JAGUAR XJ6 1994 2.G Workshop Manual

Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 401 of 521

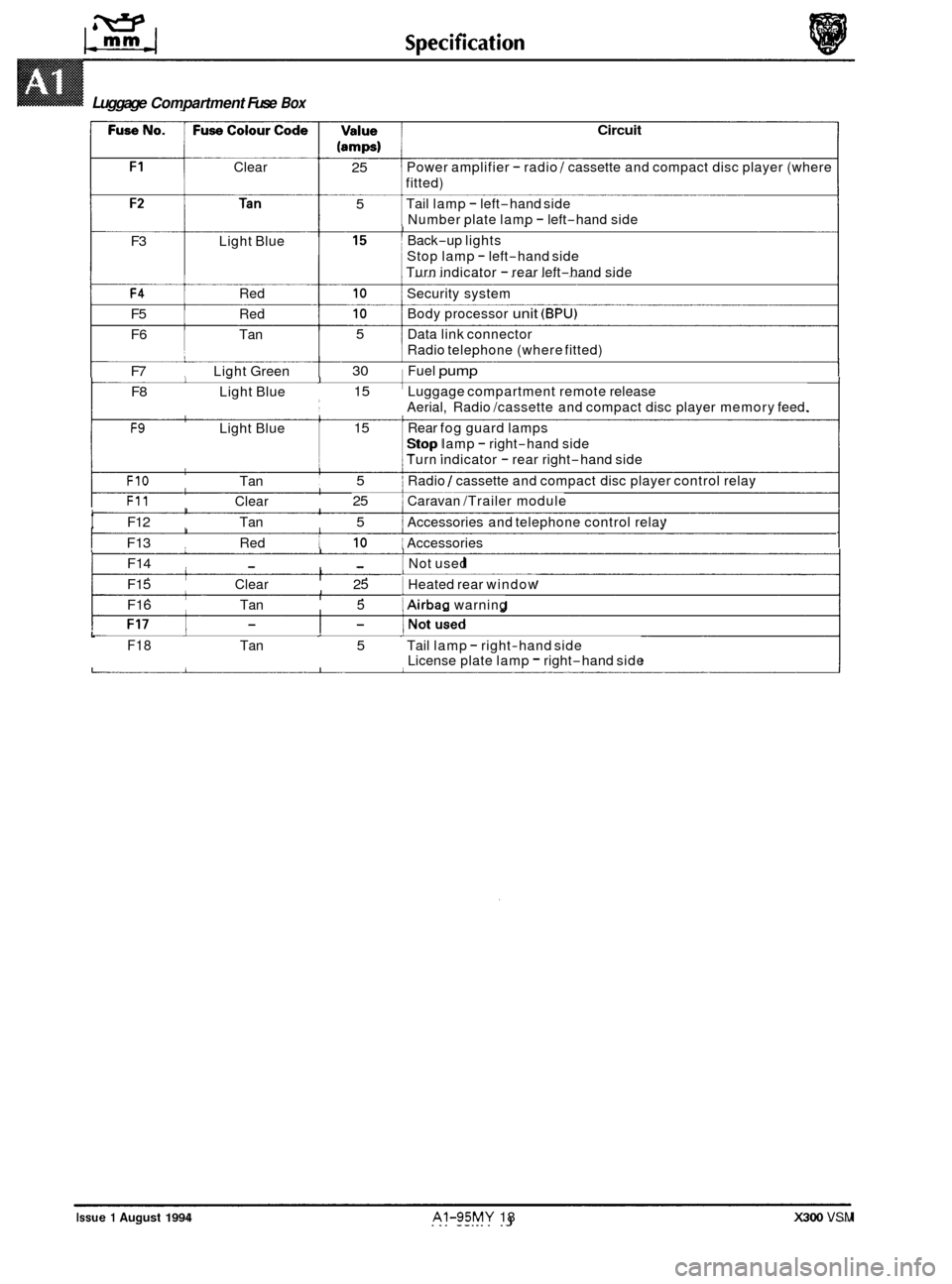

Clear

(amps) 1

Circuit

I

25 5 Power amplifier - radio / cassette and compact disc player (where

fitted)

Tail lamp

- left-hand side

Number plate lamp

- left-hand side I Back-up lights

Stop lamp

- left-hand side

Turn indicator

- rear left-hand side

F3 Light Blue

F4 Red 10 Security system

F5 Red 10 Body processor unit (BPU)

F6 Tan 5 Data link connector

F7 Light Green 30 Fuel pump

F8 Light Blue 15 Luggage compartment remote release

F9 Light Blue 15 i Rear fog guard lamps

Radio

telephone (where fitted)

1

Aerial, Radio /cassette and compact disc player memory feed.

