suspension JAGUAR XJ6 1994 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 216 of 521

may include:

0

0

Loose or worn wheel bearings.

Loose or worn suspensions or steering components.

0 Worn or damaged drive shaft slip yoke joint.

0 Front disc rotor runout.

o Loose engine or transmission supports.

0 Driveline alignment.

0 Engine driven accessories.

Suspension Systems

11.4 DIAGNOSIS AND TESTING

' 11.4.1 Tire Wear

Tires should be inspected as abnormal or excessive wear may becaused by incorrect wheel alignment, wheelbire im- balance, or incorrect tire pressure.

1 1.4.2 vibration and Roughness

Vibration, roughness, and shimmy conditions may be caused by excessive tire or wheel runout, worn or cupped tires,

or wheel and tire unbalance.

Most of these conditions are due to irregularities in the road surface, hence driving the vehicle on different types of

road surface will often indicate the cause of the condition.

Do not automatically suspect the tires when attempting to diagnose a vibration concern as other sources of vibration

Before investigating any other vibration concerns,

a roaG &est and a customer inter\,.dw (if possible) should be carried

out. This can provide much of the information needed to find the source of vibration.

Drive the vehicle on a road that is preferably smooth and free of undulation and

if vibration is apparent note, the speed at which thevibration occurs, whattype of vibration occurs in each speed range (mechanical or audible), howthevibra- tion is affected by changes in vehicle speed , engine speed and engine torque, and the type of vibration sensitivity

(torque sensitive, vehicle speed sensitive, or speed sensitive).

Some of the condition terms used when describing sources of vibration are explained as follows:

0 Torque Sensitive

This condition can be improved or worsened by accelerating, decelerating, coasting, maintaining

a steady

vehicle speed and application of engine torque.

0 Vehicle Speed Sensitive

This means that the vibration always occurs at the same vehicle speed and is not affected by engine torque,

engine rpm, or transmission gear selection.

B

0 Engine Speed Sensitive

This means that the vibration occurs

at varying vehicle speeds when a different transmission gear is selected.

It can sometimes be isolated by increasing or decreasing engine speed with the transmission in 'NEUTRAL', or

by stall testing with the engine in gear. If the condition is enginesensitive, the condition is not related to tires.

If the road tests indicates that the vibration is related to the tires or wheels,use a 'lire Wear Diagnosis Chart' to

investigate the cause of concern. Should the road test indicate that there is tire whine, but noshake or vibration,

the noise originates from the contact between the tire and the road surface.

X300 VSM 3 Issue 1 August 1994

Page 217 of 521

Suspension Systems

11.4.3 Front End Inspection

Do not check and adjust front wheel alignment without carrying out the following inspection for front end damage and

wear:

. Check for specified air pressure in all four tires.

Raise front of vehicle off the floor; grasping upper and lower surface of the tire, shake each front wheel to check for

. Check front suspension lower arm ball joint and mounts for looseness, wear and damage.

Check steering gear mountings and all steering linkages for looseness.

. Renew parts if necessary.

. Grasp upper and lower surface of tire and shake each wheel to check wheel bearing end play.

. Check the action of the front dampers and the condition of their attachments, as sticking or binding front dampers

worn

bearings.

Check brake caliper mountings.

may not allow the vehicle to settle in to a normal level position, possibly affecting the front-wheel alignment.

m: Front wheel bearings are adjustable (0.001 to 0.003 in. endfloat).

11.4.4

. Check the wheel bearings.

. Inspect the front suspension upper joint and renew front suspension lower wishbone if needed.

Raise vehicle and position floor jacks beneath the front suspension lower wishbone.

Grasp the lower edge of the tire and move the wheel in and out.

While moving the wheel, observe the upper and lower wishbone.

. Movement between the vertical links and the wishbones indicates abnormal ball joint wear.

. Renew ball joints.

. Check the front wheel bearings.

. Check for excessive play and wear.

Upper / Lower Ball Joint Inspection

11.4.5 Damper Inspection

m: The gas-pressurized hydraulic front dampers are not serviceable, adjustable or refillable.

Verify that all attachments of the suspension components and the front dampers are tight. Renew any front damper

. Check front dampers for external damage.

