Fuel JAGUAR XFR 2010 1.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 174 of 3039

DTC Description Possible Causes Action P007D-00

Charge Air Cooler

Temperature Sensor Circuit

High (Bank 1) - No sub type

information

NOTE: - Circuit TMAP_TEMP_SENSOR

-

Charge air cooler temperature

sensor (Bank 1) circuit short circuit

to power, open circuit, high

resistance

Charge air cooler temperature

sensor (Bank 1) failure

Refer to the electrical circuit

diagrams and check charge air cooler

temperature sensor (Bank 1) circuit

for short circuit to power, open

circuit, high resistance

Check and install a new charge air

cooler temperature sensor (Bank 1)

as required. Refer to the warranty

policy and procedures manual, or

determine if any prior approval

programme is in operation, prior to

the installation of a new

module/component P0087-00

Fuel Rail/System Pressure -

Too Low - No sub type

information

NOTE: - Circuit

FUEL_HIGH_PRESS_SENSOR -

Fuel rail pressure sensor circuit

short circuit to ground, open

circuit, high resistance

Fuel rail pressure sensor failure

Fuel lines leaking or restricted

Fuel pump failure

Using the manufacturer approved

diagnostic system check datalogger

signal, Fuel Rail Pressure Sensor -

High Range Sensor Voltage (0x0377)

Refer to the electrical circuit

diagrams and check fuel rail pressure

sensor circuit for short circuit to

ground, open circuit, high resistance

Check for fuel pump related DTCs.

Check fuel lines for leakage or

restriction

Check and install new fuel rail

pressure sensor as required. Check

and install a new fuel pump as

required. Refer to the warranty policy

and procedures manual, or determine

if any prior approval programme is in

operation, prior to the installation of

a new module/component P0088-00

Fuel Rail/System Pressure -

Too High - No sub type

information

NOTE: - Circuit

FUEL_HIGH_PRESS_SENSOR -

Fuel rail pressure sensor circuit

short to each other, high

resistance, short circuit to power

Fuel rail pressure sensor failure

Using the manufacturer approved

diagnostic system check datalogger

signal, Fuel Rail Pressure Sensor -

High Range Sensor Voltage (0x0377)

Refer to the electrical circuit

diagrams and check fuel rail pressure

sensor circuit for short to each other,

high resistance, short circuit to

power

Check and install new fuel rail

pressure sensor as required. Refer to

the warranty policy and procedures

manual, or determine if any prior

approval programme is in operation,

prior to the installation of a new

module/component P008A-00

Low Pressure Fuel System

Pressure - Too Low - No sub

type information

NOTE: - Circuit

LOW_PRESS_FUEL_PRESS_SENSOR -

Low pressure fuel sensor circuit

failure, short circuit to ground,

short circuit to power, open circuit

Fuel pump driver module circuit

short circuit to ground, short circuit

to power, open circuit

Low pressure fuel

Fuel pump driver module failure

Using the manufacturer approved

diagnostic system check datalogger

signal, Fuel Rail Pressure - Low

Range Sensor Voltage (0x0376)

Check fuel system for leakage

Refer to the electrical circuit

diagrams and check low pressure

fuel sensor circuit for short circuit to

ground, short circuit to power, open

circuit

Refer to the electrical circuit

diagrams and check fuel pump driver

module circuit short circuit to

ground, short circuit to power, open

circuit

Check and install a new low pressure

fuel sensor as required. Check and

install a new fuel pump driver

module as required. Refer to the

warranty policy and procedures

manual, or determine if any prior

approval programme is in operation,

prior to the installation of a new

module/component

Page 188 of 3039

DTC Description Possible Causes Action Instrument cluster power

and ground supply circuits -

short, open circuit

Incorrect CJB or instrument

cluster installed

Target SID synchronization

error following

re-programming

Noise/EMC related error electrical circuit diagrams and check CJB ignition,

power and ground supply circuits for short, open

circuit and instrument cluster power and ground

supply circuits for short, open circuit. Check

correct CJB and instrument cluster installed.

Perform the Immobilisation application from the

Set-up menu using the manufacturer approved

diagnostic system. Check CAN network for

interference/EMC related issues B1009-87

Ignition Authorisation -

Missing message

CJB ignition, power and

ground supply circuits -

short, open circuit

LS CAN fault

Instrument cluster power

and ground supply circuits -

short, open circuit

Low battery voltage <9

volts

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check CJB ignition, power and ground supply

circuits for short, open circuit and instrument

cluster power and ground supply circuits for

short, open circuit. Check CAN communications

between CJB and instrument cluster. Check

battery is in serviceable condition and fully

charged B100A-62 Fuel Pump Authorisation

- Signal compare failure

LS CAN fault

RJB power and ground

supply circuits - short, open

circuit

Instrument cluster power

and ground supply circuits -

short, open circuit

Incorrect RJB or instrument

cluster installed

Target SID synchronization

error following

re-programming

Noise/EMC related error

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check CAN communications between

RJB and instrument cluster. Refer to the

electrical circuit diagrams and check RJB power

and ground supply circuits for short, open circuit

and instrument cluster power and ground supply

circuits for short, open circuit. Check correct RJB

and instrument cluster installed. Perform the

Immobilisation application from the Set-up menu

using the manufacturer approved diagnostic

system. Check CAN network for interference/EMC

related issues B100A-64 Fuel Pump Authorisation

- Signal plausibility

failure

Target SID synchronization

error following

re-programming

RJB power and ground

supply circuits - short, open

circuit

LS CAN fault

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Perform the Immobilisation application

from the Set-up menu using the manufacturer

approved diagnostic system. Refer to the

electrical circuit diagrams and check RJB power

and ground supply circuits for short, open circuit.

Check CAN communications between RJB and

instrument cluster B100A-87 Fuel Pump Authorisation

- Missing message

RJB power and ground

supply circuits - short, open

circuit

LS CAN fault

Instrument cluster power

and ground supply circuits -

short, open circuit

Low battery voltage <9

volts

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check RJB power and ground supply circuits

for short, open circuit and instrument cluster

power and ground supply circuits for short, open

circuit. Check CAN communications between RJB

and instrument cluster. Check battery is in

serviceable condition and fully charged B100B-67

Column Lock Ground

Authorisation - Signal

incorrect after event

Algorithm based failure-

signal is incorrect after the

event

Instrument cluster power

and ground supply circuits -

short, open circuit

LS CAN fault

RJB power and ground

supply circuits - short, open

circuit

Vehicle speed present when

attempting to power ESCL

Engine speed present when

attempting to power ESCL

PowerMode status > 4 when

attempting to perform lock

action

If a non start issue has not been identified,

clear the DTC and check vehicle starts correctly.

