JAGUAR XFR 2010 1.G Workshop Manual

Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1701 of 3039

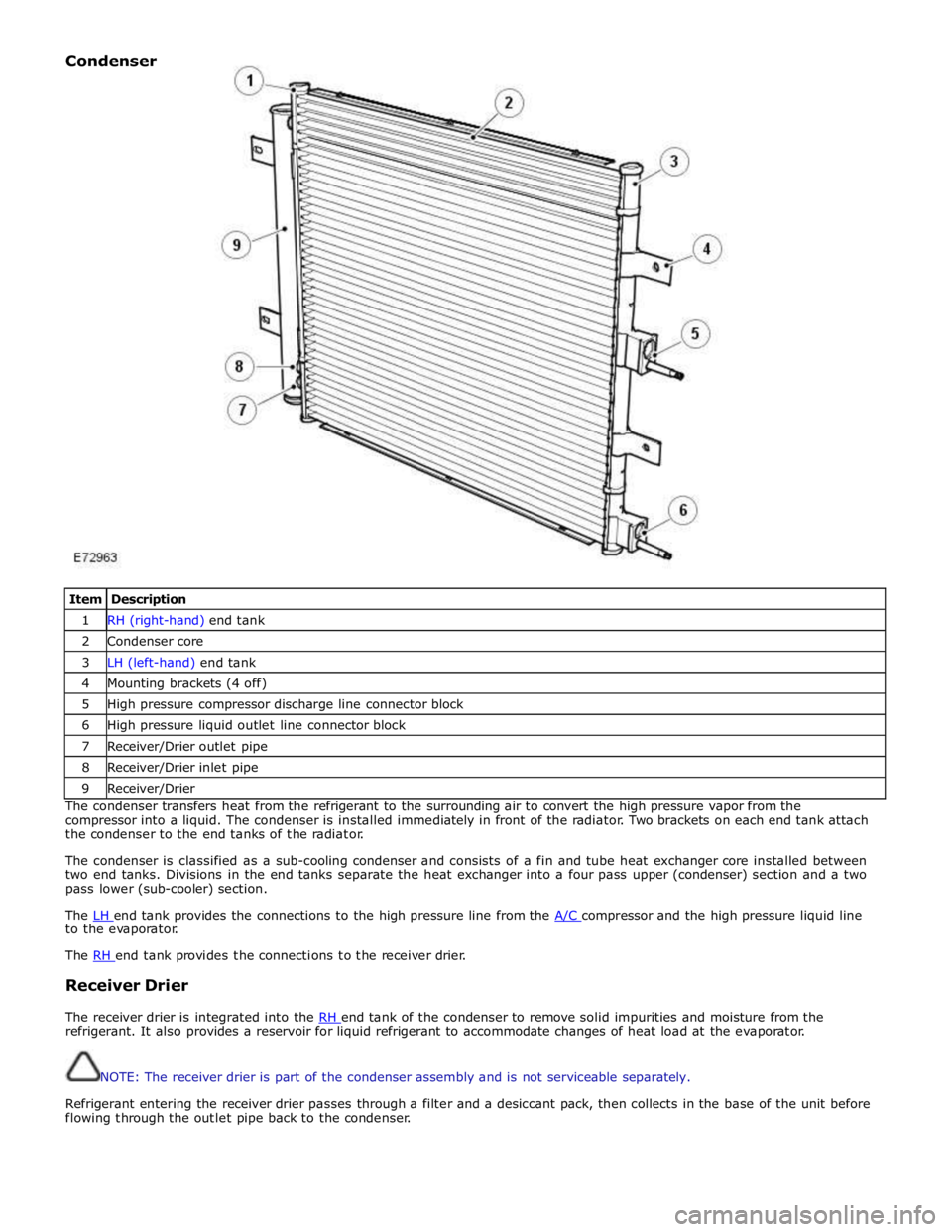

Item Description 1 RH (right-hand) end tank 2 Condenser core 3 LH (left-hand) end tank 4 Mounting brackets (4 off) 5 High pressure compressor discharge line connector block 6 High pressure liquid outlet line connector block 7 Receiver/Drier outlet pipe 8 Receiver/Drier inlet pipe 9 Receiver/Drier The condenser transfers heat from the refrigerant to the surrounding air to convert the high pressure vapor from the

compressor into a liquid. The condenser is installed immediately in front of the radiator. Two brackets on each end tank attach

the condenser to the end tanks of the radiator.

