JAGUAR XJ6 1994 2.G Workshop Manual

Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 431 of 521

Body Systems & Body Repair

A4.1.5 GENERAL REPAIR NOTES

The following advice should be noted before ANY repair work is carried out.

0 Disconnect the vehicle battery ground lead (disconnect the alternator where electric welding is used) and take

note of the reconnection procedures as detailed in Section 15.

0 Where structural parts are straightened or renewed, a body alignment / straightening jig must be used.

0 Where appropriate, structural sections should be straightened by cold processes. Heat, especially excessive

heat, will reduce the strength of steels.

0 Repairs may only be carried out successfully, and any warranties protected, if genuine Jaguar replacement parts

and Jaguar approved materials are used.

0 Tools, procedures and facilities must be right for the job. Do not compromise the quality of the work by using

inappropriate methods.

0 All trim and electrical components in the locality of the repair must be removed or disconnected prior to panel

removal / replacement; this is especially important where hollow sections may contain harnesses, tubes or

foam, see section

A4.3.5.

0 The welding and gas processes detailed in the following sections are the only ones recommended by Jaguar

Cars Ltd.

0 Ensure that you have read and understood the safety related procedures in this and other relevant sections.

WARNING: DO NOT WORK

IN THE VICINITY OF A LIVE AIR BAG, REMOVE IT COMPLETELY. READ WORKING PRAC- TICES AIR BAG, SECTION 15. ANY SEAT BELT WHICH HAS BEEN WORN IN AN ACCIDENT MUST BE RENEWED. PLEASE SEE SECTION

AGE LOCATIONS. 13 FOR IMPORTANT INFORMATION REGARDING 'TEAR LOOP' SEAT BELTS / BUCKLES AND ANCHOR-

CAUTION: Electric arc welding should not be used on Jaguar vehicles. The high vottages produced by this process will cause irreparable damage to the electrical control and microprocessor systems.

A4.1.5.1 Welding and Gas Processes Special Notes

Resistance spot welding, MIG welding and all gas processes may only be carried out on bare, unpainted or unplated,

metal.

The flanges of panels which are to be welded together must be clean, corrosion free and treated as appropriate,

with either weld-through primer or inter-weld sealer; use only materials and processes in accordance with the 'Body Seal-

ing and Preservation Manual' and relevant application areas in section A4.3.1.1.

See 'Zinc Coated Panels' section A4.2.

Generally, the resistance spot welding equipment used in the motor vehicle repair industry does not produce a weld

of equivalent strength to that of the manufacturer. Therefore, the expression 'single row of resistance spot welds'

means that the spots should be spaced on a pitch of

19mm to 25mm. This will usually result in more spot welds than

found in the original factory joint.

To remove resistance spot welds, a resistance spot weld cutter should be used.

If the new joint is to be MIG plug welded, the old resistance spot welds should be cut from the panel which is to be

retained and those holes used for plug welding.

Suitable holes may also be drilled or punched;

8,O mm dia for sections up to 1,6 mm, and 10,O mm dia for thicker sec- tions.

0

0

0

X300 VSM Issue 1 August 1994 4

Page 432 of 521

Body Systems & Body Repair

Term

ABS

ABS

/ PA

ABS

/ PC

ABS / PBT

A#. 1.6 PLASTICS - EXPLANATORY NOTES

A#. 1.6.1 Plastic component and trim materials.

This table, in conjunction with the illustrations on the following pages will enable rapid identification of the particular

material of any major plastic part.

Material Name

Acrylonitrile Butadiene Styrene

Acrylonitrile Butadiene Styrene

& Polyamide (nylon) blend

Acrylonitrile Butadiene Styrene

& Polycarbonate blend

Acrylonitrile Styrene Acrylate

& Polybutylene Terephthalate

PC

PE

PMMA

POM

PP

PPO

PUR

PVC

SMA

I PA 1 Polyamide (nylon) I

Polycarbonate

Polyethylene

Polymethyl

Methacrylate

Polyoxymethylene (acetal)

Polypropylene

Modified Polyphenylene Oxide

Polyurethane

Polyvinylchloride

Styrene Maleic Anhydride

w: Not all plastic components are nominated, only those suitable for economic reclamation.

A#. 1.6.2 Plastics - Handling Notes

w: With reference to the following conditions, consider the properties of those plastic components which may

be affected by a repair or rectification procedure.

0 As mentioned elsewhere, the exterior panel temperature of the vehicle must not exceed 95OC at any time and

may only be held at this upper limit for a maximum of 2 (two) hours.

0 Interior vehicle temperature must not exceed 86OC, the time limit being 2 (two) hours.

0 Temperatures above those specified in 1 and 2, may result in distorted or permanently damaged components. If there is any doubt whatsoever, remove those components which may be affected by the application of heat.