If a non start issue has been identified run the

manufacturers approved diagnostic system Start

Authorisation Application. Carry out any pinpoint

tests associated with this DTC using the

manufacturer approved diagnostic system. Refer

to the electrical circuit diagrams and check RJB

power and ground supply circuits for short, open

circuit and instrument cluster power and ground

supply circuits for short, open circuit. Check CAN

communications between RJB and instrument

cluster. Check for invalid vehicle speed signal

from ABS/instrument cluster gateway. Check for

invalid engine speed signal from ECM/instrument

cluster gateway. Check for invalid signal from

CJB

Page 191 of 3039

DTC Description Possible Causes Action B10A0-11

Wiper/ Washer Switch -

Circuit short to ground

Wash/wipe circuit - short to

ground

Refer to the electrical circuit diagrams and check

wash/wipe circuit for short to ground B10A0-15

Wiper/ Washer Switch -

Circuit short to battery

or open

Wash/wipe circuit - short to

power, open circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check wash/wipe circuit for short to power,

open circuit B10A6-11

Main Light Switch -

Circuit short to ground

Master lighting switch circuit

- short to ground

Refer to the electrical circuit diagrams and check

master lighting switch circuit for short to ground B10A6-15

Main Light Switch -

Circuit short to battery

or open

Master lighting switch circuit

- short to power, open

circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check master lighting switch circuit for short

to power, open circuit B112B-87

Steering Wheel Module -

Missing message

Steering wheel module

failure - slave node not

responding

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check the clockspring LIN circuit for short,

open circuit. Suspect the clockspring, check and

install a new clockspring as required, refer to the

new module/component installation note at the

top of the DTC Index B115C-7A Transfer Fuel Pump -

Fluid leak or seal failure

Fuel pump system fault

Check for fuel system jet pump or jet pump fuel

level sensor fault B1A85-15

Ambient Light Sensor -

Circuit short to battery

or open

Autolamp sensor circuit -

short to power, open circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check autolamp sensor circuit for short to

power, open circuit B1B01-00

Key Transponder - No

sub type information

Operator only cycles one key

During transponder key

programming the instrument

cluster, smartcard docking

station or key loses

power/circuit failure

Faulty key during key

programming

Unable to program

transponder key due to

noise/EMC related error

Ensure all keys to be programmed are available.

Refer to electrical circuit diagrams and check

power and ground supply circuits to all relevant

modules. Replace faulty key and repeat key

programming. Check CAN network for

interference/EMC related issues B1B01-05

Key Transponder -

System programming

failures

Error following SCU

replacement

Smartcard docking station

power and ground supply

circuits - short, open circuit

LIN fault

Instrument cluster power

and ground supply circuits -

short, open circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Perform the Immobilisation application

from the Set-up menu using the manufacturer

approved diagnostic system. Refer to the

electrical circuit diagrams and check smartcard

docking station power and ground supply circuits

for short, open circuit and instrument cluster

power and ground supply circuits for short, open

circuit. Check LIN communications between

smartcard docking station and instrument cluster B1B01-51

Key Transponder - Not

programmed

LIN fault

Instrument cluster power

and ground supply circuits -

short, open circuit

Key fault

Smartcard docking station

power and ground supply

circuits - short, open circuit

Attempted to program a non

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check LIN communications between

smartcard docking station and instrument

cluster. Refer to the electrical circuit diagrams

and check smartcard docking station power and

ground supply circuits for short, open circuit and

instrument cluster power and ground supply

circuits for short, open circuit. Confirm www.JagDocs.com

Page 218 of 3039

Published: 12-May-2014

General Information - Diagnostic Trouble Code (DTC) Index DTC: Rear

Junction Box (RJB)

Description and Operation

Rear Junction Box (RJB)

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTES:

If a control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the Warranty

Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation of a new

module/component.

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer-approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places, and with

an up-to-date calibration certificate. When testing resistance always take the resistance of the digital multimeter leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required.

The table below lists all Diagnostic Trouble Codes (DTCs) that could be logged in the Rear Junction Box (RJB). For additional

diagnosis and testing information, refer to the relevant Diagnosis and Testing section in the workshop manual.

For additional information, refer to: Communications Network (418-00 Module Communications Network, Diagnosis and Testing).