Stop lamp

- right-hand side

1 Turn indicator - rear right-hand side I.

I FIO Tan 5 i Radio / cassette and compact disc player control relay

F11 Clear 25 1 Caravan /Trailer module I

t F12 Tan 5 ~ Accessories

and telephone control relay I I

I I I F13 Red 10 ~ Accessories 1 1 I I F14 - - I Not used 1 I I F15 Clear 25 1 Heated

rear window I I I F16 Tan 5 1 Airbag warning

Luggage Compartment Fuse Box

Issue 1 August 1994 AI-95MY 18 X300 VSM

L F18 Tan 5 Tail lamp - right-hand side

License plate lamp - right-hand side

Page 402 of 521

Routine Maintenance

CON TENTS

Title

Routine Maintenance, 1995 Model Year Vehicles . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fluids & Lubricants Service Points, 6 Cylinder Vehicles . . . . . . . . . . . . . . . . .

Fluids & Lubricants Service Points, 12 Cylinder Vehicles . . . . . . . . . . . . . . . .

Service Schedule, U.K., Europe, R.O. W. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Schedule, USA / Canada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

....

....

....

....

....

-

...

...

...

...

..................

..................

..................

..................

..................

....

....

....

....

....

.... 7

.... 1

.... 2

.... 3

.... 5

Issue 1 August 1994 A2-95MY i X300 VSM

Page 403 of 521

A2-95MY ii

Page 404 of 521

Routine

e

0

0

0

-

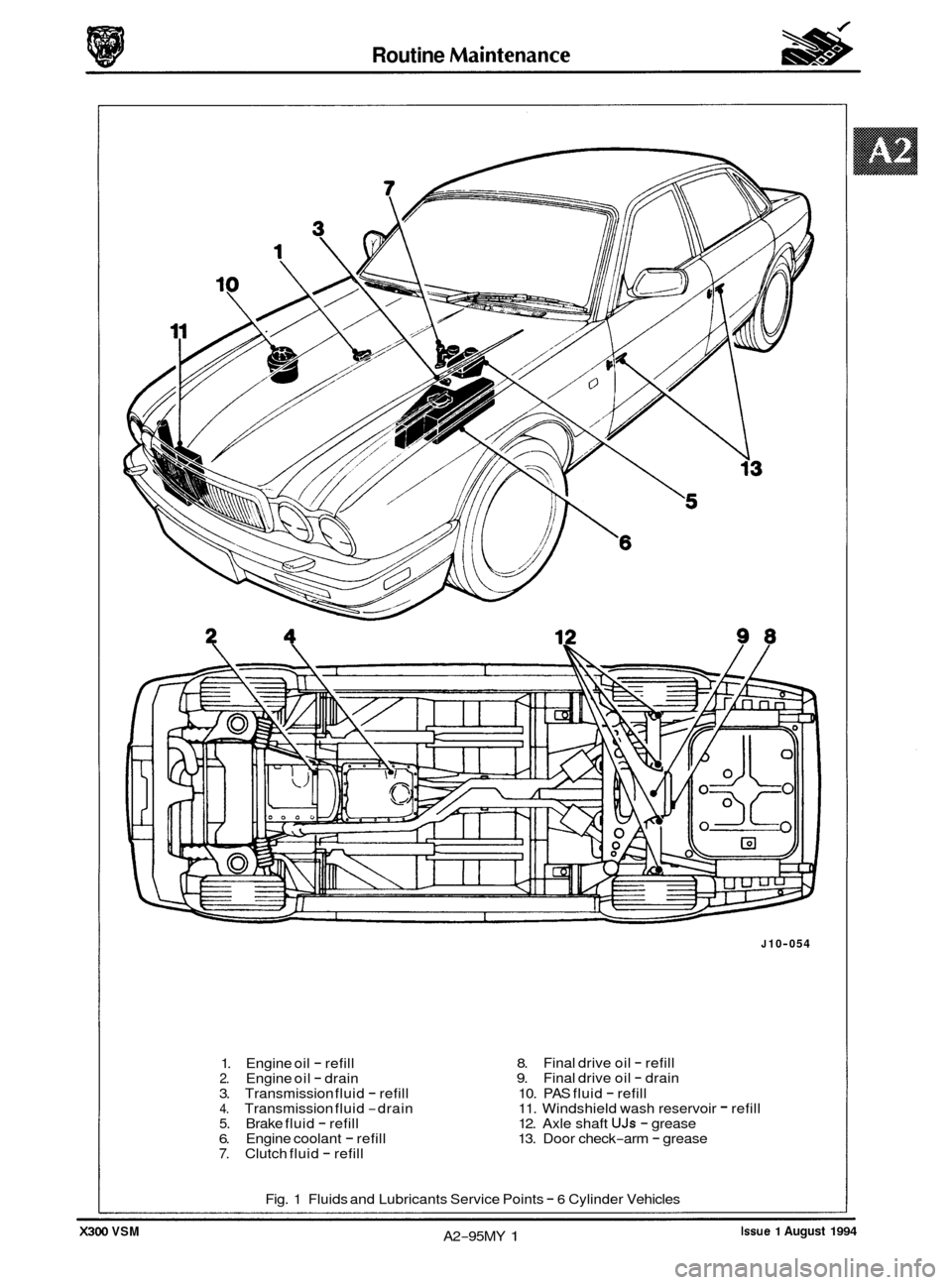

1. Engine oil - refill 2. Engine oil - drain

3. Transmission fluid - refill 4. Transmission fluid -drain 5. Brake fluid - refill 6. Engine coolant - refill 7. Clutch fluid - refill

J 10-054

8. 9.

