sensor JAGUAR XJ6 1994 2.G Electrical Diagnostic Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 327, PDF Size: 13.73 MB

Page 89 of 327

Climate Control Systems

14.7.2 Fault Code 12

Ambient Temperature Sensor

0 Sensor, harness or A 1 CCM open circuit.

0 Sensor, harness or A 1 CCM short circuit to ground.

If the signal on pin 27 (12-way connector, AI CCM) remains at less than 1 volt, suspect either a short circuit to ground

on the signal wire or an open circuit on the 5 volt supply to the sensor. If the signal on pin 27 rises to approximately 5 volts, suspect an open circuit on the earth supply to the sensor.

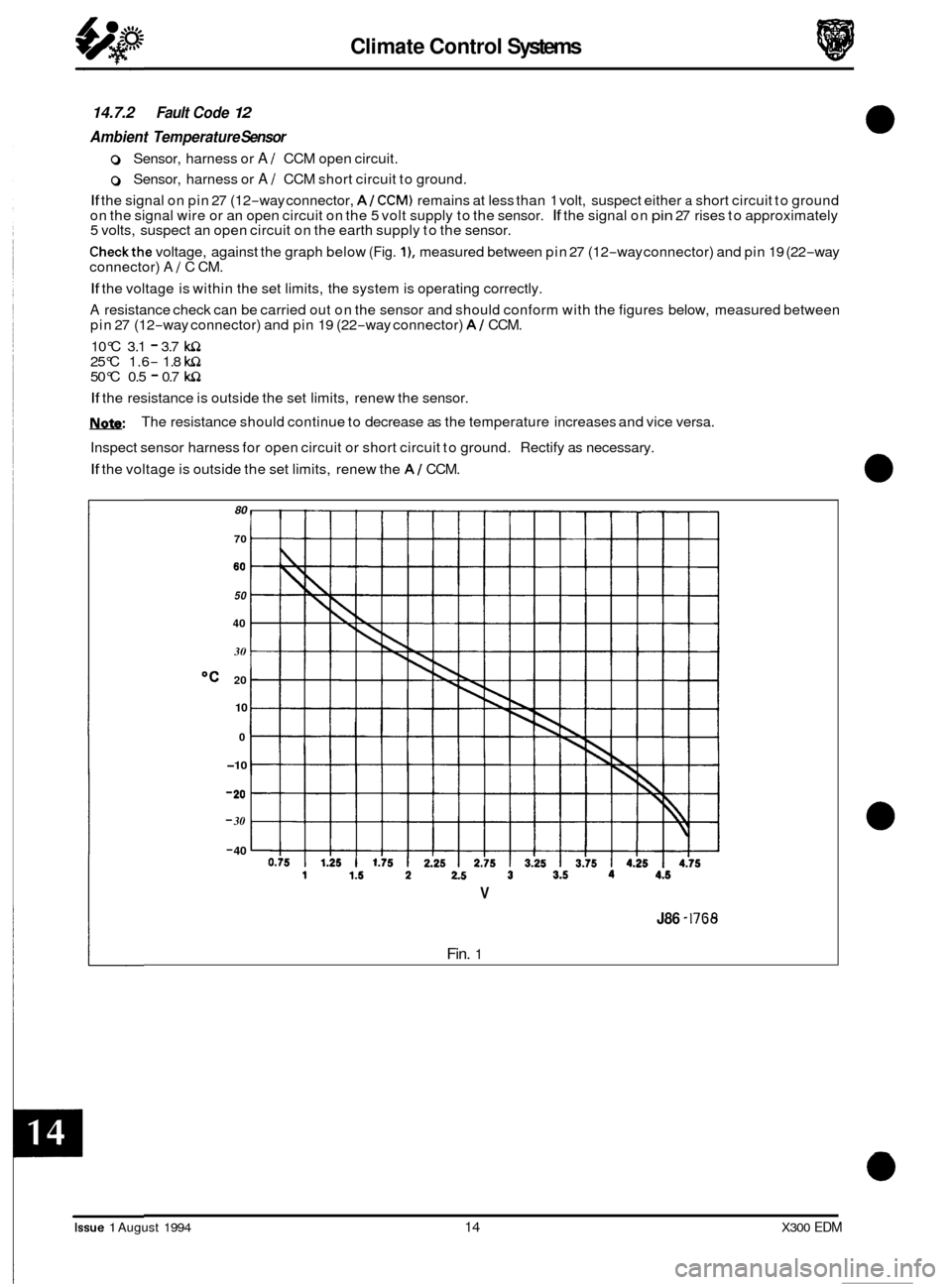

Checkthe voltage, against the graph below (Fig. I), measured between pin 27 (12-way connector) and pin 19 (22-way

connector) A 1 C CM.

If the voltage is within the set limits, the system is operating correctly.

A resistance check can be carried out on the sensor and should conform with the figures below, measured between

pin 27 (12-way connector) and pin 19 (22-way connector) AI CCM.

10°C 3.1

- 3.7 w1 25°C 1.6- 1.8 w1 50°C 0.5 - 0.7 w1

If the resistance is outside the set limits, renew the sensor.

Nnfe:

Inspect sensor harness for open circuit or short circuit to ground. Rectify as necessary.

If the voltage is outside the set limits, renew the AI CCM.

The resistance

should continue to decrease as the temperature increases and vice versa.

80

70

80

50

40

30

OC 20

10

0

-10

- 20

- 30

- 40

V

Fin. 1

J86 -17'38

0

0

0

0

Issue 1 August 1994 14 X300 EDM

Page 90 of 327

Climate Control Systems

14.7.3 Faultcode 13

Evaporator Temperature Sensor

0 Sensor, harness or A / CCM open circuit.

0 Sensor, harness or A/ CCM short circuit to ground.

This sensor monitors the temperature of the evaporator matrix, the output is used to trigger the compressor circuit

via the

A/ CCM pin 34 (12-way connector).