DTC Description Possible Causes Action P0460-11

Fuel Level Sensor A

Circuit - Circuit short to

ground

Fuel level sensor A

analogue input circuit -

short to ground

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

fuel level sensor A analogue input circuit for short to

ground P0460-15

Fuel Level Sensor A

Circuit - Circuit short to

battery or open

Fuel level sensor A

analogue input circuit -

short to power, open

circuit

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

fuel level sensor A analogue input circuit for short to

power, open circuit P0571-12

Brake Switch A Circuit -

Circuit short to battery

Footbrake switch digital

input signal circuits -

short to power

Refer to the electrical circuit diagrams and check

footbrake switch digital input signal circuits for

short to power P1230-12

Fuel Pump Low Speed

Malfunction (VLCM) -

Circuit short to battery

High Side output not

driven - Diagnosis

feedback indicates

output is short to power

Refer to the electrical circuit diagrams and check

fuel pump delivery module for short to power

Page 219 of 3039

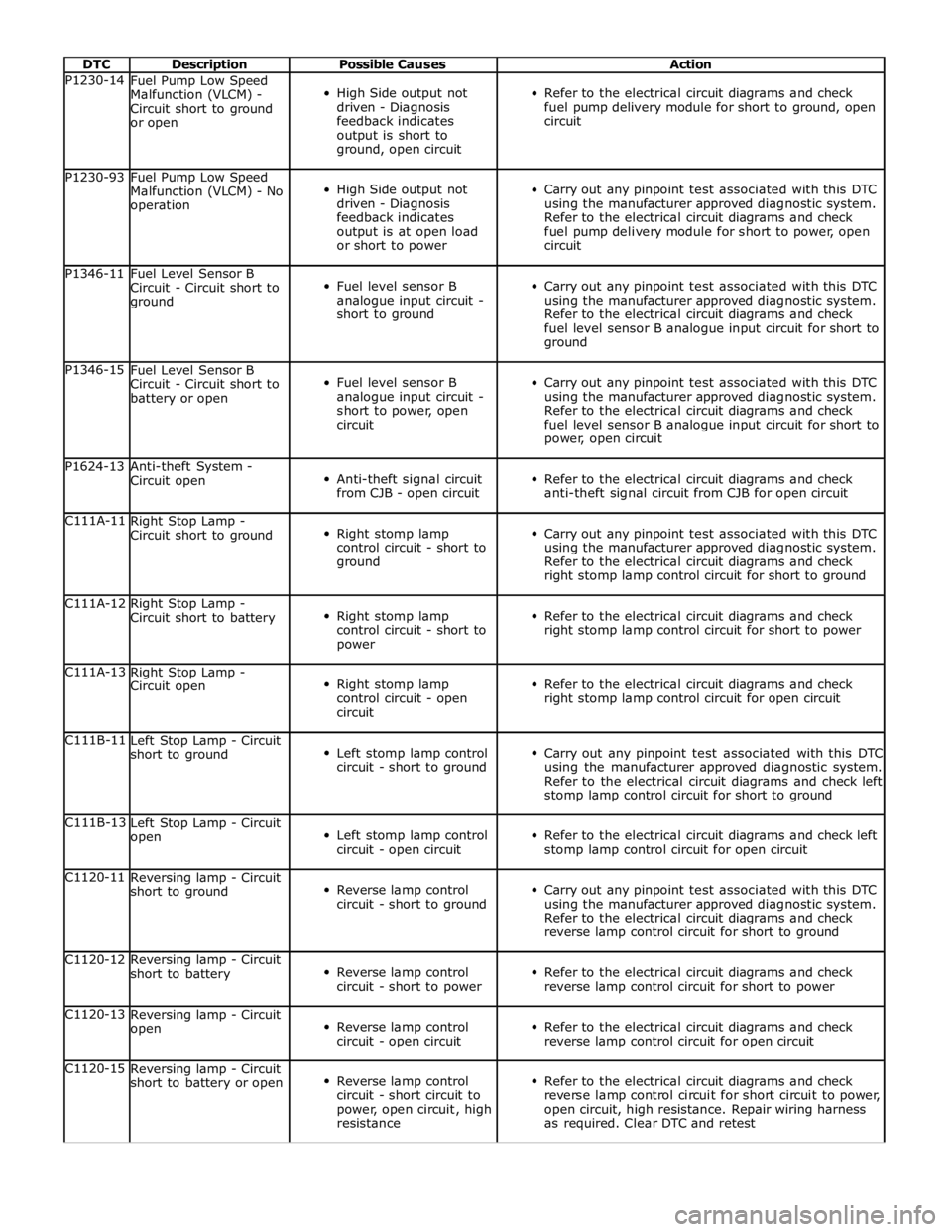

DTC Description Possible Causes Action P1230-14

Fuel Pump Low Speed

Malfunction (VLCM) -

Circuit short to ground

or open

High Side output not

driven - Diagnosis

feedback indicates

output is short to

ground, open circuit

Refer to the electrical circuit diagrams and check

fuel pump delivery module for short to ground, open

circuit P1230-93

Fuel Pump Low Speed

Malfunction (VLCM) - No

operation

High Side output not

driven - Diagnosis

feedback indicates

output is at open load

or short to power

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

fuel pump delivery module for short to power, open

circuit P1346-11

Fuel Level Sensor B

Circuit - Circuit short to

ground

Fuel level sensor B

analogue input circuit -

short to ground

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

fuel level sensor B analogue input circuit for short to

ground P1346-15

Fuel Level Sensor B

Circuit - Circuit short to

battery or open

Fuel level sensor B

analogue input circuit -

short to power, open

circuit

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

fuel level sensor B analogue input circuit for short to

power, open circuit P1624-13

Anti-theft System -

Circuit open

Anti-theft signal circuit

from CJB - open circuit

Refer to the electrical circuit diagrams and check

anti-theft signal circuit from CJB for open circuit C111A-11

Right Stop Lamp -

Circuit short to ground

Right stomp lamp

control circuit - short to

ground

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

right stomp lamp control circuit for short to ground C111A-12

Right Stop Lamp -

Circuit short to battery

Right stomp lamp

control circuit - short to

power

Refer to the electrical circuit diagrams and check

right stomp lamp control circuit for short to power C111A-13

Right Stop Lamp -

Circuit open

Right stomp lamp

control circuit - open

circuit

Refer to the electrical circuit diagrams and check

right stomp lamp control circuit for open circuit C111B-11

Left Stop Lamp - Circuit

short to ground

Left stomp lamp control