. Check for oil leakage and vehicle sag.

that

has a damaged integral lower mounting bushing.

0 Oil Leak

Leakage is the condition in which the entire damper body is covered with oil and from where

it will drip on to

the pavement. Due to correct damper lubrication a light film of oil (weepage) can usually be seen on the upper

portion of the damper.

Should there be any leakage, ensure that the fluid does not originate from sources other than the front damper.

Renew worn or damaged dampers.

0 Vehicle Sag

Renewing front dampers will not correct the problem of vehicle sag, as basically this is controlled by the spring

units.

issue 1 August 1994 4 X300 VSM

Page 218 of 521

Suspension Systems

1 1.4.6 Rear Suspension lnspe&on

Check damper operation.

Check condition of rear wishbone bushings and rear suspension strut bushings.

Renew damaged or worn components.

0 Check for evidence of fluid leaks on rear dampers.

11.4.7 Vehicle Inspection

Check all tires for correct inflation pressure.

Checktire condition to confirm correct front end alignment, tire balance and overall tire conditions such as separation

Check the vehicle attitude for evidence of possible overload or sagging.

Check luggage compartment area.

. Road test vehicle to confirm customer's concern.

or

bulges.

X300 VSM 5 Issue 1 August 1994 ~ ~~

Page 219 of 521

Suspension Systems

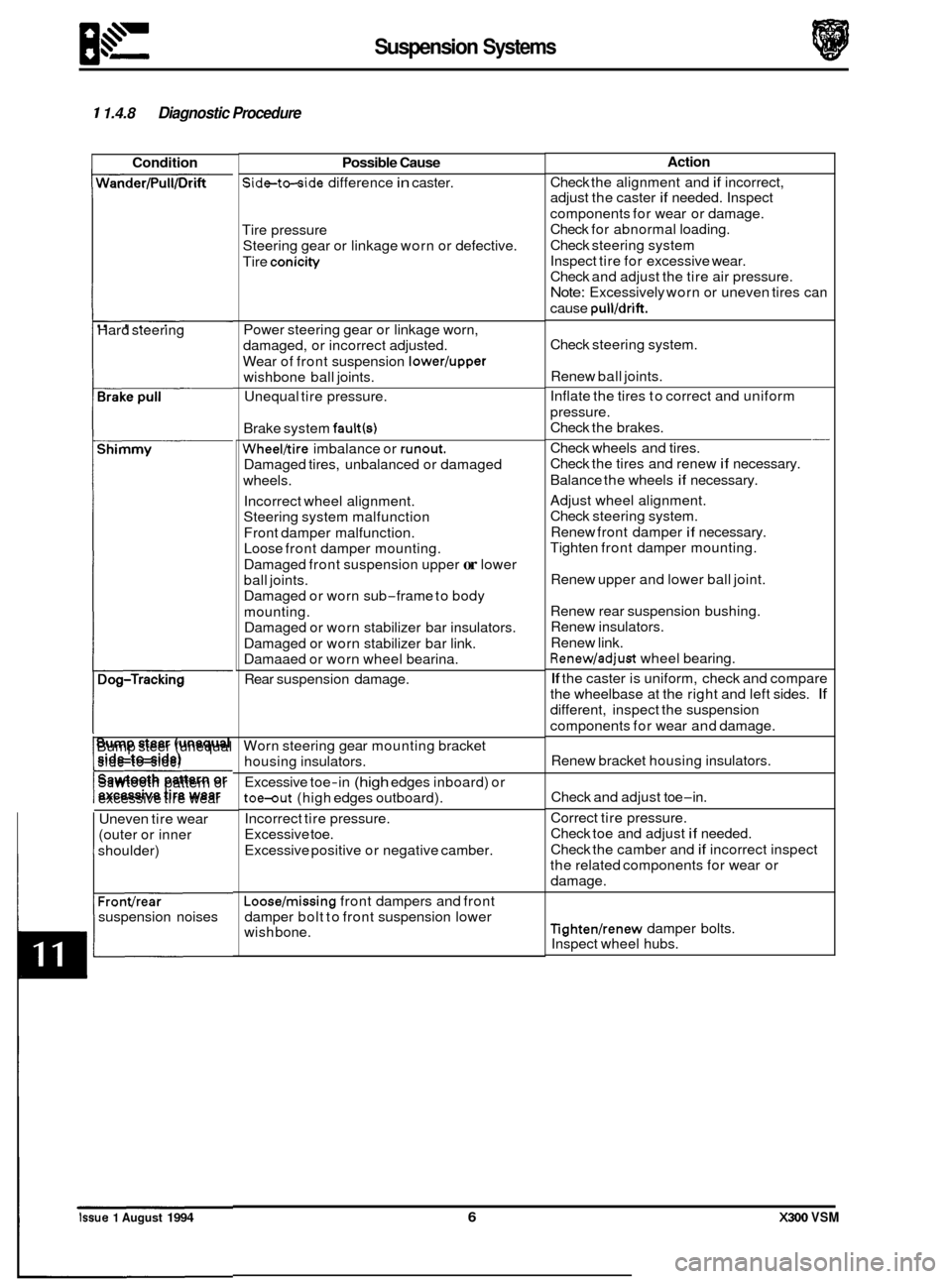

1 1.4.8 Diagnostic Procedure

Condition

Hard steering

Shimmy

I----

Bump steer (unequal

side-to-side)

Sawtooth pattern or

t excessive tire wear

Uneven tire wear

(outer or inner

shoulder)

Fronvrear

suspension noises

Possible Cause

Side-to-side difference in caster.

Tire pressure Steering gear or linkage worn or defective.

Tire

conicity

Power steering gear or linkage worn,

damaged, or incorrect adjusted.

Wear of front suspension

lower/upper

wishbone ball joints.

Unequal tire pressure.

Brake system

fault(s)

Wheel/tire imbalance or runout.

Damaged tires, unbalanced or damaged

wheels.

Incorrect wheel alignment.

Steering system malfunction

Front damper malfunction.

Loose front damper mounting.

Damaged front suspension upper

or lower

ball joints.

Damaged or worn sub