10. PAS fluid

- refill

11. Windshield wash reservoir - refill

12. Axle shaft UJs - grease

13. Door check-arm - grease

Final

drive oil

- refill

Final drive oil - drain

Fig. 1 Fluids and Lubricants Service Points

- 6 Cylinder Vehicles

Issue 1 August 1994 A2-95MY 1 X300 VSM

Page 405 of 521

2 4 11 87

* * Rout ine Maintenance

- X300 VSM

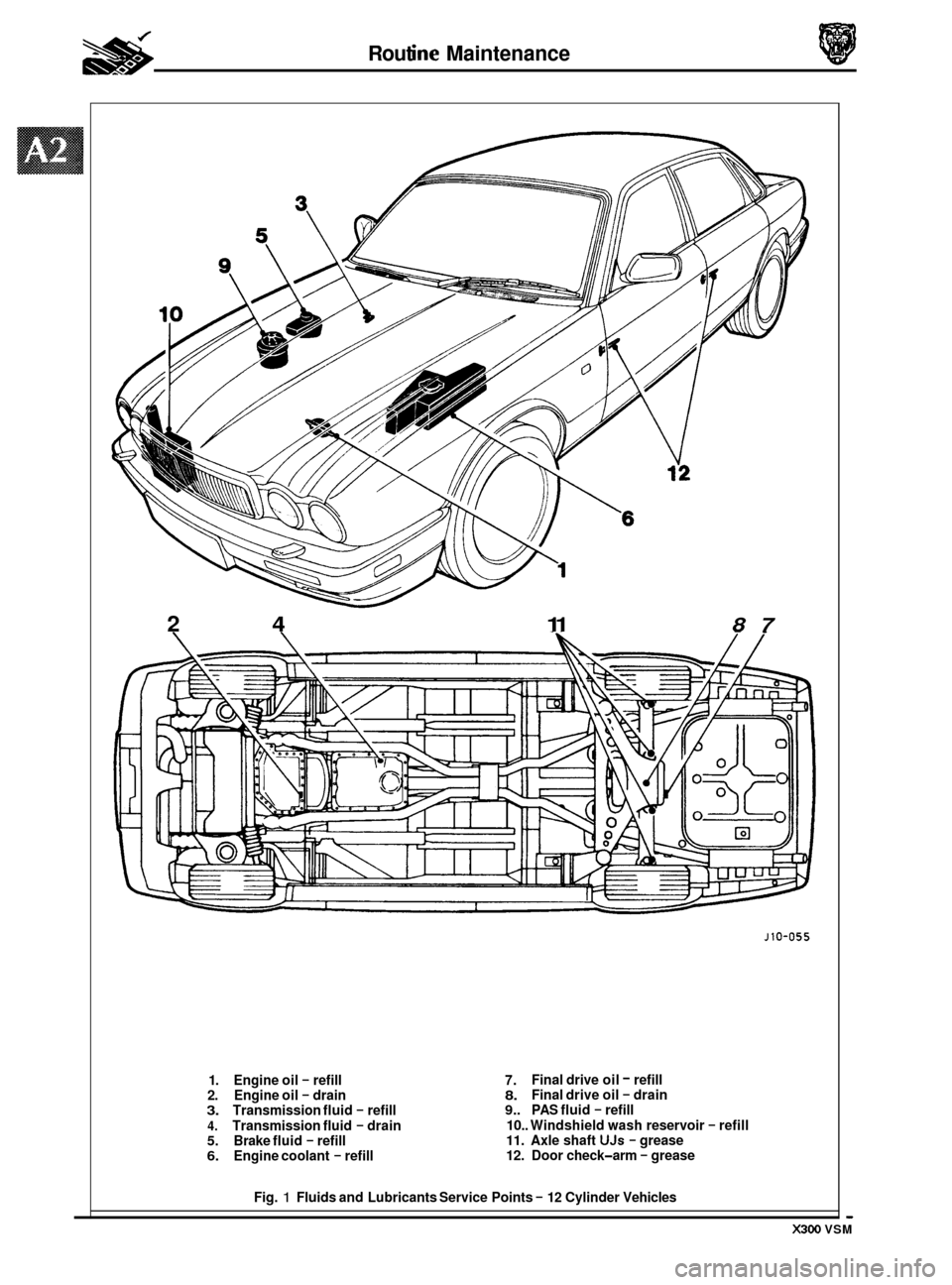

1. Engine oil - refill

2. Engine oil - drain 3. Transmission fluid - refill

4. Transmission fluid - drain 5. Brake fluid - refill 6. Engine coolant - refill

J10-055

7. 8. 9.. PAS fluid - refill

10.. Windshield wash reservoir

- refill 11. Axle shaft UJs - grease

12. Door check-arm - grease

Final drive

oil

- refill

Final drive oil - drain

Fig.

1 Fluids and Lubricants Service Points - 12 Cylinder Vehicles

Page 406 of 521

Routine Maintenance

SERVICE SCHEDULE - UK, EUROPe ROW

3.2 Liter, 4.0 Liter, 4.0 Liter SC and 6.0 Liter

0

0

Note: This note only applies to VI2 engines.

When renewing spark plugs, apply silicon grease

(TBA) to the spark plug and coil terminals of the ignition

cable. This will ensure that the terminal covers remain supple throughout their service life, thus maintaining

a good contact and preventing HT leakage.

