service JAGUAR XJ6 1997 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1997, Model line: XJ6, Model: JAGUAR XJ6 1997 2.GPages: 227, PDF Size: 7.2 MB

Page 169 of 227

11 Fuel, oil and temperature

gauges- check

1

Warning: Later models are

equipped with airbags. To

prevent accidental deployment

of the airbag, which could cause

personal injury or damage to the airbag

system, DO NOT work in the vicinity of the

steering column or instrument panel. The

manufacturer recommends that, on airbag

equipped models, the following procedure

be performed at a dealer service

department or other properly equipped

repair facility because of the special tools

and techniques required to disable the

airbag system.

1All tests below require the ignition switch to

be turned to ON position when testing.

2Check the fuse if the gauge pointer does

not move from the empty, low or cold

positions. If the fuse is OK, locate the

particular sender unit for the circuit you’re

working on (see Chapter 4 for fuel sender unit

location, Chapter 2 for oil sender unit location,

or Chapter 3 for temperature sender unit

location). Connect the sender unit connector

to earth If the pointer goes to the full, high or

hot position renew the sender unit. If the

pointer stays in same position use a jumper

wire to earth the terminal on the back of the

gauge. If the pointer moves with the back of

the gauge earthed the problem lies in the wire

between the gauge and the sender unit. If the

pointer does not moves with the back of the

gauge earthed check for voltage at the other

terminal of the gauge. If voltage is present

renew the gauge.

12 Instrument cluster-

removal and refitting

1

Warning: Later models are

equipped with airbags. To

prevent accidental deployment

of the airbag, which could cause

personal injury or damage to the airbag

system, DO NOT work in the vicinity of the

steering column or instrument panel. The

manufacturer recommends that, on airbag

equipped models, the following procedure

be performed at a dealer service

department or other properly equipped

repair facility because of the special tools

and techniques required to disable the

airbag system.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

1Disconnect the negative battery cable.

2Remove the instrument cluster housing (see

Chapter 11).

3Remove the instrument cluster mounting

screws (see illustration). Separate the

instrument cluster from the cluster housing.

4Refitting is the reverse of removal.

13 Radio and speakers-

removal and refitting

2

Warning: Later models are

equipped with airbags. To

prevent accidental deployment

of the airbag, which could cause

personal injury or damage to the airbag

system, DO NOT work in the vicinity of the

steering column or instrument panel. The

manufacturer recommends that, on airbagequipped models, the following procedure

be performed at a dealer service

department or other properly equipped

repair facility because of the special tools

and techniques required to disable the

airbag system.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

1Disconnect the negative battery cable.

Radio

2Remove the radio trim bezel (Chapter 11).

3Remove the retaining screws (see

illustration), pull the radio/control panel

outward to access the backside and

disconnect the electrical connectors and

aerial lead. Detach the retaining clips and

separate the radio from the control panel.

4Refitting is the reverse of removal.

Speakers

5Remove the door trim panel (Chapter 11).

6Remove the nuts from the speaker

mounting studs (see illustration). Disconnect

the electrical connector and remove the

speaker from the vehicle.

7Refitting is the reverse of removal.

Body electrical system 12•7

12

3261 Jaguar XJ6 12.3 Remove the instrument cluster retaining screws (arrowed)

then separate the instrument cluster from the cluster housing

13.3 Remove the retaining screws (arrowed) and pull the

radio/control panel out enough to unplug the connectors

13.6 Remove the nuts from the retaining

studs (arrowed) to remove the speaker

Page 173 of 227

8Adjustment should be made with the

vehicle parked 25 feet from the wall, sitting

level, the petrol tank half-full and no unusually

heavy load in the vehicle.

9Starting with the low beam adjustment,

position the high intensity zone so it is two

inches below the horizontal line and two

inches to the right of the headlight vertical

line. Adjustments are made by turning the

knobs located behind the headlight housings

(see illustration 18.2).

10With the high beams on, the high intensity

zone should be vertically centred with the

exact centre just below the horizontal line.

Note:It may not be possible to position the

headlight aim exactly for both high and low

beams. If a compromise must be made, keep

in mind that the low beams are the most used

and have the greatest effect on safety.

11Have the headlights adjusted by a dealer

service department or service station at the

earliest opportunity.

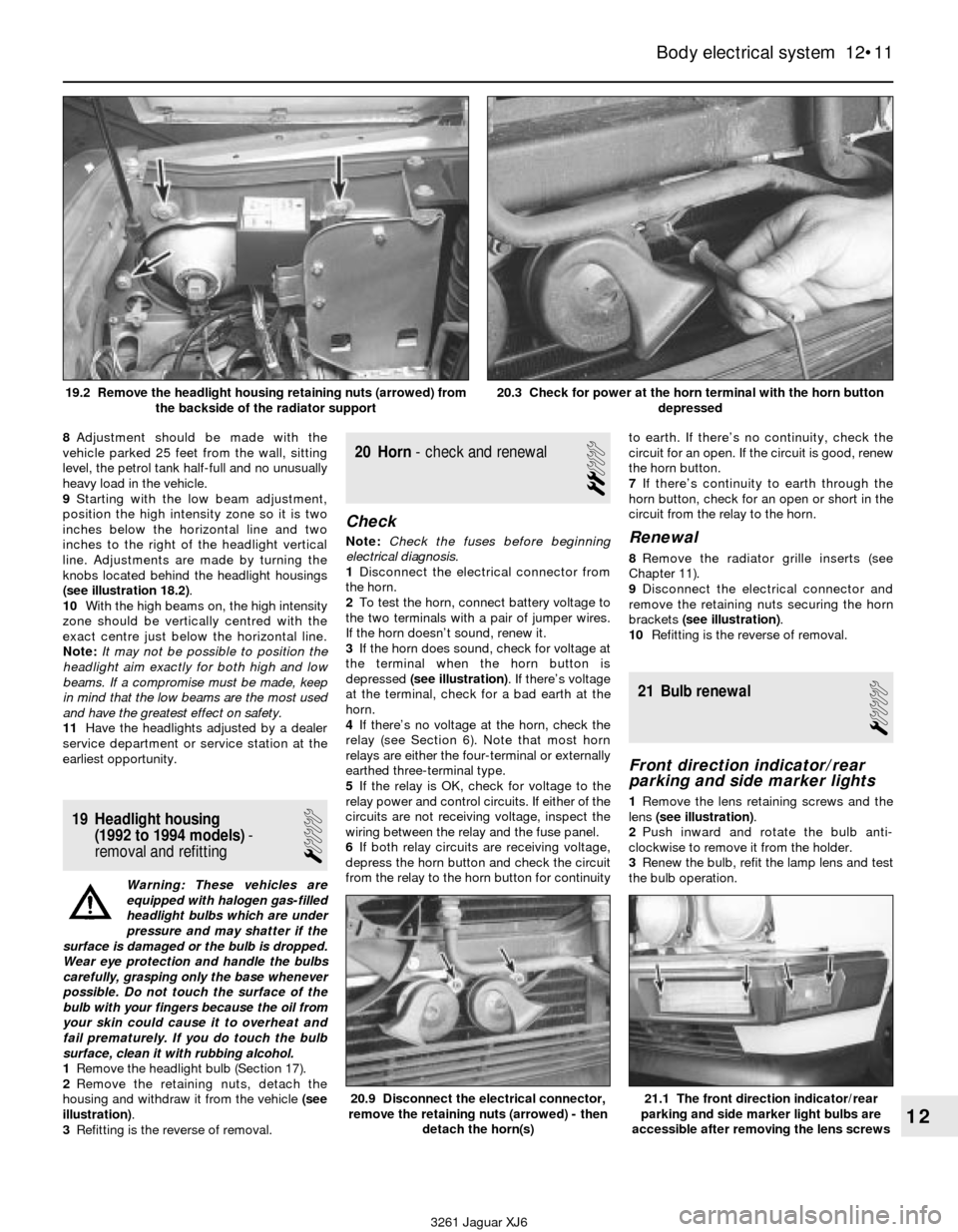

19 Headlight housing

(1992 to 1994 models)-

removal and refitting

1

Warning: These vehicles are

equipped with halogen gas-filled

headlight bulbs which are under

pressure and may shatter if the

surface is damaged or the bulb is dropped.

