JEEP CJ 1953 Service Manual

Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 341 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

R

FRAME

Contents

SUBJECT

PAR.

Draw

Bar

R-6

Frame

Alignment

.R-2

Frame

Dimensions

.R-3

Front

Axle Alignment.

R-5

Straightening

Frame

R-4

R-1.

GENERAL

equipped with V6 engines, refer

to

measurements

The

frame

is the

structural center

of

the vehicle,

B£?wn

in

FiB-

R"f

, _ , r' .

for in addition

to

carrying

the load,

it

provides and The inost convenient method

of

making this check,

maintains

correct relationship

between

other units

Particularly

when

the

body

is on the

chassis,

is by

to assure their normal functioning. marking

on the

floor

all

dimensional points from

Of

rugged design, the frame

is

constructed of heavy

fhlch

measurements should

be

taken.

This

is

channel

steel side

rails

and cross-members.

Brack-

known

a\

Plumb-bobbing

the

frame Select

a

ets and diagonal braces

are

used

to

maintain

the

?Pace

on the

floof

^hlch

»

extr«nely

level If

work-

proper

longitudinal position

of the

side

rails

rela-

ing Pn

a.,fPen^

c*ean

* s°

that

the fha*k

tive

to

each other, and

at the

same time provide

*****

Jl!*

be

vJs.lble

underneath

the

frame

to be

additional

resistance

to

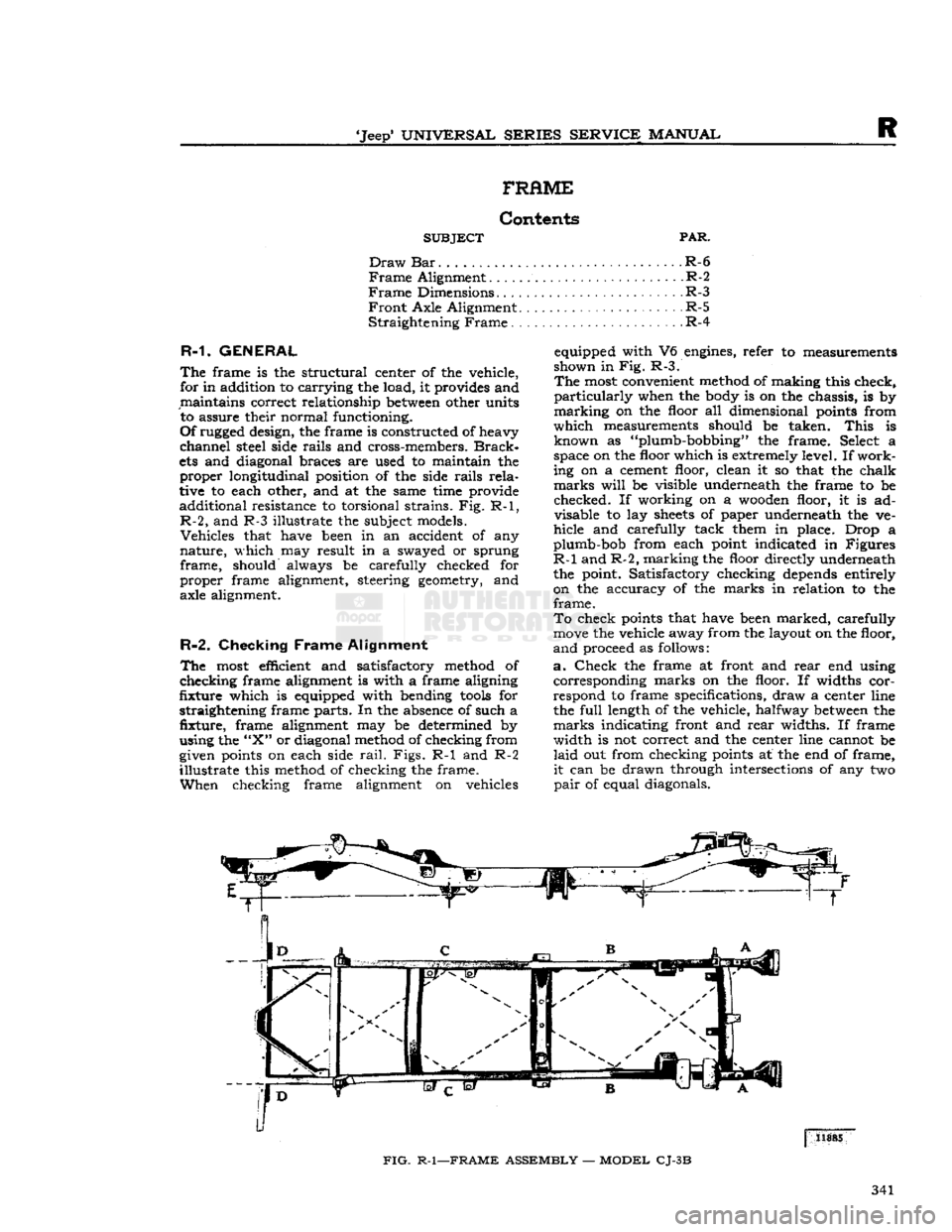

torsional strains. Fig. R-1, checked

If

workmg

on a

wooden

floor

it is ad-

R-2,

and R-3 illustrate

the

subject models. disable

la^

f f * V

Underneath

*he ve"

Vehicles

that have been

in an

accident

of any

hide

and

carefully tack them

m

place. Drop

a

nature,

which

may

result

in a

swayed

or

sprung gumb-bob from each point indicated

in

Figures

frame,

should always

be

carefully checked

for ^

an?

L'maJkl?g the uflo?r

Meetly underneath

proper

frame alignment, steering geometry,

and the

point. Satisfactory checking depends entirely

axle alignment.

on the

accuracy

of the

marks

in

relation

to the

frame.

To

check points that have been marked, carefully

move

the vehicle away from the layout on the floor,

R-2.

Checking

Frame

Alignment

anci

proceed

as

follows:

The

most efficient

and

satisfactory method

of a.

Check

the

frame

at

front

and

rear

end

using

checking

frame alignment

is

with

a

frame aligning corresponding marks

on the

floor.

If

widths

cor-

fixture

which

is

equipped with bending

tools

for

respond

to

frame specifications, draw

a

center line

straightening frame parts. In the absence

of

such

a the

full

length

of

the vehicle, halfway

between

the

fixture,

frame

alignment

may be

determined

by

marks indicating front and

rear

widths.

If

frame

using the

"X"

or diagonal method of checking from width

is not

correct and

the

center line cannot

be

given points

on

each side

rail.

Figs.

R-1 and R-2

laid

out

from checking points

at the

end

of

frame,

illustrate

this method

of

checking

the

frame.

it

can

be

drawn through intersections

of

any

two

When

checking frame alignment

on

vehicles

pair

of

equal diagonals.