The condenser is classified as a sub-cooling condenser and consists of a fin and tube heat exchanger core installed between

two end tanks. Divisions in the end tanks separate the heat exchanger into a four pass upper (condenser) section and a two

pass lower (sub-cooler) section.

The LH end tank provides the connections to the high pressure line from the A/C compressor and the high pressure liquid line to the evaporator.

The RH end tank provides the connections to the receiver drier.

Receiver Drier

The receiver drier is integrated into the RH end tank of the condenser to remove solid impurities and moisture from the refrigerant. It also provides a reservoir for liquid refrigerant to accommodate changes of heat load at the evaporator.

NOTE: The receiver drier is part of the condenser assembly and is not serviceable separately.

Refrigerant entering the receiver drier passes through a filter and a desiccant pack, then collects in the base of the unit before

flowing through the outlet pipe back to the condenser. Condenser

Page 1702 of 3039

Thermostatic Expansion Valve

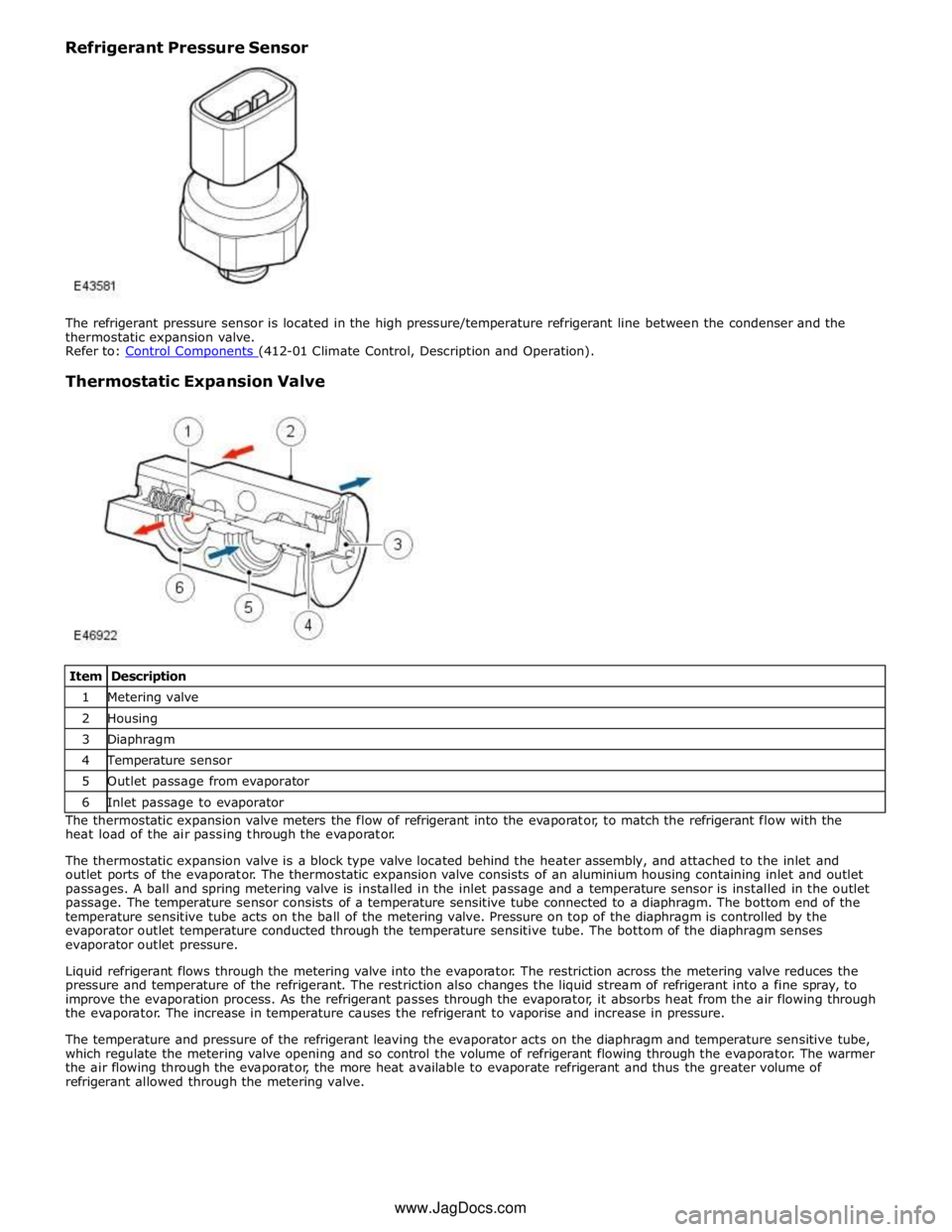

Item Description 1 Metering valve 2 Housing 3 Diaphragm 4 Temperature sensor 5 Outlet passage from evaporator 6 Inlet passage to evaporator The thermostatic expansion valve meters the flow of refrigerant into the evaporator, to match the refrigerant flow with the

heat load of the air passing through the evaporator.

The thermostatic expansion valve is a block type valve located behind the heater assembly, and attached to the inlet and

outlet ports of the evaporator. The thermostatic expansion valve consists of an aluminium housing containing inlet and outlet

passages. A ball and spring metering valve is installed in the inlet passage and a temperature sensor is installed in the outlet

passage. The temperature sensor consists of a temperature sensitive tube connected to a diaphragm. The bottom end of the

temperature sensitive tube acts on the ball of the metering valve. Pressure on top of the diaphragm is controlled by the