circuit - short to ground

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check left

stomp lamp control circuit for short to ground C111B-13

Left Stop Lamp - Circuit

open

Left stomp lamp control

circuit - open circuit

Refer to the electrical circuit diagrams and check left

stomp lamp control circuit for open circuit C1120-11

Reversing lamp - Circuit

short to ground

Reverse lamp control

circuit - short to ground

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

reverse lamp control circuit for short to ground C1120-12

Reversing lamp - Circuit

short to battery

Reverse lamp control

circuit - short to power

Refer to the electrical circuit diagrams and check

reverse lamp control circuit for short to power C1120-13

Reversing lamp - Circuit

open

Reverse lamp control

circuit - open circuit

Refer to the electrical circuit diagrams and check

reverse lamp control circuit for open circuit C1120-15

Reversing lamp - Circuit

short to battery or open

Reverse lamp control

circuit - short circuit to

power, open circuit, high

resistance

Refer to the electrical circuit diagrams and check

reverse lamp control circuit for short circuit to power,

open circuit, high resistance. Repair wiring harness

as required. Clear DTC and retest

Page 220 of 3039

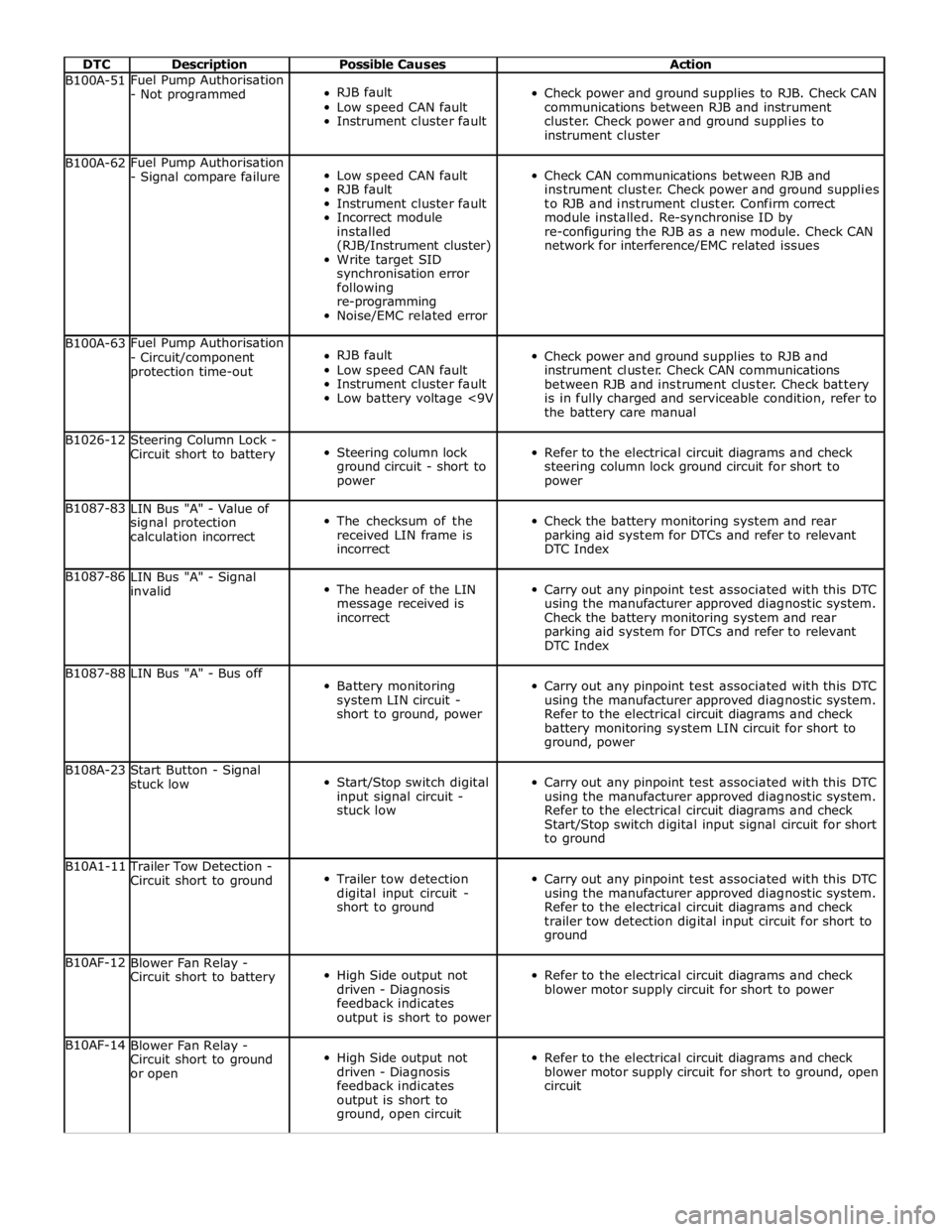

DTC Description Possible Causes Action B100A-51 Fuel Pump Authorisation

- Not programmed

RJB fault

Low speed CAN fault

Instrument cluster fault

Check power and ground supplies to RJB. Check CAN

communications between RJB and instrument

cluster. Check power and ground supplies to

instrument cluster B100A-62 Fuel Pump Authorisation

- Signal compare failure

Low speed CAN fault

RJB fault

Instrument cluster fault

Incorrect module

installed

(RJB/Instrument cluster)

Write target SID

synchronisation error

following

re-programming

Noise/EMC related error

Check CAN communications between RJB and

instrument cluster. Check power and ground supplies

to RJB and instrument cluster. Confirm correct

module installed. Re-synchronise ID by

re-configuring the RJB as a new module. Check CAN

network for interference/EMC related issues B100A-63 Fuel Pump Authorisation

- Circuit/component

protection time-out

RJB fault

Low speed CAN fault

Instrument cluster fault

Low battery voltage <9V

Check power and ground supplies to RJB and

instrument cluster. Check CAN communications

between RJB and instrument cluster. Check battery

is in fully charged and serviceable condition, refer to

the battery care manual B1026-12

Steering Column Lock -

Circuit short to battery

Steering column lock

ground circuit - short to

power

Refer to the electrical circuit diagrams and check

steering column lock ground circuit for short to

power B1087-83

LIN Bus "A" - Value of

signal protection

calculation incorrect

The checksum of the

received LIN frame is

incorrect

Check the battery monitoring system and rear

parking aid system for DTCs and refer to relevant

DTC Index B1087-86

LIN Bus "A" - Signal

invalid

The header of the LIN

message received is

incorrect

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Check the battery monitoring system and rear