-frame to body

mounting. Damaged or worn stabilizer bar insulators.

Damaged or worn stabilizer bar link.

Damaaed or worn wheel bearina.

Rear suspension damage.

Worn steering gear mounting bracket

housing insulators.

Excessive toe

-in (high edges inboard) or

toe-out (high edges outboard).

Incorrect tire pressure.

Excessive toe.

Excessive positive or negative camber.

Loose/missing front dampers and front

damper bolt to front suspension lower

wish bone.

Action

Check the alignment and if incorrect,

adjust the caster

if needed. Inspect

components for wear or damage.

Check for abnormal loading.

Check steering system

Inspect tire for excessive wear.

Check and adjust the tire air pressure.

Note: Excessively worn or uneven tires can

cause

pull/drift.

Check steering system.

Renew ball joints.

Inflate the tires to correct and uniform

pressure.

Check the brakes.

Check wheels and tires.

Check the tires and renew

if necessary.

Balance the wheels

if necessary.

Adjust wheel alignment.

Check steering system.

Renew front damper

if necessary.

Tighten front damper mounting.

-

Renew upper and lower ball joint.

Renew rear suspension bushing.

Renew insulators.

Renew link.

Renew/adjust wheel bearing.

If the caster is uniform, check and compare

the wheelbase at the right and left sides.

If

different, inspect the suspension

components for wear and damage.

Renew bracket housing insulators.

Check and adjust toe

-in.

Correct tire pressure.

Check toe and adjust

if needed.

Check the camber and

if incorrect inspect

the related components for wear or

damage.

Tighten/renew damper bolts.

Inspect wheel hubs.

0

0

0

lssue 1 August 1994 6 X300 VSM

Page 220 of 521

Suspension Systems I.\" b-

1 1.4.8 Diagnostic Procedure (continued)

Condition

30dy 'rolls'

3ody leans

'oor ride comfort

Seneral driving

nstability

Steering wheel does

lot return properly

Steering wheel pulls

:o one side

4bnormal noise

from suspension

system

Possible Cause

Weak front stabilizer bar.

Damaged or worn lower wishbone stabilizer

bar insulator. Damaged or worn stabilizer bar link

Damaged or worn rear suspension

wishbone bushing.

Damper malfunction.

