.

33. Open the valve on the oil charger.

34. Move the pointer on the refrigerant gauge to mark the position of the

refrigerant drop.

35. Slowly open the correct valve on the refrigerant to allow the vacuum to

pull the refrigerant into the system.

36. Close the valve on the refrigerant station when the correct amount of

refrigerant has been drawn into the air conditioning system.

37. Turn the main switch 'OFF'.

38. Close the valves on the connections.

39. Disconnect the high and low pressure connections.