parking aid system for DTCs and refer to relevant

DTC Index B1087-88 LIN Bus "A" - Bus off

Battery monitoring

system LIN circuit -

short to ground, power

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

battery monitoring system LIN circuit for short to

ground, power B108A-23

Start Button - Signal

stuck low

Start/Stop switch digital

input signal circuit -

stuck low

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

Start/Stop switch digital input signal circuit for short

to ground B10A1-11 Trailer Tow Detection -

Circuit short to ground

Trailer tow detection

digital input circuit -

short to ground

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

trailer tow detection digital input circuit for short to

ground B10AF-12

Blower Fan Relay -

Circuit short to battery

High Side output not

driven - Diagnosis

feedback indicates

output is short to power

Refer to the electrical circuit diagrams and check

blower motor supply circuit for short to power B10AF-14

Blower Fan Relay -

Circuit short to ground

or open

High Side output not

driven - Diagnosis

feedback indicates

output is short to

ground, open circuit

Refer to the electrical circuit diagrams and check

blower motor supply circuit for short to ground, open

circuit

Page 221 of 3039

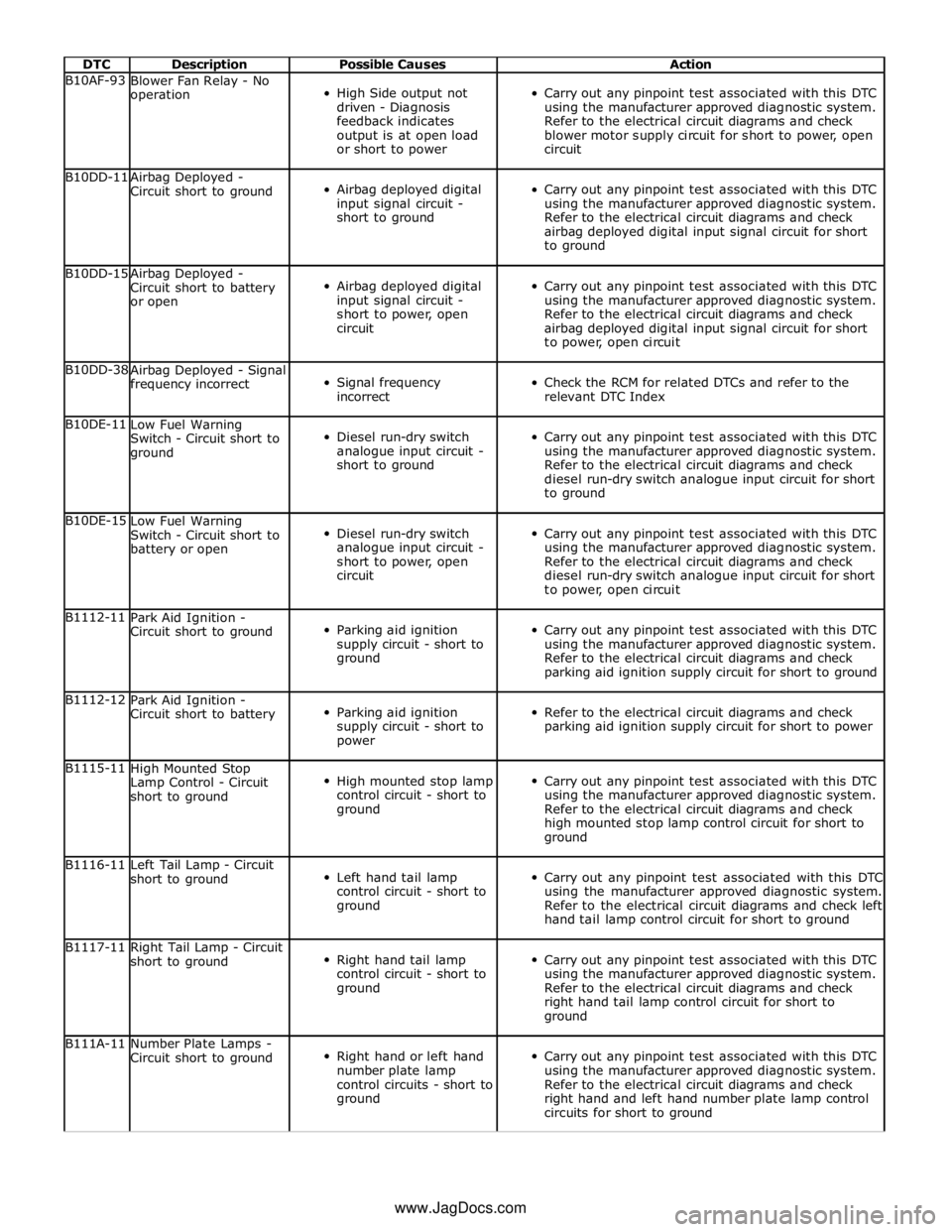

DTC Description Possible Causes Action B10AF-93

Blower Fan Relay - No

operation

High Side output not

driven - Diagnosis

feedback indicates

output is at open load

or short to power

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

blower motor supply circuit for short to power, open

circuit B10DD-11

Airbag Deployed -

Circuit short to ground

Airbag deployed digital

input signal circuit -

short to ground

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

airbag deployed digital input signal circuit for short

to ground B10DD-15

Airbag Deployed -

Circuit short to battery

or open

Airbag deployed digital

input signal circuit -

short to power, open

circuit

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

airbag deployed digital input signal circuit for short

to power, open circuit B10DD-38

Airbag Deployed - Signal

frequency incorrect

Signal frequency

incorrect

Check the RCM for related DTCs and refer to the

relevant DTC Index B10DE-11

Low Fuel Warning

Switch - Circuit short to

ground

Diesel run-dry switch

analogue input circuit -

short to ground

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

diesel run-dry switch analogue input circuit for short

to ground B10DE-15

Low Fuel Warning

Switch - Circuit short to

battery or open

Diesel run-dry switch

analogue input circuit -

short to power, open

circuit

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

diesel run-dry switch analogue input circuit for short

to power, open circuit B1112-11

Park Aid Ignition -

Circuit short to ground

Parking aid ignition

supply circuit - short to

ground

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

parking aid ignition supply circuit for short to ground B1112-12

Park Aid Ignition -

Circuit short to battery

Parking aid ignition

supply circuit - short to

power