A2-95MY 3 Issue 1 August 1994 X300 VSM

Page 407 of 521

* Routine Maintenance

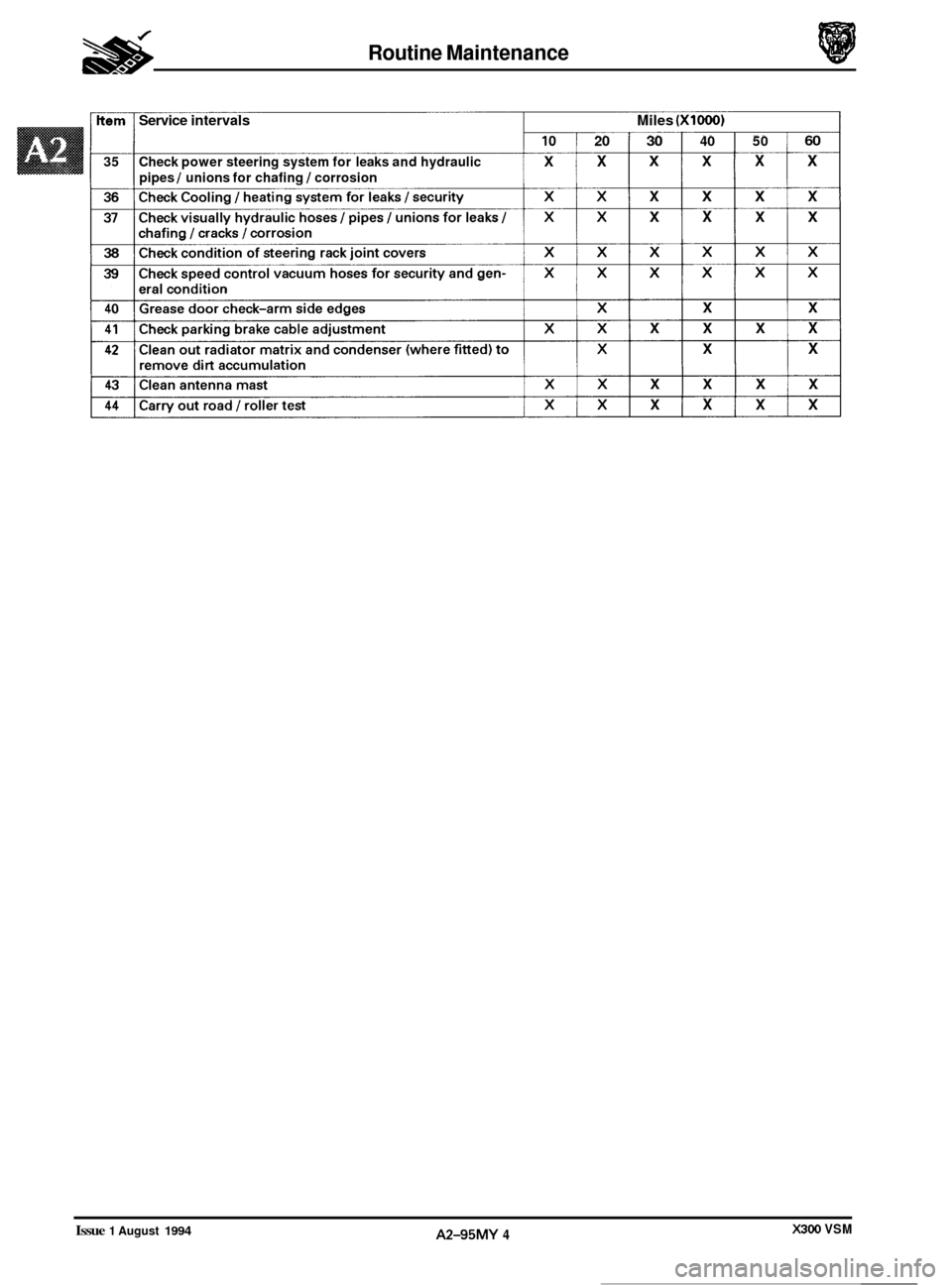

Item Service intervals Miles (XlOOO)

10 20

35 Check power steering system for leaks and hydraulic X X

pipes 1 unions for chafing I corrosion

30 40 50 60

X X X X

X X X X

X X X X

X X

X X X

X

X X

X X X X

X

X X X

.

