JAGUAR XFR 2010 1.G Workshop Manual

Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 2061 of 3039

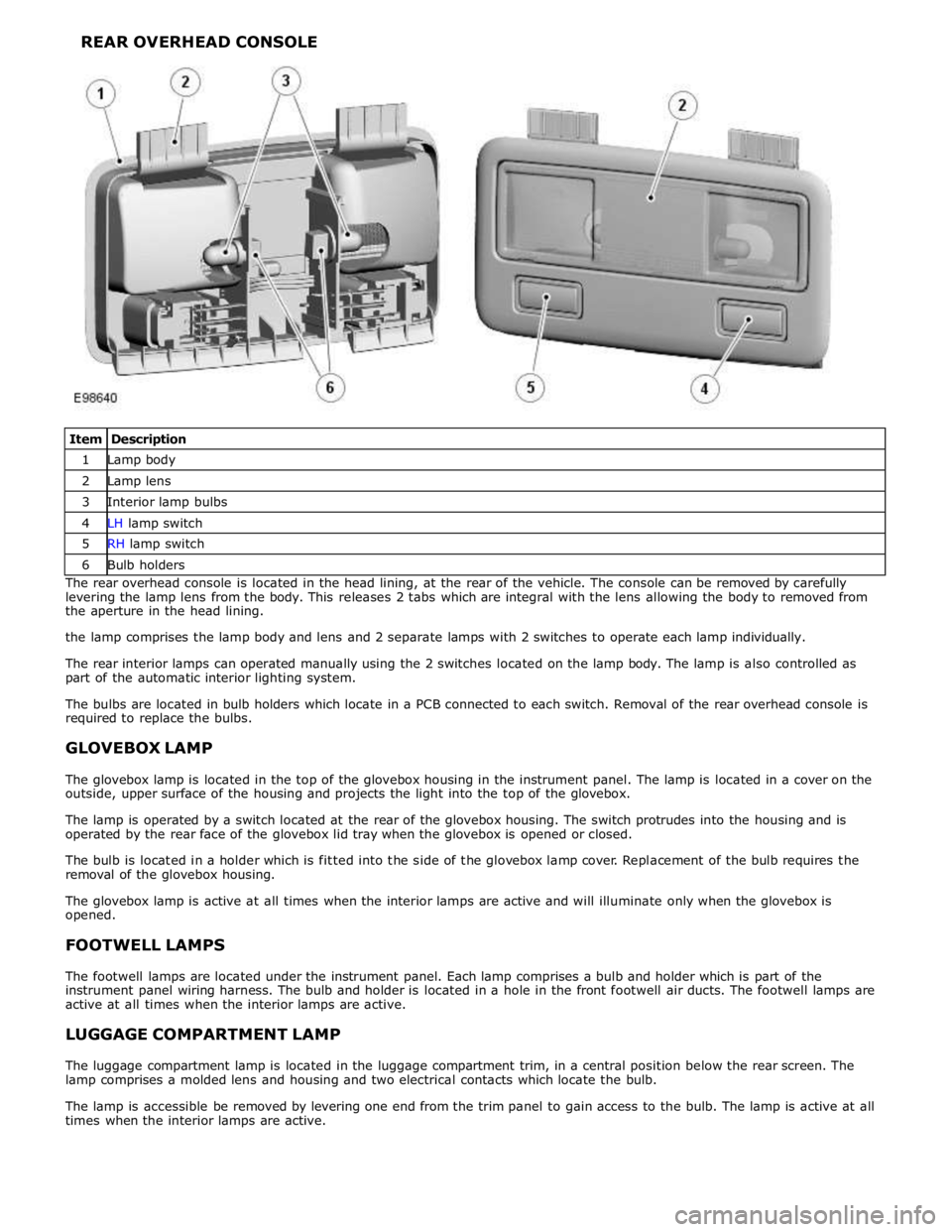

1 Lamp body 2 Lamp lens 3 Interior lamp bulbs 4 LH lamp switch 5 RH lamp switch 6 Bulb holders The rear overhead console is located in the head lining, at the rear of the vehicle. The console can be removed by carefully

levering the lamp lens from the body. This releases 2 tabs which are integral with the lens allowing the body to removed from

the aperture in the head lining.

the lamp comprises the lamp body and lens and 2 separate lamps with 2 switches to operate each lamp individually.

The rear interior lamps can operated manually using the 2 switches located on the lamp body. The lamp is also controlled as

part of the automatic interior lighting system.

The bulbs are located in bulb holders which locate in a PCB connected to each switch. Removal of the rear overhead console is

required to replace the bulbs.

GLOVEBOX LAMP

The glovebox lamp is located in the top of the glovebox housing in the instrument panel. The lamp is located in a cover on the

outside, upper surface of the housing and projects the light into the top of the glovebox.