If the signal on pin 34 (12-way connector) remains at less than 1 volt, suspect either a short circuit to ground on the

signal wire or an open circuit on the 5 volt supply to the sensor. If the signal on pin 34 rises to approximately 5 volts

then suspect an open circuit on the sensor ground.

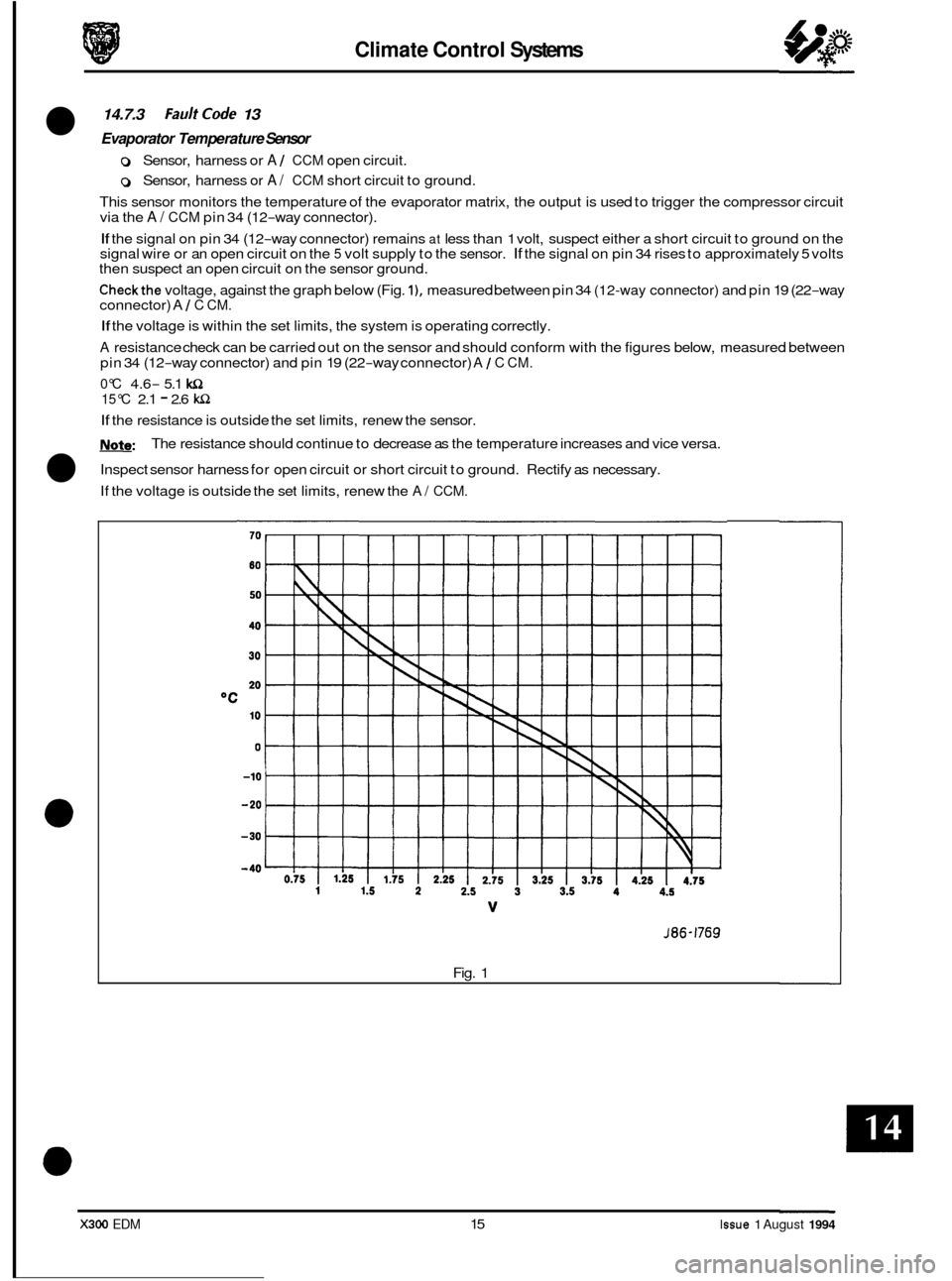

Checkthe voltage, against the graph below (Fig. I), measured between pin 34 (12-way connector) and pin 19 (22-way

connector) A / C CM.

If the voltage is within the set limits, the system is operating correctly.

A resistance check can be carried out on the sensor and should conform with the figures below, measured between

pin 34 (12

-way connector) and pin 19 (22-way connector) A / C CM.

0°C

4.6- 5.1 WZ

15°C 2.1 - 2.6 WZ

If the resistance is outside the set limits, renew the sensor.

Note:

Inspect sensor harness for open circuit or short circuit to ground. Rectify as necessary.

If the voltage is outside the set limits, renew the

A/ CCM.

The resistance should continue to decrease as the temperature increases and vice versa.

*C

J86-1769

Fig. 1

X300 EDM 15 Issue 1 August 1994

Page 91 of 327

Climate Control Systems

14.7.4 Fault Code 14

Coolant Temperature

Input

0 Sensor, harness or A / CCM open circuit.

0 Sensor, harness or A / CCM short circuit to ground.

This input is derived from the instrument pack,

a continuity check can be carried out from pin 22, instrument pack (24-wayconnector), to pin 40 (16-way connector) of the A / C CM.

The instrument pack input from the engine coolant temperature sensor, is covered in the EDM, section 15, Instrument

Pack and Trip Computer.

14.7.5 Fault Code 15

Heater Matrix Temperature Sensor

0 Sensor, harness or A/ CCM open circuit.

0 Sensor, harness or A / CCM short circuit to ground.

This sensor measures the temperature of the heater matrix.