X300 VSM Issue 1 August 1994 A2-95MY 4

Page 408 of 521

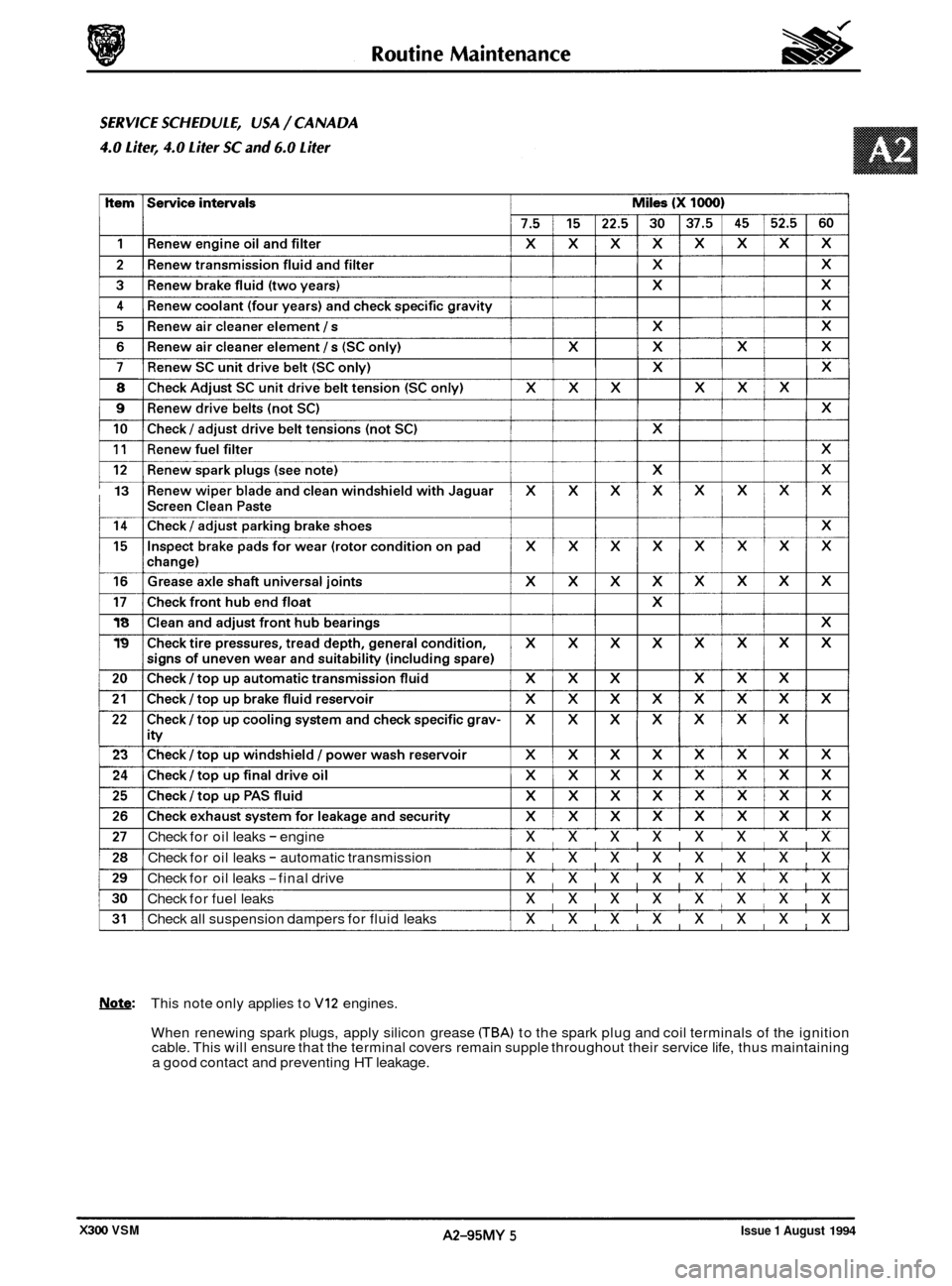

j

8

9

10

13 I

18

19

23

24

Check for oil leaks - engine xxxxxxxx

Check for oil leaks - automatic transmission xxxxxxxx

Check for oil leaks -final drive xxxxxxxx

Check for fuel leaks xxxxxxxx

Check all suspension dampers for fluid leaks xxxxxxxx

Note: This note only applies to VI2 engines.

When renewing spark plugs, apply silicon grease

CTBA) to the spark plug and coil terminals of the ignition

cable. This will ensure that the terminal covers remain supple throughout their service life, thus maintaining

a good contact and preventing HT leakage.