FIG.

R-1—FRAME

ASSEMBLY

—

MODEL

CJ-3B

341

Page 342 of 376

R

FRAME

11900

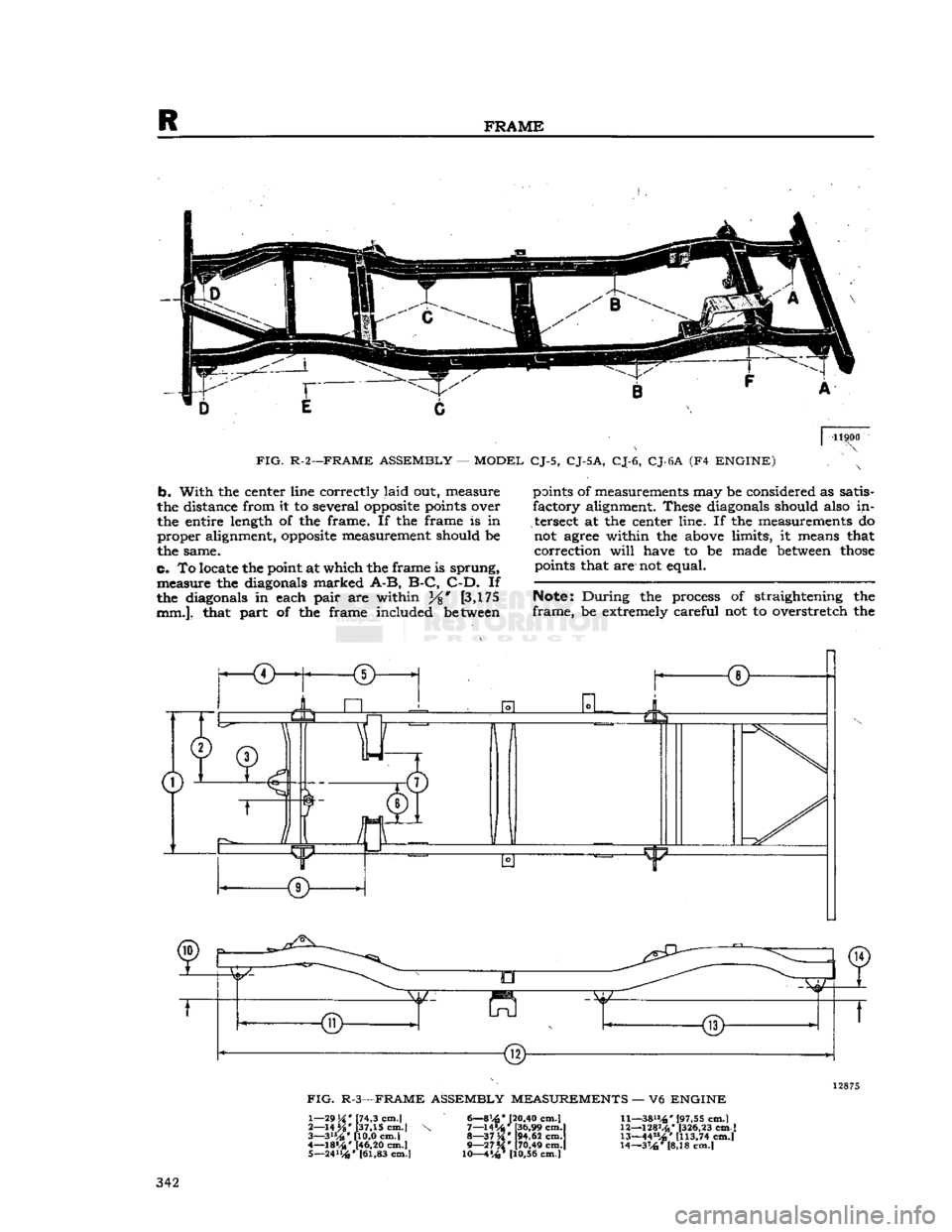

FIG.

R-2—FRAME ASSEMBLY

—

MODEL

CJ-5,

CJ-5A,

CJ-6,

CJ-6A

(F4

ENGINE)

b.

With

the

center line correctly

laid

out,

measure

the distance from

it to

several

opposite

points over

the entire length

of the

frame.

If the

frame

is in

proper

alignment,

opposite

measurement should

be

the same.

c.

To locate the point at

which

the

frame

is

sprung,

measure

the

diagonals marked

A-B,

B-C,

C-D.

If

the diagonals

in

each

pair

are

within [3,175

mm.],

that

part

of the

frame included between points

of

measurements may

be

considered

as

satis

factory

alignment. These diagonals should also

in

tersect

at the

center line.

If the

measurements

do

not agree within

the

above limits,

it

means that

correction

will

have

to be

made between

those

points that are not equal.

Note:

During

the

process

of

straightening

the

frame,

be

extremely careful

not to

overstretch

the

JiL

R

TET

12875

FIG.

R-3—FRAME ASSEMBLY MEASUREMENTS

— V6

ENGINE

1—

29H'

[74,3 cm.l 6—8[20.40 Cm.|

11—38»4*

[97,55 cm.)

2—

14 %' [37,15 cm.|

\ 7—14»4*t36,99

cm.l

12—128Mb'

[326,23

cm.]

3—

3i*4*

110,0 cm.l

8—37K*

[94.62

cm.l

13—44"^' [113,74 cm.l

4— 18«4* [46,20

cm.|

9—27**' [70,49 cm.j 14—316'

[8,18

cm.l

5—

24114»

[61,83 cm.) 10—4%* [10.56 cm.] 342

Page 343 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

R

frame.

This

could cause the already aligned sec

tions of the frame to

become

misaligned or weak ened.

R-3.

Frame Dimensions

Points for measuring frame alignment on vehicles

equipped with the F4

engine

are shown in

Fig.

R-l

and

R-2.

The correct measurements for each model

are

given in the table. Point A is at the front of the

frame.

A-B

and C-D are the distances

between

spring

shackle

bolt and spring pivot bolt frame centers

measured

on a line parallel with the frame center-

line.

E and F show the shackle bolt centers in

rela

tion (above or below) to the pivot bolt centers.

On

vehicles equipped with V6

engines

the frame dimensions are shown in Fig. R-3.

CJ-3B

A-B

44.31"

[112,55

cm.]

C-D

. . . . . .48.48"

[123,14

cm.]

Width

Front

29%" [74,3 cm.]

Width

Rear

29M" [74,3 cm.]

"E"

above .3W [8,18 cm.]

"F"

above 4%* [10,56 cm.]

CJ-5,

CJ-5A,

CJ-6,

CJ-6A,

DJ-5, DJ-6

A-B

.47.08"

[119,58

cm.]

