instrument panel JAGUAR XFR 2010 1.G Service Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1746 of 3039

Climate Control - Instrument Panel Register Trim Panel

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details. Published: 11-May-2011

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. Refer to: Center Registers (412-01 Climate Control, Removal and Installation).

3.

4.

Page 1750 of 3039

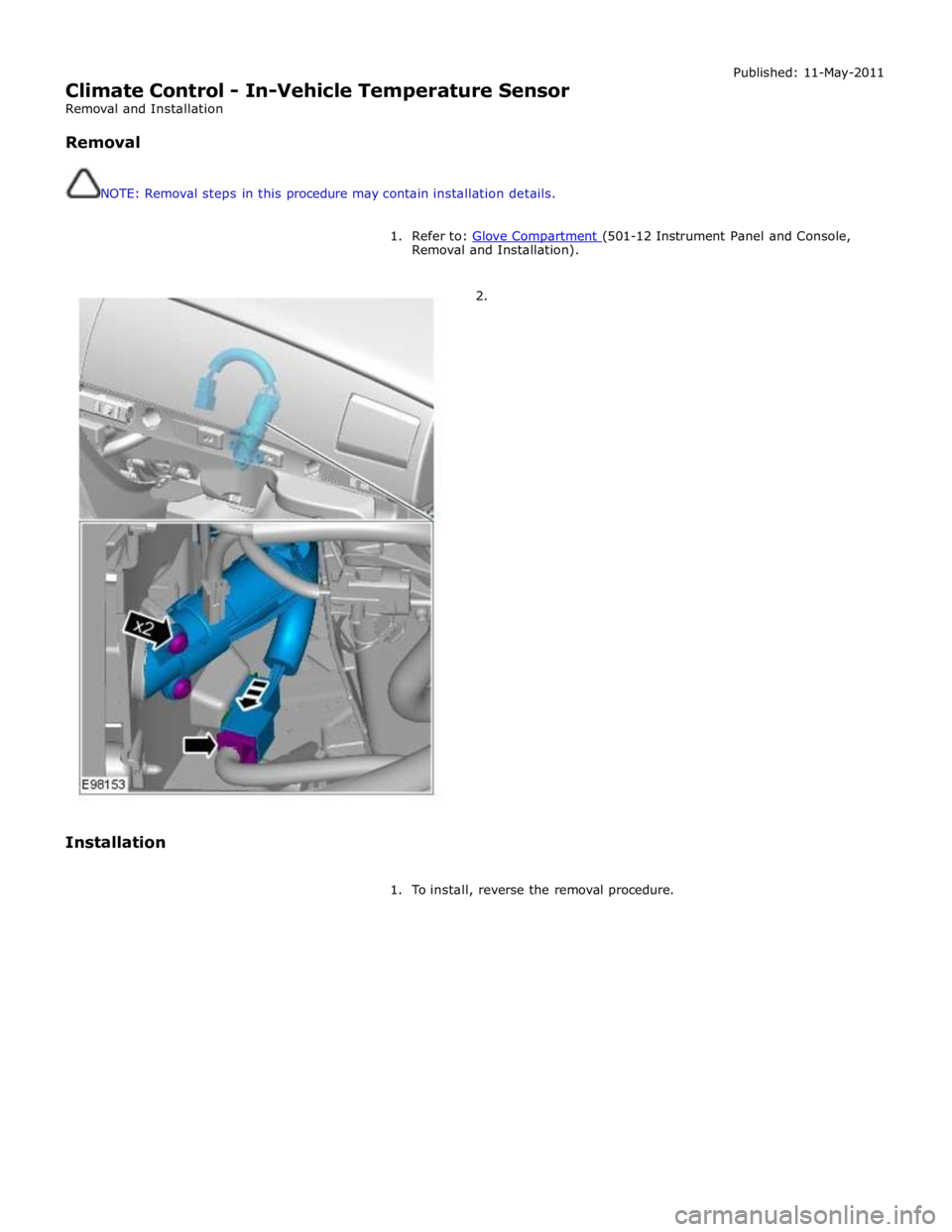

Climate Control - In-Vehicle Temperature Sensor

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details. Published: 11-May-2011

1. Refer to: Glove Compartment (501-12 Instrument Panel and Console, Removal and Installation).

2.