Issue 1 August 1994 A2-95MY 5 X300 VSM

Page 409 of 521

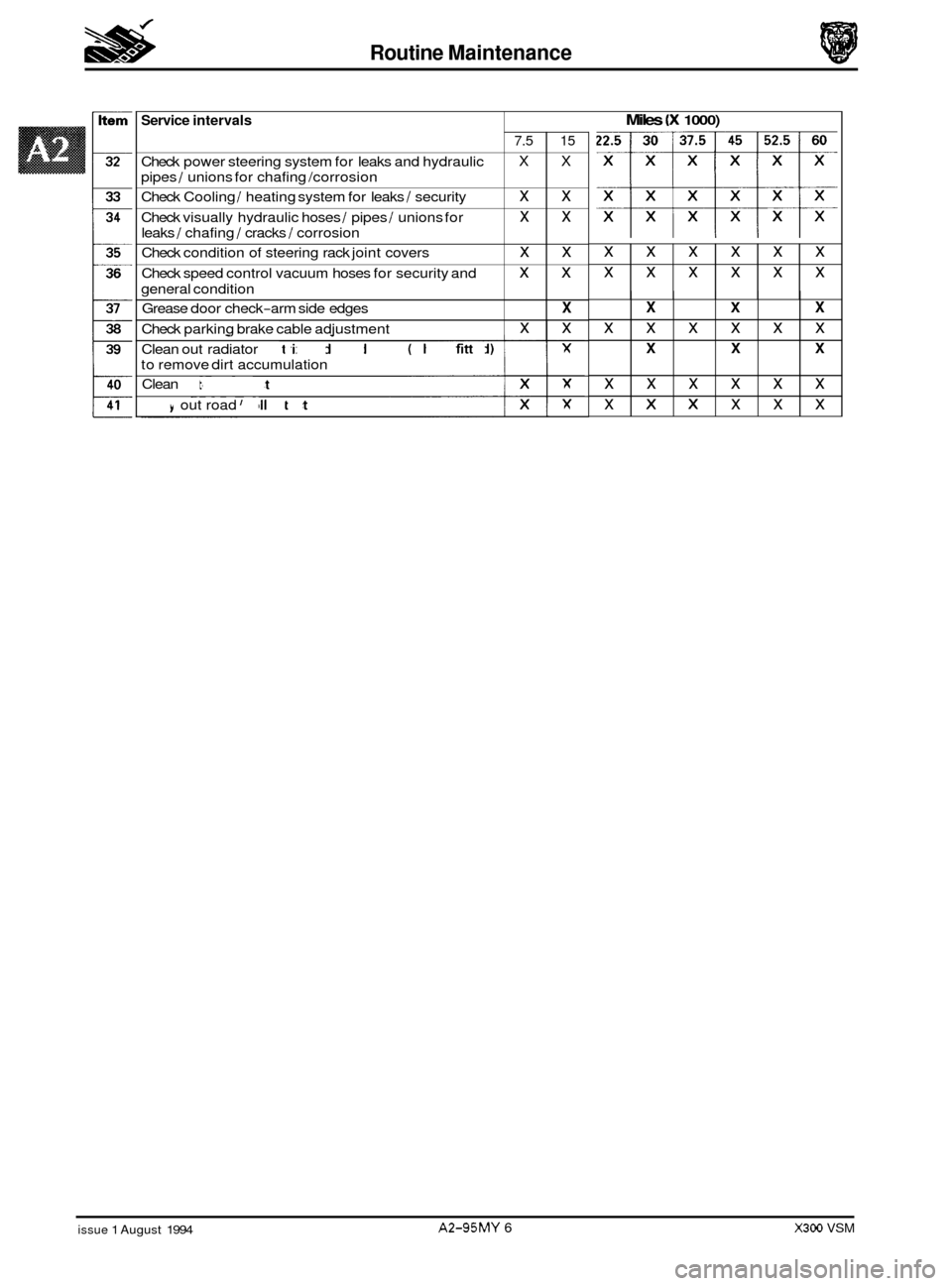

Routine Maintenance

Service intervals

Check power steering system for leaks and hydraulic

pipes

/ unions for chafing /corrosion

Check Cooling

/ heating system for leaks / security

Check visually hydraulic hoses

/ pipes / unions for

leaks

/ chafing / cracks / corrosion

Check condition of steering rack joint covers

Check speed control vacuum hoses for security and

general condition

Grease door check

-arm side edges

Check parking brake cable adjustment

Miles (X 1000)

7.5 15

X X

xx

xx

xx

xx

X

xx

xxxxxx

xxxxxx

x

X X X

xxxxxx

X X X

xxxxxx

XIX x x x

-

Clean out radiator matrix and condenser (where fitted)