The lamp is operated by a switch located at the rear of the glovebox housing. The switch protrudes into the housing and is

operated by the rear face of the glovebox lid tray when the glovebox is opened or closed.

The bulb is located in a holder which is fitted into the side of the glovebox lamp cover. Replacement of the bulb requires the

removal of the glovebox housing.

The glovebox lamp is active at all times when the interior lamps are active and will illuminate only when the glovebox is

opened.

FOOTWELL LAMPS

The footwell lamps are located under the instrument panel. Each lamp comprises a bulb and holder which is part of the

instrument panel wiring harness. The bulb and holder is located in a hole in the front footwell air ducts. The footwell lamps are

active at all times when the interior lamps are active.

LUGGAGE COMPARTMENT LAMP

The luggage compartment lamp is located in the luggage compartment trim, in a central position below the rear screen. The

lamp comprises a molded lens and housing and two electrical contacts which locate the bulb.

The lamp is accessible be removed by levering one end from the trim panel to gain access to the bulb. The lamp is active at all

times when the interior lamps are active.

Page 2062 of 3039

VANITY MIRROR LAMPS

Four vanity mirror lamps are fitted, two in each vanity mirror. The lamps are illuminated when the mirror cover is raised. The

vanity mirror lamps operate at all times when the interior lamps are active.

The vanity mirrors use low voltage, 1.2W festoon type bulbs.

DOOR MIRROR APPROACH LAMPS

A door mirror approach lamp is located on the underside of each exterior door mirror.

The approach lamps are active at all times when the interior lamps are active.

Page 2063 of 3039

Interior Lighting - Interior Lighting

Diagnosis and Testing

Principles of Operation Published: 11-May-2011

For a detailed description of the interior lighting system, refer to the relevant Description and Operation sections in the

workshop manual. REFER to: (417-02 Interior Lighting)

Interior Lighting (Description and Operation), Interior Lighting (Description and Operation), Interior Lighting (Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical

Bulbs

Fuses/relays (refer to electrical guide)

Wiring harness

Correct engagement of electrical connectors

Loose or corroded connections

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, check for Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

DTC Index

CAUTION: When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit, part

number 3548-1358-00

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual (section B1.2), or determine if any prior approval programme is in operation, prior to

the installation of a new module/component.

Generic scan tools may not read the codes listed, or may read only five digit codes. Match the five digits from the scan

tool to the first five digits of the seven digit code listed to identify the fault (the last two digits give extra information read by

the manufacturer-approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal places and

with a current calibration certificate. When testing resistance, always take the resistance of the DMM leads into account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

DTC Description Possible Cause Action B116511

Left Front

Puddle Lamp

Output

Left front puddle lamp

control circuit - short to

ground Refer to the electrical circuit diagrams and test left front puddle

lamp control circuit for short to ground

Page 2064 of 3039

DTC Description Possible Cause Action B116515

Left Front

Puddle Lamp

Output

Left front puddle lamp

control circuit - short to

power, open circuit Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and test left front puddle lamp control circuit

for short to power, open circuit B116611

Right Front

Puddle Lamp

Output

Right front puddle lamp

control circuit - short to

ground Refer to the electrical circuit diagrams and test right front

puddle lamp control circuit for short to ground B116615

Right Front

Puddle Lamp

Output

Right front puddle lamp

control circuit - short to

power, open circuit Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and test right front puddle lamp control circuit

for short to power, open circuit B111E11

Boot/Trunk

Lamps

Luggage compartment lamp

control circuit - short to

ground Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check luggage compartment lamp control

circuit for short to ground B111E15

Boot/Trunk

Lamps

Luggage compartment lamp

control circuit - short to

power, open circuit Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check luggage compartment lamp control

circuit for short to power, open circuit B112412

Lamp Fade

Control

Interior lamp fade control

circuit - short to power Refer to the electrical circuit diagrams and check interior lamp

fade control circuit for short to power B113C12

Hazard Switch

Illumination

Hazard switch illumination

control circuit - short to

power Refer to the electrical circuit diagrams and check hazard switch

illumination control circuit for short to power B1A8596

Ambient Light

Sensor

Light sensor internal

electronic failure Check and install a new sensor as required U201012

Switch

Illumination

Switch/interior illumination

PWM supply circuit - short to

power Refer to the electrical circuit diagrams and check switch/interior

illumination PWM supply circuit for short to power U201014

Switch

Illumination

Switch/interior illumination

PWM supply circuit - short to

ground, open circuit Refer to the electrical circuit diagrams and check switch/interior

illumination PWM supply circuit for short to ground, open circuit

Page 2065 of 3039

www.JagDocs.com

Page 2066 of 3039

Published: 11-May-2011

Daytime Running Lamps (DRL) - Daytime Running Lamps (DRL) - System

Operation and Component Description

Description and Operation

CENTRAL JUNCTION BOX (CJB) System Operation

The CJB (central junction box) controls the operation of the DRL (daytime running lamps). The DRL are activated once the CJB detects an ignition on power mode 6 signal.