If the signal on pin 28 (12-way connector) remains at less than 1 volt, suspect either a short circuit to ground on the

signal wire or an open circuit on the 5 volt supply to the sensor. If the signal on pin 28 rises to approximately 5 volts

then suspect an open circuit on the sensor ground.

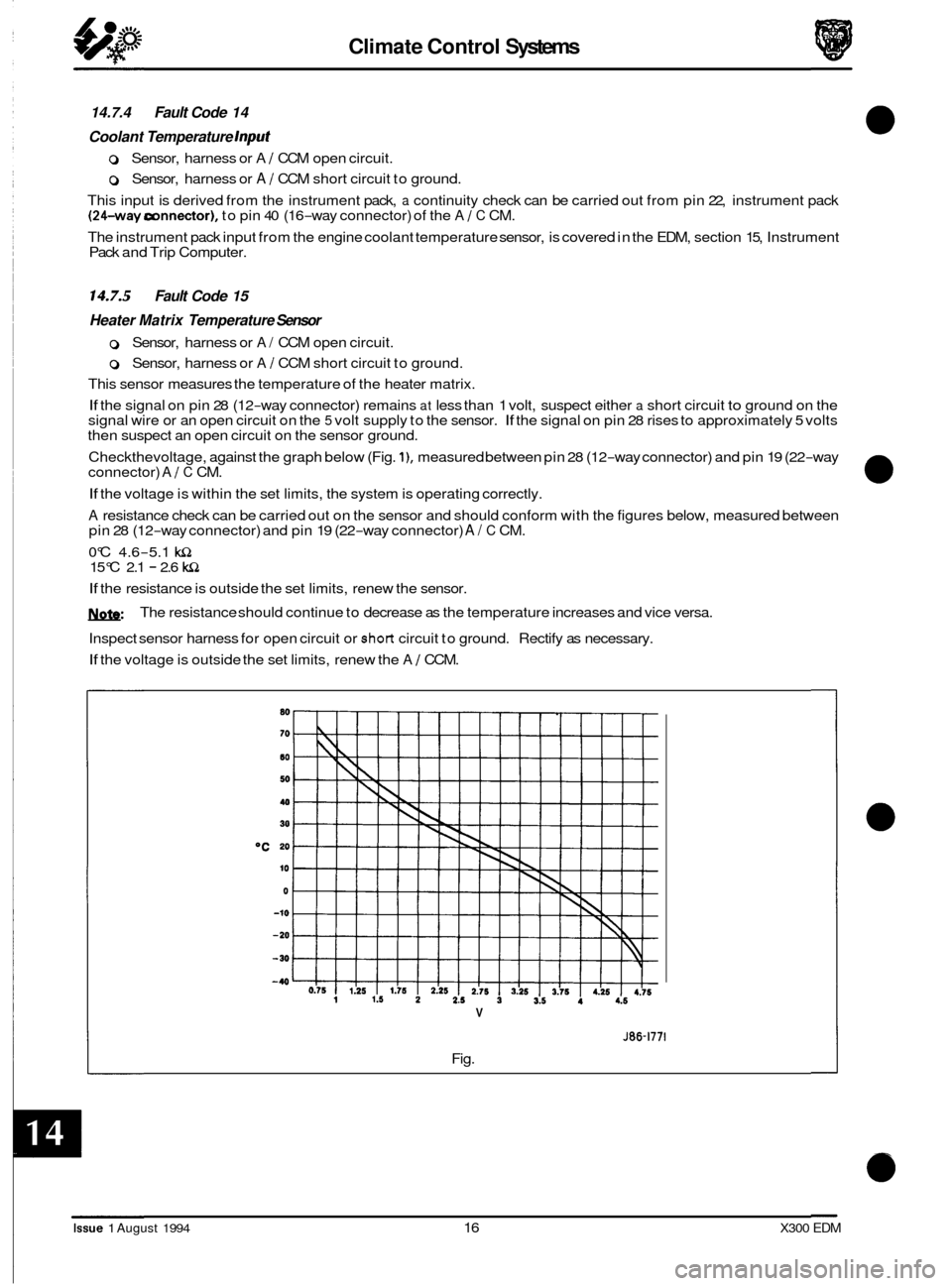

Checkthevoltage, against the graph below (Fig.

I), measured between pin 28 (12-way connector) and pin 19 (22-way

connector) A / C CM.

If the voltage is within the set limits, the system is operating correctly.

A resistance check can be carried out on the sensor and should conform with the figures below, measured between

pin 28 (12-way connector) and pin 19 (22-way connector) A/ C CM.

0°C 4.6

-5.1 lclL 15°C 2.1 - 2.6 lclL

If the resistance is outside the set limits, renew the sensor.

1ynfe:

Inspect sensor harness for open circuit or short circuit to ground. Rectify as necessary.

If the voltage is outside the set limits, renew the A / CCM.

The

resistance should continue to decrease as the temperature increases and vice versa.

*C

V

J86-1771

Fig.

Issue 1 August 1994 16 X300 EDM

Page 92 of 327

Climate Control Systems

14.7.6 FaulfCode21

Solar Sensor

0 Sensor, harness or A / CCM open circuit.

0 Sensor, harness or A / CCM short circuit to ground.

The sensor provides a linear output response signal to

pin 35 (16-way connector) A/ CCM; the output ranges from 0 to 5 volts, the voltage will drop as light intensity increases.

A resistance check can be carried out on the sensor and should conform with the figures below:

With no light on the sensor, the resistance should read approximately 15

kL2.

With increasing light intensity, the resistance should decrease from 15 kQ.

Inspect the sensor harness for open circuit or short circuit to ground. Rectify as necessary.