Wear eye protection and handle the bulbs

carefully, grasping only the base whenever

possible. Do not touch the surface of the

bulb with your fingers because the oil from

your skin could cause it to overheat and

fail prematurely. If you do touch the bulb

surface, clean it with rubbing alcohol.

1Remove the headlight bulb (Section 17).

2Remove the retaining nuts, detach the

housing and withdraw it from the vehicle (see

illustration).

3Refitting is the reverse of removal.

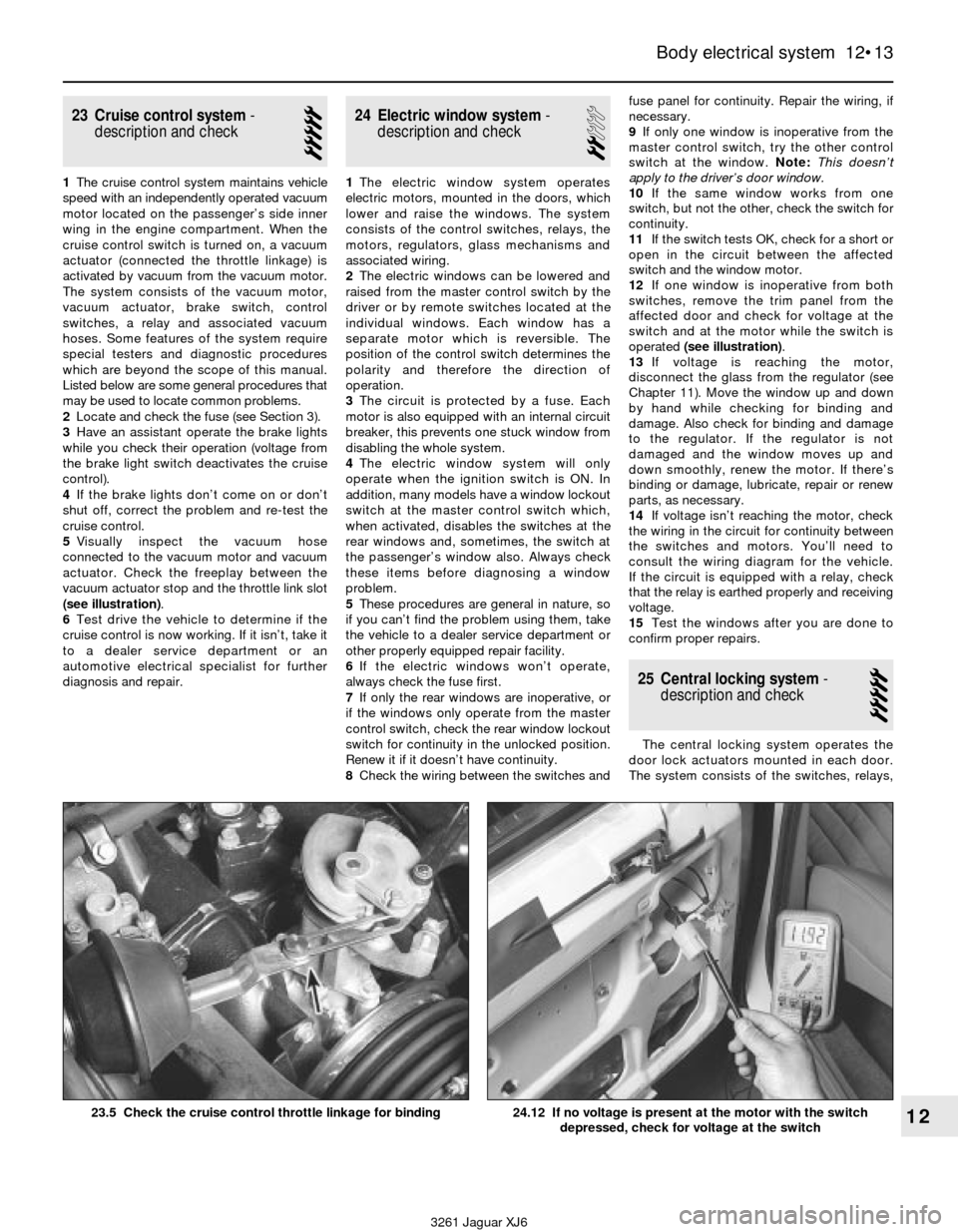

20 Horn- check and renewal

2

Check

Note:Check the fuses before beginning

electrical diagnosis.

1Disconnect the electrical connector from

the horn.

2To test the horn, connect battery voltage to

the two terminals with a pair of jumper wires.

If the horn doesn’t sound, renew it.

3If the horn does sound, check for voltage at

the terminal when the horn button is

depressed (see illustration). If there’s voltage

at the terminal, check for a bad earth at the

horn.

4If there’s no voltage at the horn, check the

relay (see Section 6). Note that most horn

relays are either the four-terminal or externally

earthed three-terminal type.

5If the relay is OK, check for voltage to the

relay power and control circuits. If either of the

circuits are not receiving voltage, inspect the

wiring between the relay and the fuse panel.

6If both relay circuits are receiving voltage,

depress the horn button and check the circuit

from the relay to the horn button for continuityto earth. If there’s no continuity, check the

circuit for an open. If the circuit is good, renew

the horn button.

7If there’s continuity to earth through the

horn button, check for an open or short in the

circuit from the relay to the horn.Renewal

8Remove the radiator grille inserts (see

Chapter 11).

9Disconnect the electrical connector and

remove the retaining nuts securing the horn

brackets (see illustration).

10Refitting is the reverse of removal.

21 Bulb renewal

1

Front direction indicator/rear

parking and side marker lights

1Remove the lens retaining screws and the

lens (see illustration).

2Push inward and rotate the bulb anti-

clockwise to remove it from the holder.

3Renew the bulb, refit the lamp lens and test

the bulb operation.