to remove dirt accumulation

Clean antenna mast

xx

Carry out road / roller test Ix

i

0

0

0

X

x

issue 1 August 1994 A2-95MY 6 X300 VSM

Page 410 of 521

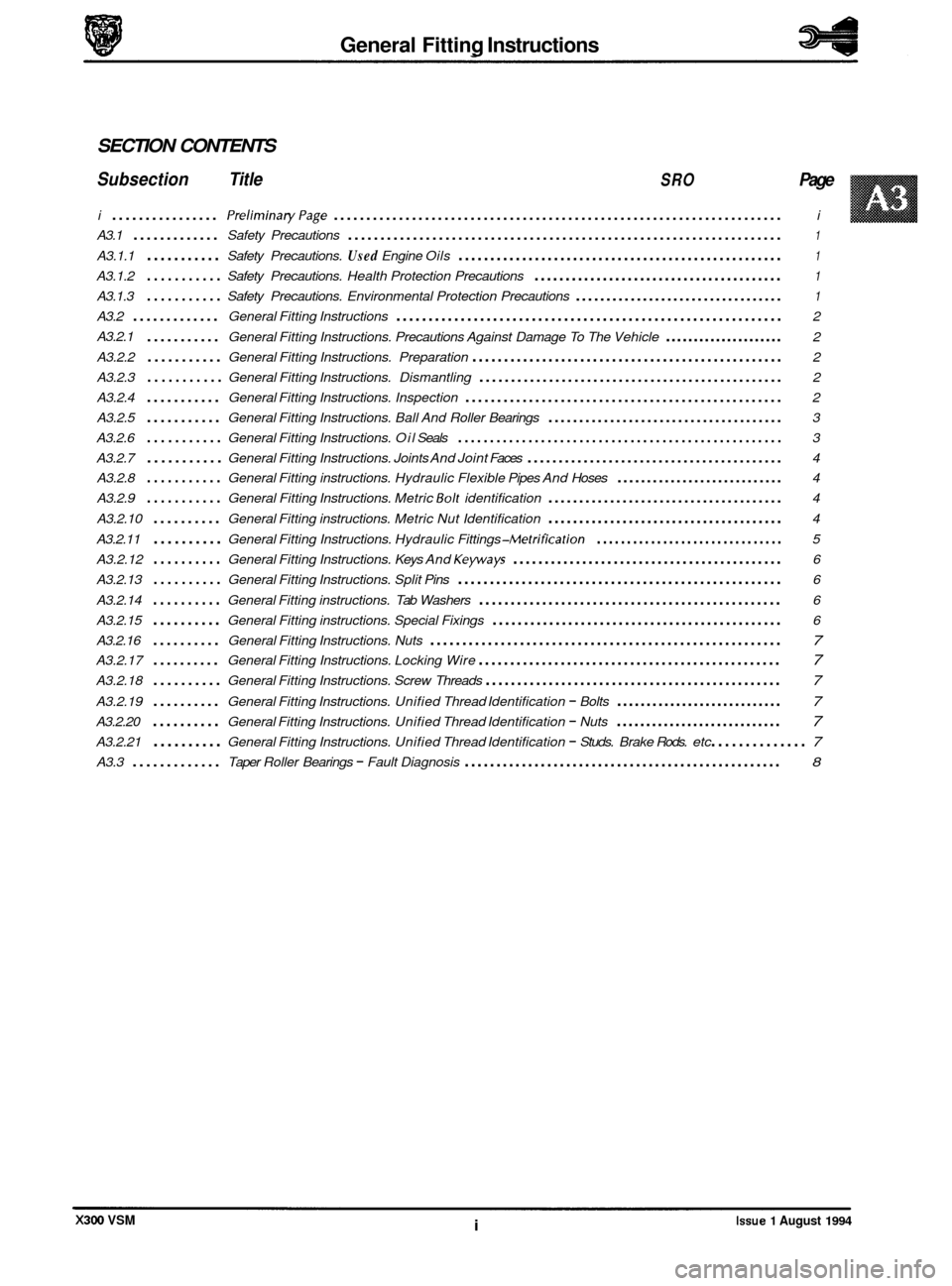

General Fitting Instructions

SECTION CONTENTS

Subsection Title SRO Page

i ................ PreliminaryPage ..................................................................... i

A3.1 ............. Safety Precautions ................................................................... 1

A3.1.1 ........... Safety Precautions. Used Engine Oils ................................................... 1

A3.1.2 ........... Safety Precautions. Health Protection Precautions ........................................ 1

A3.1.3 ........... Safety Precautions. Environmental Protection Precautions .................................. 1

A3.2 ............. General Fitting Instructions ............................................................ 2

A3.2.1

........... General Fitting Instructions. Precautions Against Damage To The Vehicle ..................... 2

A3.2.2

........... General Fitting Instructions. Preparation ................................................. 2

A3.2.3

........... General Fitting Instructions. Dismantling ................................................ 2

A3.2.4

........... General Fitting Instructions. Inspection .................................................. 2

A3.2.5

........... General Fitting Instructions. Ball And Roller Bearings ...................................... 3

A3.2.6

........... General Fitting Instructions. Oil Seals ................................................... 3

A3.2.7

........... General Fitting Instructions. Joints And Joint Faces ......................................... 4

A3.2.8