Refer to the electrical circuit diagrams and check

parking aid ignition supply circuit for short to power B1115-11

High Mounted Stop

Lamp Control - Circuit

short to ground

High mounted stop lamp

control circuit - short to

ground

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

high mounted stop lamp control circuit for short to

ground B1116-11

Left Tail Lamp - Circuit

short to ground

Left hand tail lamp

control circuit - short to

ground

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check left

hand tail lamp control circuit for short to ground B1117-11

Right Tail Lamp - Circuit

short to ground

Right hand tail lamp

control circuit - short to

ground

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

right hand tail lamp control circuit for short to

ground B111A-11

Number Plate Lamps -

Circuit short to ground

Right hand or left hand

number plate lamp

control circuits - short to

ground

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

right hand and left hand number plate lamp control

circuits for short to ground www.JagDocs.com

Page 225 of 3039

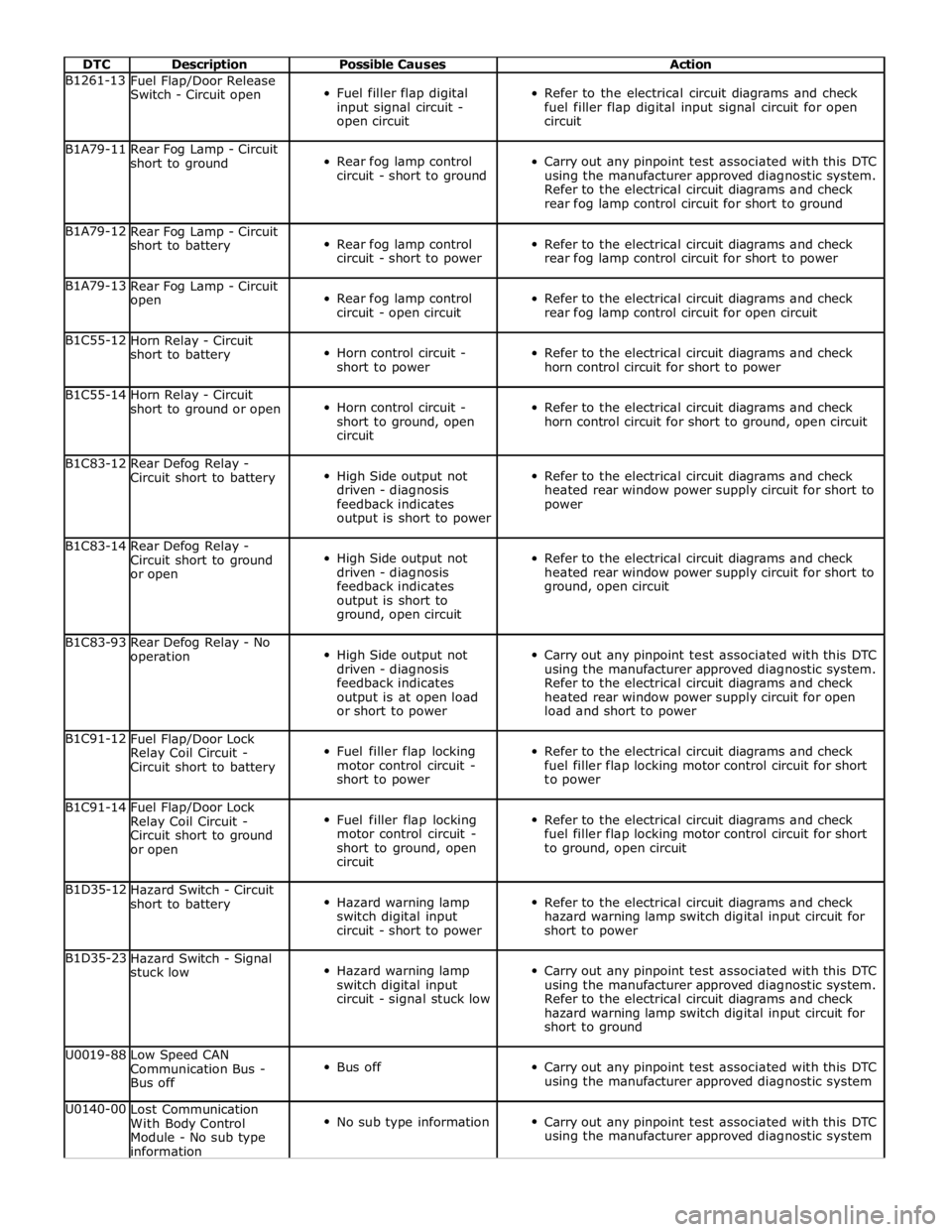

DTC Description Possible Causes Action B1261-13

Fuel Flap/Door Release

Switch - Circuit open

Fuel filler flap digital

input signal circuit -

open circuit

Refer to the electrical circuit diagrams and check

fuel filler flap digital input signal circuit for open

circuit B1A79-11

Rear Fog Lamp - Circuit

short to ground

Rear fog lamp control

circuit - short to ground

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

rear fog lamp control circuit for short to ground B1A79-12

Rear Fog Lamp - Circuit

short to battery

Rear fog lamp control

circuit - short to power

Refer to the electrical circuit diagrams and check

rear fog lamp control circuit for short to power B1A79-13

Rear Fog Lamp - Circuit

open

Rear fog lamp control

circuit - open circuit

Refer to the electrical circuit diagrams and check

rear fog lamp control circuit for open circuit B1C55-12

Horn Relay - Circuit

short to battery

Horn control circuit -

short to power

Refer to the electrical circuit diagrams and check

horn control circuit for short to power B1C55-14

Horn Relay - Circuit

short to ground or open

Horn control circuit -

short to ground, open

circuit

Refer to the electrical circuit diagrams and check

horn control circuit for short to ground, open circuit B1C83-12

Rear Defog Relay -

Circuit short to battery

High Side output not

driven - diagnosis

feedback indicates

output is short to power

Refer to the electrical circuit diagrams and check

heated rear window power supply circuit for short to

power B1C83-14

Rear Defog Relay -

Circuit short to ground

or open

High Side output not

driven - diagnosis

feedback indicates

output is short to

ground, open circuit

Refer to the electrical circuit diagrams and check

heated rear window power supply circuit for short to

ground, open circuit B1C83-93

Rear Defog Relay - No

operation

High Side output not

driven - diagnosis

feedback indicates

output is at open load

or short to power

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

heated rear window power supply circuit for open