C-D.

52.37"

[133,02

cm.]

Width

Front

2934"

[74,3 cm.]

Width

Rear

29j|" [74,3 cm.]

"E"

above 3%" [8,18 cm.]

"F"

above. .5%" [15,0 cm.]

R-4.

Straightening Frame

In

case the bending or twisting of the frame is not

excessive, it may be straightened.

This

should be

done

cold, as excessive heat applied to the frame

will

weaken it. For this reason it is recommended that badly damaged frame parts be replaced.

Note:

A technique known as "controlled heat" can

be utilized where a frame section is "squashed" and must be brought out without "tearing" or excessive

stretch

to the metal.

R-5.

Front

Axle

Alignment

After

it has been determined that the frame is prop

erly

aligned, the front axle alignment with the

frame

can be checked. The front axle is square

with

the frame if the distance

between

the front

and

rear

axle is the same on both sides. The dis

tance from the spring upper bushings to the front

axle on both sides should be equal.

Note:

Always inspect the springs for broken spring

center

bolts

when checking the frame and axle

alignment.

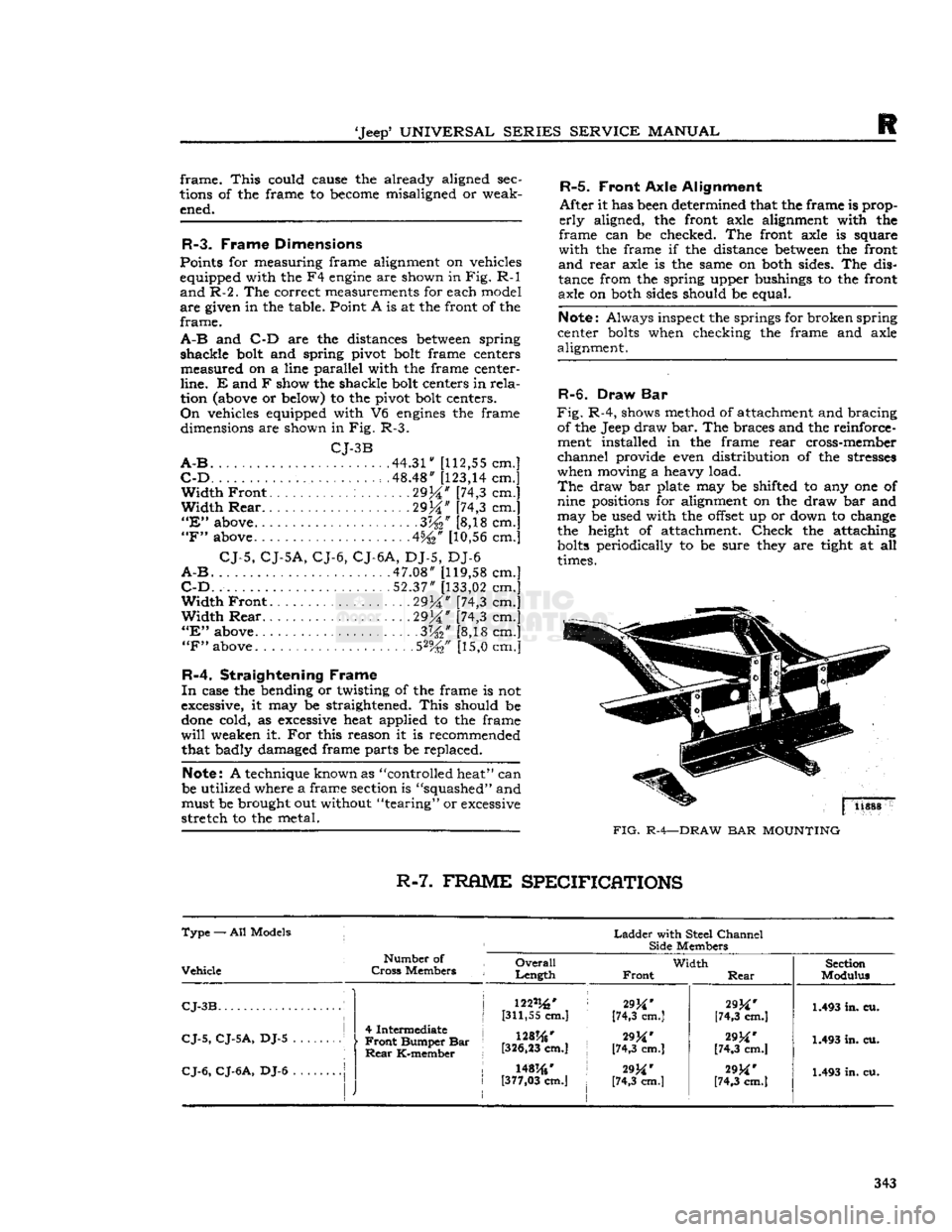

R-6. Draw Bar

Fig.

R-4, shows method of attachment and bracing of the Jeep draw bar. The braces and the reinforce

ment installed in the frame

rear

cross-member

channel

provide even distribution of the stresses

when moving a heavy load.

The

draw bar plate may be shifted to any one of

nine positions for alignment on the draw bar and

may

be used with the

offset

up or down to change

the height of attachment.

Check

the attaching

bolts

periodically to be sure they are tight at all

times.

FIG.

R-4—DRAW

BAR

MOUNTING

R-7.

FRflME

SPECIFICATIONS

Type

— All Models j

Ladder

with Steel

Channel

Side

Members

Vehicle

Number

of

Cross

Members

Overall

Length

Width

Front

Rear

Section

Modulus

CJ-3B

i

CJ-5,

CJ-5A,

DJ-5 1

j

4 Intermediate j

•

Front

Bumper Bar

Rear

K-member 122%'

[311,55 cm.]

128%'

[326,23

cm.] 29^*

[74,3 cm.]

[74,3 cm.]

29M'

[74,3 cm.]

[74,3 cm.] 1.493 in. cu.

1.493 in. cu.

CJ-6,

CJ-6A,

DJ-6

|

J

1

I

r

\mw t

[377,03

cm.]

29M'

[74,3 cm.]

29M'

[74,3 cm.] 1.493 in. cu.

343

Page 344 of 376

Page 345 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

s

SPRINGS

AND

SHOCK

ABSORBERS

Contents

SUBJECT

PAR. SUBJECT PAR.