evaporator outlet temperature conducted through the temperature sensitive tube. The bottom of the diaphragm senses

evaporator outlet pressure.

Liquid refrigerant flows through the metering valve into the evaporator. The restriction across the metering valve reduces the

pressure and temperature of the refrigerant. The restriction also changes the liquid stream of refrigerant into a fine spray, to

improve the evaporation process. As the refrigerant passes through the evaporator, it absorbs heat from the air flowing through

the evaporator. The increase in temperature causes the refrigerant to vaporise and increase in pressure.

The temperature and pressure of the refrigerant leaving the evaporator acts on the diaphragm and temperature sensitive tube,

which regulate the metering valve opening and so control the volume of refrigerant flowing through the evaporator. The warmer

the air flowing through the evaporator, the more heat available to evaporate refrigerant and thus the greater volume of

refrigerant allowed through the metering valve. www.JagDocs.com

Page 1703 of 3039

pressure/temperature regimes. Larger diameter pipes are installed in the low pressure/temperature regime and smaller

diameter pipes are installed in the high pressure/temperature regime.

Low and high pressure charging connections are incorporated into the refrigerant lines for system servicing.

Page 1704 of 3039

Climate Control - Control Components - Component Location

Description and Operation

NOTE: RHD (right-hand drive) vehicle shown, LHD (left-hand drive) vehicle similar.

Component Location Published: 29-May-2014

Item Description 1 Pollution sensor Comments:

where fitted 2 Sunload sensor 3 Ambient air temperature sensor 4 Windshield (Defrost) distribution stepper motor 5 Evaporator temperature sensor

Page 1705 of 3039

7 LH (left-hand) temperature blend stepper motor 8 Control switches 9 Humidity and temperature sensor 10 Air inlet servo motor 11 Blower 12 ATC (automatic temperature control) module 13 Blower control module 14 Face/Feet distribution stepper motor 15 Refrigerant pressure sensor 16 A/C (air conditioning) compressor solenoid valve