Installation

1. To install, reverse the removal procedure.

Page 1757 of 3039

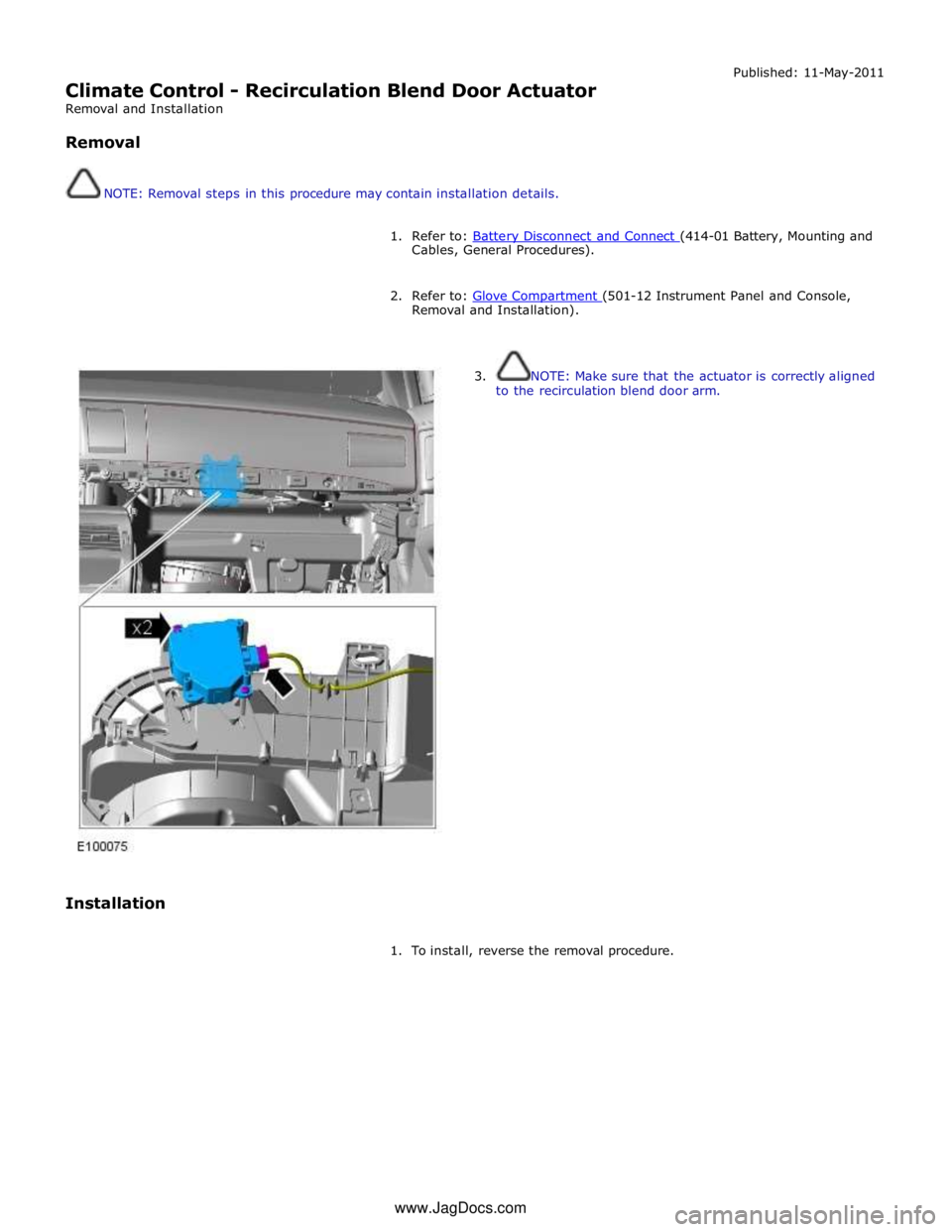

Climate Control - Recirculation Blend Door Actuator

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details. Published: 11-May-2011

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. Refer to: Glove Compartment (501-12 Instrument Panel and Console, Removal and Installation).

Installation

3. NOTE: Make sure that the actuator is correctly aligned

to the recirculation blend door arm.

1. To install, reverse the removal procedure. www.JagDocs.com

Page 1766 of 3039

Published: 11-May-2011

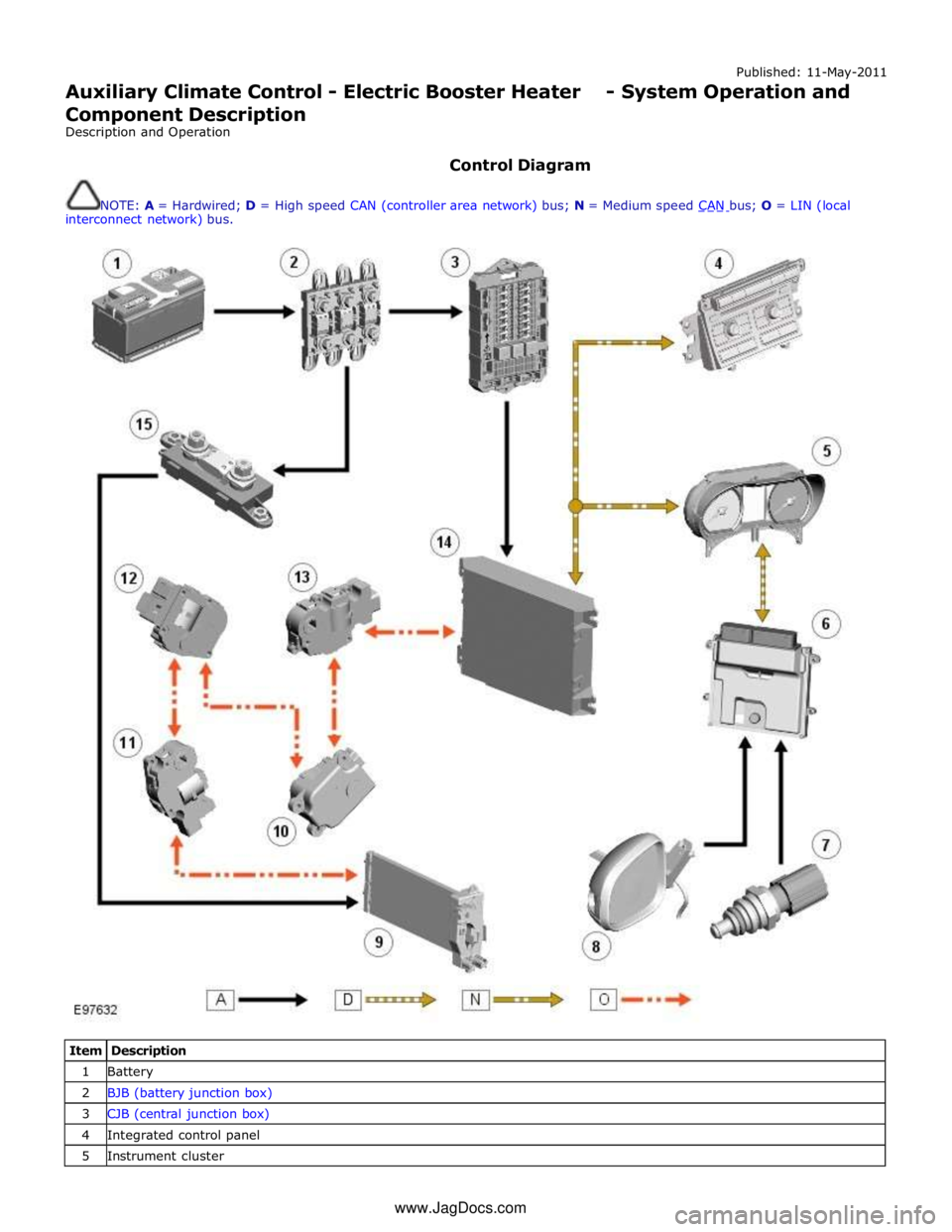

Auxiliary Climate Control - Electric Booster Heater - System Operation and

Component Description

Description and Operation

Control Diagram

NOTE: A = Hardwired; D = High speed CAN (controller area network) bus; N = Medium speed CAN bus; O = LIN (local interconnect network) bus.