If the sensor and harness appear correct, suspect the A/ CCM.

14.7.7 Fadf Code 22

Compressor lock Signal

(12 cy/. vehicles only)

0 Sensor, harness or A / CCM open circuit.

0 Sensor, harness or A/ CCM short circuit to ground.

The compressor lock sensor provides an

a.c. signal proportional to engine speed. As engine speed increases the a.c. signal voltage value will increase.

A voltage checkcan be carried out on the sensor and should read approximately 0.5V a.c. whilst the compressor is ON and OV whilst the compressor is OFF, measured between pin 26 (12-way connector) and pin 19 (22-way connector) A

/ C CM.

If the reading is OV whilst the compressor is ON, suspect the sensor or the sensor harness (open circuit or short circuit

to ground).

Check the resistance between pins 1 and 2 of the compressor lock sensor, value should be

190a & 20%.

If the resistance measured falls outside the limits, renew the compressor lock sensor.

Inspect the sensor harness for open circuit or short circuit to ground. Rectify as necessary.

If the sensor and harness appear correct, suspect the AI CCM.

X300 EDM 17 Issue 1 August 1994

Page 101 of 327

E I ect r ica I rl

SECTION CONTENTS

m: For ease of access to the required information, this Section has been divided into four sub-sections with the

page numbers of each prefixed 15.1, 15.2, 15.3 or 15.4. Each subsection has its own contents list, and these

are given on the following pages

Sub-Section 15.1 Supplemental Restraint Systems

Subsection Title SRO Page

15.1 ............. Supplemental Restraint System .................................................... 15.1-1

15.1.1 ............ System Description .............................................................. 15.1- 1

15.1.2 ............ Component Descriptions ......................................................... 15.1- 7

15.1.2.1 .......... Diagnostic Module .............................................................. 7 5.1 - 7

15.1.2.2 .......... Wiring Harness ................................................................. 15.1-1

15.1.2.3 .......... AirBagModules ................................................................ 75.1-7

15.1.3 ............ Air Bag Disarming / Arming Procedure ............................................. 15.1-3

15.1.4

............ Diagnostic Module Fault Codes ................................................... 15.1-4

15.1.2.4 .......... ImpactSensors ................................................................. 15.7-2

X300 EDM i Issue 1 August 1994

Page 107 of 327

E I ect r ica I

15.1 SUPPLEMENTAL RESTRAINT SYSTEM

15.1.1 System Description

The Supplemental Restraint System (SRS) installation comprises:

0 electronic Diagnostic Module (DM)

0 driver and passenger-side air bag modules (including firing mechanisms)

0 two front impact sensors (left and right)

0 one safing sensor

0 dedicated wiring harness

0 two cable reel cassettes (integral part of the steering column harness)

0 Malfunction Indicator Lamp (MIL) and driver information message

The system is designed to provide protection for both driver and front seat passenger by automatically deploying air

bags in the event of a collision during forward travel. The driver

-side air bag is located in the centre of the steering

wheel assembly and the passenger-side air bag in the fascia panel.

In the event of a collision the impact

/ safing sensors operate, completing the electrical firing circuit and causing the

air bags to inflate within 32 milliseconds. At least two of the three sensors (at least one impact, and the safing sensor)

.must be activated to initiate firing. System operation is dependent upon battery voltage supplied directly, and via the

ignition switch, to the DM and the correct installation and operation of all system components, including the wiring

harness. Faults in system components, installation or wiring will be indicated by the MIL Lamp, located on the instru

- ment panel, which will illuminate 'SRS AIR BAG'. Indication is also given by the driver information message'AIR BAG'

displayed on the LCD panel below the speedometer.