Page 1706 of 3039

Climate Control - Control Components - Overview

Description and Operation

Overview Published: 11-May-2011

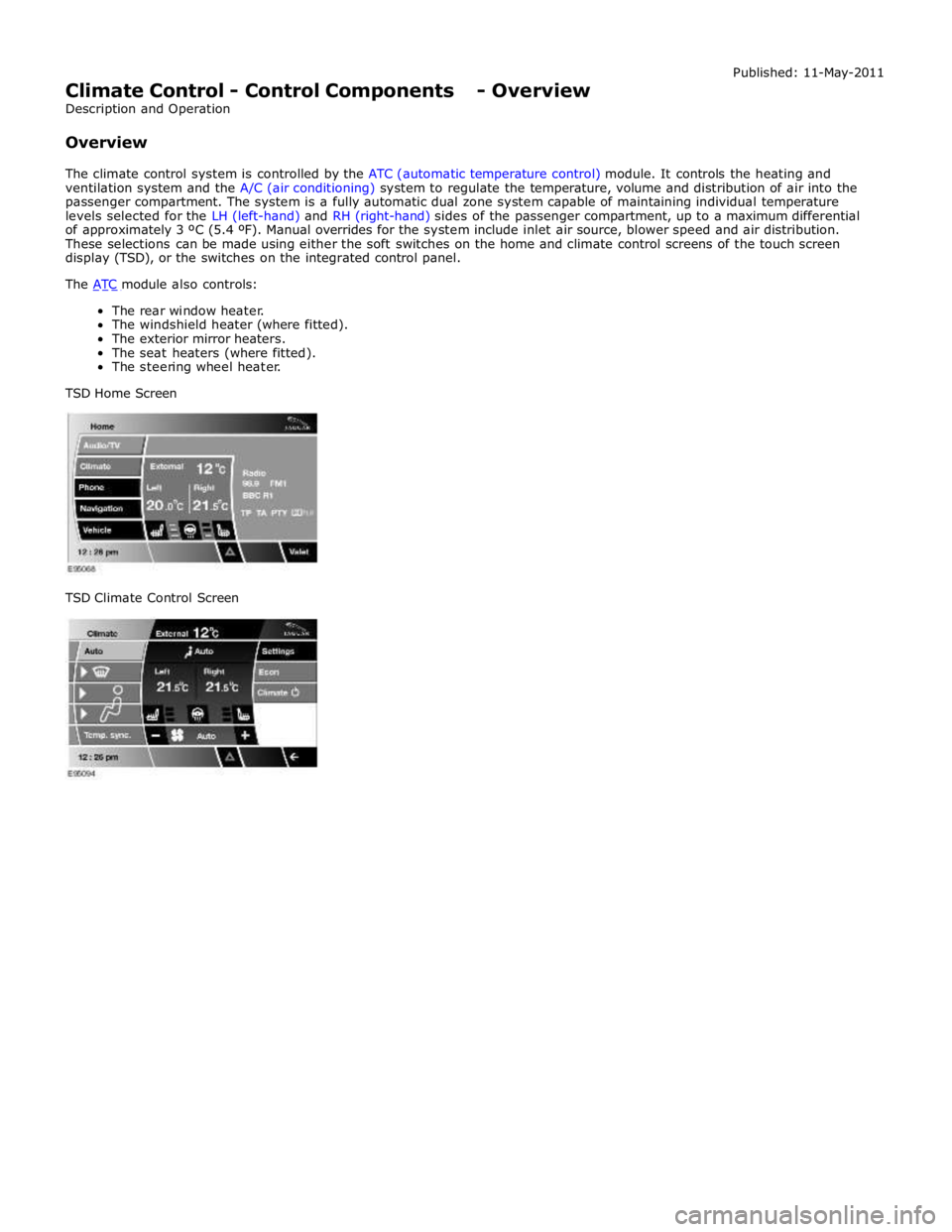

The climate control system is controlled by the ATC (automatic temperature control) module. It controls the heating and

ventilation system and the A/C (air conditioning) system to regulate the temperature, volume and distribution of air into the

passenger compartment. The system is a fully automatic dual zone system capable of maintaining individual temperature

levels selected for the LH (left-hand) and RH (right-hand) sides of the passenger compartment, up to a maximum differential

of approximately 3 ºC (5.4 ºF). Manual overrides for the system include inlet air source, blower speed and air distribution.