Body electrical system 12•11

12

20.9 Disconnect the electrical connector,

remove the retaining nuts (arrowed) - then

detach the horn(s)21.1 The front direction indicator/rear

parking and side marker light bulbs are

accessible after removing the lens screws

3261 Jaguar XJ6 19.2 Remove the headlight housing retaining nuts (arrowed) from

the backside of the radiator support

20.3 Check for power at the horn terminal with the horn button

depressed

Page 175 of 227

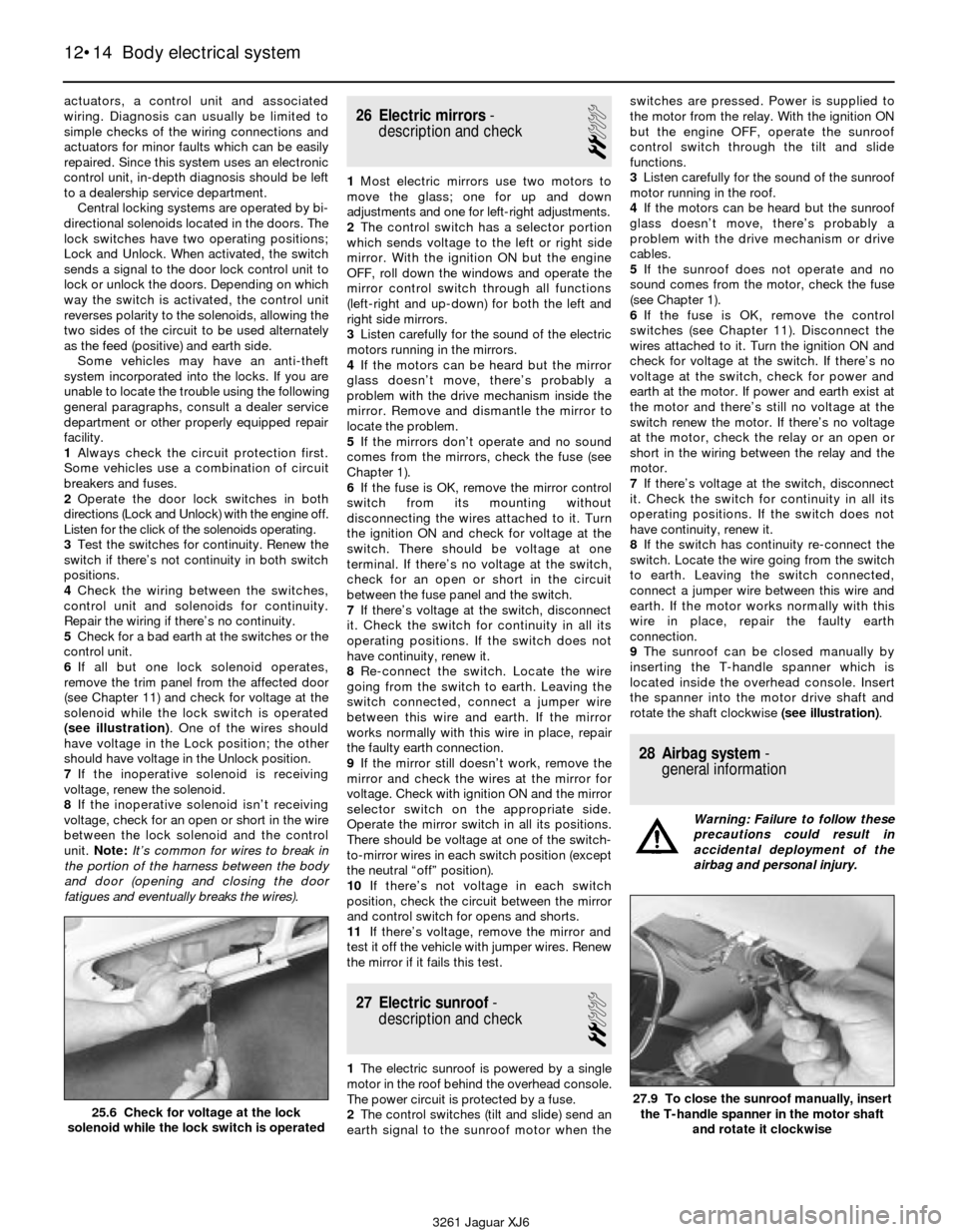

23 Cruise control system-

description and check

5

1The cruise control system maintains vehicle

speed with an independently operated vacuum

motor located on the passenger’s side inner

wing in the engine compartment. When the

cruise control switch is turned on, a vacuum

actuator (connected the throttle linkage) is

activated by vacuum from the vacuum motor.

The system consists of the vacuum motor,

vacuum actuator, brake switch, control

switches, a relay and associated vacuum

hoses. Some features of the system require

special testers and diagnostic procedures

which are beyond the scope of this manual.

Listed below are some general procedures that

may be used to locate common problems.

2Locate and check the fuse (see Section 3).

3Have an assistant operate the brake lights

while you check their operation (voltage from

the brake light switch deactivates the cruise

control).

4If the brake lights don’t come on or don’t

shut off, correct the problem and re-test the

cruise control.

5Visually inspect the vacuum hose

connected to the vacuum motor and vacuum

actuator. Check the freeplay between the

vacuum actuator stop and the throttle link slot

(see illustration).

6Test drive the vehicle to determine if the

cruise control is now working. If it isn’t, take it

to a dealer service department or an

automotive electrical specialist for further

diagnosis and repair.