........... General Fitting instructions. Hydraulic Flexible Pipes And Hoses ............................ 4

A3.2.9

........... General Fitting Instructions. Metric Bolt identification ...................................... 4

A3.2.10

.......... General Fitting instructions. Metric Nut Identification ...................................... 4

A3.2.11

.......... General Fitting Instructions. Hydraulic Fittings -Metrification ............................... 5

A3.2.12

.......... General Fitting Instructions. Keys And Keyways ........................................... 6

A3.2.13

.......... General Fitting Instructions. Split Pins ................................................... 6

A3.2.14

.......... General Fitting instructions. Tab Washers ................................................ 6

A3.2.15

.......... General Fitting instructions. Special Fixings .............................................. 6

A3.2.16

.......... General Fitting Instructions. Nuts ....................................................... 7

A3.2.17 .......... General Fitting Instructions. Locking Wire ................................................ 7

A3.2.18 .......... General Fitting Instructions. Screw Threads ............................................... 7

A3.2.19 .......... General Fitting Instructions. Unified Thread Identification - Bolts ............................ 7

A3.2.20 .......... General Fitting Instructions. Unified Thread Identification - Nuts ............................ 7

A3.2.21 .......... General Fitting Instructions. Unified Thread Identification - Studs. Brake Rods. etc .............. 7

A3.3 ............. Taper Roller Bearings - Fault Diagnosis .................................................. 8

X300 VSM i Issue 1 August 1994