These selections can be made using either the soft switches on the home and climate control screens of the touch screen

display (TSD), or the switches on the integrated control panel.

The ATC module also controls: The rear window heater.

The windshield heater (where fitted).

The exterior mirror heaters.

The seat heaters (where fitted).

The steering wheel heater.

TSD Home Screen

TSD Climate Control Screen

Page 1707 of 3039

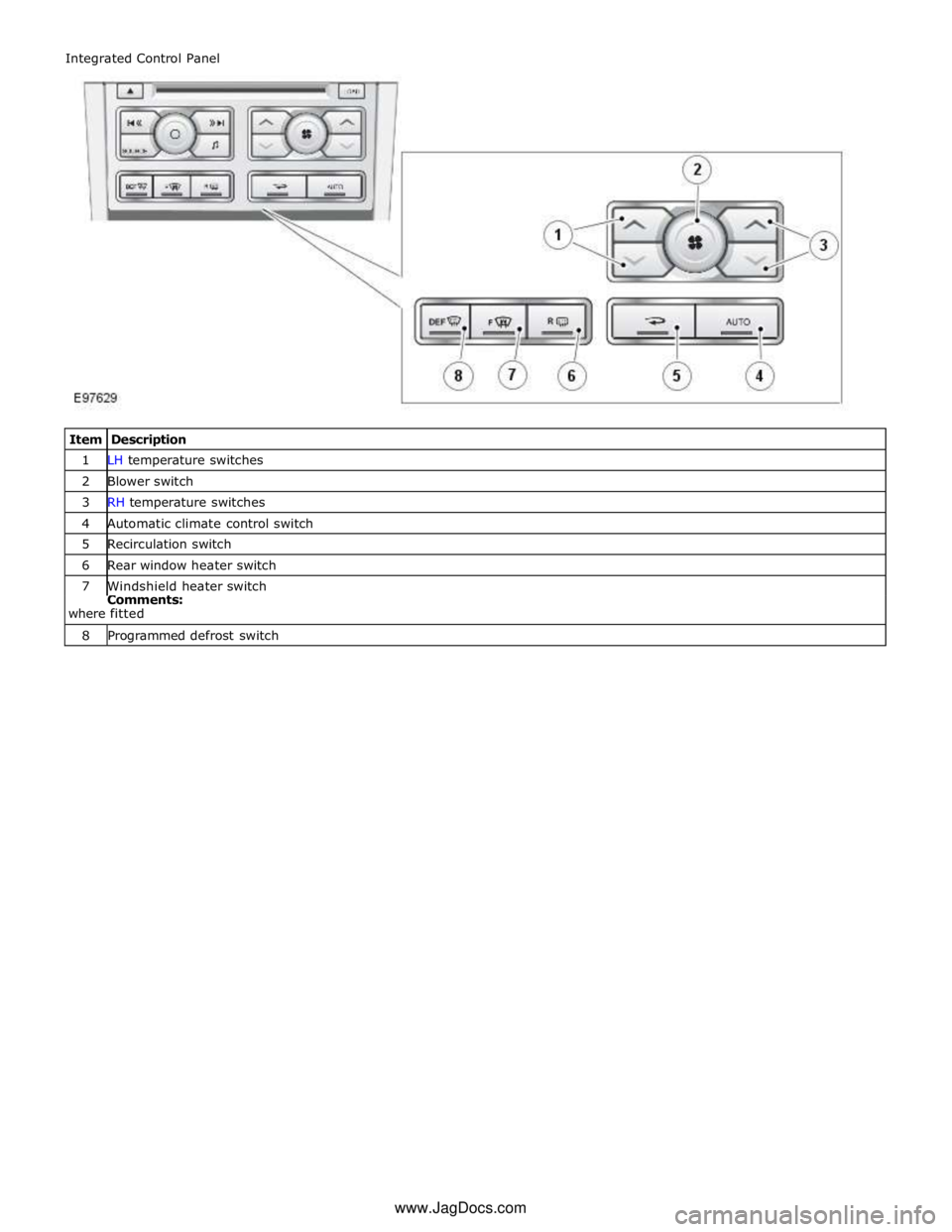

1 LH temperature switches 2 Blower switch 3 RH temperature switches 4 Automatic climate control switch 5 Recirculation switch 6 Rear window heater switch 7 Windshield heater switch Comments:

where fitted 8 Programmed defrost switch Integrated Control Panel

www.JagDocs.com

Page 1708 of 3039

Published: 11-May-2011

Climate Control - Control Components - System Operation and Component Description