0 Certain items may be manufactured from 'blended' materials; these must NOT be recycled with pure materials.

For example do not mix PC/ABS (wheel trim) with ABS ('B' pillar upper trim).

0 Should plastic components become greasy, they may be cleaned with an 'SBP 3' spirit wipe, or equivalent.

A4.1.6.3 Recycled Materials

Any of the materials listed in A4.1.6.1 may be recycled provided that they are not contaminated by other incompatible

plastics or metals. For instance, the air conditioning unit case, manufactured from PP (polypropylene), must be separ- ated from the heater matrix, evaporator, control devices (electronic and mechanical) and all fixings before it can be

considered for recycling.

After disassembly, the case must be placed for disposal only

with materials of the same generic type.

w: The bumper cover assemblies have side armatures (non-eerviceable items) rivetted to them; because they

are dissimilar materials the armatures and fixings must be removed prior to recycling.

In the bumper cover intake aperture there is a cosmetic 'black-out' piece; a similar component may be found

on the fog lamp blanks (where fitted). These items should be separated from the major component for recycl- ing.

Issue 1 August 1994 5 X300 VSM

Page 433 of 521

a- P

Body Systems & Body Repair

6 0

0

0

Page 434 of 521

0

0

0

A4.1.6.5 PlasticS, Component location & Type - lntemal

n. n.

Issue 1 August 1994 7 X300 VSM

Page 435 of 521

P

X300 VSM issue 1 August 1994 8

Page 436 of 521

Body Systems

A4.2.1.1 Constructional Steel Classification

Material 1 dnnlirdiam I

High strength low alloy (HLSA).

Double sided zinc plated mild steel.