Pivot Bolts S-3 Spring Removal S-4

Shock

Absorbers S-7 Spring Shackles S-2

Spring

Installation S-5 U-Shackles S-6

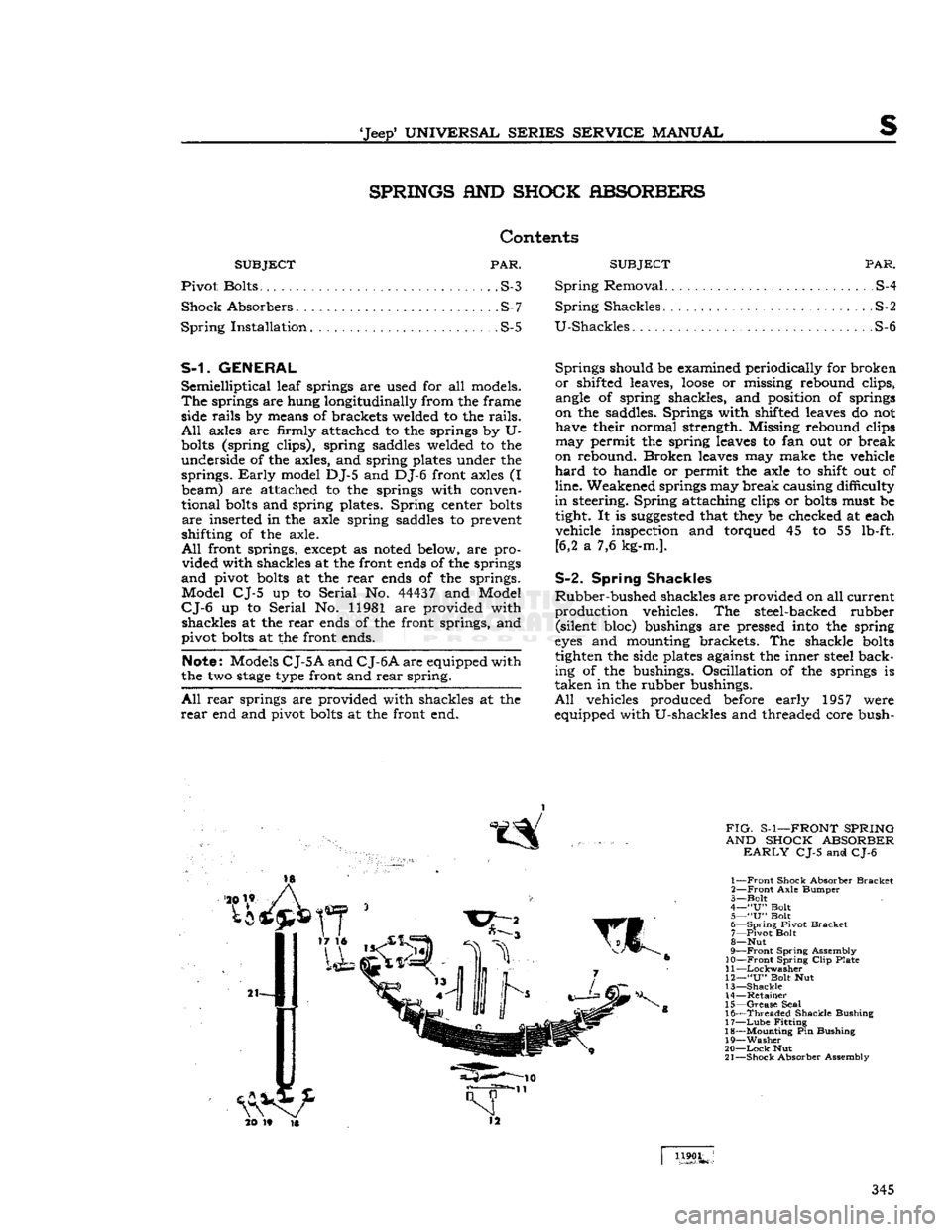

S-1.

GENERAL

Semielliptical

leaf springs are used for all models.

The

springs are hung longitudinally from the frame

side rails by means of brackets welded to the

rails.

All

axles are firmly attached to the springs by U-

bolts

(spring clips), spring saddles welded to the

underside of the axles, and spring plates under the

springs.

Early

model DJ-5 and DJ-6 front axles (I beam) are attached to the springs with conven

tional

bolts

and spring plates. Spring center

bolts

are

inserted in the axle spring saddles to prevent

shifting of the axle.

All

front springs, except as noted below, are provided with shackles at the front ends of the springs

and

pivot

bolts

at the

rear

ends of the springs. Model CJ-5 up to

Serial

No. 44437 and Model

CJ-6

up to

Serial

No. 11981 are provided with shackles at the

rear

ends of the front springs, and

pivot

bolts

at the front ends.

Note:

Models

CJ-5A

and

CJ-6A

are equipped with

the two

stage

type front and

rear

spring.

All

rear

springs are provided with shackles at the

rear

end and pivot

bolts

at the front end.

Springs

should be examined periodically for broken

or

shifted leaves,

loose

or missing rebound clips,

angle of spring shackles, and position of springs

on the saddles. Springs with shifted leaves do not have their normal strength. Missing rebound clips may permit the spring leaves to fan out or break

on rebound. Broken leaves may make the vehicle

hard

to handle or permit the axle to shift out of

line.

Weakened springs may break causing difficulty

in

steering. Spring attaching clips or

bolts

must be tight. It is

suggested

that they be checked at each

vehicle inspection and torqued 45 to 55 lb-ft. [6,2 a 7,6 kg-m.].

S-2.

Spring Shackles

Rubber-bushed

shackles are provided on all current

production vehicles. The steel-backed rubber (silent bloc) bushings are pressed into the spring

eyes

and mounting brackets. The shackle

bolts

tighten the side plates against the inner steel back

ing of the bushings. Oscillation of the springs is

taken in the rubber bushings.

All

vehicles produced before early 1957 were

equipped with U-shackles and threaded core bush-

*3(

21-

to It is

FIG-

S-1—FRONT SPRING

AND SHOCK ABSORBER

EARLY

CJ-5 and CJ-6

1—

Front

Shock Absorber

Bracket

2—

Front

Axle

Bumper

3—

Bolt

4—

"U"

Bolt

5—

"U"

Bolt

6—

Spring

Pivot

Bracket

7—

Pivot

Bolt

8—

Nut

9—

Front

Spring

Assembly

10—Front

Spring

Clip

Plate

11

—Lockwasher

12—

"U"