Worn or deteriorated rear stabilizer bar

bushing(s). (supercharged, sports and XJ12

only)

Damaged or worn rear wishbone bushing

and weak springs.

Worn or deteriorated rear stabilizer bar

bushing(s). (supercharged, sports and XJ12

only)

Front or rear damper malfunction.

Weak

spring(s1

Damaged tires or unbalanced wheels.

Incorrect wheel alignment.

Steering system malfunction.

Damaged front suspension lower and upper

ball joints.

Damaged or worn sub

-frame to body

mounting.

Damaged or worn stabilizer bar link

Damaged or worn lower wishbone stabilizer

bar insulator.

Weak

spring(s)

Worn or deteriorated rear stabilizer bushing

(s). (supercharged, sports and XJ12 only)

Damaged tires or unbalanced wheels and

incorrect tire pressure.

Incorrect wheel alignment.

Steering system malfunction.

Damaged front suspension lower and upper

ball joints.

Incorrect tire pressure.

Damaged front suspension lower and upper

ball joints. Braking system malfunction.

Steering system malfunction.

Damaged or worn sub

-frame to body

mounting.

Damaged tires, unbalanced wheels and

incorrect tire pressure.

Poor lubrication /wear of wheel bearing.

Wear of front suspension lower and upper

ball joints.

Damaged or worn front stabilizer bar

Damaged or worn stabilizer bar link.

Damaged or worn stabilizer bar bracket.

Looseness of suspension connections.

Damaged or worn rear wishbone bushing.

Front and rear damper malfunction.

Weak

spring.Worn or deteriorated rear

stabilizer bushing

(s). (supercharged, sports

and

XJ12 only)

Action

3enew front stabilizer bar.

3enew insulators.

3enew link.

Renew bushing.

Renew damper

if necessary.

Renew Bushina

Renew bushings and springs.

Renew Bushings.

Renew dampers.

Renew springs.

Check the tires.

Adjust the wheel alignment.

Check steering system.

Renew ball joints.

Renew bushing.

Renew link.

Renew insulator.

Renew springs.

Renew bushing

Check tires.

Adjust the wheel alignment.

Check steering system.

Renew ball joints.

Check and correct tire pressure.

Renew ball joints.

Check brakes.

Check steering system.

Renew bushing.

Check tires.

Renew wheel bearing.

Renew ball joints.

Renew stabilizer bar.

Renew link.

Renew bracket.

Tighten connections.

Renew bushing.

Renew dampers.