1 Boron steel

1 Mild steel.

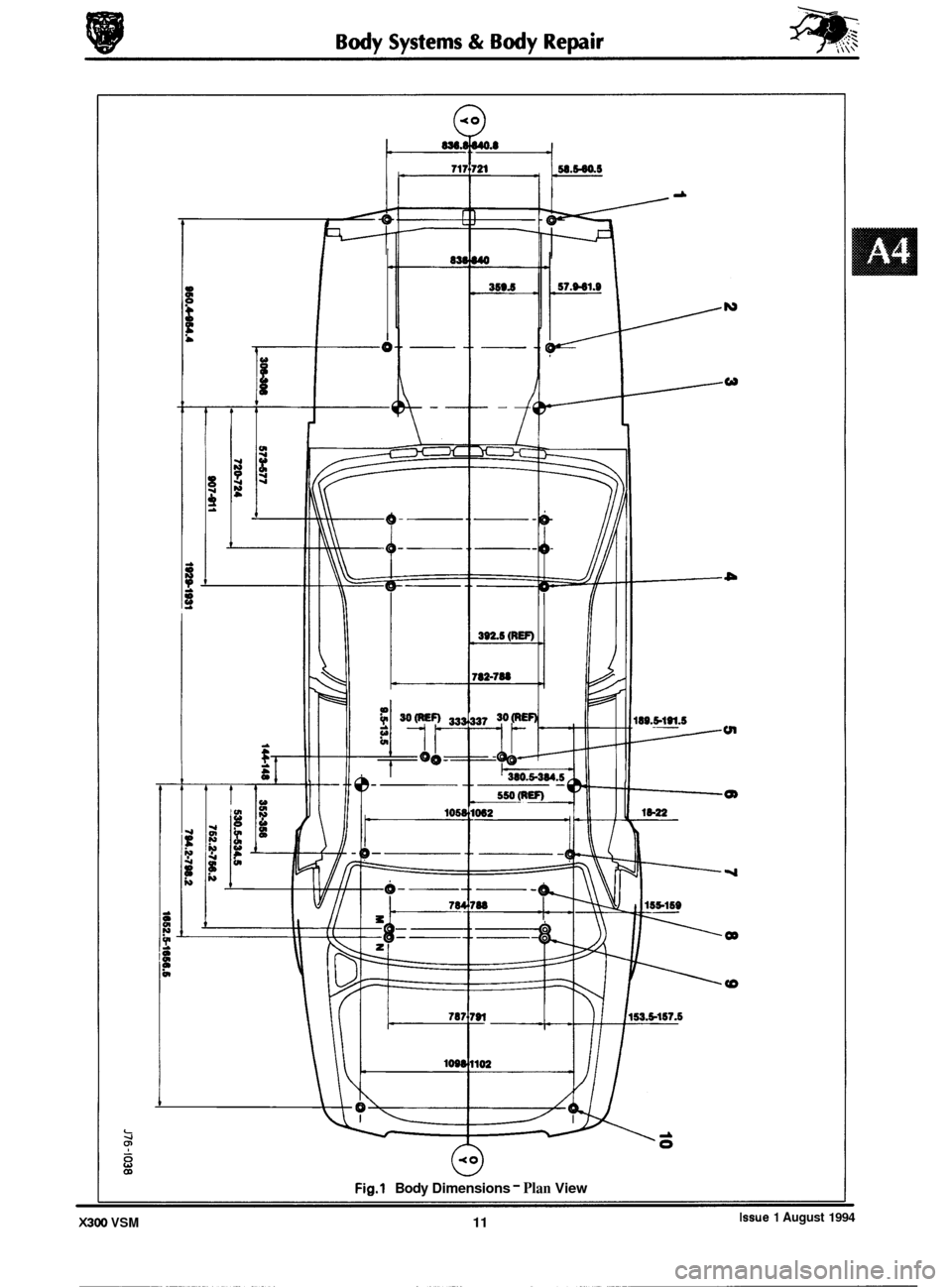

A4.2.2 BODY ALIGNMENT

The illustrations on pages 11 - Body Dimensions PLAN, and 13 -Body Dimensions SIDE VIEW, provide specifications

for damage assessment and location of replacement parts.

These dimensions must be strictly applied whether they are used for damage assessment, component location or post

repair verification.

The plan view MASTER datums are nominated on the right

-hand side of the body with the left-hand datums dimen- sioned from them. Therefore, the right-hand datums must be known to be correct before any other cross-ar dimen- sions are checked.

W: The right-hand side is always looking towards the front, from the rear of the vehicle.

All dimensions are derived from a single

(ZERO) datum point for all three axes; X for length, Z for height and V cross- car.

Issue 1 August 1994 9 X300 VSM

A4.2 BODY STRUCTURE

A4.2.1

Introduction

The Jaguar sedan range (with standard wheelbase) has a unit construction monocoque body structure with bolt-on

front fenders and welded rear fenders. The doors feature 'lift-off' hinges and welded dropglass frames.

n@#pn.s..v..

Impact prone areas, ie. seat frame and bumper mount- ings.

Exterior body panels subject to severe conditions such

as stone chipping and weather exposure (excluding

roof panel).

Door intrusion beams

Internal brackets, fillets and strengtheners.

I

Page 437 of 521

Body Systems & Body Repair

Location

Centre line of the front crossmember rear mounting, at the

main floor

RH longitudinal

A4.2.2.1 Datum location, Example

The FRONT MASTER DATUM (front crossmember rear mounting at the inner face ofthe main floor RH longitudi- nal) is nominally 359,5mm to the right-hand side of the body center line. The LH side front datum is measured 717,0/ 721,Omm from the RH. Please refer to the illustration on the following page.

Expressed as

a true position in three planes, the front master datum is:

Position

X 300,O

Y 359.5 Z -50.0

0

Datum

Front Master Datum

Plan

A4.2.2.2 Key, Plan View

Please refer to the illustration on the opposite page.

Key Location

1

2

3

4

5 Driveshaft centre bearing fixings

6

7

8

9

10 Front

face body

- bumper strut / mounting point

Rearmost hole, Vee

-mount to crush tube

Front Master Datum Plan, centre line

of the front crossmember rear mounting at the main floor RH longi-

tudinal

Rearmost hole, transmission mounting

at the main floor RH longitudinal

Rear Master Datum Plan, rear longitudinal

Tapped boss, rear suspension

'A' frame mounting bush

Rear suspension spring

-pan damper mounting

Rear suspension differential strut mounting

Rear face body

- bumper strut / mounting point

X300 VSM Issue 1 August 1994 10

Page 438 of 521

0

0

0

-

0

w

tn

Q)