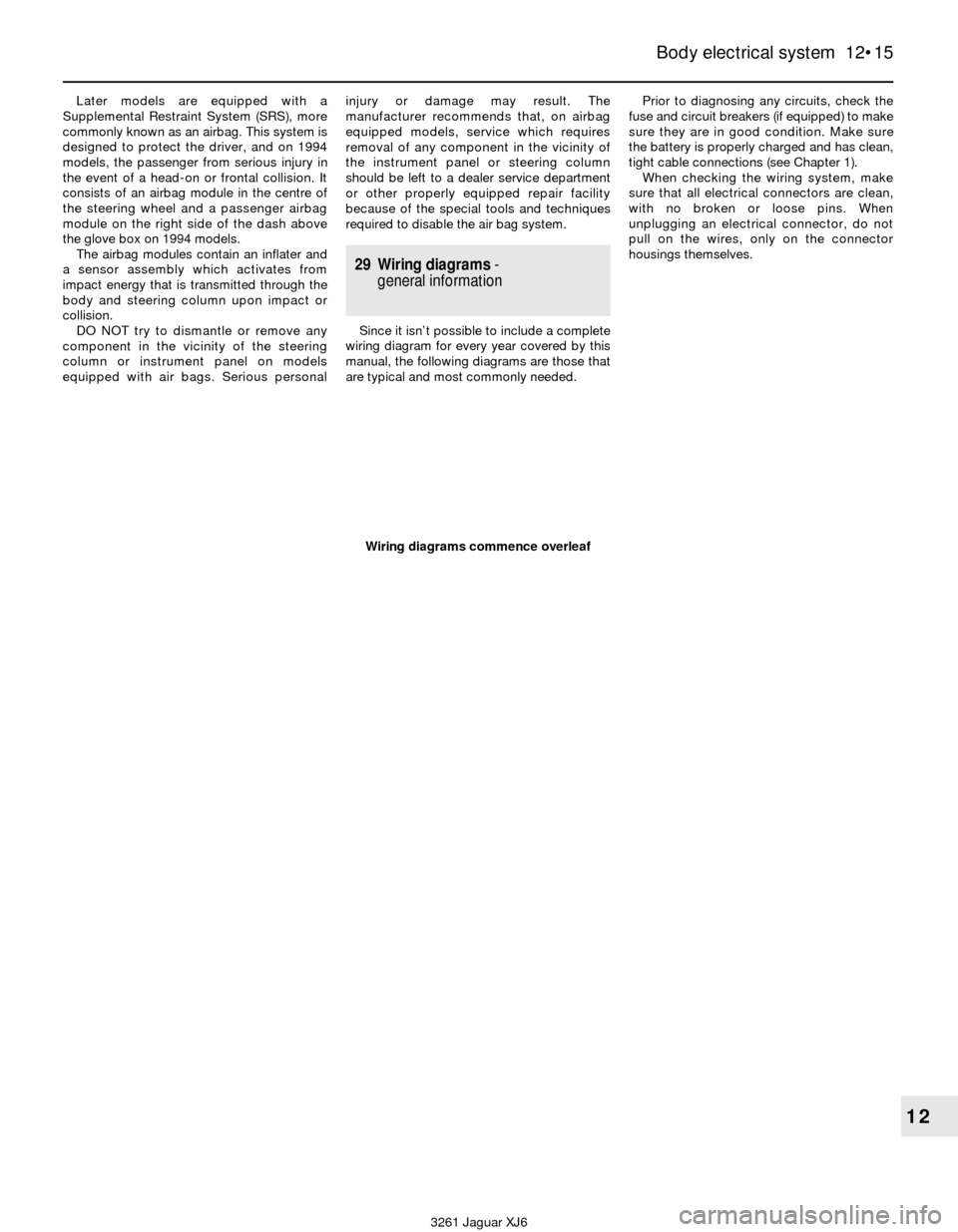

24 Electric window system-

description and check

2

1The electric window system operates

electric motors, mounted in the doors, which

lower and raise the windows. The system

consists of the control switches, relays, the

motors, regulators, glass mechanisms and

associated wiring.

2The electric windows can be lowered and

raised from the master control switch by the

driver or by remote switches located at the

individual windows. Each window has a

separate motor which is reversible. The

position of the control switch determines the

polarity and therefore the direction of

operation.

3The circuit is protected by a fuse. Each

motor is also equipped with an internal circuit

breaker, this prevents one stuck window from

disabling the whole system.

4The electric window system will only

operate when the ignition switch is ON. In

addition, many models have a window lockout

switch at the master control switch which,

when activated, disables the switches at the

rear windows and, sometimes, the switch at

the passenger’s window also. Always check

these items before diagnosing a window

problem.

5These procedures are general in nature, so

if you can’t find the problem using them, take

the vehicle to a dealer service department or

other properly equipped repair facility.

6If the electric windows won’t operate,

always check the fuse first.

7If only the rear windows are inoperative, or

if the windows only operate from the master

control switch, check the rear window lockout

switch for continuity in the unlocked position.

Renew it if it doesn’t have continuity.

8Check the wiring between the switches andfuse panel for continuity. Repair the wiring, if

necessary.

9If only one window is inoperative from the

master control switch, try the other control

switch at the window. Note:This doesn’t

apply to the driver’s door window.

10If the same window works from one

switch, but not the other, check the switch for

continuity.

11If the switch tests OK, check for a short or

open in the circuit between the affected

switch and the window motor.

12If one window is inoperative from both

switches, remove the trim panel from the

affected door and check for voltage at the

switch and at the motor while the switch is

operated (see illustration).

13If voltage is reaching the motor,

disconnect the glass from the regulator (see

Chapter 11). Move the window up and down

by hand while checking for binding and

damage. Also check for binding and damage

to the regulator. If the regulator is not

damaged and the window moves up and

down smoothly, renew the motor. If there’s

binding or damage, lubricate, repair or renew

parts, as necessary.

14If voltage isn’t reaching the motor, check

the wiring in the circuit for continuity between

the switches and motors. You’ll need to

consult the wiring diagram for the vehicle.

If the circuit is equipped with a relay, check

that the relay is earthed properly and receiving

voltage.

15Test the windows after you are done to

confirm proper repairs.

25 Central locking system-

description and check

5

The central locking system operates the

door lock actuators mounted in each door.

The system consists of the switches, relays,

Body electrical system 12•13

12

3261 Jaguar XJ6 23.5 Check the cruise control throttle linkage for binding

24.12 If no voltage is present at the motor with the switch

depressed, check for voltage at the switch

Page 176 of 227

actuators, a control unit and associated

wiring. Diagnosis can usually be limited to

simple checks of the wiring connections and

actuators for minor faults which can be easily

repaired. Since this system uses an electronic

control unit, in-depth diagnosis should be left

to a dealership service department.

Central locking systems are operated by bi-

directional solenoids located in the doors. The

lock switches have two operating positions;

Lock and Unlock. When activated, the switch

sends a signal to the door lock control unit to

lock or unlock the doors. Depending on which

way the switch is activated, the control unit

reverses polarity to the solenoids, allowing the

two sides of the circuit to be used alternately

as the feed (positive) and earth side.

Some vehicles may have an anti-theft

system incorporated into the locks. If you are

unable to locate the trouble using the following

general paragraphs, consult a dealer service

department or other properly equipped repair

facility.

1Always check the circuit protection first.

Some vehicles use a combination of circuit

breakers and fuses.

2Operate the door lock switches in both

directions (Lock and Unlock) with the engine off.

Listen for the click of the solenoids operating.

3Test the switches for continuity. Renew the

switch if there’s not continuity in both switch

positions.

4Check the wiring between the switches,

control unit and solenoids for continuity.

Repair the wiring if there’s no continuity.

5Check for a bad earth at the switches or the

control unit.

6If all but one lock solenoid operates,

remove the trim panel from the affected door

(see Chapter 11) and check for voltage at the

solenoid while the lock switch is operated

(see illustration). One of the wires should

have voltage in the Lock position; the other

should have voltage in the Unlock position.

7If the inoperative solenoid is receiving

voltage, renew the solenoid.

8If the inoperative solenoid isn’t receiving

voltage, check for an open or short in the wire

between the lock solenoid and the control

unit. Note:It’s common for wires to break in

the portion of the harness between the body

and door (opening and closing the door

fatigues and eventually breaks the wires).26 Electric mirrors-

description and check

2

1Most electric mirrors use two motors to

move the glass; one for up and down

adjustments and one for left-right adjustments.

2The control switch has a selector portion

which sends voltage to the left or right side

mirror. With the ignition ON but the engine

OFF, roll down the windows and operate the

mirror control switch through all functions

(left-right and up-down) for both the left and

right side mirrors.

3Listen carefully for the sound of the electric

motors running in the mirrors.

4If the motors can be heard but the mirror

glass doesn’t move, there’s probably a

problem with the drive mechanism inside the

mirror. Remove and dismantle the mirror to

locate the problem.

5If the mirrors don’t operate and no sound

comes from the mirrors, check the fuse (see

Chapter 1).

6If the fuse is OK, remove the mirror control

switch from its mounting without

disconnecting the wires attached to it. Turn

the ignition ON and check for voltage at the

switch. There should be voltage at one

terminal. If there’s no voltage at the switch,

check for an open or short in the circuit

between the fuse panel and the switch.

7If there’s voltage at the switch, disconnect

it. Check the switch for continuity in all its

operating positions. If the switch does not

have continuity, renew it.