load and short to power B1C91-12

Fuel Flap/Door Lock

Relay Coil Circuit -

Circuit short to battery

Fuel filler flap locking

motor control circuit -

short to power

Refer to the electrical circuit diagrams and check

fuel filler flap locking motor control circuit for short

to power B1C91-14

Fuel Flap/Door Lock

Relay Coil Circuit -

Circuit short to ground

or open

Fuel filler flap locking

motor control circuit -

short to ground, open

circuit

Refer to the electrical circuit diagrams and check

fuel filler flap locking motor control circuit for short

to ground, open circuit B1D35-12

Hazard Switch - Circuit

short to battery

Hazard warning lamp

switch digital input

circuit - short to power

Refer to the electrical circuit diagrams and check

hazard warning lamp switch digital input circuit for

short to power B1D35-23

Hazard Switch - Signal

stuck low

Hazard warning lamp

switch digital input

circuit - signal stuck low

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

hazard warning lamp switch digital input circuit for

short to ground U0019-88

Low Speed CAN

Communication Bus -

Bus off

Bus off

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system U0140-00

Lost Communication

With Body Control

Module - No sub type

information

No sub type information

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system

Page 306 of 3039

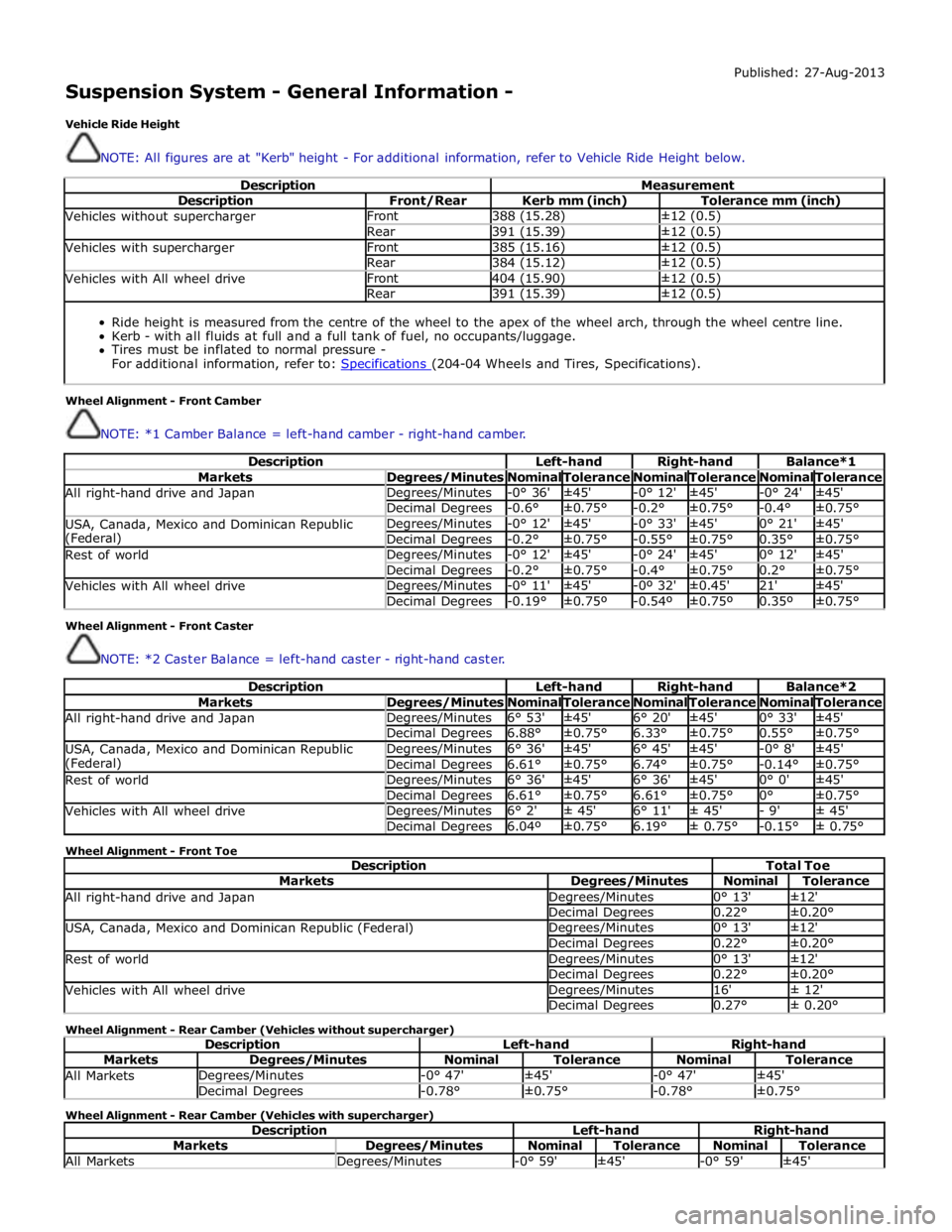

Suspension System - General Information -

Vehicle Ride Height Published: 27-Aug-2013

NOTE: All figures are at "Kerb" height - For additional information, refer to Vehicle Ride Height below.

Description Measurement Description Front/Rear Kerb mm (inch) Tolerance mm (inch) Vehicles without supercharger Front 388 (15.28) ±12 (0.5) Rear 391 (15.39) ±12 (0.5) Vehicles with supercharger Front 385 (15.16) ±12 (0.5) Rear 384 (15.12) ±12 (0.5) Vehicles with All wheel drive Front 404 (15.90) ±12 (0.5) Rear 391 (15.39) ±12 (0.5)

Ride height is measured from the centre of the wheel to the apex of the wheel arch, through the wheel centre line.

Kerb - with all fluids at full and a full tank of fuel, no occupants/luggage.

Tires must be inflated to normal pressure -

For additional information, refer to: Specifications (204-04 Wheels and Tires, Specifications). Wheel Alignment - Front Camber

NOTE: *1 Camber Balance = left-hand camber - right-hand camber.

Description Left-hand Right-hand Balance*1 Markets Degrees/Minutes Nominal Tolerance Nominal Tolerance Nominal Tolerance All right-hand drive and Japan Degrees/Minutes -0° 36' ±45' -0° 12' ±45' -0° 24' ±45' Decimal Degrees -0.6° ±0.75° -0.2° ±0.75° -0.4° ±0.75° USA, Canada, Mexico and Dominican Republic

(Federal) Degrees/Minutes -0° 12' ±45' -0° 33' ±45' 0° 21' ±45' Decimal Degrees -0.2° ±0.75° -0.55° ±0.75° 0.35° ±0.75° Rest of world Degrees/Minutes -0° 12' ±45' -0° 24' ±45' 0° 12' ±45' Decimal Degrees -0.2° ±0.75° -0.4° ±0.75° 0.2° ±0.75° Vehicles with All wheel drive Degrees/Minutes -0° 11' ±45' -0º 32' ±0.45' 21' ±45' Decimal Degrees -0.19° ±0.75º -0.54º ±0.75º 0.35º ±0.75° Wheel Alignment - Front Caster

NOTE: *2 Caster Balance = left-hand caster - right-hand caster.