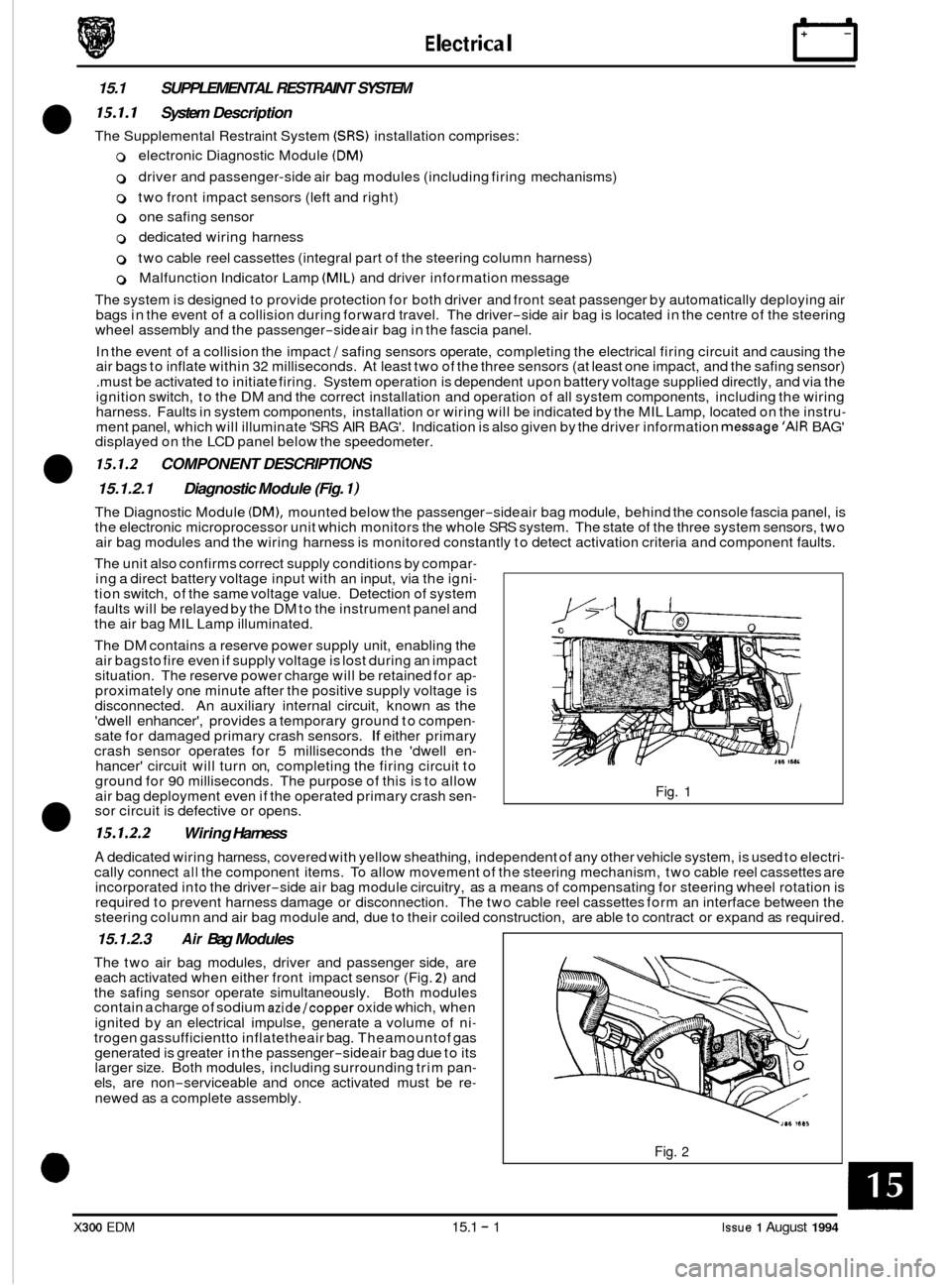

15.1.2.1 Diagnostic Module (Fig. I)

The Diagnostic Module (DM), mounted below the passenger-side air bag module, behind the console fascia panel, is

the electronic microprocessor unit which monitors the whole SRS system. The state of the three system sensors, two

air bag modules and the wiring harness is monitored constantly to detect activation criteria and component faults.

15.1.2 COMPONENT DESCRIPTIONS

The unit also confirms correct supply conditions by compar- ing a direct battery voltage input with an input, via the igni- tion switch, of the same voltage value. Detection of system

faults will be relayed by the DM to the instrument panel and

the air bag MIL Lamp illuminated.

The DM contains a reserve power supply unit, enabling the

air bagsto fire even if supply voltage is lost during an impact

situation. The reserve power charge will be retained for ap

- proximately one minute after the positive supply voltage is

disconnected. An auxiliary internal circuit, known as the

'dwell enhancer', provides a temporary ground to compen

- sate for damaged primary crash sensors. If either primary

crash sensor operates for 5 milliseconds the 'dwell en- hancer' circuit will turn on, completing the firing circuit to

ground for 90 milliseconds. The purpose of this is to allow

air bag deployment even if the operated primary crash sen- sor circuit is defective or opens.

15.1.2.2 Wiring Harness

Fig. 1

A dedicated wiring harness, covered with yellow sheathing, independent of any other vehicle system, is used to electri- cally connect all the component items. To allow movement of the steering mechanism, two cable reel cassettes are

incorporated into the driver-side air bag module circuitry, as a means of compensating for steering wheel rotation is

required to prevent harness damage or disconnection. The two cable reel cassettes form an interface between the

steering column and air bag module and, due to their coiled construction, are able to contract or expand as required.

15.1.2.3 Air Bag Modules

The two air bag modules, driver and passenger side, are

each activated when either front impact sensor (Fig. 2) and

the safing sensor operate simultaneously. Both modules

contain a charge of sodium

azide/copper oxide which, when

ignited by an electrical impulse, generate a volume of ni

- trogen gassufficientto inflatetheair bag. Theamountof gas

generated is greater in the passenger-side air bag due to its

larger size. Both modules, including surrounding trim pan- els, are non-serviceable and once activated must be re-

newed as a complete assembly.