Description and Operation

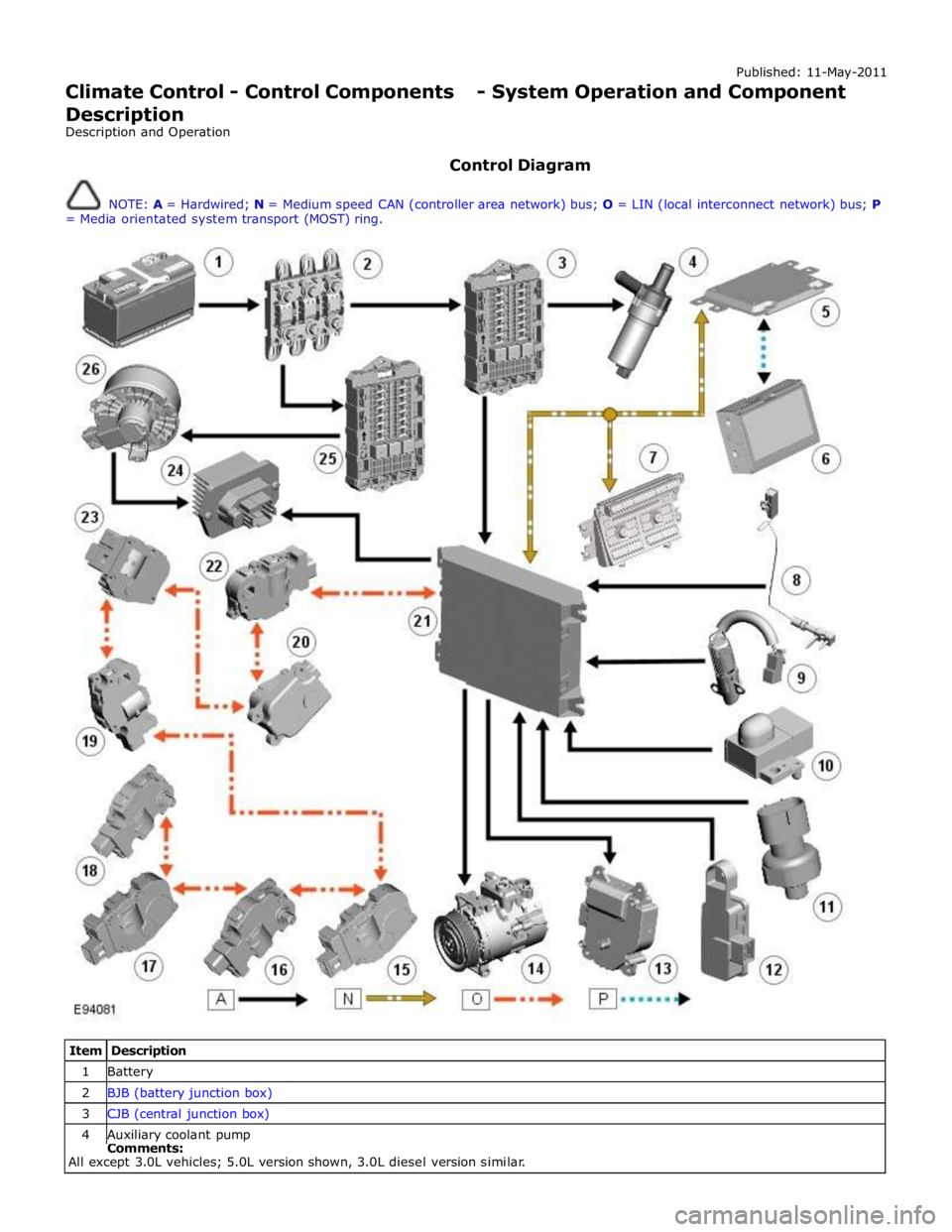

Control Diagram

NOTE: A = Hardwired; N = Medium speed CAN (controller area network) bus; O = LIN (local interconnect network) bus; P

= Media orientated system transport (MOST) ring.

Item Description 1 Battery 2 BJB (battery junction box) 3 CJB (central junction box) 4 Auxiliary coolant pump Comments:

All except 3.0L vehicles; 5.0L version shown, 3.0L diesel version similar.

Page 1709 of 3039

6 TSD (touch screen display) 7 Integrated control panel 8 Evaporator temperature sensor 9 Humidity and temperature sensor 10 Sunload sensor 11 Refrigerant pressure sensor 12 Pollution sensor Comments:

where fitted 13 Air inlet servo motor 14 A/C (air conditioning) compressor solenoid valve 15 RH (right-hand) outer face level register 16 RH inner face level register 17 LH (left-hand) inner face level register 18 LH outer face level register 19 RH temperature blend stepper motor 20 Face/Feet distribution stepper motor 21 ATC (automatic temperature control) module 22 LH temperature blend stepper motor 23 Windshield (Defrost) stepper motor 24 Blower control module 25 RJB (rear junction box) 26 Blower

Air Inlet Control System Operation

The source of inlet air is automatically controlled unless overridden by pressing the air recirculation switch on the integrated

control panel. During automatic control, the ATC module determines the required position of the recirculation door from its 'comfort' algorithm and, if fitted, the pollution sensor.

The ATC module provides analogue signals to the air inlet servo motor along a hardwired connection. A potentiometer in the motor supplies the ATC module with a position feedback signal for closed loop control.

Air Temperature Control