Bolt Nut

13—

Shackle

14—

Retainer

15—

Grease

Seal

16—

Threaded

Shackle

Bushing

17—

Lube

Fitting

18—

Mounting

Pin Bushing

19—

Washer

20—

Lock

Nut

21—

Shock

Absorber Assembly

1190L

345

Page 346 of 376

SPRINGS

AND

SHOCK

ABSORBERS

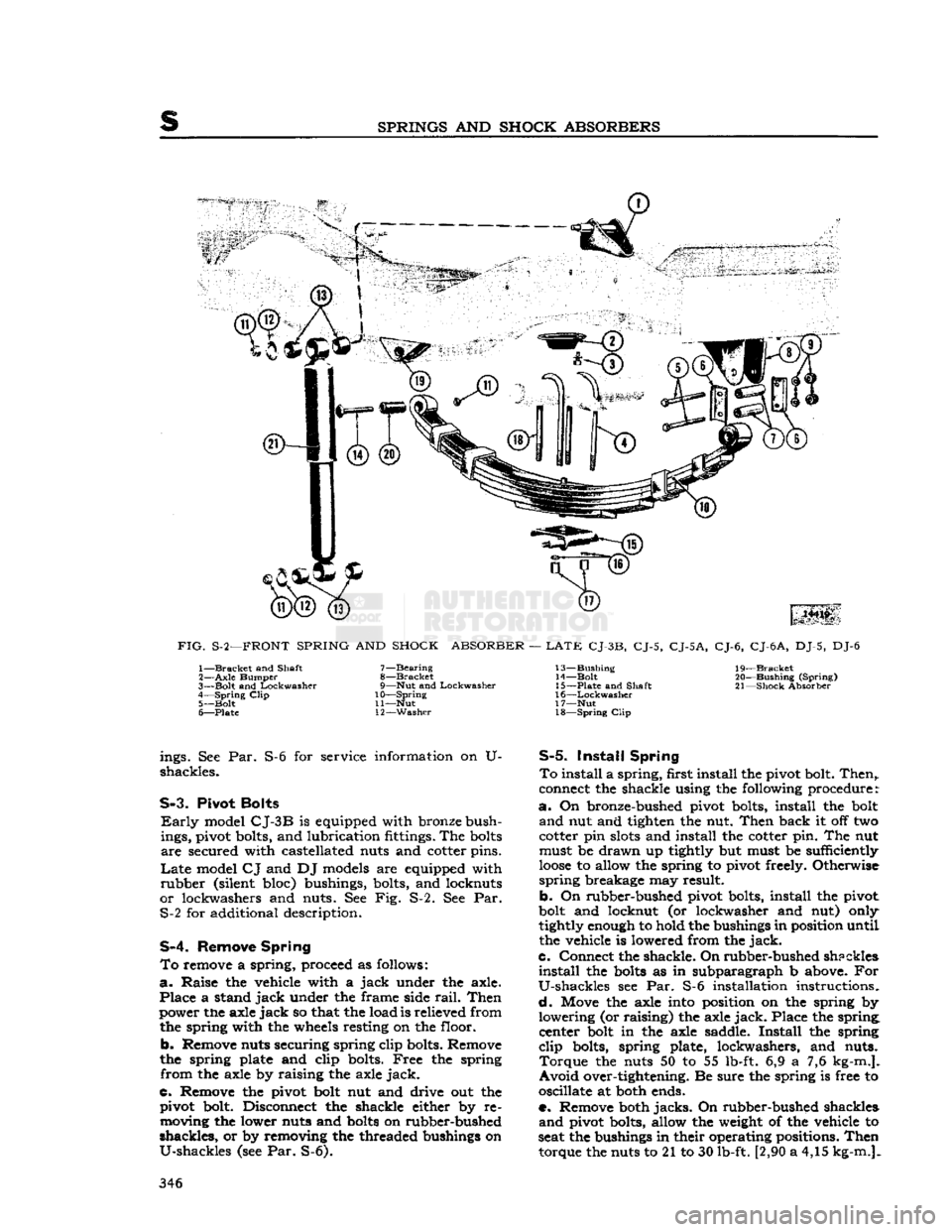

FIG.

S-2—FRONT

SPRING

AND

SHOCK

ABSORBER

—

LATE

CJ-3B,

CJ-5,

CJ-5A,

CJ-6,

CJ-6

A,

DJ-5, DJ-6 1—

Bracket

and Shaft

2—

Axle

Bumper

3—

Bolt

and

Lockwasher

4—

Spring

Clip

5—

Bolt

6—

Plate

7—

Bearing

8—

Bracket

9—

Nut

and

Lockwasher

10—

Spring

11—

Nut

12—

Washer

13—

Bushing

14—

Bolt

15—

Plate

and Shaft

16—

Lockwasher

17—

Nut

18—

Spring

Clip

19—

Bracket

20—

Bushing

(Spring)

21—

Shock

Absorber ings. See Par.

shackles.

S-6 for service information on U-

S-3.

Pivot

Bolts

Early

model

CJ-3B

is equipped with bronze bush

ings, pivot bolts, and lubrication fittings. The

bolts

are

secured with castellated nuts and cotter pins.

Late

model

CJ

and DJ models are equipped with

rubber

(silent bloc) bushings, bolts, and locknuts

or

lockwashers and nuts. See Fig. S-2. See Par. S-2 for additional description.

S-4.

Remove

Spring

To

remove a spring, proceed as follows:

a.

Raise

the vehicle with a

jack

under the axle.

Place

a stand

jack

under the frame side

rail.

Then

power the axle

jack

so that the load is relieved from the spring with the wheels resting on the floor.

b.

Remove nuts securing spring clip bolts. Remove

the spring plate and clip bolts.

Free

the spring

from

the axle by raising the axle

jack.

C.

Remove the pivot bolt nut and drive out the pivot bolt. Disconnect the shackle either by removing the lower nuts and

bolts

on rubber-bushed

shackles,

or by removing the threaded bushings on

U-shackles

(see Par. S-6).

S-5.

Install

Spring

To

install a

spring,

first install the pivot bolt.

Then,,

connect the shackle using the following procedure:

a.

On bronze-bushed pivot bolts, install the bolt

and

nut and tighten the nut.

Then

back it off two

cotter pin

slots

and install the cotter pin. The nut must be

drawn

up tightly but must be sufficiently

loose

to allow the spring to pivot freely. Otherwise

spring

breakage may result.

b.

On rubber-bushed pivot bolts, install the pivot

bolt and locknut (or lockwasher and nut) only

tightly enough to hold the bushings in position until

the vehicle is lowered from the

jack.

c.

Connect the shackle. On

rubber-bushed

shpckles

install

the

bolts

as in subparagraph b above. For

U-shackles

see Par. S-6 installation instructions.

d.

Move the axle into position on the spring by

lowering

(or raising) the axle

jack.

Place the spring, center bolt in the axle saddle.

Install

the spring

clip

bolts, spring plate, lockwashers, and nuts.

Torque

the nuts 50 to 55 lb-ft. 6,9 a 7,6 kg-m.].

Avoid

over-tightening. Be sure the spring is free to

oscillate at both ends.

e. Remove both

jacks.

On rubber-bushed shackles

and

pivot bolts, allow the weight of the vehicle to

seat the bushings in their operating positions.