Fig. 2

X300 EDM 15.1 - 1 Issue 1 August 1994

Page 108 of 327

IT Electrical

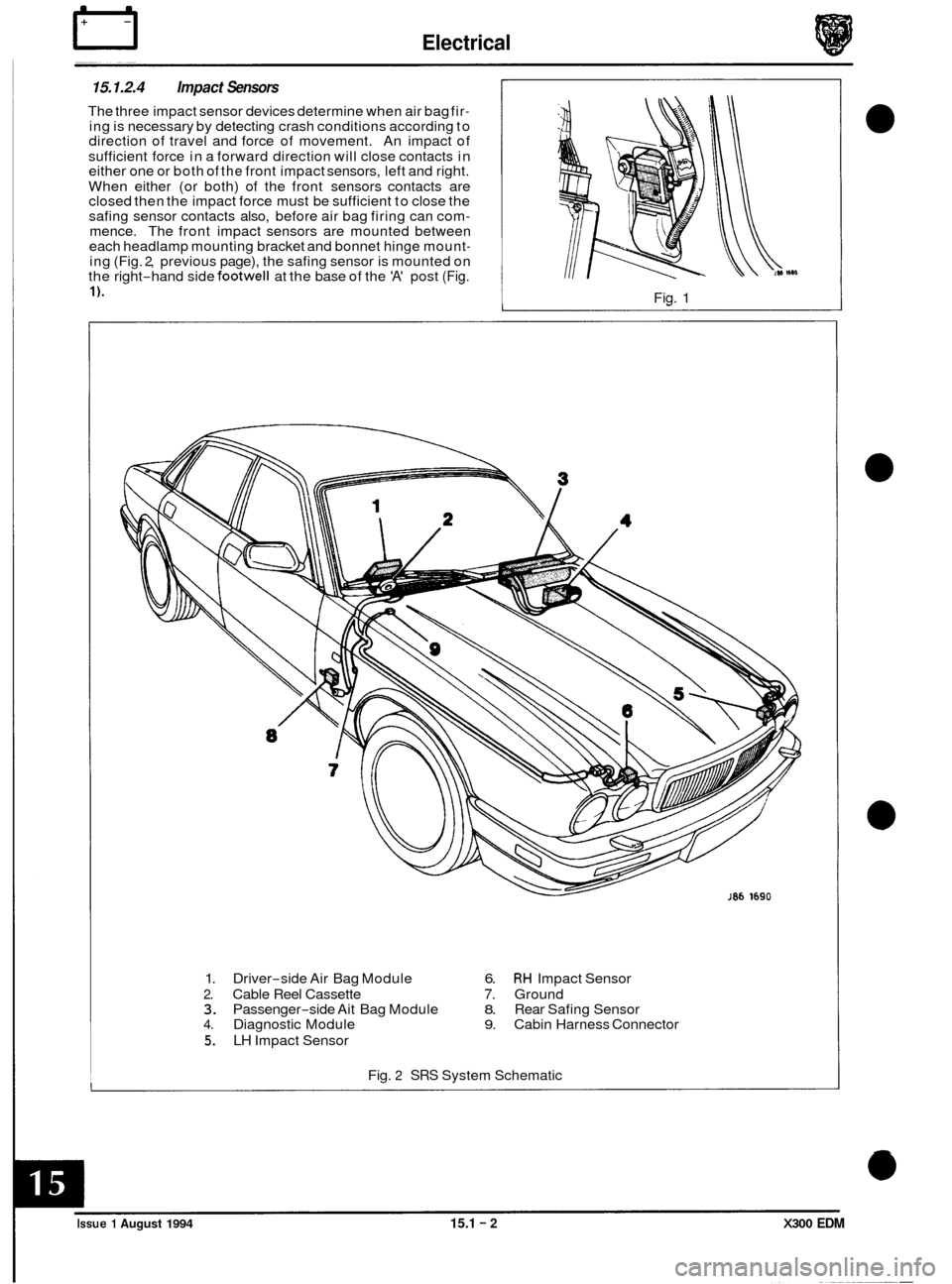

15.1.2.4 Impact Sensors

The three impact sensor devices determine when air bag fir- ing is necessary by detecting crash conditions according to

direction of travel and force of movement. An impact of

sufficient force in a forward direction will close contacts in

either one or both of

the front impact sensors, left and right.

When either (or both) of the front sensors contacts are

closed then the impact force must be sufficient to close the

safing sensor contacts also, before air bag firing can com

- mence. The front impact sensors are mounted between

each headlamp mounting bracket and bonnet hinge mount- ing (Fig. 2, previous page), the safing sensor is mounted on

the right-hand side footwell at the base of the 'A' post (Fig.

1). Fig. 1

1.

Driver-side Air Bag Module 6. RH Impact Sensor

2. Cable Reel Cassette 7. Ground 3. Passenger-side Ait Bag Module 8. Rear Safing Sensor 4. Diagnostic Module 9. Cabin Harness Connector

5. LH Impact Sensor

Fig.