Cooled air from the evaporator enters the heater assembly, where temperature blend doors direct a proportion of the air

through the heater core to produce the required output air temperature.

The two temperature blend doors operate independently to enable individual temperature settings for the left and right sides

of the passenger compartment. The temperature blend doors are operated by stepper motors, which are controlled by the ATC module using LIN bus messages.

The ATC module calculates the temperature blend stepper motor positions required to achieve the selected temperature and compares it against the current position. If there is any difference, the ATC module signals the stepper motors to adopt the new position.

Air temperature is controlled automatically unless maximum heating (HI) or maximum cooling (LO) is selected. When maximum

heating or cooling is selected, a 'comfort' algorithm in the ATC module adopts an appropriate strategy for air distribution, blower speed, and air source.

Temperature control in one side of the passenger compartment can be compromised by the other side of the passenger

compartment being set to a high level of heating or cooling. True maximum heating or cooling (displayed as 'HI' or 'LO' on the

TSD) can only be selected for the driver's side of the passenger compartment. If 'HI' or 'LO' is selected for the driver's side, the

temperature for the front passenger's side is automatically set to match the driver's side.

If A/C is selected off in the automatic mode, no cooling of the inlet air will take place. The minimum output air temperature from the system will be ambient air temperature plus any heat pick up in the air inlet path.

If the Temp. sync. soft button on the TSD is pressed, the ATC module synchronizes the temperature of the passenger side of the passenger compartment with the driver's side.