OD

Fig.1 Body Dimensions - Plan View

Issue 1 August 1994 X300 VSM 11

Page 439 of 521

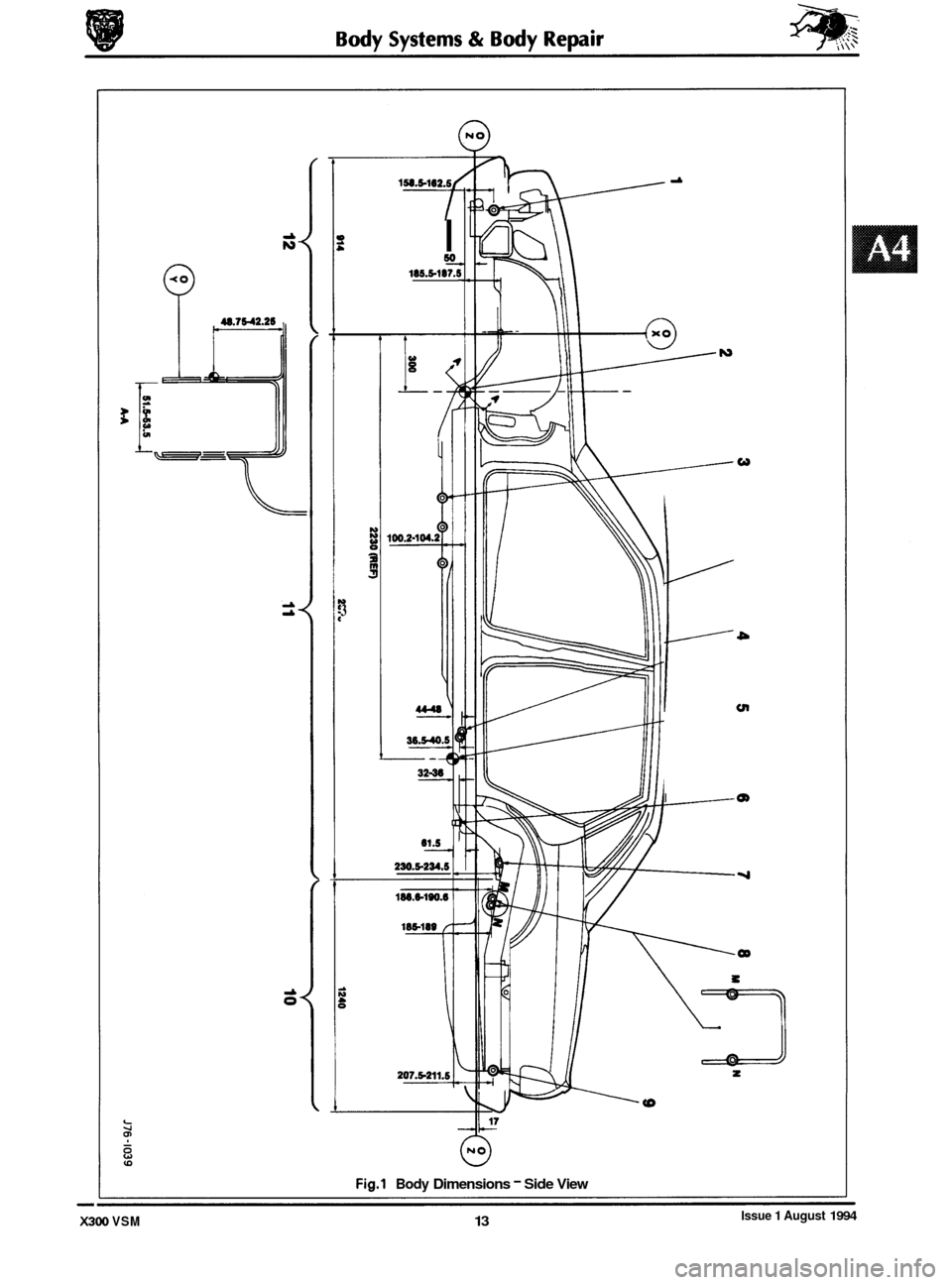

E 12

Rear face bodv - bumDer strut / mountina Doint

Body Systems

I

& Body

side vww

the illustration on the opposite page.

Repair

Location

Front face body - bumper strut / mounting point

Front Master Datum Vertical. centre line of the front crossmember rear mountina

Front

face body - bumper strut / mounting point

Front Master Datum Vertical, centre line of the front crossmember rear mounting

Transmission mountings

at the main floor longitudinal

Driveshaft centre bearing fixings

Rear Master Datum

Vertical, rear longitudinal

Tapped boss, rear suspension

'A' frame mounting bush

Rear suspension spring

-pan damper mounting

Rear suspension differential strut mounting

Rear face body

- bumper strut / mounting point

Transmission

mountings

at the main floor longitudinal

Driveshaft centre bearing fixings

Rear Master Datum

Vertical, rear longitudinal

Tapped boss, rear suspension

'A' frame mounting bush

Rear suspension spring

-pan damper mounting

Rear

susoension differential strut mounting

Wheel centre to

bummr cover face I

Wheel base I

Wheel centre to bumper cover face

Body Systems & Body Repair

A4.2.2.3 Key, Side Vww

Please refer to the illustration on the opposite page.

0

0

0

X300 VSM Issue 1 August 1994 12

Page 440 of 521

0

0

0

-

0

v 3

I so 185.5-187.!

t

4

230.5-234.5

i:: cn

I m

8

Fig.1 Body Dimensions - Side View

Issue 1 August 1994 X300 VSM 13