8Re-connect the switch. Locate the wire

going from the switch to earth. Leaving the

switch connected, connect a jumper wire

between this wire and earth. If the mirror

works normally with this wire in place, repair

the faulty earth connection.

9If the mirror still doesn’t work, remove the

mirror and check the wires at the mirror for

voltage. Check with ignition ON and the mirror

selector switch on the appropriate side.

Operate the mirror switch in all its positions.

There should be voltage at one of the switch-

to-mirror wires in each switch position (except

the neutral “off” position).

10If there’s not voltage in each switch

position, check the circuit between the mirror

and control switch for opens and shorts.

11If there’s voltage, remove the mirror and

test it off the vehicle with jumper wires. Renew

the mirror if it fails this test.

27 Electric sunroof-

description and check

2

1The electric sunroof is powered by a single

motor in the roof behind the overhead console.

The power circuit is protected by a fuse.

2The control switches (tilt and slide) send an

earth signal to the sunroof motor when theswitches are pressed. Power is supplied to

the motor from the relay. With the ignition ON

but the engine OFF, operate the sunroof

control switch through the tilt and slide

functions.

3Listen carefully for the sound of the sunroof

motor running in the roof.

4If the motors can be heard but the sunroof

glass doesn’t move, there’s probably a

problem with the drive mechanism or drive

cables.

5If the sunroof does not operate and no

sound comes from the motor, check the fuse

(see Chapter 1).

6If the fuse is OK, remove the control

switches (see Chapter 11). Disconnect the

wires attached to it. Turn the ignition ON and

check for voltage at the switch. If there’s no

voltage at the switch, check for power and

earth at the motor. If power and earth exist at

the motor and there’s still no voltage at the

switch renew the motor. If there’s no voltage

at the motor, check the relay or an open or

short in the wiring between the relay and the

motor.

7If there’s voltage at the switch, disconnect

it. Check the switch for continuity in all its

operating positions. If the switch does not

have continuity, renew it.

8If the switch has continuity re-connect the

switch. Locate the wire going from the switch

to earth. Leaving the switch connected,

connect a jumper wire between this wire and

earth. If the motor works normally with this

wire in place, repair the faulty earth

connection.

9The sunroof can be closed manually by

inserting the T-handle spanner which is

located inside the overhead console. Insert

the spanner into the motor drive shaft and

rotate the shaft clockwise (see illustration).

28 Airbag system-

general information

Warning: Failure to follow these

precautions could result in

accidental deployment of the

airbag and personal injury.

12•14 Body electrical system

25.6 Check for voltage at the lock

solenoid while the lock switch is operated27.9 To close the sunroof manually, insert

the T-handle spanner in the motor shaft

and rotate it clockwise

3261 Jaguar XJ6

Page 177 of 227

Later models are equipped with a

Supplemental Restraint System (SRS), more

commonly known as an airbag. This system is

designed to protect the driver, and on 1994

models, the passenger from serious injury in

the event of a head-on or frontal collision. It

consists of an airbag module in the centre of

the steering wheel and a passenger airbag

module on the right side of the dash above

the glove box on 1994 models.

The airbag modules contain an inflater and

a sensor assembly which activates from

impact energy that is transmitted through the

body and steering column upon impact or

collision.

DO NOT try to dismantle or remove any

component in the vicinity of the steering

column or instrument panel on models

equipped with air bags. Serious personalinjury or damage may result. The

manufacturer recommends that, on airbag

equipped models, service which requires

removal of any component in the vicinity of

the instrument panel or steering column

should be left to a dealer service department

or other properly equipped repair facility

because of the special tools and techniques

required to disable the air bag system.

29 Wiring diagrams-

general information

Since it isn’t possible to include a complete

wiring diagram for every year covered by this

manual, the following diagrams are those that

are typical and most commonly needed.Prior to diagnosing any circuits, check the

fuse and circuit breakers (if equipped) to make

sure they are in good condition. Make sure

the battery is properly charged and has clean,

tight cable connections (see Chapter 1).

When checking the wiring system, make

sure that all electrical connectors are clean,

with no broken or loose pins. When

unplugging an electrical connector, do not

pull on the wires, only on the connector

housings themselves.

Body electrical system 12•15

12

3261 Jaguar XJ6 Wiring diagrams commence overleaf

Page 205 of 227

3261 Jaguar XJ6

REF•4Buying spare parts

Spare parts are available from many

sources, including maker’s appointed

garages, accessory shops, and motor factors.

To be sure of obtaining the correct parts, it

will sometimes be necessary to quote the

vehicle identification number. If possible, it

can also be useful to take the old parts along

for positive identification. Items such as

starter motors and alternators may be

available under a service exchange scheme -

any parts returned should be clean.

Our advice regarding spare parts is as

follows.

Officially appointed garages

This is the best source of parts which are

peculiar to your car, and which are not

otherwise generally available (eg, badges,

interior trim, certain body panels, etc). It is

also the only place at which you should buy

parts if the vehicle is still under warranty.

Accessory shops

These are very good places to buy

materials and components needed for themaintenance of your car (oil, air and fuel

filters, light bulbs, drivebelts, greases, brake

pads, touch-up paint, etc). Components of

this nature sold by a reputable shop are

usually of the same standard as those used

by the car manufacturer.

Besides components, these shops also sell

tools and general accessories, usually have

convenient opening hours, charge lower

prices, and can often be found close to home.

Some accessory shops have parts counters

where components needed for almost any

repair job can be purchased or ordered.

Motor factors

Good factors will stock all the more

important components which wear out

comparatively quickly, and can sometimes

supply individual components needed for the

overhaul of a larger assembly (eg, brake seals

and hydraulic parts, bearing shells, pistons,

valves). They may also handle work such as

cylinder block reboring, crankshaft regrinding,

etc.

Tyre and exhaust specialists

These outlets may be independent, or

members of a local or national chain. They

frequently offer competitive prices when

compared with a main dealer or local garage,

but it will pay to obtain several quotes before

making a decision. When researching prices,

also ask what “extras” may be added - for

instance fitting a new valve and balancing the

wheel are both commonly charged on top of

the price of a new tyre.

Other sources

Beware of parts or materials obtained from

market stalls, car boot sales or similar outlets.

Such items are not invariably sub-standard,

but there is little chance of compensation if

they do prove unsatisfactory. In the case of

safety-critical components such as brake

pads, there is the risk of financial loss, and

also of an accident causing injury or death.

Second-hand parts or assemblies obtained

from a car breaker can be a good buy in some

circumstances, but this sort of purchase is

best made by the experienced DIY mechanic.