Renew bushing

Issue 1 August 1994 X300 VSM 7

Page 230 of 521

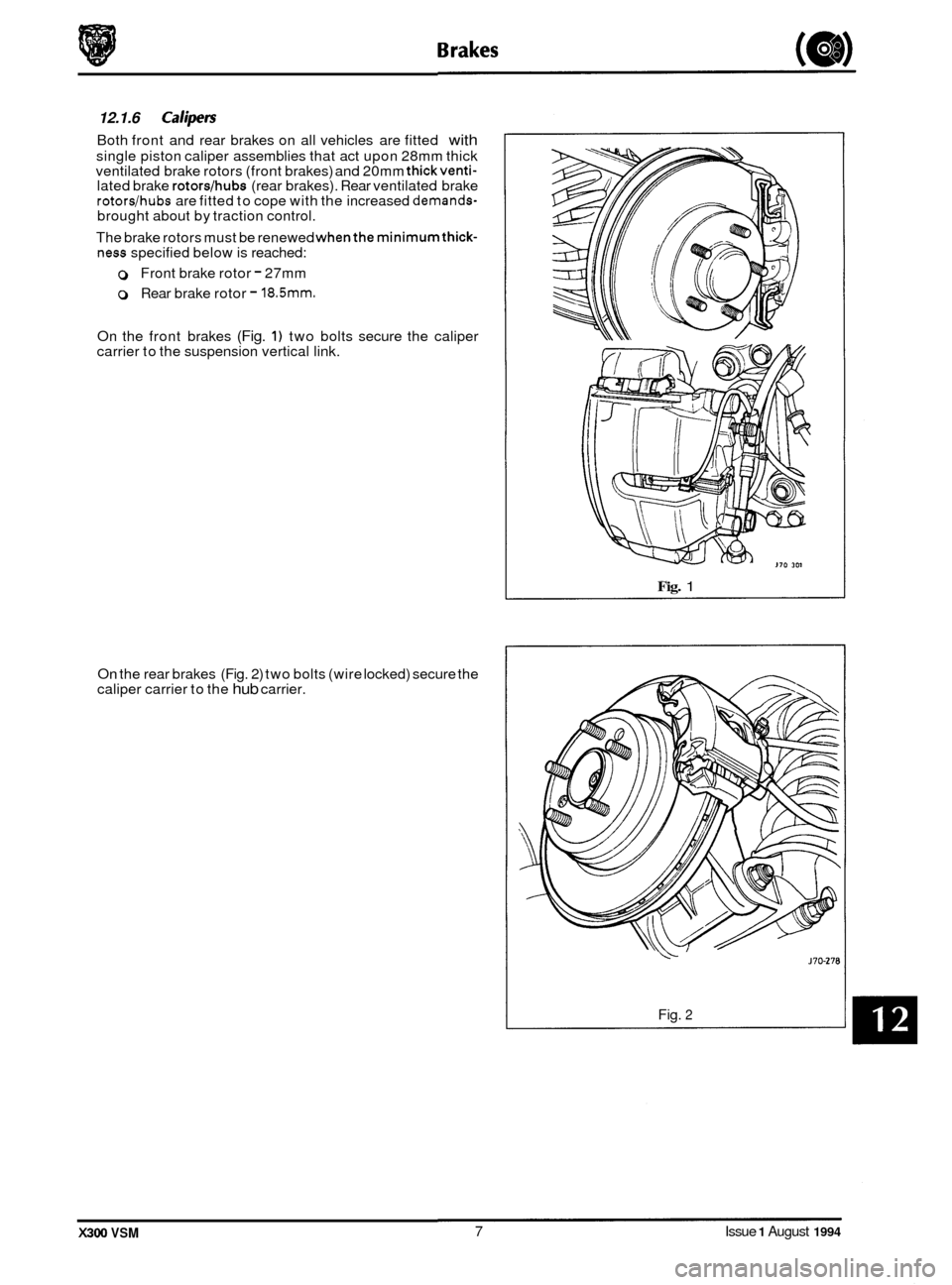

0 12.1.6 Calipers

Both front and rear brakes on all vehicles are fitted with

single piston caliper assemblies that act upon 28mm thick

ventilated brake rotors (front brakes) and 20mm thickventi- lated brake rotors/hubs (rear brakes). Rear ventilated brake rotordhubs are fitted to cope with the increased demands- brought about by traction control.

The brake rotors must be renewed

whenthe minimumthick- ness specified below is reached:

0 Front brake rotor - 27mm

0 Rear brake rotor - 18.5mm.

On the front brakes (Fig. 1) two bolts secure the caliper

carrier to the suspension vertical link.

On the rear brakes (Fig. 2) two bolts (wire locked) secure the

caliper carrier to the hub carrier.

Fig. 1

\

Fig. 2

J70-278

X300 VSM 7 Issue 1 August 1994

Page 382 of 521

Snecif icat ion W -I- ..........

e

0

CON TENTS

Title Page

Specification. 1995 Model Year Vehicles ................................................................... 1

EngineManagementSystem ........................................................................\

. 1

Cooling System ........................................................................\

............ 7

Fuelsystem Pump ........................................................................\

......... 7

Clutch ........................................................................\

................... 7

Manual Transmission Ratios ........................................................................\

. 1

Automatic Transmission Ratios ....................................................................... \

2

Final Drive Unit Ratios ........................................................................\

..... 2

Climate Control System ........................................................................\

..... 2

Braking System ........................................................................\

............ 3

Steering&Suspension ........................................................................\

...... 4

Electrical Equipment ........................................................................\

....... 5

Lubricants & Fluids ........................................................................\

......... 7

Vehicle Weights ........................................................................\

........... 9

Tires ........................................................................\

.................... 10

Snowchains ........................................................................\

............. 17

Bulbs ........................................................................\

................... 12

Fuses ........................................................................\

................... 14

Issue 1 August 1994 AI-95MY i X300 VSM

Page 387 of 521

Steering and Suspension

W: When checking the steering geometry, use the pull-down tools front and rear to set the ride height front and

rear to the following dimensions:

Front ride height

................................................... 153 f 5mm to underside of front

crossbeam

Rear ride height

.................................................... 160 f 5mm to underside of rear

edge of A frame

Front ride height

................................................... 143 f 5mm to underside of front

crossbeam

Rear ride height

.................................................... 160 f 5mm to underside of rear

edge of A frame

U: Sportspack derivatives whose kerb height is below the above figures can have their geometry checked at that

height.