Then

torque the nuts to 21 to 30 lb-ft. [2,90 a 4,15 kg-m.]. 346

Page 347 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

S

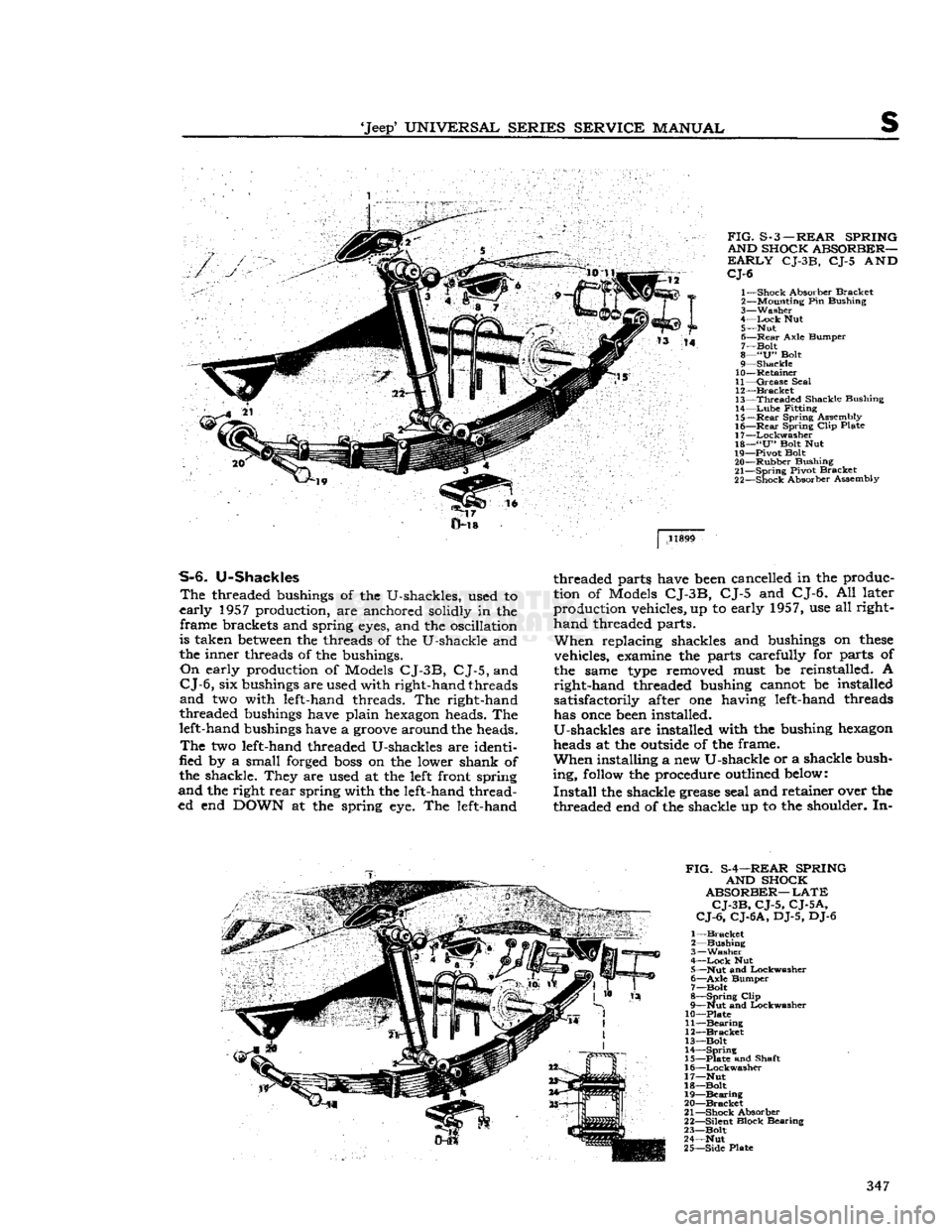

FIG.

S-3—REAR SPRING

AND SHOCK ABSORBER—

EARLY

CJ-3B,

CJ-5 AND

CJ-6

1— Shock Absorber Bracket

2— Mounting Pin Bushing

3—

Washer

4—

Lock

Nut 5— Nut

6—

Rear

Axle Bumper

7— Bolt

8—

"U"

Bolt

9—

Shackle

10—

Retainer

11—

Grease

Seal

12—

Bracket

13—

Threaded

Shackle Bushing

14—

Lube

Fitting

15—

Rear

Spring Assembly

16—

Rear

Spring

Clip

Plate

17—

Lockwasher

18—

"U"

Bolt Nut

19— Pivot Bolt 20—

Rubber

Bushing

21—

Spring

Pivot Bracket

22— Shock Absorber Assembly 11899

S-6. U-Shackles

The

threaded bushings of the U-shackles, used to

early

1957 production, are anchored solidly in the frame brackets and spring

eyes,

and the oscillation

is taken

between

the threads of the U-shackle and

the inner threads of the bushings.

On

early production of Models

CJ-3B, CJ-5,

and

CJ-6,

six bushings are used with right-hand threads

and

two with left-hand threads. The right-hand

threaded bushings have plain

hexagon

heads. The

left-hand bushings have a

groove

around the heads.

The

two left-hand threaded U-shackles are identi

fied by a small forged

boss

on the lower shank of

the shackle. They are used at the

left

front spring

and

the right

rear

spring with the left-hand thread

ed end

DOWN

at the spring eye. The left-hand threaded parts have

been

cancelled in the produc

tion of Models

CJ-3B,

CJ-5 and CJ-6. All later production vehicles, up to early 1957, use all right-

hand

threaded parts.

When

replacing shackles and bushings on

these

vehicles, examine the parts carefully for parts of

the same

type

removed must be reinstalled. A right-hand threaded bushing cannot be installed

satisfactorily after one having left-hand threads

has

once

been

installed.

U-shackles are installed with the bushing

hexagon

heads at the

outside

of the frame.

When

installing a new U-shackle or a shackle bush

ing,

follow

the procedure outlined

below:

Install

the shackle grease seal and retainer over the threaded end of the shackle up to the shoulder. In-

FIG.