Description Left-hand Right-hand Balance*2 Markets Degrees/Minutes Nominal Tolerance Nominal Tolerance Nominal Tolerance All right-hand drive and Japan Degrees/Minutes 6° 53' ±45' 6° 20' ±45' 0° 33' ±45' Decimal Degrees 6.88° ±0.75° 6.33° ±0.75° 0.55° ±0.75° USA, Canada, Mexico and Dominican Republic

(Federal) Degrees/Minutes 6° 36' ±45' 6° 45' ±45' -0° 8' ±45' Decimal Degrees 6.61° ±0.75° 6.74° ±0.75° -0.14° ±0.75° Rest of world Degrees/Minutes 6° 36' ±45' 6° 36' ±45' 0° 0' ±45' Decimal Degrees 6.61° ±0.75° 6.61° ±0.75° 0° ±0.75° Vehicles with All wheel drive Degrees/Minutes 6° 2' ± 45' 6° 11' ± 45' - 9' ± 45' Decimal Degrees 6.04º ±0.75° 6.19° ± 0.75° -0.15° ± 0.75° Wheel Alignment - Front Toe

Description Total Toe Markets Degrees/Minutes Nominal Tolerance All right-hand drive and Japan Degrees/Minutes 0° 13' ±12' Decimal Degrees 0.22° ±0.20° USA, Canada, Mexico and Dominican Republic (Federal) Degrees/Minutes 0° 13' ±12' Decimal Degrees 0.22° ±0.20° Rest of world Degrees/Minutes 0° 13' ±12' Decimal Degrees 0.22° ±0.20° Vehicles with All wheel drive Degrees/Minutes 16' ± 12' Decimal Degrees 0.27° ± 0.20° Wheel Alignment - Rear Camber (Vehicles without supercharger)

Description Left-hand Right-hand Markets Degrees/Minutes Nominal Tolerance Nominal Tolerance All Markets Degrees/Minutes -0° 47' ±45' -0° 47' ±45' Decimal Degrees -0.78° ±0.75° -0.78° ±0.75° Wheel Alignment - Rear Camber (Vehicles with supercharger)

Description Left-hand Right-hand Markets Degrees/Minutes Nominal Tolerance Nominal Tolerance All Markets Degrees/Minutes -0° 59' ±45' -0° 59' ±45'

Page 412 of 3039

Rear Suspension - Rear Stabilizer Bar

Removal and Installation Published: 06-Jun-2013

Removal

1. Disconnect the battery ground cable.

For additional information, refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

3. Remove both rear wheels and tires.

For additional information, refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and Installation).

4. Drain the fuel tank.

For additional information, refer to: Fuel Tank Draining (310-00 Fuel System - General Information, General Procedures).

5. Remove the exhaust system.

For additional information, refer to: Front Muffler (309-00B Exhaust System - V6 3.0L Petrol, Removal and Installation).

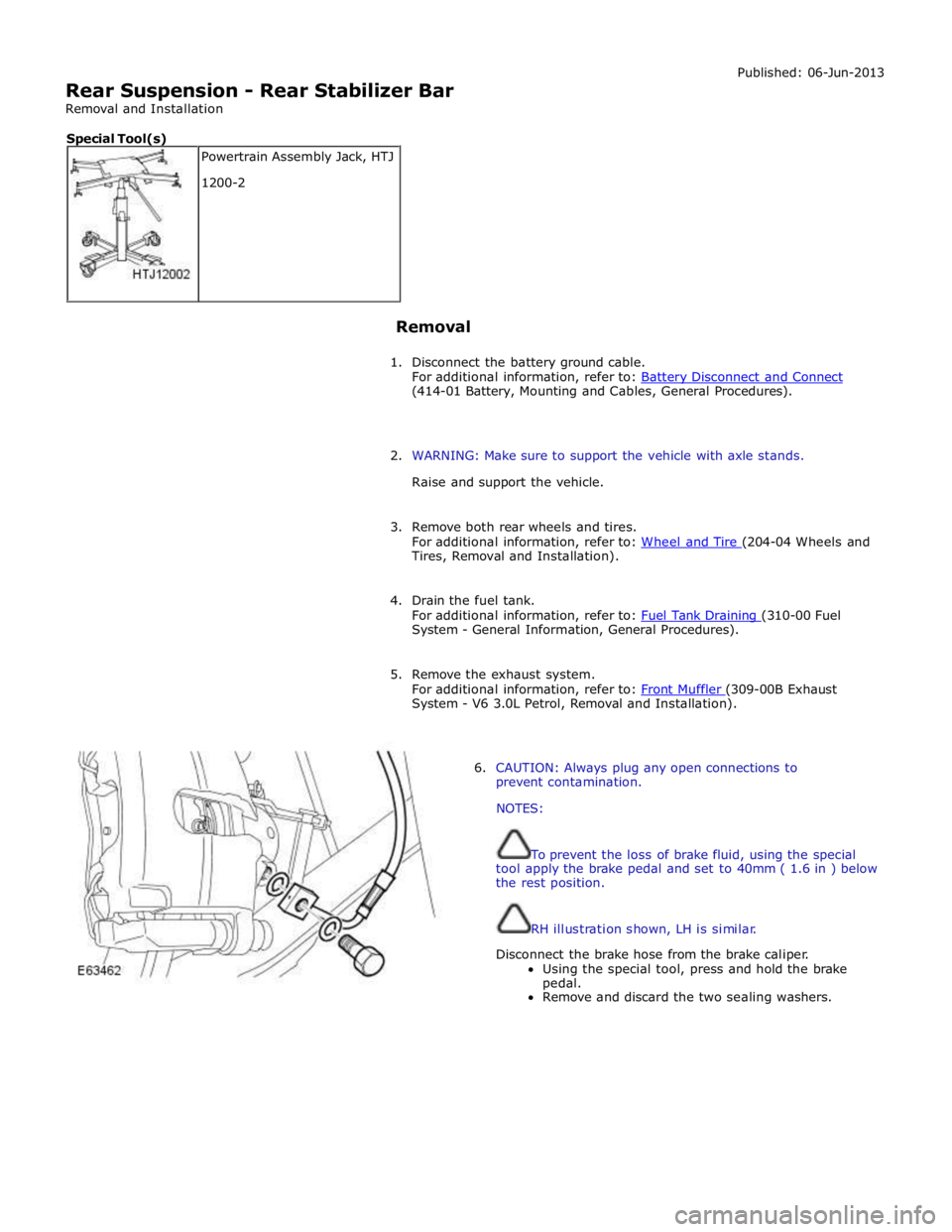

6. CAUTION: Always plug any open connections to

prevent contamination.

NOTES:

To prevent the loss of brake fluid, using the special

tool apply the brake pedal and set to 40mm ( 1.6 in ) below

the rest position.

RH illustration shown, LH is similar.

Disconnect the brake hose from the brake caliper.

Using the special tool, press and hold the brake

pedal.

Remove and discard the two sealing washers. Powertrain Assembly Jack, HTJ

1200-2 Special Tool(s)