Item Description 1 Battery 2 BJB (battery junction box) 3 CJB (central junction box) 4 Integrated control panel 5 Instrument cluster www.JagDocs.com

Page 1770 of 3039

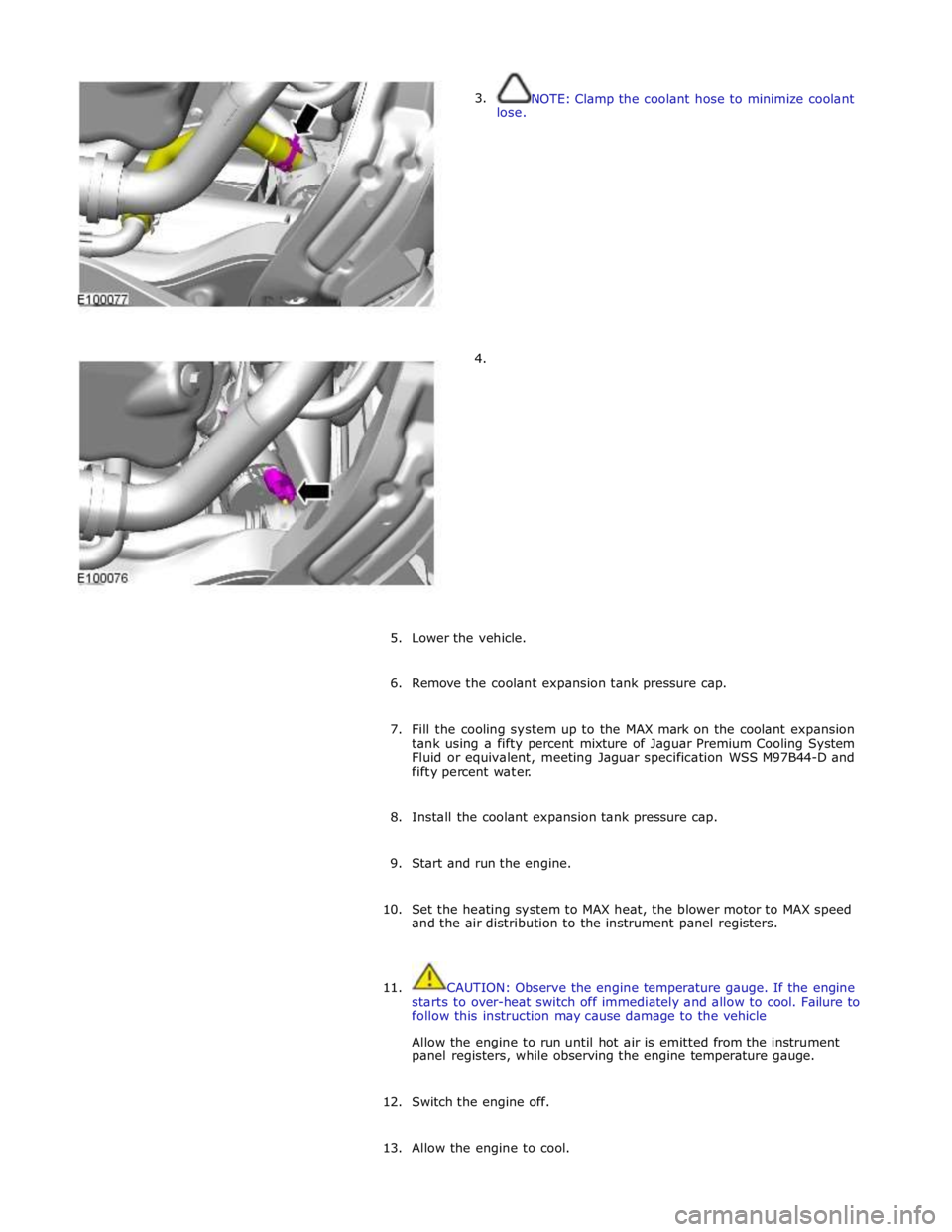

3.

lose.

4. NOTE: Clamp the coolant hose to minimize coolant

5. Lower the vehicle.

6. Remove the coolant expansion tank pressure cap.

7. Fill the cooling system up to the MAX mark on the coolant expansion

tank using a fifty percent mixture of Jaguar Premium Cooling System

Fluid or equivalent, meeting Jaguar specification WSS M97B44-D and

fifty percent water.

8. Install the coolant expansion tank pressure cap.

9. Start and run the engine.

10. Set the heating system to MAX heat, the blower motor to MAX speed

and the air distribution to the instrument panel registers.

11. CAUTION: Observe the engine temperature gauge. If the engine

starts to over-heat switch off immediately and allow to cool. Failure to

follow this instruction may cause damage to the vehicle

Allow the engine to run until hot air is emitted from the instrument

panel registers, while observing the engine temperature gauge.