2 SRS System Schematic

Issue 1 August 1994 15.1 - 2 X300 EDM

Page 111 of 327

Electrical IT

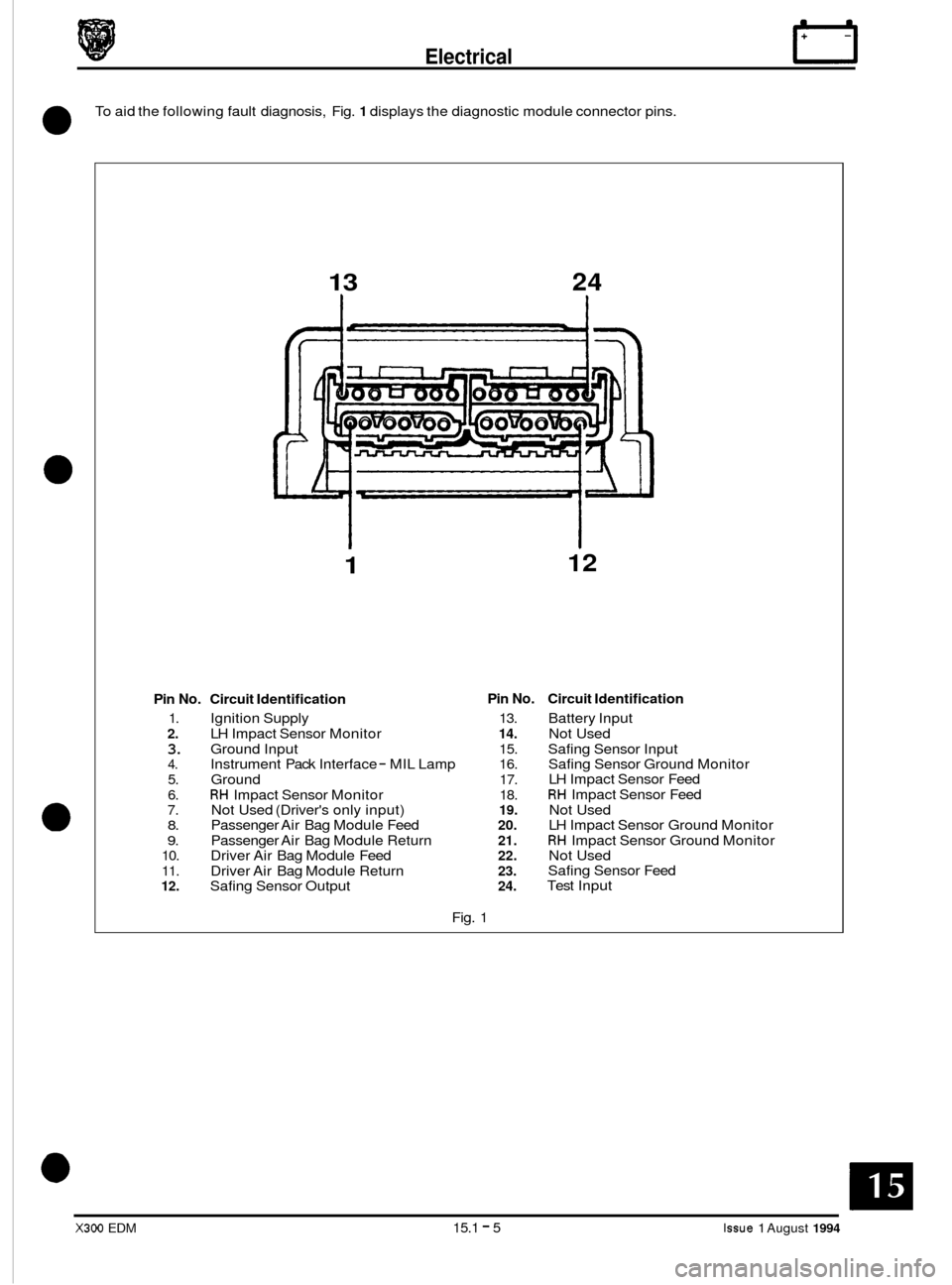

To aid the following fault diagnosis, Fig. 1 displays the diagnostic module connector pins.

0

13 24

1

Pin No. Circuit Identification

1. Ignition Supply

2. LH Impact Sensor Monitor

3. Ground Input 4.

5. Ground

6. RH Impact Sensor Monitor 7. 8.

9. 10.

11.

12. Safing Sensor Output

Instrument

Pack Interface

- MIL Lamp

Not Used (Driver's only input)

Passenger Air Bag Module Feed

Passenger Air Bag Module Return

Driver Air Bag Module Feed

Driver Air Bag Module Return

Fig.

1

Pin No.

13.

14.

15.

16. 17.

18.

19.

20.

21.

22.

23.

24.