Vehicle identification

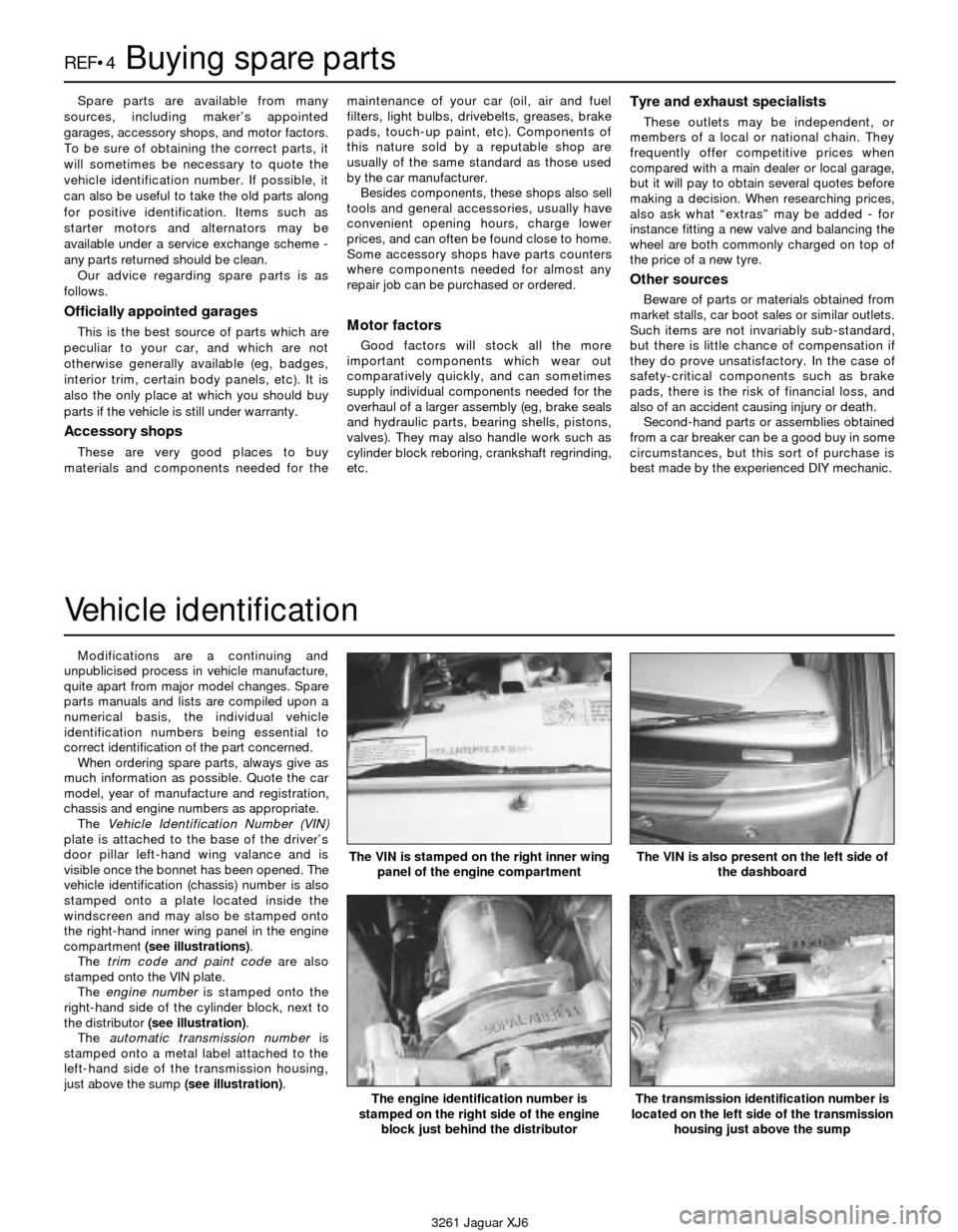

Modifications are a continuing and

unpublicised process in vehicle manufacture,

quite apart from major model changes. Spare

parts manuals and lists are compiled upon a

numerical basis, the individual vehicle

identification numbers being essential to

correct identification of the part concerned.

When ordering spare parts, always give as

much information as possible. Quote the car

model, year of manufacture and registration,

chassis and engine numbers as appropriate.

The Vehicle Identification Number (VIN)

plate is attached to the base of the driver’s

door pillar left-hand wing valance and is

visible once the bonnet has been opened. The

vehicle identification (chassis) number is also

stamped onto a plate located inside the

windscreen and may also be stamped onto

the right-hand inner wing panel in the engine

compartment (see illustrations).

The trim code and paint codeare also

stamped onto the VIN plate.

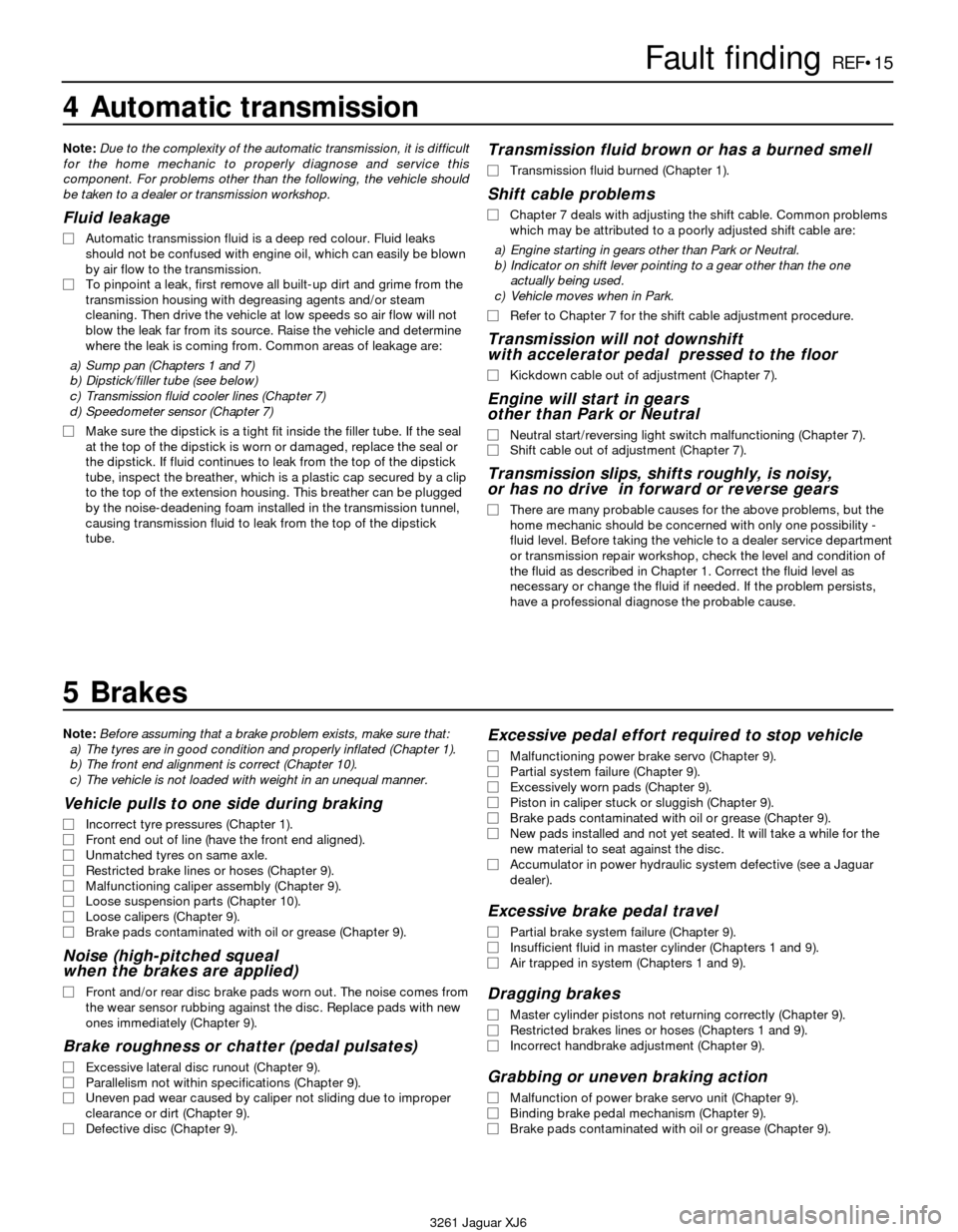

The engine numberis stamped onto the

right-hand side of the cylinder block, next to

the distributor (see illustration).