12. Switch the engine off.

13. Allow the engine to cool.

Page 1797 of 3039

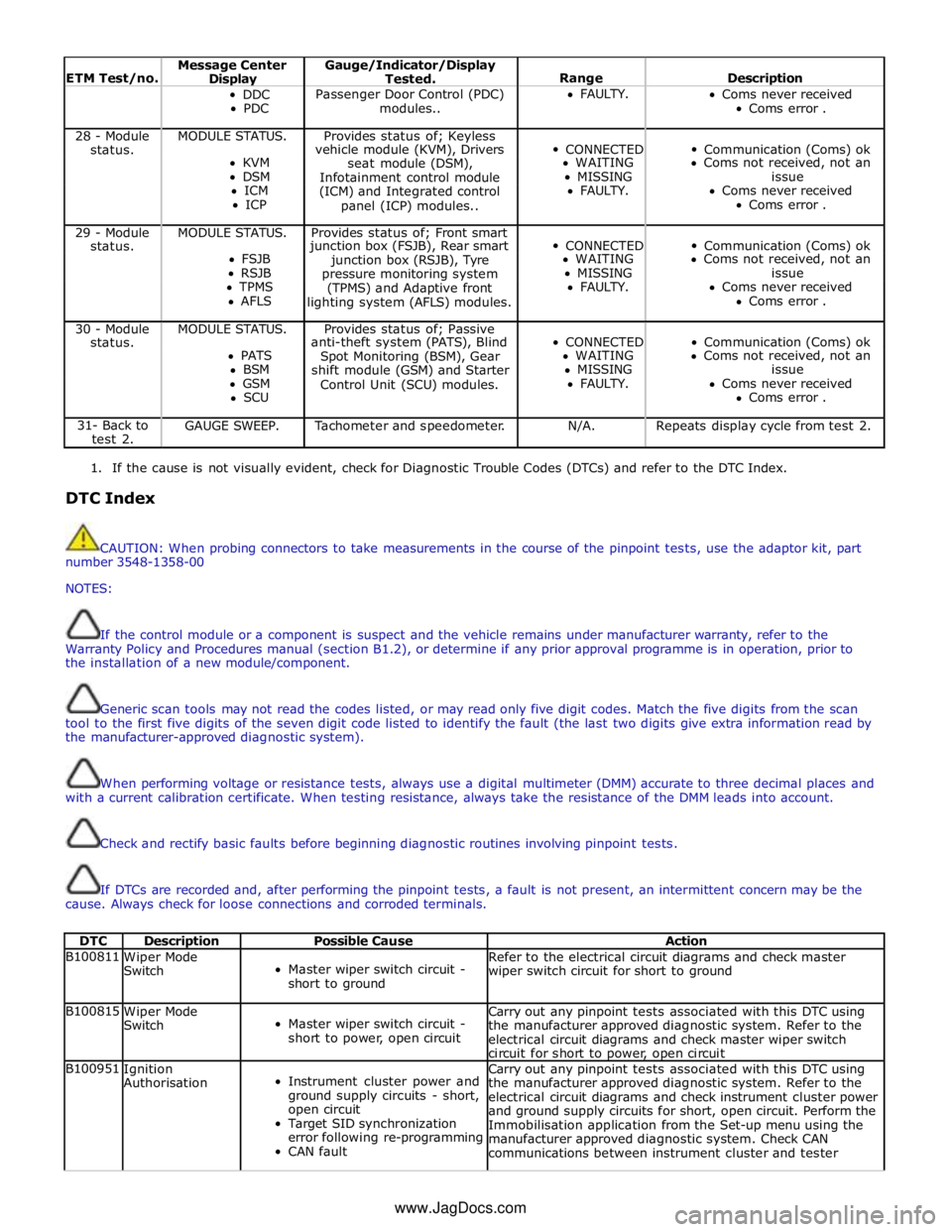

ETM Test/no. Message Center Display Gauge/Indicator/Display

Tested.

Range

Description DDC

PDC Passenger Door Control (PDC)

modules.. FAULTY.

Coms never received

Coms error . 28 - Module MODULE STATUS. Provides status of; Keyless

CONNECTED

Communication (Coms) ok status. vehicle module (KVM), Drivers KVM

seat module (DSM), WAITING Coms not received, not an DSM

Infotainment control module MISSING issue ICM

(ICM) and Integrated control FAULTY. Coms never received ICP

panel (ICP) modules.. Coms error . 29 - Module MODULE STATUS. Provides status of; Front smart

CONNECTED

Communication (Coms) ok status. junction box (FSJB), Rear smart FSJB

junction box (RSJB), Tyre WAITING Coms not received, not an RSJB

pressure monitoring system MISSING issue TPMS

(TPMS) and Adaptive front FAULTY. Coms never received AFLS

lighting system (AFLS) modules. Coms error . 30 - Module MODULE STATUS. Provides status of; Passive

CONNECTED

Communication (Coms) ok status. anti-theft system (PATS), Blind PATS

Spot Monitoring (BSM), Gear WAITING Coms not received, not an BSM

shift module (GSM) and Starter MISSING issue GSM

Control Unit (SCU) modules. FAULTY. Coms never received SCU Coms error . 31- Back to

test 2. GAUGE SWEEP. Tachometer and speedometer. N/A. Repeats display cycle from test 2.

1. If the cause is not visually evident, check for Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

DTC Index

CAUTION: When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit, part

number 3548-1358-00

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual (section B1.2), or determine if any prior approval programme is in operation, prior to

the installation of a new module/component.

Generic scan tools may not read the codes listed, or may read only five digit codes. Match the five digits from the scan

tool to the first five digits of the seven digit code listed to identify the fault (the last two digits give extra information read by

the manufacturer-approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal places and

with a current calibration certificate. When testing resistance, always take the resistance of the DMM leads into account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