The CJB also monitors the lighting control switch and the auto lamps feature and overrides the DRL if required.

DAYTIME RUNNING LAMPS - CANADA Component Description

The DRL for this market use full intensity low beam headlamps. The side marker lamps, tail lamps and license plate lamps will be on, but instrument cluster illumination will be off. DRL are active when the following parameters are met:

PARK is not selected on the electronic transmission selector

Electronic Parking Brake (EPB) is off

Power mode 6 (ignition on) detected by the CJB The CJB receives an engine running signal The lighting control switch is in the off or side lamps position.

NOTES:

If the lighting control switch is moved to the headlamp position, DRL are deactivated and normal side lamp and headlamp functionality is operational.

When DRL are active, the headlamp flash function using the left hand steering column multifunction switch will operate normally.

The high beam headlamp function using the left hand steering column stalk switch will be deactivated. When the transmission

is in PARK, DRL are turned off. This is to reduce battery discharge during long periods of engine idling in cold climate conditions. When the electronic transmission selector is moved from the PARK position, normal DRL functionality is restored.

DAYTIME RUNNING LAMPS - DENMARK, HOLLAND, NORWAY, SWEDEN, FINLAND AND POLAND

NOTE: DRL for Poland is on vehicles from 2008MY.

DRL for these markets use full intensity low beam headlamps. Side lamps and license plate lamps will be on, but instrument cluster illumination will be off. DRL are active when the following parameters are met:

Power mode 6 (ignition on) detected by the CJB The CJB receives an engine running signal The lighting control switch is in the off position.

NOTE: When DRL are active, the headlamp flash function using the left hand steering column multifunction switch will operate normally. The high beam headlamp function using the left hand steering column stalk switch will be deactivated.

If the lighting control switch is moved to the side lamp or headlamp positions, DRL are deactivated and normal side lamp and headlamp functionality is operational.

AUTOMATIC HEADLAMPS

On vehicles fitted with the automatic headlamps feature, DRL are overridden if the lighting control switch is in the 'Auto' position and the CJB receives a signal from the rain/light sensor to activate the exterior lights.

When the CJB receives a signal to de-activate the automatic headlamps feature the DRL function is restored providing the parameters for DRL activation are met.

Page 2067 of 3039

Published: 11-May-2011

Module Communications Network - Communications Network - Overview

Description and Operation

OVERVIEW

A number of different types of communication network are incorporated into the vehicle wiring harnesses for the transmission

of commands and information between control modules. The configuration installed on a particular vehicle depends on the

model and equipment level.

NOTE: The control diagrams shown later in this section are schematics reflecting communications networks fitted to LH

(left-hand) vehicles only. For detailed layouts of the various communications networks fitted to LHD (left-hand drive) and RHD

(right-hand drive) vehicles, refer to the Electrical Guide.

The communications networks available on the vehicle are shown in the table below.

Network Baud Rate LIN (local interconnect network) bus 9.6 kbits/s Medium speed CAN (controller area network) bus 125 kbits/s High speed CAN bus 500 kbits/s Media Orientated System Transport (MOST) ring 24 mbits/s

Page 2068 of 3039

Published: 11-May-2011

Module Communications Network - Communications Network - System

Operation and Component Description

Description and Operation

Control Diagram

NOTE:

CONTROL DIAGRAM - LIN BUS - SHEET 1 OF 2

Item Description O = LIN (local interconnect network) bus 1 CJB (central junction box) 2 Battery backed sounder 3 Intrusion detection module

Page 2069 of 3039

5 RJB (rear junction box) 6 Battery monitoring system module 7 Rear view camera 8 TCM (transmission control module) 9 Generator 10 Driver's door switch pack 11 Rear door control module 12 Driver's door control module 13 ECM (engine control module) 14 Electronic transmission selector 15 Driver's seat module 16 Driver's seat switch pack 17 Rear door control module 18 Front passenger door control module 19 Clockspring 20 Audio and telephone steering wheel switches 21 Instrument cluster 22 Start control module

Page 2070 of 3039

O = LIN bus 1 ATC (automatic temperature control) module 2 Stepper motor - Windshield defrost 3 Stepper motor - Face/feet distribution 4 Stepper motor - LH (left-hand) temperature blend 5 Stepper motor - RH (right-hand) temperature blend 6 Electric booster heater 7 Stepper motor - RH outer face level vent 8 Stepper motor - RH inner face level vent 9 Stepper motor - LH inner face level vent 10 Stepper motor - LH outer face level vent CONTROL DIAGRAM - LIN BUS - SHEET 2 OF 2

www.JagDocs.com