The automatic transmission numberis

stamped onto a metal label attached to the

left-hand side of the transmission housing,

just above the sump (see illustration).The VIN is stamped on the right inner wing

panel of the engine compartment

The engine identification number is

stamped on the right side of the engine

block just behind the distributorThe transmission identification number is

located on the left side of the transmission

housing just above the sump

The VIN is also present on the left side of

the dashboard

Page 208 of 227

3261 Jaguar XJ6

Tools and working facilitiesREF•7

Special tools

The tools in this list are those which are not

used regularly, are expensive to buy, or which

need to be used in accordance with their

manufacturers’ instructions. Unless relatively

difficult mechanical jobs are undertaken

frequently, it will not be economic to buy

many of these tools. Where this is the case,

you could consider clubbing together with

friends (or joining a motorists’ club) to make a

joint purchase, or borrowing the tools against

a deposit from a local garage or tool hire

specialist. It is worth noting that many of the

larger DIY superstores now carry a large

range of special tools for hire at modest rates.

The following list contains only those tools

and instruments freely available to the public,

and not those special tools produced by the

vehicle manufacturer specifically for its dealer

network. You will find occasional references

to these manufacturers’ special tools in the

text of this manual. Generally, an alternative

method of doing the job without the vehicle

manufacturers’ special tool is given. However,

sometimes there is no alternative to using

them. Where this is the case and the relevant

tool cannot be bought or borrowed, you will

have to entrust the work to a dealer.

MValve spring compressor

MValve grinding tool

MPiston ring compressor

MPiston ring removal/installation tool

MCylinder bore hone

MBalljoint separator

MCoil spring compressors (where applicable)

MTwo/three-legged hub and bearing puller

MImpact screwdriver

MMicrometer and/or vernier calipers

MDial gauge

MStroboscopic timing light

MDwell angle meter/tachometer

MUniversal electrical multi-meter

MCylinder compression gauge

MHand-operated vacuum pump and gauge

MClutch plate alignment set

MBrake shoe steady spring cup removal tool

MBush and bearing removal/installation set

MStud extractors

MTap and die set

MLifting tackle

MTrolley jack

Buying tools

Reputable motor accessory shops and

superstores often offer excellent quality tools

at discount prices, so it pays to shop around.

Remember, you don’t have to buy the most

expensive items on the shelf, but it is always

advisable to steer clear of the very cheap

tools. Beware of ‘bargains’ offered on market

stalls or at car boot sales. There are plenty of

good tools around at reasonable prices, but

always aim to purchase items which meet the

relevant national safety standards. If in doubt,

ask the proprietor or manager of the shop for

advice before making a purchase.

Care and maintenance of tools

Having purchased a reasonable tool kit, it is

necessary to keep the tools in a clean and

serviceable condition. After use, always wipe

off any dirt, grease and metal particles using a

clean, dry cloth, before putting the tools away.

Never leave them lying around after they have

been used. A simple tool rack on the garage

or workshop wall for items such as

screwdrivers and pliers is a good idea. Store

all normal spanners and sockets in a metal

box. Any measuring instruments, gauges,

meters, etc, must be carefully stored where

they cannot be damaged or become rusty.

Take a little care when tools are used.

Hammer heads inevitably become marked,

and screwdrivers lose the keen edge on their

blades from time to time. A little timely

attention with emery cloth or a file will soon

restore items like this to a good finish.

Working facilities

Not to be forgotten when discussing tools

is the workshop itself. If anything more than

routine maintenance is to be carried out, a

suitable working area becomes essential.

It is appreciated that many an owner-

mechanic is forced by circumstances to

remove an engine or similar item without the

benefit of a garage or workshop. Having done

this, any repairs should always be done under

the cover of a roof.

Wherever possible, any dismantling should

be done on a clean, flat workbench or table at

a suitable working height.

Any workbench needs a vice; one with a jaw

opening of 100 mm is suitable for most jobs.

As mentioned previously, some clean dry

storage space is also required for tools, as well

as for any lubricants, cleaning fluids, touch-up

paints etc, which become necessary.

Another item which may be required, and

which has a much more general usage, is an

electric drill with a chuck capacity of at least 8

mm. This, together with a good range of twist

drills, is virtually essential for fitting

accessories.

Last, but not least, always keep a supply of

old newspapers and clean, lint-free rags

available, and try to keep any working area as

clean as possible.

Stroboscopic timing light Stud extractor setCompression tester

Dial test indicator (“dial gauge”)Micrometer set

Page 216 of 227

3261 Jaguar XJ6

Fault findingREF•15

4 Automatic transmission

Note:Due to the complexity of the automatic transmission, it is difficult

for the home mechanic to properly diagnose and service this

component. For problems other than the following, the vehicle should

be taken to a dealer or transmission workshop.

Fluid leakage

m mAutomatic transmission fluid is a deep red colour. Fluid leaks

should not be confused with engine oil, which can easily be blown

by air flow to the transmission.

m mTo pinpoint a leak, first remove all built-up dirt and grime from the

transmission housing with degreasing agents and/or steam

cleaning. Then drive the vehicle at low speeds so air flow will not

blow the leak far from its source. Raise the vehicle and determine

where the leak is coming from. Common areas of leakage are:

a) Sump pan (Chapters 1 and 7)

b) Dipstick/filler tube (see below)

c) Transmission fluid cooler lines (Chapter 7)

d) Speedometer sensor (Chapter 7)

m mMake sure the dipstick is a tight fit inside the filler tube. If the seal

at the top of the dipstick is worn or damaged, replace the seal or

the dipstick. If fluid continues to leak from the top of the dipstick

tube, inspect the breather, which is a plastic cap secured by a clip

to the top of the extension housing. This breather can be plugged

by the noise-deadening foam installed in the transmission tunnel,

causing transmission fluid to leak from the top of the dipstick

tube.

Transmission fluid brown or has a burned smell

m mTransmission fluid burned (Chapter 1).

Shift cable problems

m

mChapter 7 deals with adjusting the shift cable. Common problems

which may be attributed to a poorly adjusted shift cable are:

a) Engine starting in gears other than Park or Neutral.

b) Indicator on shift lever pointing to a gear other than the one

actually being used.

c) Vehicle moves when in Park.

m mRefer to Chapter 7 for the shift cable adjustment procedure.

Transmission will not downshift

with accelerator pedal pressed to the floor

m mKickdown cable out of adjustment (Chapter 7).

Engine will start in gears

other than Park or Neutral

m mNeutral start/reversing light switch malfunctioning (Chapter 7).

m mShift cable out of adjustment (Chapter 7).

Transmission slips, shifts roughly, is noisy,

or has no drive in forward or reverse gears

m mThere are many probable causes for the above problems, but the

home mechanic should be concerned with only one possibility -

fluid level. Before taking the vehicle to a dealer service department

or transmission repair workshop, check the level and condition of

the fluid as described in Chapter 1. Correct the fluid level as

necessary or change the fluid if needed. If the problem persists,

have a professional diagnose the probable cause.