Front Suspension

..............................................................

0

Type Independent front suspension

consisting of double wishbones

with coil springs and separate

dampers and anti

-roll bar.

Dampers

.......................................................... Telescopic, gas pressurised

Caster angle

....................................................... 3,0° to 6,0° and with opposing

wheels within Io of each other

Camberangle

...................................................... 0,3°to-0,80

Front wheel alignment .............................................. Total toe: 5 minutes in f 10 minutes

Rear Suspension

Type .............................................................. Fully independent rear suspension of double wishbone principle with

axle shaft operating as upper

wishbone incorporating coaxial

springs and dampers with optional

rear anti

-roll bar.

Camber angle

(at design ride height):

all vehicles except supercharged ................................. -0,75O f 0,4O

supercharged only -1,6O f 0,4O ..............................................

0 Rear wheel alignment .............................................. Total toe: 15 minutes in f20

Dampers .......................................................... Telescopic, gas pressurised

minutes

Power Assisted Steering

Type .............................................................. ZF

Servotronic speed-sensitive rack

and pinion

Number

of turns lock to lock ........................................ 2,768

Turning circle: (wall to wall)

....................................................... 12,9m (42ft 4in)

(curb to curb) ...................................................... 12,4m (40ft 8in)

0

X300 VSM Issue 1 August 1994 AI-95MY 4 ~~~~

Page 408 of 521

j

8

9

10

13 I

18

19

23

24

Check for oil leaks - engine xxxxxxxx

Check for oil leaks - automatic transmission xxxxxxxx

Check for oil leaks -final drive xxxxxxxx

Check for fuel leaks xxxxxxxx

Check all suspension dampers for fluid leaks xxxxxxxx

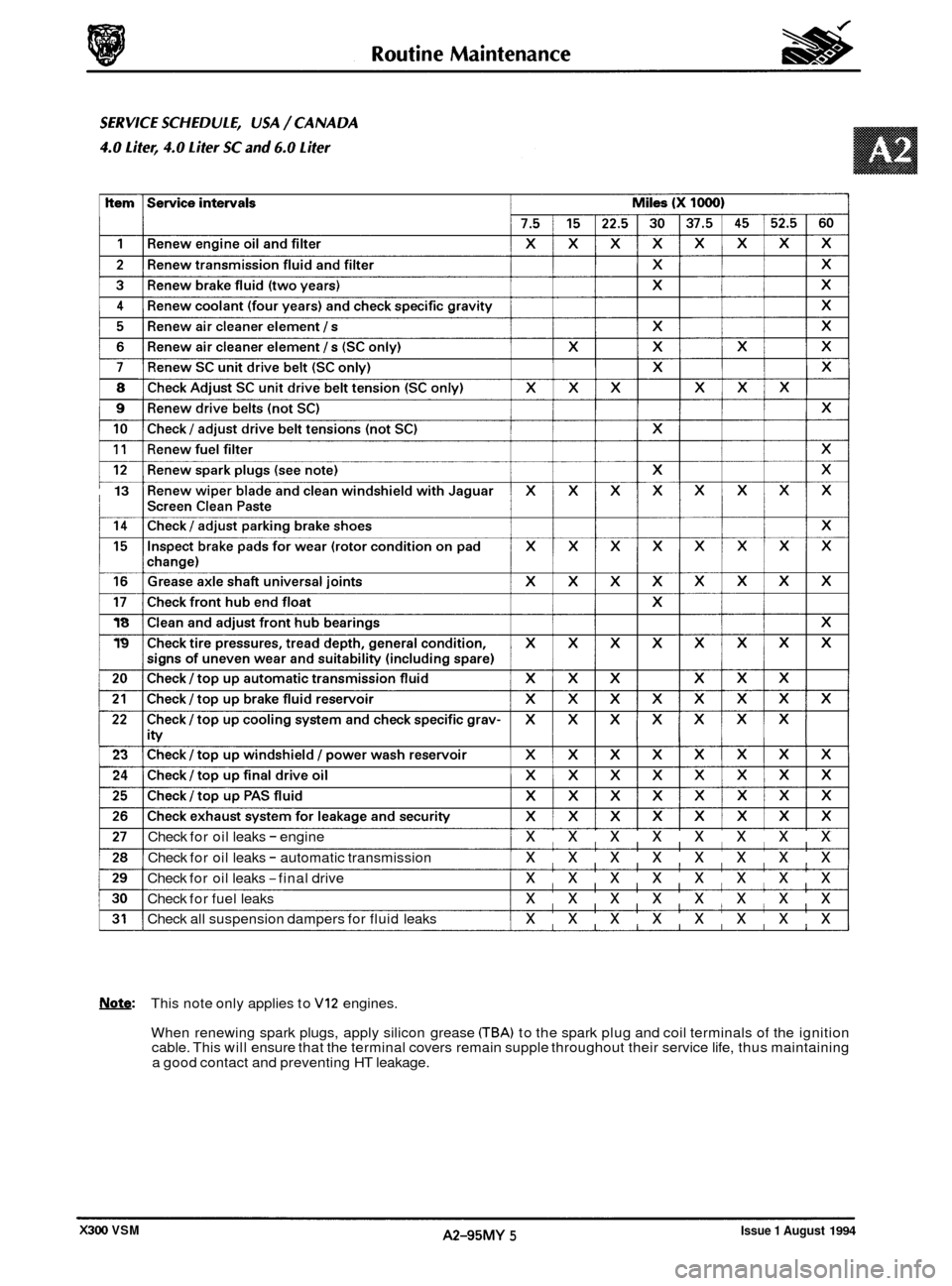

Note: This note only applies to VI2 engines.

When renewing spark plugs, apply silicon grease

CTBA) to the spark plug and coil terminals of the ignition