S-4—REAR SPRING AND SHOCK

ABSORBER—

LATE

CJ-3B, CJ-5, CJ-5A,

CJ-6, CJ-6 A, DJ-5,

DJ-6

1—

Bracket

2—

Bushing

3—

Washer

4—

Lock

Nut

5— Nut and Lockwasher 6—

Axle

Bumper 7—Bolt

8—

Spring

Clip

9— Nut and Lockwasher

10— Plate 11—

Bearing

12—

Bracket

13— Bolt

14—

Spring

15— Plate and Shaft

16—

Lockwasher

17— Nut

18—Bolt 19—

Bearing

20—

Bracket

21— Shock Absorber

22— Silent Block Bearing

23—Bolt

24—Nut

25— Side Plate 347

Page 348 of 376

SPRINGS

AND

SHOCK ABSORBERS

10016

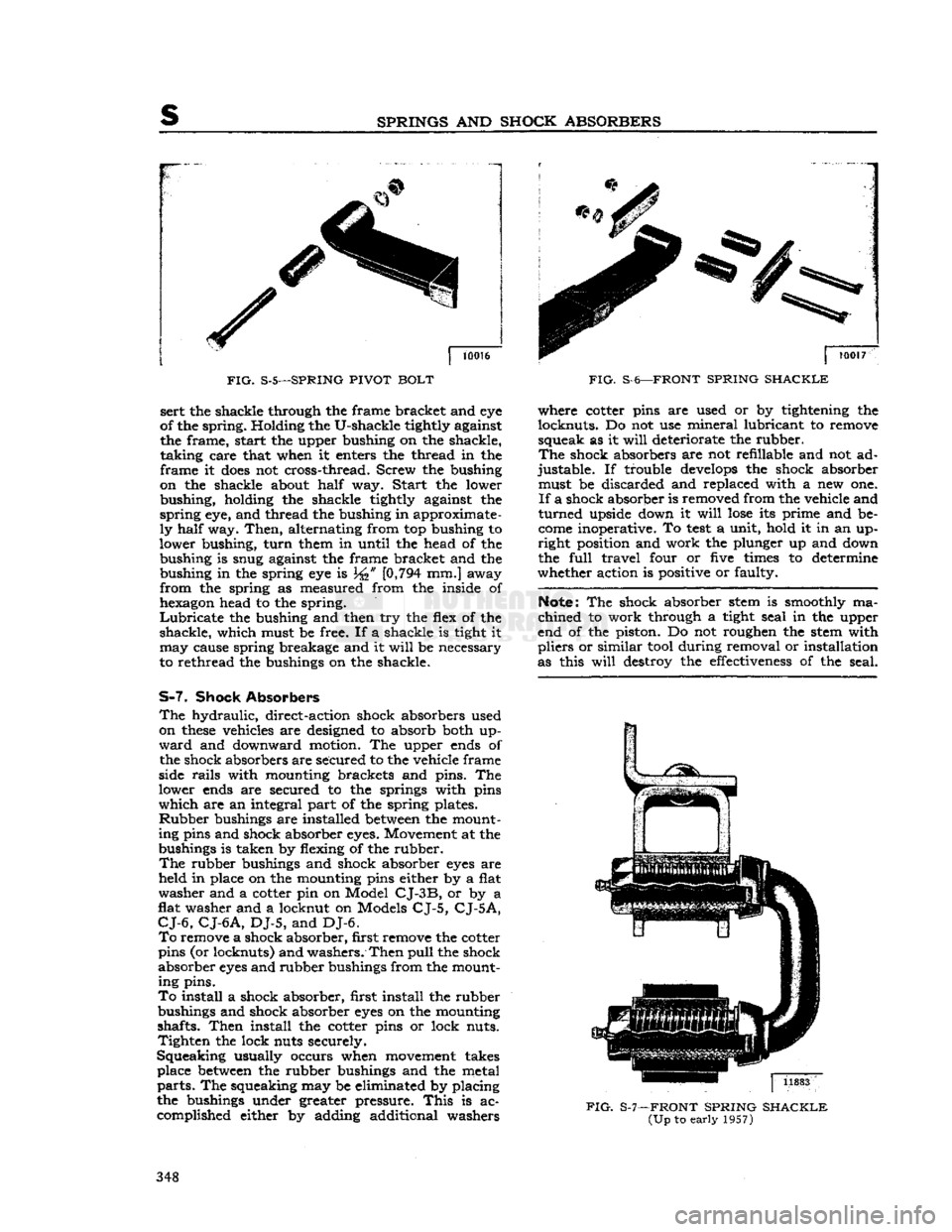

FIG.

S-5—SPRING

PIVOT BOLT

FIG.

S-6—FRONT

SPRING SHACKLE

sert the shackle through the frame bracket and eye

of the spring. Holding the U-shackle tightly against

the frame, start the upper bushing on the shackle,

taking

care that when it enters the thread in the

frame it

does

not cross-thread. Screw the bushing

on the shackle about

half

way.

Start

the lower bushing, holding the shackle tightly against the

spring

eye, and thread the bushing in approximate

ly

half

way.

Then,

alternating from top bushing to

lower bushing,

turn

them in until the head of the bushing is snug against the frame bracket and the bushing in the spring eye is

\{%

[0,794

mm.] away

from

the spring as measured from the inside of hexagon head to the spring.

Lubricate

the bushing and then try the flex of the

shackle,

which must be free. If a shackle is tight it may cause spring breakage and it

will

be necessary

to rethread the bushings on the shackle.

S-7. Shock Absorbers

The

hydraulic, direct-action shock absorbers used

on

these

vehicles are designed to absorb both up

ward

and downward motion. The upper ends of the shock absorbers are secured to the vehicle frame

side

rails

with mounting brackets and pins. The

lower ends are secured to the springs with pins

which

are an integral part of the spring plates.

Rubber

bushings are installed

between

the mount

ing pins and shock absorber

eyes.

Movement at the

bushings is taken by flexing of the rubber.

The

rubber bushings and shock absorber

eyes

are

held in place on the mounting pins either by a flat

washer and a cotter pin on Model

CJ-3B,

or by a

flat washer and a locknut on Models

CJ-5, CJ-5A,

CJ-6, CJ-6A,

DJ-5, and DJ-6.

To

remove a shock absorber, first remove the cotter

pins (or locknuts) and washers.

Then

pull

the shock

absorber

eyes

and rubber bushings from the mount ing pins.

To

install a shock absorber, first install the rubber

bushings and shock absorber

eyes

on the mounting

shafts.

Then

install the cotter pins or lock nuts.

Tighten

the lock nuts securely.

Squeaking usually occurs when movement takes place

between

the rubber bushings and the metal

parts.

The squeaking may be eliminated by placing

the bushings under greater pressure.

This

is ac

complished either by adding additional washers where cotter pins are used or by tightening the

locknuts. Do not use mineral lubricant to remove squeak as it

will

deteriorate the rubber.

The

shock absorbers are not refillable and not ad

justable.

If trouble

develops

the shock absorber must be discarded and replaced with a new one.

If

a shock absorber is removed from the vehicle and

turned

upside down it

will

lose

its prime and be

come

inoperative. To

test

a unit, hold it in an up

right

position and work the plunger up and down

the

full

travel four or five times to determine

whether action is positive or faulty.

Note:

The shock absorber stem is smoothly ma

chined to work through a tight seal in the upper

end of the piston. Do not roughen the stem with

pliers

or similar tool during removal or installation

as this

will

destroy the

effectiveness

of the seal. 11883

FIG.