5 Brakes

Note:Before assuming that a brake problem exists, make sure that:

a) The tyres are in good condition and properly inflated (Chapter 1).

b) The front end alignment is correct (Chapter 10).

c) The vehicle is not loaded with weight in an unequal manner.

Vehicle pulls to one side during braking

m mIncorrect tyre pressures (Chapter 1).

m mFront end out of line (have the front end aligned).

m mUnmatched tyres on same axle.

m mRestricted brake lines or hoses (Chapter 9).

m mMalfunctioning caliper assembly (Chapter 9).

m mLoose suspension parts (Chapter 10).

m mLoose calipers (Chapter 9).

m mBrake pads contaminated with oil or grease (Chapter 9).

Noise (high-pitched squeal

when the brakes are applied)

m mFront and/or rear disc brake pads worn out. The noise comes from

the wear sensor rubbing against the disc. Replace pads with new

ones immediately (Chapter 9).

Brake roughness or chatter (pedal pulsates)

m mExcessive lateral disc runout (Chapter 9).

m mParallelism not within specifications (Chapter 9).

m mUneven pad wear caused by caliper not sliding due to improper

clearance or dirt (Chapter 9).

m mDefective disc (Chapter 9).

Excessive pedal effort required to stop vehicle

m

mMalfunctioning power brake servo (Chapter 9).

m mPartial system failure (Chapter 9).

m mExcessively worn pads (Chapter 9).

m mPiston in caliper stuck or sluggish (Chapter 9).

m mBrake pads contaminated with oil or grease (Chapter 9).

m mNew pads installed and not yet seated. It will take a while for the

new material to seat against the disc.

m mAccumulator in power hydraulic system defective (see a Jaguar

dealer).

Excessive brake pedal travel

m mPartial brake system failure (Chapter 9).

m mInsufficient fluid in master cylinder (Chapters 1 and 9).

m mAir trapped in system (Chapters 1 and 9).

Dragging brakes

m

mMaster cylinder pistons not returning correctly (Chapter 9).

m mRestricted brakes lines or hoses (Chapters 1 and 9).

m mIncorrect handbrake adjustment (Chapter 9).

Grabbing or uneven braking action

m

mMalfunction of power brake servo unit (Chapter 9).

m mBinding brake pedal mechanism (Chapter 9).

m mBrake pads contaminated with oil or grease (Chapter 9).

Page 222 of 227

3261 Jaguar XJ6

Glossary of technical termsREF•21

RotorIn a distributor, the rotating device

inside the cap that connects the centre

electrode and the outer terminals as it turns,

distributing the high voltage from the coil

secondary winding to the proper spark plug.

Also, that part of an alternator which rotates

inside the stator. Also, the rotating assembly

of a turbocharger, including the compressor

wheel, shaft and turbine wheel.

RunoutThe amount of wobble (in-and-out

movement) of a gear or wheel as it’s rotated.

The amount a shaft rotates “out-of-true.” The

out-of-round condition of a rotating part.

SSealantA liquid or paste used to prevent

leakage at a joint. Sometimes used in

conjunction with a gasket.

Sealed beam lampAn older headlight design

which integrates the reflector, lens and

filaments into a hermetically-sealed one-piece

unit. When a filament burns out or the lens

cracks, the entire unit is simply replaced.

Serpentine drivebeltA single, long, wide

accessory drivebelt that’s used on some

newer vehicles to drive all the accessories,

instead of a series of smaller, shorter belts.

Serpentine drivebelts are usually tensioned by

an automatic tensioner.

ShimThin spacer, commonly used to adjust

the clearance or relative positions between

two parts. For example, shims inserted into or

under bucket tappets control valve

clearances. Clearance is adjusted by

changing the thickness of the shim.

Slide hammerA special puller that screws

into or hooks onto a component such as a

shaft or bearing; a heavy sliding handle on the

shaft bottoms against the end of the shaft to

knock the component free.SprocketA tooth or projection on the

periphery of a wheel, shaped to engage with a

chain or drivebelt. Commonly used to refer to

the sprocket wheel itself.

Starter inhibitor switchOn vehicles with an

automatic transmission, a switch that

prevents starting if the vehicle is not in Neutral

or Park.

StrutSee MacPherson strut.

TTappetA cylindrical component which

transmits motion from the cam to the valve

stem, either directly or via a pushrod and

rocker arm. Also called a cam follower.

ThermostatA heat-controlled valve that

regulates the flow of coolant between the

cylinder block and the radiator, so maintaining

optimum engine operating temperature. A

thermostat is also used in some air cleaners in

which the temperature is regulated.

Thrust bearingThe bearing in the clutch

assembly that is moved in to the release

levers by clutch pedal action to disengage the

clutch. Also referred to as a release bearing.

Timing beltA toothed belt which drives the

camshaft. Serious engine damage may result

if it breaks in service.

Timing chainA chain which drives the

camshaft.

Toe-inThe amount the front wheels are

closer together at the front than at the rear. On

rear wheel drive vehicles, a slight amount of

toe-in is usually specified to keep the front

wheels running parallel on the road by

offsetting other forces that tend to spread the

wheels apart.

Toe-outThe amount the front wheels are

closer together at the rear than at the front. On

front wheel drive vehicles, a slight amount of

toe-out is usually specified.

ToolsFor full information on choosing and

using tools, refer to the Haynes Automotive

Tools Manual.

TracerA stripe of a second colour applied to

a wire insulator to distinguish that wire from

another one with the same colour insulator.

Tune-upA process of accurate and careful

adjustments and parts replacement to obtain

the best possible engine performance.TurbochargerA centrifugal device, driven by

exhaust gases, that pressurises the intake air.

Normally used to increase the power output

from a given engine displacement, but can

also be used primarily to reduce exhaust

emissions (as on VW’s “Umwelt” Diesel

engine).

UUniversal joint or U-jointA double-pivoted

connection for transmitting power from a

driving to a driven shaft through an angle. A

U-joint consists of two Y-shaped yokes and a

cross-shaped member called the spider.

VValveA device through which the flow of

liquid, gas, vacuum, or loose material in bulk

may be started, stopped, or regulated by a

movable part that opens, shuts, or partially

obstructs one or more ports or passageways.

A valve is also the movable part of such a

device.

Valve clearanceThe clearance between the

valve tip (the end of the valve stem) and the

rocker arm or tappet. The valve clearance is

measured when the valve is closed.

Vernier caliperA precision measuring

instrument that measures inside and outside

dimensions. Not quite as accurate as a

micrometer, but more convenient.

ViscosityThe thickness of a liquid or its

resistance to flow.

VoltA unit for expressing electrical

“pressure” in a circuit. One volt that will

produce a current of one ampere through a

resistance of one ohm.

WWeldingVarious processes used to join metal

items by heating the areas to be joined to a

molten state and fusing them together. For

more information refer to the Haynes

Automotive Welding Manual.

Wiring diagramA drawing portraying the

components and wires in a vehicle’s electrical

system, using standardised symbols. For

more information refer to the Haynes

Automotive Electrical and Electronic Systems

Manual.

Serpentine drivebelt