DTC Description Possible Cause Action B100811

Wiper Mode

Switch

Master wiper switch circuit -

short to ground Refer to the electrical circuit diagrams and check master

wiper switch circuit for short to ground B100815

Wiper Mode

Switch

Master wiper switch circuit -

short to power, open circuit Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check master wiper switch

circuit for short to power, open circuit B100951

Ignition

Authorisation

Instrument cluster power and

ground supply circuits - short,

open circuit

Target SID synchronization

error following re-programming

CAN fault Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check instrument cluster power

and ground supply circuits for short, open circuit. Perform the

Immobilisation application from the Set-up menu using the

manufacturer approved diagnostic system. Check CAN

communications between instrument cluster and tester www.JagDocs.com

Page 1805 of 3039

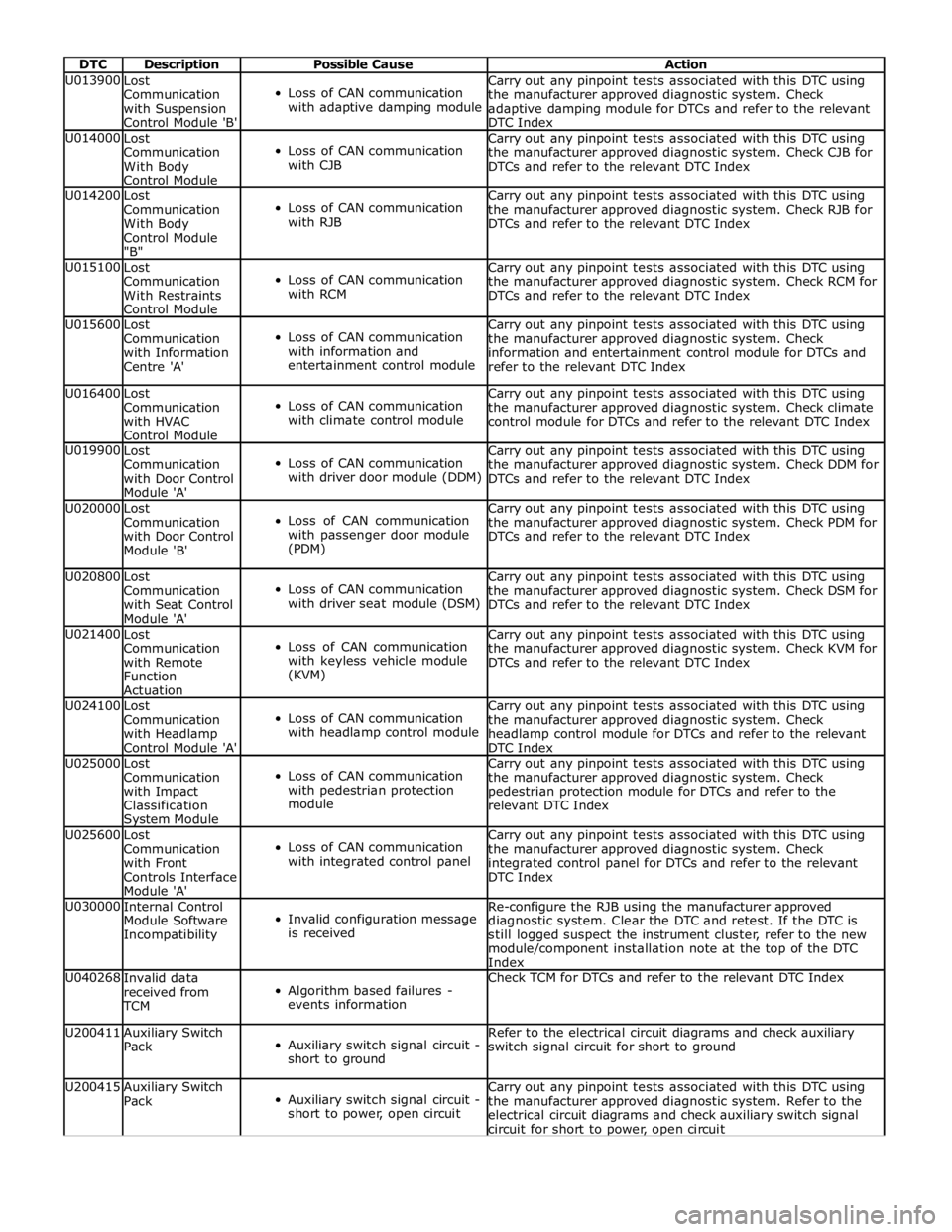

DTC Description Possible Cause Action U013900

Lost

Communication

with Suspension

Control Module 'B'

Loss of CAN communication

with adaptive damping module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

adaptive damping module for DTCs and refer to the relevant

DTC Index U014000

Lost

Communication

With Body

Control Module

Loss of CAN communication

with CJB Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check CJB for

DTCs and refer to the relevant DTC Index U014200

Lost

Communication

With Body

Control Module

"B"

Loss of CAN communication

with RJB Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check RJB for

DTCs and refer to the relevant DTC Index U015100

Lost

Communication

With Restraints

Control Module

Loss of CAN communication

with RCM Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check RCM for

DTCs and refer to the relevant DTC Index U015600

Lost

Communication

with Information

Centre 'A'

Loss of CAN communication

with information and

entertainment control module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

information and entertainment control module for DTCs and

refer to the relevant DTC Index U016400

Lost

Communication

with HVAC

Control Module

Loss of CAN communication

with climate control module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check climate

control module for DTCs and refer to the relevant DTC Index U019900

Lost

Communication

with Door Control

Module 'A'

Loss of CAN communication

with driver door module (DDM) Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check DDM for

DTCs and refer to the relevant DTC Index U020000

Lost

Communication

with Door Control

Module 'B'

Loss of CAN communication

with passenger door module

(PDM) Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check PDM for

DTCs and refer to the relevant DTC Index U020800

Lost

Communication

with Seat Control

Module 'A'

Loss of CAN communication

with driver seat module (DSM) Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check DSM for

DTCs and refer to the relevant DTC Index U021400

Lost

Communication

with Remote

Function

Actuation

Loss of CAN communication

with keyless vehicle module

(KVM) Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check KVM for

DTCs and refer to the relevant DTC Index U024100

Lost

Communication

with Headlamp

Control Module 'A'

Loss of CAN communication

with headlamp control module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

headlamp control module for DTCs and refer to the relevant

DTC Index U025000

Lost

Communication

with Impact

Classification System Module

Loss of CAN communication

with pedestrian protection

module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

pedestrian protection module for DTCs and refer to the

relevant DTC Index U025600

Lost

Communication

with Front

Controls Interface

Module 'A'