cable. This will ensure that the terminal covers remain supple throughout their service life, thus maintaining

a good contact and preventing HT leakage.

Issue 1 August 1994 A2-95MY 5 X300 VSM

Page 428 of 521

0

0

0

Body Systems Body Repair

A4.1 BODY REPAIR

Introduction

This section contains information, specifications and procedures for body repair and rectification of the Jaguar sedan

range (with standard wheelbase).

All repairs, whether structural or cosmetic, must ensure the continuance of the Paint Surface and Corrosion warranty,

where applicable.

Following repair or rectification, the vehicle must be returned to the original manufactured condition with regard to

occupant safety, dimensional accuracy, finish and corrosion protection.

Similarly, repaired vehicles must be fully checked, and where appropriate reset, with regard to steering, suspension,

restraint and

braking systems.

A4.1.1 Health and Safety

(Please Read The

Fol/owing Notes Carethlly)

Where legislation governing working conditions and practises is applicable, you should observe it. Do not forget that

you have a duty, to yourself and those around you, to act in a responsible manner in the workplace.

In the United Kingdom the Health and Safety

at Work Act (1974) places a duty on employers and employees to ensure,

whenever possible, safe working conditions and practices. Wherever a potential hazard is notified to, or identified by

the operator, he must employ the correct safety procedures and equipment.

Should

a personal injury occur as a result of any workshop activity, seek medical help as soon as possible and do not

attempt self-treatment other than by the application of first aid.

With the constant introduction of new materials in the manufacture of vehicles,

it is important that potential risks are

identified and precautions made known.

WARNING: READ AND UNDERSTAND WORKING PRACTICES CLIMATE CONTROL SYSTEMS, SECTION 14, WITH SPECIAL REFERENCE TO

ERY

/ RECYCLE / RECHARGE EQUIPMENT.

WEAR SUITABLE EYE AND SKIN PROTECTION.

OBSERVE ALL APPLICABLE SAFETY REQUIREMENTS.

DO

NOT VENT REFRIGERANT DIRECTLY TO ATMOSPHERE, ALWAYS USE JAGUAR APPROVED RECOV

-

Issue 1 August 1994 1 X300 VSM