Blower Control

When the system is in the automatic mode, the ATC module determines the blower speed required from a comfort algorithm. When the system is in the manual mode, the ATC module operates the blower at the speed selected using either the rotary

Page 1710 of 3039

control switch on the integrated control panel or the + and - soft buttons on the touch screen display (TSD). The ATC module also adjusts blower speed to compensate for the ram effect on inlet air produced by forward movement of the vehicle. As

vehicle speed and ram effect increases, blower motor speed is reduced, and vice versa.

Air Distribution Control

Two air distribution doors are used to direct air into the passenger compartment. The doors are operated by stepper motors,

which are controlled by the ATC module using LIN bus messages.

When the A/C system is in automatic mode, the ATC module automatically controls air distribution into the passenger compartment in line with its 'comfort' algorithm. Automatic control is overridden if any of the TSD air distribution soft buttons

are selected. Air distribution in the passenger compartment will remain as selected until the 'Auto' switch is pressed or a

different manual selection is made.

A/C Compressor Control

When A/C is selected the ATC module maintains the evaporator at an operating temperature that varies with the passenger compartment cooling requirements. If the requirement for cooled air decreases, the ATC module raises the evaporator operating temperature by reducing the flow of refrigerant provided by the A/C compressor. The ATC module closely controls the rate of temperature increase to avoid introducing moisture into the passenger compartment.

If the requirement for cooled air increases, the ATC module lowers the evaporator operating temperature by increasing the flow of refrigerant provided by the A/C compressor.

When A/C is off, the compressor current signal supplied by the ATC module holds the A/C compressor solenoid valve in the minimum flow position, effectively switching off the A/C function.

The ATC module incorporates limits for the operating pressure of the refrigerant system. If the system approaches the high pressure limit, the compressor current signal is progressively reduced until the system pressure decreases. If the system falls

below the low pressure limit, the compressor current signal is held at its lowest setting so that the A/C compressor is maintained at its minimum stroke. This avoids depletion of the lubricant from the A/C compressor.

A/C Compressor Torque

The ATC module transmits refrigerant pressure and A/C compressor current values to the ECM (engine control module) over the medium speed then high speed CAN bus, using the CJB as a gateway. The ECM uses these values to calculate the torque being used to drive the A/C compressor. The ECM compares the calculated value with its allowable value and if necessary forces the ATC module to inhibit the A/C compressor by transmitting the 'ACClutchInhibit' CAN message. This forces the ATC module to reduce the drive current to the A/C compressor solenoid valve, which reduces refrigerant flow. This in turn reduces the torque required to drive the A/C compressor.

By reducing the maximum A/C compressor torque, the ECM is able to reduce the load on the engine when it needs to maintain vehicle performance or cooling system integrity.

Cooling Fan Control

The ATC module determines the amount of condenser cooling required from the refrigerant pressure sensor, since there is a direct relationship between the temperature and pressure of the refrigerant. The cooling requirement is broadcast to the ECM on the medium speed CAN bus. The ECM then controls the temperature of the condenser using the cooling fan.

Programmed Defrost

The programmed defrost DEF switch is located on the integrated control panel. When the switch is pressed, the ATC module instigates the programmed defrost function. When selected, the ATC module configures the system as follows:

Automatic mode off.

A/C on. Selected temperature unchanged.

Air inlet set to fresh air.

Air distribution set to windshield.

Blower speed set to level 6.

Windshield heater (where fitted) and rear window heater on.

The programmed defrost function can be cancelled by one of the following:

Selecting any air distribution switch on the TSD.

Pressing the AUTO switch on the integrated control panel.

A second press of the DEF button.

Switching the ignition OFF.

The blower speed can be adjusted without terminating the programmed defrost function.

Rear Window Heater

Rear window heater operation is only enabled when the engine is running. The ATC module controls operation of the rear window heater using a relay in the RJB. When rear window heater operation is required, the ATC module broadcasts a message to the RJB on the medium speed CAN bus. On receipt of the message, the RJB energizes the relay by providing a ground path for the relay coil. This allows a battery feed to flow across the relay to power the rear window heater element.