Loss of CAN communication

with integrated control panel Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

integrated control panel for DTCs and refer to the relevant

DTC Index U030000

Internal Control

Module Software

Incompatibility

Invalid configuration message

is received Re-configure the RJB using the manufacturer approved

diagnostic system. Clear the DTC and retest. If the DTC is

still logged suspect the instrument cluster, refer to the new

module/component installation note at the top of the DTC

Index U040268

Invalid data

received from

TCM

Algorithm based failures -

events information Check TCM for DTCs and refer to the relevant DTC Index U200411

Auxiliary Switch

Pack

Auxiliary switch signal circuit -

short to ground Refer to the electrical circuit diagrams and check auxiliary

switch signal circuit for short to ground U200415

Auxiliary Switch

Pack

Auxiliary switch signal circuit -

short to power, open circuit Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check auxiliary switch signal

circuit for short to power, open circuit

Page 1821 of 3039

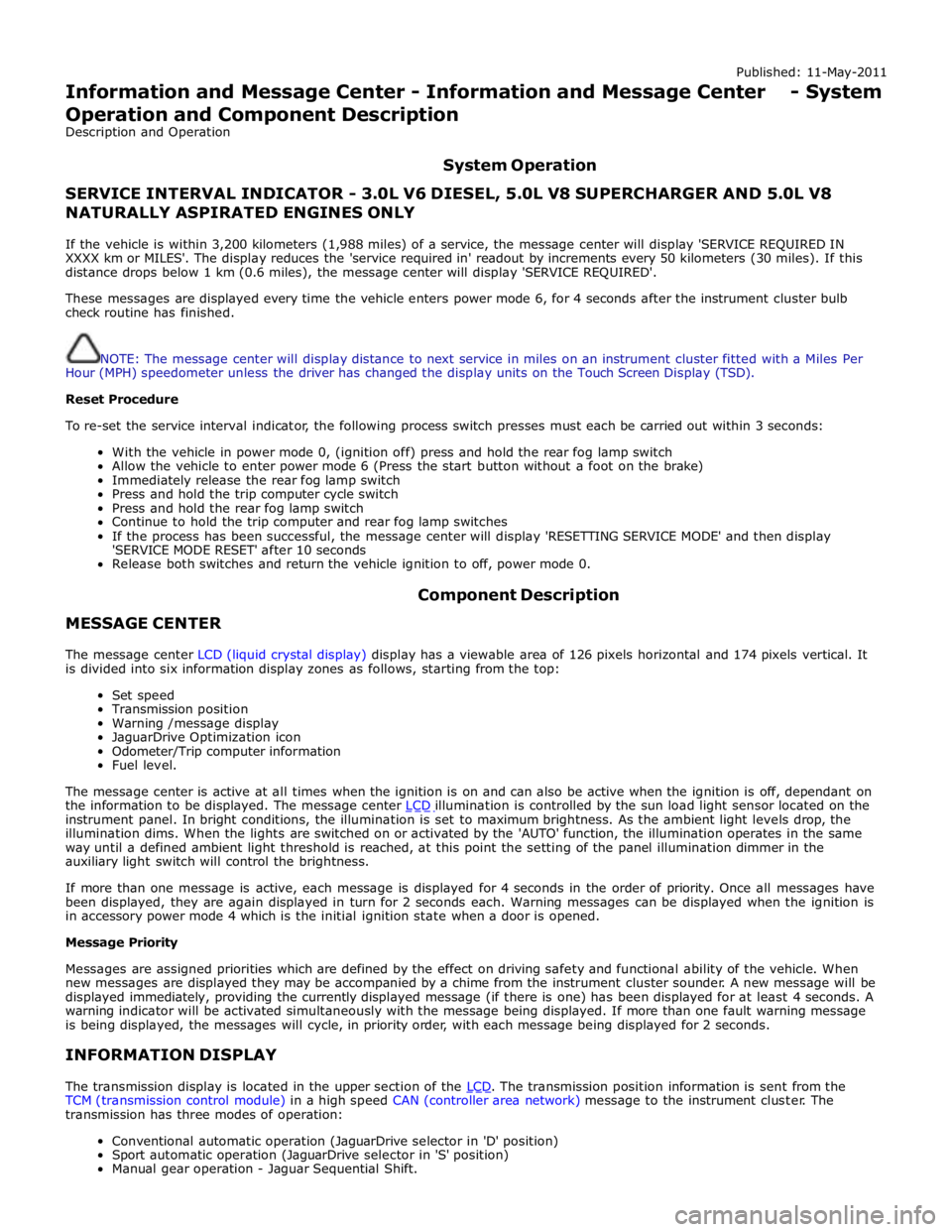

Published: 11-May-2011

Information and Message Center - Information and Message Center - System

Operation and Component Description

Description and Operation

System Operation

SERVICE INTERVAL INDICATOR - 3.0L V6 DIESEL, 5.0L V8 SUPERCHARGER AND 5.0L V8 NATURALLY ASPIRATED ENGINES ONLY

If the vehicle is within 3,200 kilometers (1,988 miles) of a service, the message center will display 'SERVICE REQUIRED IN

XXXX km or MILES'. The display reduces the 'service required in' readout by increments every 50 kilometers (30 miles). If this

distance drops below 1 km (0.6 miles), the message center will display 'SERVICE REQUIRED'.

These messages are displayed every time the vehicle enters power mode 6, for 4 seconds after the instrument cluster bulb

check routine has finished.

NOTE: The message center will display distance to next service in miles on an instrument cluster fitted with a Miles Per

Hour (MPH) speedometer unless the driver has changed the display units on the Touch Screen Display (TSD).