S-7—FRONT

SPRING SHACKLE (Up

to early 1957)

348

Page 349 of 376

•Jeep'

UNIVERSAL SERIES SERVICE

MANUAL

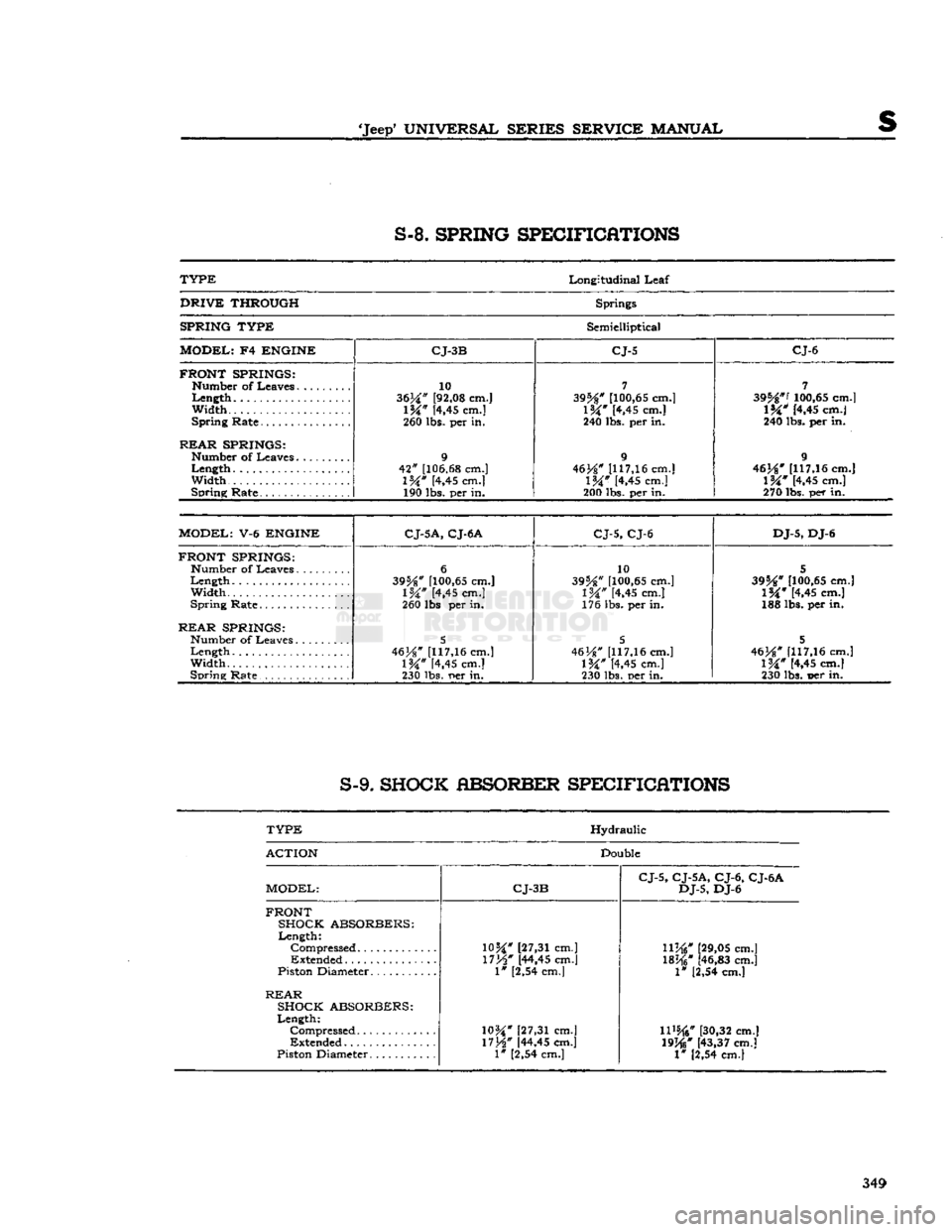

S-8.

SPRING SPECIFICATIONS

TYPE

Longitudinal

Leaf

DRIVE

THROUGH

Springs

SPRING TYPE

Semielliptical

MODEL;

F4

ENGINE CJ-3B CJ-5 CJ-6

FRONT SPRINGS:

Width...

REAR

SPRINGS:

Width

Spring

Rate

10

3634" [92,08 cm.]

\W

[4,45 cm.]

260 lbs. per in.

9

42"

[106.68 cm.]

l%"

[4,45 cm.] 190 lbs. per in.

7

395**

[100,65 cm.]

1&"

[4,45 cm.]

240 lbs. per in.

9

46J*#

[117,16 cm.]

IW

[4,45 cm.]

200 lbs. per in.

7

395*"'

100,65 cm.]

l%"

[4.45 cm.]

240 lbs. per in.

9

46}*"

1117,16 cm.]

l%"

[4,45 cm.]

270

lbs.

per in.

MODEL:

V-6

ENGINE

C

J-5A, CJ-6 A

CJ-5, CJ-6 DJ-5,

DJ-6

FRONT SPRINGS:

Number

of

Leaves

Width.....

Spring

Rate

REAR

SPRINGS:

Width

Spring

Rate

6

395*"

[100,65 cm.]

1%"

[4,45 cm.]

260 lbs per in.

5

46H"

[117,16 cm.]

\W

K,45

cm.]

230 lbs.

r»er

in. 10

39%"

[100,65 cm.]

IW

[4,45 cm.]

176 lbs. per in.

5

46

H"

[117,16 cm.]

IW

[4,45 cm.]

230 lbs. per in.

5

395**

[100,65 cm.]

1%"

[4,45 cm.]

188 lbs. per in.

5

463*"

[117,16 cm.]

1%"

[4,45 cm.]

230 lbs. t>er in.

S-9.

SHOCK ABSORBER SPECIFICATIONS

TYPE

Hydraulic

ACTION

Double

MODEL:

CJ-3B CJ-5, CJ-5A, CJ-6, CJ-6A

DJ-5,

DJ-6

FRONT SHOCK ABSORBERS:

Length:

"

[27,31 cm.]

Compressed

"

[27,31 cm.]

llj*i"

[29,05 cm.]

Extended

*

[44,45 cm.]

1%W

[46,83 cm.]

Piston Diameter

I" [2,54 cm.]

1* [2,54 cm.]

REAR

SHOCK ABSORBERS:

Length:

Compressed

10H

[27,31 cm.]

11%*

[30,32 cm.]

Extended

17H"

[44,45 cm.]

19j*j"

[43,37 cm.]

Piston Diameter

1"

[2,54 cm.] 1" [2,54 cm.]

349

Page 350 of 376