12

Circuit Identification

Battery Input

Not Used

Safing Sensor Input

Safing Sensor Ground Monitor

LH Impact Sensor Feed

RH Impact Sensor Feed

Not Used

LH Impact Sensor Ground Monitor

RH Impact Sensor Ground Monitor

Not Used

Safing Sensor Feed

Test Input

X300 EDM 15.1 - 5 Issue 1 August 1994

Page 113 of 327

E I ect r ica I rl

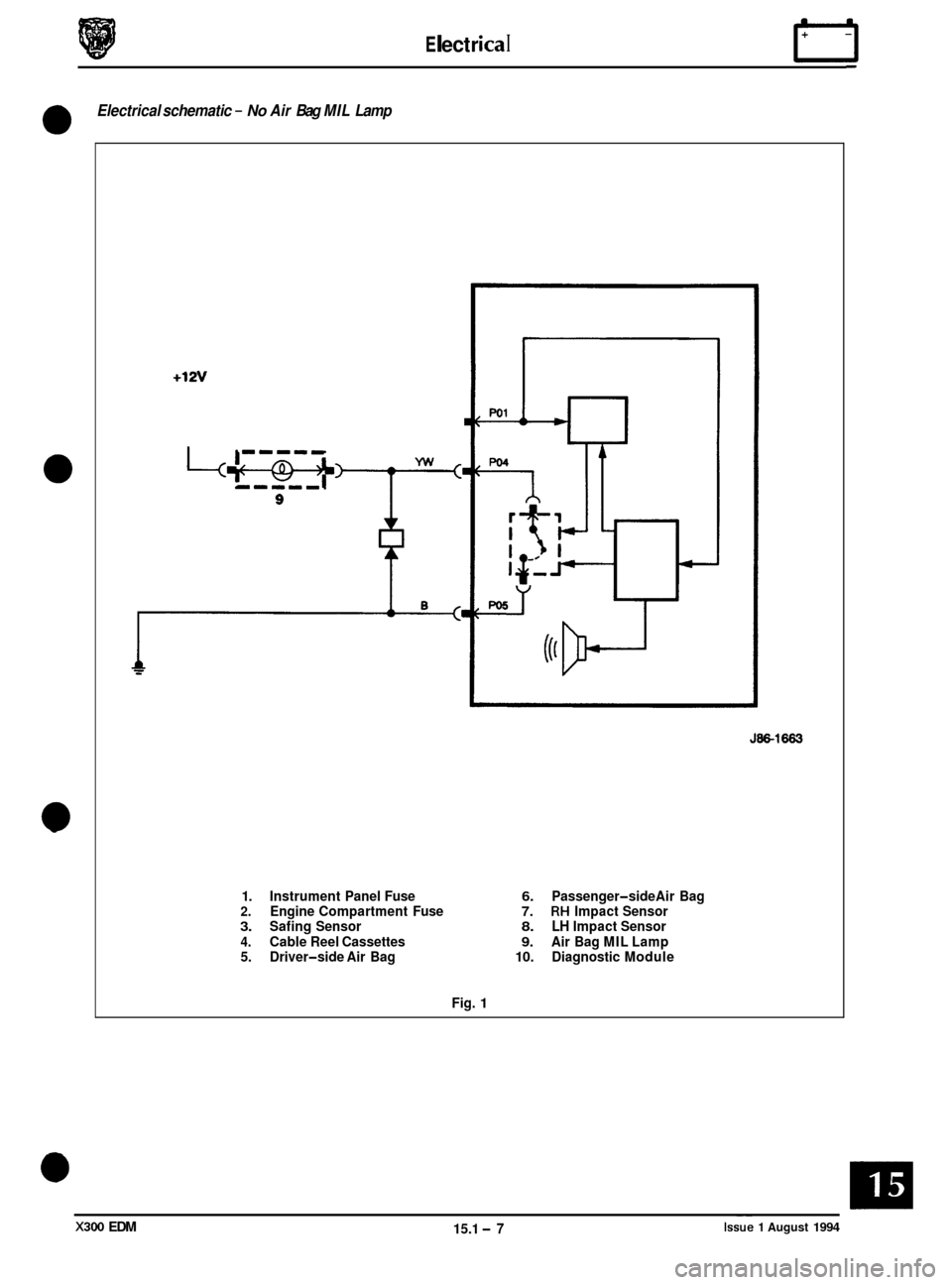

Electrical schematic - No Air Bag MIL Lamp

0

+12v

1. Instrument Panel Fuse 2. Engine Compartment Fuse 3. Safing Sensor

4. Cable Reel Cassettes

5. Driver-side Air Bag

Fig.

1

J86-1663

6. Passenger-side Air Bag 7. RH Impact Sensor 8. LH Impact Sensor

9. Air Bag MIL Lamp

10. Diagnostic Module

X300 EDM 15.1 -7 ~~ Issue 1 August 1994

Page 115 of 327

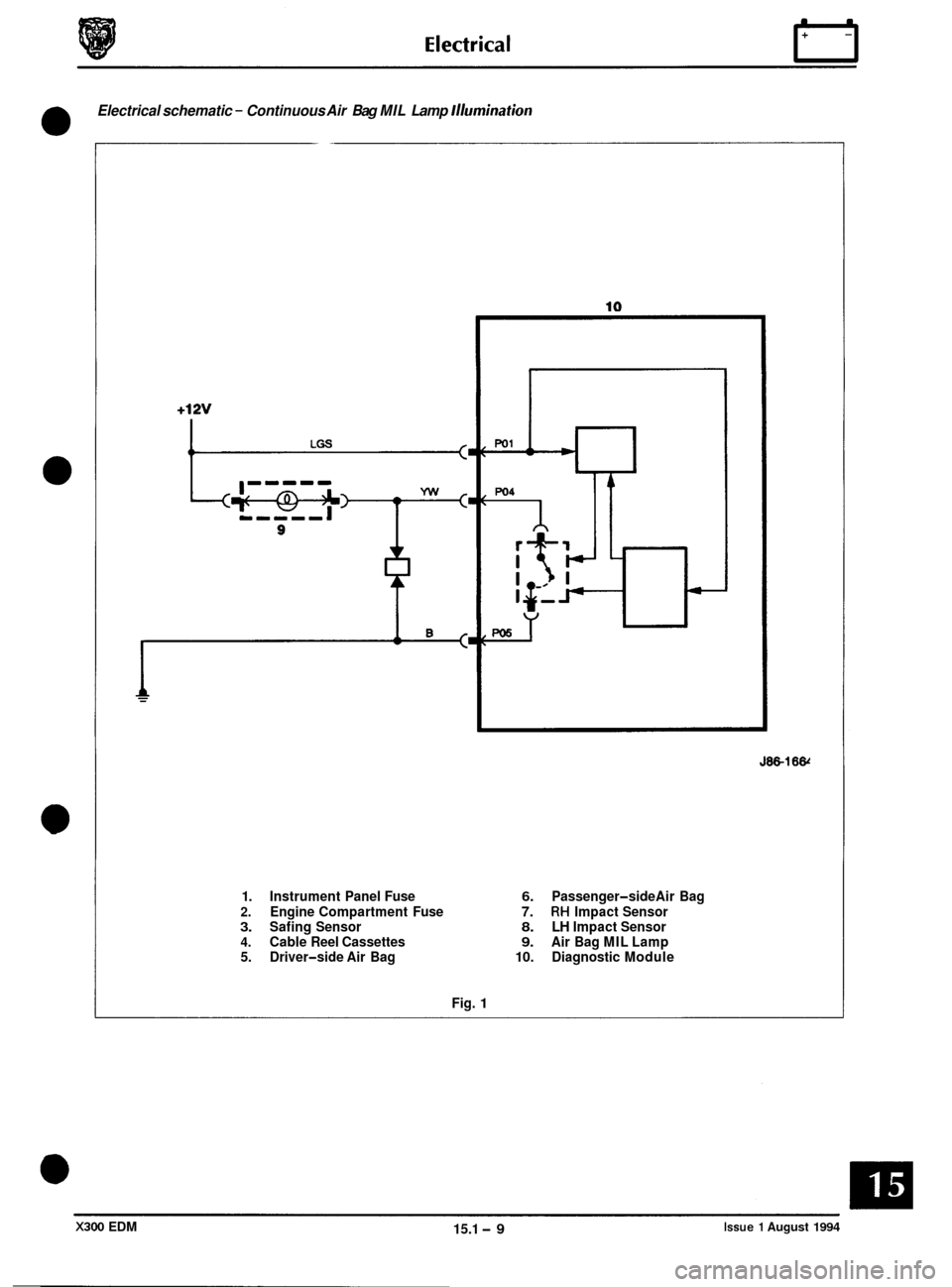

Electrical schematic - Continuous Air Bag MIL Lamp Illumination

0

J86-16&

1. Instrument Panel Fuse

2. Engine Compartment Fuse 3. Safing Sensor 4. Cable Reel Cassettes

5. Driver-side Air Bag

Fig.

1

6. Passenger-side Air Bag

7. RH Impact Sensor 8. LH Impact Sensor 9. Air Bag MIL Lamp

10. Diagnostic Module

X300 EDM 15.1 -9 Issue 1 August 1994