Reset Procedure

To re-set the service interval indicator, the following process switch presses must each be carried out within 3 seconds:

With the vehicle in power mode 0, (ignition off) press and hold the rear fog lamp switch

Allow the vehicle to enter power mode 6 (Press the start button without a foot on the brake)

Immediately release the rear fog lamp switch

Press and hold the trip computer cycle switch

Press and hold the rear fog lamp switch

Continue to hold the trip computer and rear fog lamp switches

If the process has been successful, the message center will display 'RESETTING SERVICE MODE' and then display

'SERVICE MODE RESET' after 10 seconds

Release both switches and return the vehicle ignition to off, power mode 0.

MESSAGE CENTER Component Description

The message center LCD (liquid crystal display) display has a viewable area of 126 pixels horizontal and 174 pixels vertical. It

is divided into six information display zones as follows, starting from the top:

Set speed

Transmission position

Warning /message display

JaguarDrive Optimization icon

Odometer/Trip computer information

Fuel level.

The message center is active at all times when the ignition is on and can also be active when the ignition is off, dependant on

the information to be displayed. The message center LCD illumination is controlled by the sun load light sensor located on the instrument panel. In bright conditions, the illumination is set to maximum brightness. As the ambient light levels drop, the

illumination dims. When the lights are switched on or activated by the 'AUTO' function, the illumination operates in the same

way until a defined ambient light threshold is reached, at this point the setting of the panel illumination dimmer in the

auxiliary light switch will control the brightness.

If more than one message is active, each message is displayed for 4 seconds in the order of priority. Once all messages have

been displayed, they are again displayed in turn for 2 seconds each. Warning messages can be displayed when the ignition is

in accessory power mode 4 which is the initial ignition state when a door is opened.

Message Priority

Messages are assigned priorities which are defined by the effect on driving safety and functional ability of the vehicle. When

new messages are displayed they may be accompanied by a chime from the instrument cluster sounder. A new message will be

displayed immediately, providing the currently displayed message (if there is one) has been displayed for at least 4 seconds. A

warning indicator will be activated simultaneously with the message being displayed. If more than one fault warning message

is being displayed, the messages will cycle, in priority order, with each message being displayed for 2 seconds.

INFORMATION DISPLAY

The transmission display is located in the upper section of the LCD. The transmission position information is sent from the TCM (transmission control module) in a high speed CAN (controller area network) message to the instrument cluster. The

transmission has three modes of operation:

Conventional automatic operation (JaguarDrive selector in 'D' position)

Sport automatic operation (JaguarDrive selector in 'S' position)

Manual gear operation - Jaguar Sequential Shift.

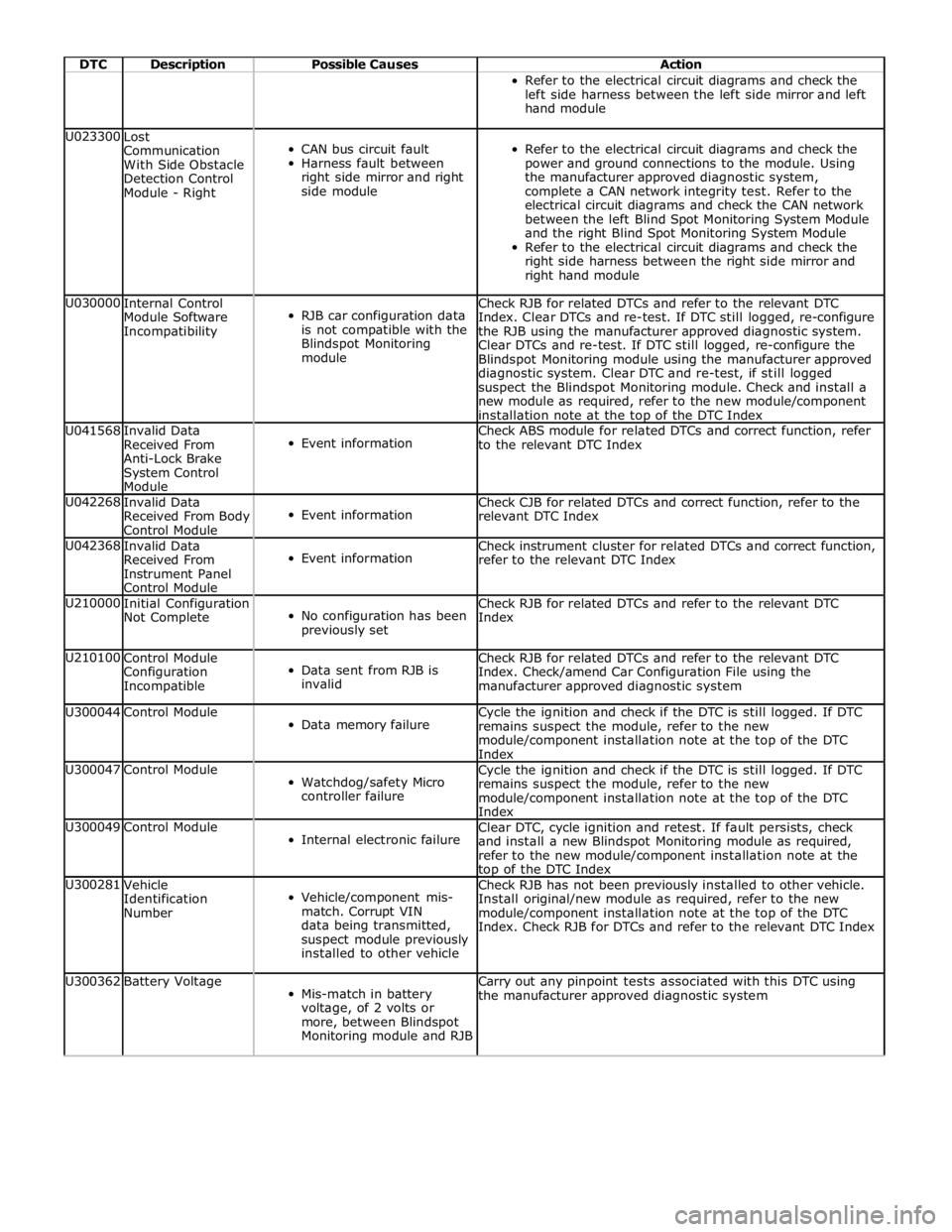

Page 1838 of 3039

Generic scan tools may not read the codes listed, or may read only five digit codes. Match the five digits from the scan

tool to the first five digits of the seven digit code listed to identify the fault (the last two digits give additional information

read by the manufacturer approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal places,

and with an up-to-date calibration certificate. When testing resistance always take the resistance of the DMM leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

When carrying out repair/diagnosis of the system, on removal of the front or rear bumper inspect the sensor connectors

to ensure they were correctly latched and check fly leads for signs of chaffing or trapped wires.

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required

DTC Description Possible Causes Action B11C911

Driver Display

Status LED

Driver Display Status LED

circuit - short to ground Refer to the electrical circuit diagrams and check driver display

status LED circuit for short to ground B11C915

Driver Display

Status LED

Driver Display Status LED

circuit - short to power,

open circuit Refer to the electrical circuit diagrams and check driver display

status LED circuit for short to power, open circuit B11D611

Driver Display Alert

LED

Driver Display Alert LED

circuit - short to ground Refer to the electrical circuit diagrams and check driver display

alert LED circuit for short to ground B11D615

Driver Display Alert

LED

Driver Display Alert LED

circuit - short to power,

open circuit Refer to the electrical circuit diagrams and check driver display

alert LED circuit for short to power, open circuit U001000

Medium Speed CAN

Communication Bus

No sub type information Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check MS CAN

bus state, carry out CAN network integrity tests using the

manufacturer approved diagnostic system U014000

Lost

Communication

With Body Control

Module

Lost communication with

CJB Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check CJB for

related DTCs and correct function, refer to the relevant DTC

Index U014200

Lost

Communication

With Body Control

Module "B"

Lost communication with

RJB Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check RJB for

related DTCs and correct function, refer to the relevant DTC

Index U014600

Lost

Communication

With Gateway "A"

Lost communication with

information and

entertainment module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

information and entertainment module for related DTCs and

correct function, refer to the relevant DTC Index U015500

Lost

Communication

With Instrument

Panel Cluster (IPC)

Control Module

Lost communication with

instrument cluster Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

instrument cluster for related DTCs and correct function, refer

to the relevant DTC Index U023200

Lost

Communication

With Side Obstacle

Detection Control

Module - Left

CAN bus circuit fault

Harness fault between left

side mirror and left side

module

Refer to the electrical circuit diagrams and check the

power and ground connections to the module. Using

the manufacturer approved diagnostic system,

complete a CAN network integrity test. Refer to the

electrical circuit diagrams and check the CAN network

between the left Blind Spot Monitoring System Module

and the right Blind Spot Monitoring System Module

Page 1839 of 3039

DTC Description Possible Causes Action Refer to the electrical circuit diagrams and check the

left side harness between the left side mirror and left

hand module U023300

Lost

Communication

With Side Obstacle

Detection Control

Module - Right

CAN bus circuit fault

Harness fault between

right side mirror and right

side module

Refer to the electrical circuit diagrams and check the

power and ground connections to the module. Using

the manufacturer approved diagnostic system,

complete a CAN network integrity test. Refer to the

electrical circuit diagrams and check the CAN network

between the left Blind Spot Monitoring System Module

and the right Blind Spot Monitoring System Module

Refer to the electrical circuit diagrams and check the

right side harness between the right side mirror and

right hand module U030000

Internal Control

Module Software

Incompatibility

RJB car configuration data

is not compatible with the

Blindspot Monitoring

module Check RJB for related DTCs and refer to the relevant DTC

Index. Clear DTCs and re-test. If DTC still logged, re-configure

the RJB using the manufacturer approved diagnostic system.

Clear DTCs and re-test. If DTC still logged, re-configure the

Blindspot Monitoring module using the manufacturer approved

diagnostic system. Clear DTC and re-test, if still logged

suspect the Blindspot Monitoring module. Check and install a

new module as required, refer to the new module/component

installation note at the top of the DTC Index U041568

Invalid Data

Received From

Anti-Lock Brake

System Control

Module

Event information Check ABS module for related DTCs and correct function, refer

to the relevant DTC Index U042268

Invalid Data

Received From Body

Control Module

Event information Check CJB for related DTCs and correct function, refer to the

relevant DTC Index U042368

Invalid Data

Received From

Instrument Panel

Control Module

Event information Check instrument cluster for related DTCs and correct function,

refer to the relevant DTC Index U210000

Initial Configuration

Not Complete

No configuration has been

previously set Check RJB for related DTCs and refer to the relevant DTC

Index U210100

Control Module

Configuration

Incompatible

Data sent from RJB is

invalid Check RJB for related DTCs and refer to the relevant DTC

Index. Check/amend Car Configuration File using the

manufacturer approved diagnostic system U300044 Control Module

Data memory failure Cycle the ignition and check if the DTC is still logged. If DTC

remains suspect the module, refer to the new

module/component installation note at the top of the DTC

Index U300047 Control Module

Watchdog/safety Micro

controller failure Cycle the ignition and check if the DTC is still logged. If DTC

remains suspect the module, refer to the new

module/component installation note at the top of the DTC

Index U300049 Control Module

Internal electronic failure Clear DTC, cycle ignition and retest. If fault persists, check

and install a new Blindspot Monitoring module as required,

refer to the new module/component installation note at the top of the DTC Index U300281

Vehicle

Identification

Number

Vehicle/component mis-

match. Corrupt VIN

data being transmitted,

suspect module previously

installed to other vehicle Check RJB has not been previously installed to other vehicle.

Install original/new module as required, refer to the new

module/component installation note at the top of the DTC

Index. Check RJB for DTCs and refer to the relevant DTC Index U300362 Battery Voltage

Mis-match in battery

voltage, of 2 volts or

more, between Blindspot

Monitoring module and RJB Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system